The induction heating boiler features good economy and long service life.

When choosing a boiler for heating a house, the owners are guided, first of all, by what source of heating is available for the room. Gas is the cheapest fuel, but settlements are far from supplied. Electricity is the most common, but not the cheapest. An induction heating boiler produces a fairly high efficiency, with less electricity consumption compared to other electrical options.

The principle of operation of an induction boiler

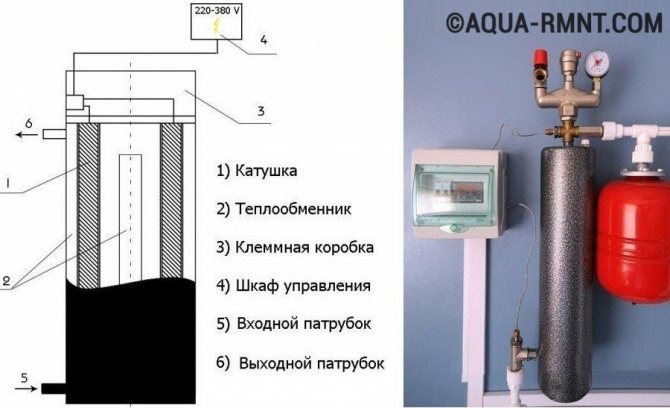

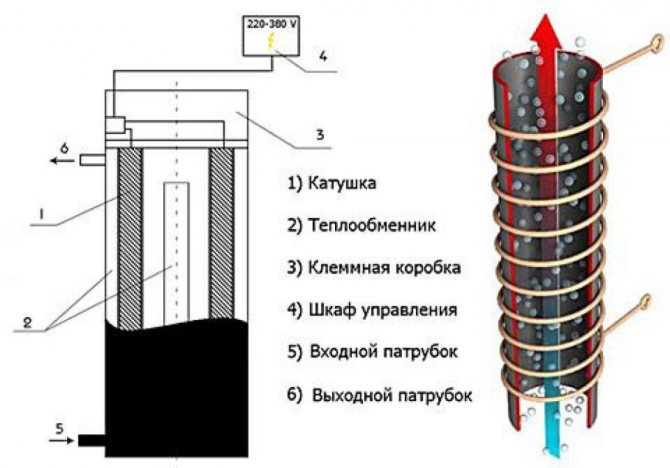

The basis of the principle of operation of the boiler is the creation of thermal energy from electrical energy. The effect of electromagnetic induction is as follows - through a coil wrapped in wire, we pass a current, an electromagnetic field arises around this winding. A metal core placed in the coil (which has the property of being attracted by a magnet) will start to heat up quickly.

Heat Generator Mechanism: It is an electrical inductor composed of a primary, secondary and core. By converting electricity into eddy currents, the primary winding directs the electric field to the secondary winding, which in turn transfers energy to the carrier. Under the influence of the electromagnetic field, eddy currents are generated in the body and core. They heat up the metal. Water picks up heat from the core and distributes it throughout the building.

But what type of heating to choose for a country house, you will find out by reading the article on the next page:

The operation of an induction hob is based on the same principle. Such tiles are much more economical than conventional electric stoves. This is achieved by avoiding heat loss by transferring heat from the heater to the cookware. Marketers today designate induction heating boilers as advanced developments created on a new principle. But in fact, this is not entirely true. Inductive principles have been applied since the last century for smelting furnaces. Also, no new materials are used for the manufacture of boilers.

M. Faraday discovered the phenomenon of induction in 1831.

Induction options are safer than other heating boilers, they practically do not need maintenance. They do not contain dynamic parts and, as a result, have no mechanical wear. With sufficient cooling, the coil's lifespan is unlimited. Such boilers do not require a separate room. Compared to gas boilers, they practically do not need maintenance work.

Induction boiler advantages:

- Constant circulation of the coolant;

- Lack of heating elements;

- Silence.

An inductive electric boiler is able to heat not only the area of a small private house, but also industrial premises, while there is no need for large installation and maintenance costs. Induction heating boilers on the market are not cheap. The reason is in the sensors of the system. The inverter used in the control system increases the cost of the heating boiler.

Heating boilers for home have many characteristics. You can read more about this on the website:

When is self-production more expedient?

