Content

- Main products of the Rockwool brand (Rockwool)

- Specifications

- Forms of issue

- Thermal conductivity