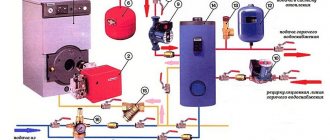

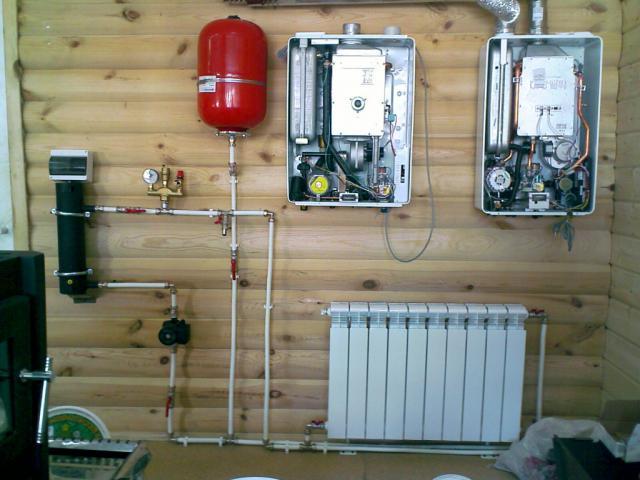

Connected system

Making a boiler with your own hands is advisable for houses with seasonal living. As a rule, low-power equipment is installed in such buildings, and there is no need to spend huge amounts of money on the purchase of a finished model. The cost of making the device with your own hands is minimal.

Even for a homemade unit, it is easy to pick up additional automation units that allow you to set the required temperature parameters. Such a device will not only allow you to set the desired indicators for a long time, but also provide remote control of the entire heating system.

How to make an induction heating boiler with your own hands

Opponents of the installation of induction boilers cite the conservation law - 1 kW of electricity is able to generate heat energy also no more than 1 kW. Yes, any water heater, consuming 1 kW of electricity, also produces 1 kW of energy. But not all of it is warm. Induction water heaters are more productive in the production of thermal energy, in comparison with heating elements. Making a homemade inductive water heater is not difficult. The materials used in this case can be found without much difficulty and at a low price. The circuit for such an inductive device is quite simple.

To convert electricity into heat, you need:

- Inductor;

- Alternating current 50 Hz;

- The core is made of a material to which the magnet "sticks";

- Drawings of an induction heating boiler (not a problem to find).

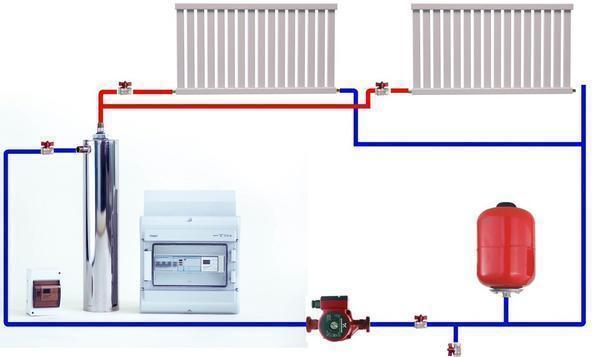

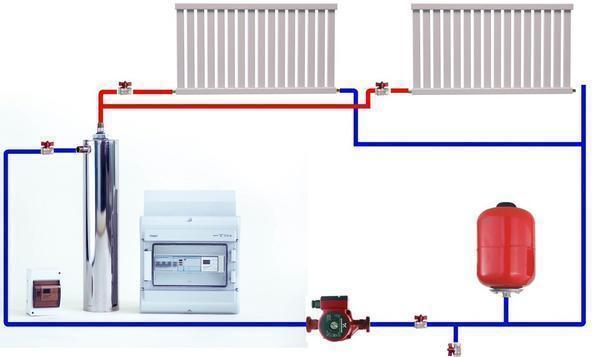

For the body of an induction boiler, you need to take a pipe with a diameter of 5 cm. The pipe is filled with pieces of wire, 5-7 cm, with a diameter of no more than 7 mm. To connect the boiler to the pipe system, you need adapters. The heating system diagram will help determine the characteristics.

It is better to install an automatic power off in case of a coolant leak. In this case, the electromagnetic field will not disappear if the power supply is not turned off, and the case with the fasteners will simply melt.

We make an induction coil - the main heating element. To do this, we take a copper wire, wrap it around the body, approximately 85-99 turns. The interval between the turns is equal. The simplest induction boiler is ready. Such an inductor can be installed anywhere in the pipeline. An induction steam generator works on the same principle.

Learn about the advantages and disadvantages of a double-circuit boiler in the following material:

Do-it-yourself inverter boiler installation

When installing electrical equipment on your own, you must have some knowledge and skills, but their list is usually small. When all materials and tools are ready, you can start installing the heating system. Considering the possibility of a sudden power outage, it is necessary to take measures to protect the equipment from damage.

An excellent solution to this problem would be the purchase of inverter heating batteries, the cost of which is quite high, but in the future they can significantly save on heating the building.

The installation of inverter batteries makes it possible to minimize the possible risk of malfunctions during a power outage: the automation will switch the equipment to the backup power mode in 10 milliseconds, which will keep the operating temperature at the same level. When the electricity turns on, the reverse procedure will be carried out, and the boiler will operate normally. In this way, inverter heating at home minimizes the control of the system.

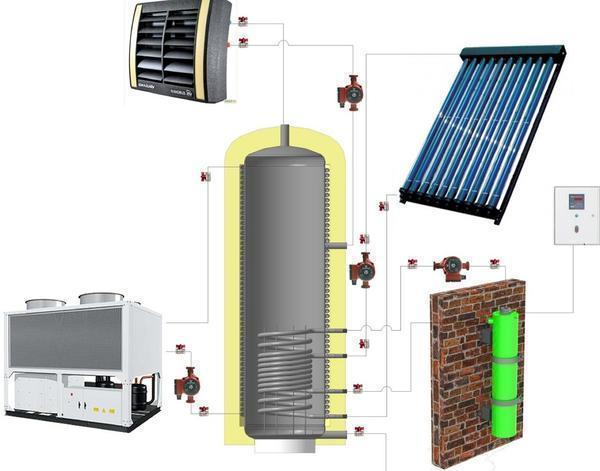

Induction heating modernization

Induction heating systems often have favorable reviews. Silence, efficiency and longevity are the indisputable advantages of the heating system. One of the varieties of the system is the operation of an induction water heater for heating. An induction water heater can be purchased and installed in the pipeline system.

You can pick up an induction heating scheme with your own hands. In this case, you can save your money well.

But, for more efficient operation of the induction system, it is important to know some of the nuances.By installing an induction cooker in the structure, it is connected to a charger, batteries and an inverter. An inverter is a device that converts direct current into alternating current. Its use reduces the amount of electricity consumed for the heating system to virtually zero.

For less energy consumption, you need:

- Inverter 4 kW;

- 2 batteries 250 A * h;

- Battery charger.

We connect 2 batteries synchronously, and charge them. They generate direct current and supply it to the inverter. The inverter converts DC to AC. The inverter then transfers current to the induction hob and the charging charges the batteries continuously. Thus, the consumption of the 24 V charger is the energy consumption of the induction heating of the house. The costs for the pump are calculated separately. Induction heaters are used only in versions with forced circulation.

Homemade options

Component elements

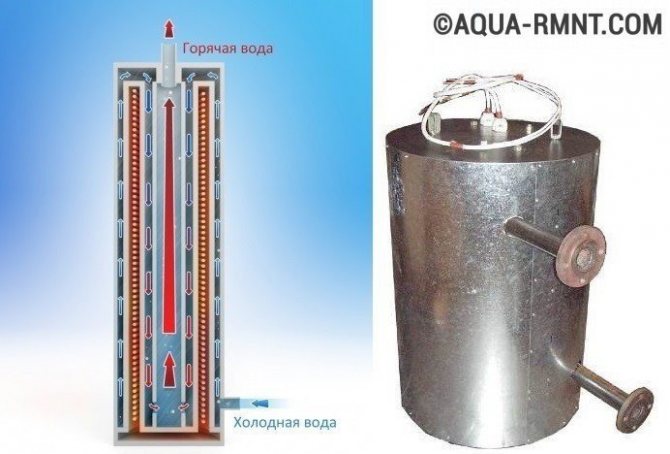

There are several design options that are easy to create with your own hands. The first option is based on a system of plastic pipes and a high-frequency inverter. The latter will have to be purchased separately. It is desirable that the model has a smooth current adjustment function. The minimum power indicator is 15 amperes, but for high-quality heating it is better to choose more powerful options.

The heated element can be assembled from steel wire rod or wire with a diameter of 7 mm. The body of the induction coil simultaneously serves as a part of the pipeline and can be made of plastic thick-walled pipes with an inner diameter of about 50 mm.

Two pipes are attached to the body. One of them supplies a cold coolant to the boiler, and the other gives off heated water. The inside of the housing is completely filled with the heated element. The ends can be closed with pieces of steel mesh.

Device in the house

In order to make an induction coil, the plastic pipe is carefully wrapped with copper wire. After that, the homemade device is mounted in the pipeline. For this purpose, a piece of pipe is simply cut out, in place of which the coil will be inserted. Before connecting the device, it is necessary to pour the coolant into the system - otherwise the body will simply melt.

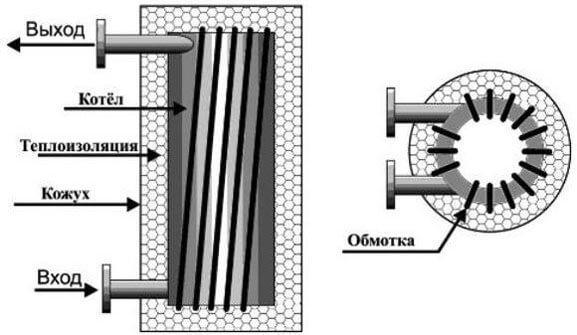

Another simple option that is easy to do with your own hands is a unit with a three-phase transformer. The two pipes are welded together in a ring shape. This design will act as a heater. A winding is wound around the body. The supply and removal of the coolant, as in the previous version, is provided by two nozzles. The entire structure can be housed in an insulating casing to minimize heat loss during operation of the equipment.

The induction boiler must be grounded. It can only be installed in closed heating networks with forced circulation. It is suitable for installation in systems with any kind of pipes, including plastic. When installing the unit, keep a distance of at least 30 cm between the boiler and the walls. From the floor and ceiling, this distance should be at least 80 cm.Even a self-made induction boiler can be equipped with an additional safety group and automation. This work is more difficult, but it will ensure the stable functioning of the entire system.

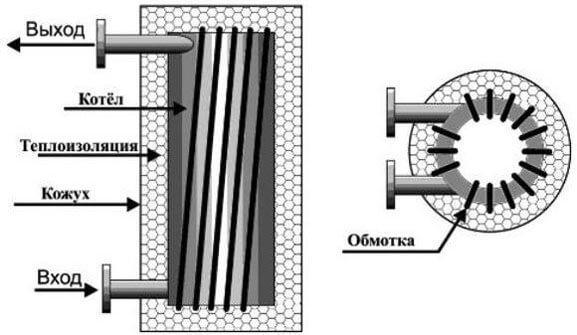

Description of inverter heating boiler

The inverter boiler has become available to the household consumer, in contrast to industrial enterprises, relatively recently. At the heart of the boiler device are 2 main cylinders placed in the outer one. The variant of such a boiler is safer. With proper installation, fire safety is orders of magnitude higher compared to gas, coal and wood-fired boilers.

The principle of operation of the inverter boiler:

- The coolant flows in the inner cylinder;

- The cylinder, which passes the current through itself, provides heating of the coolant;

- The outer cylinder acts as a heat insulator;

- The basis of the boiler operation is electromagnetic induction.

The mechanism of the inverter boiler practically eliminates the leakage of the coolant. An important quality is that any option can be used as a heat carrier (water, antifreeze, oil). The advantage of using antifreeze is that when the boiler is turned off in winter, the battery will not freeze or burst. Inverter boiler models of small capacity often have the ability to operate on battery power, which significantly reduces energy costs.

When installing an inverter boiler in a heating system, it is important to connect the ground correctly.

The inverter system will allow you to quickly reach the desired temperature, and will provide an economical consumption of electricity. Such systems are successfully used in the production of split-systems. The inverter air conditioner has a much longer service life than standard split systems.

Inverter heating boiler design

In an inverter boiler, the heating medium is heated by converting electrical energy into thermal energy, as a result, the batteries are heated from electricity. The boiler consists of two circuits: magnetic and heat exchange. A magnetic circuit is a coil of conductor attached to a dielectric. An electromagnetic field is created in this circuit, which acts on a metal core installed in the heat exchange circuit. It is the core that gives the received thermal energy to the coolant. Heating inverters are considered one of the most promising types of heating devices that can be used both for heating private houses and as a heater for industrial buildings.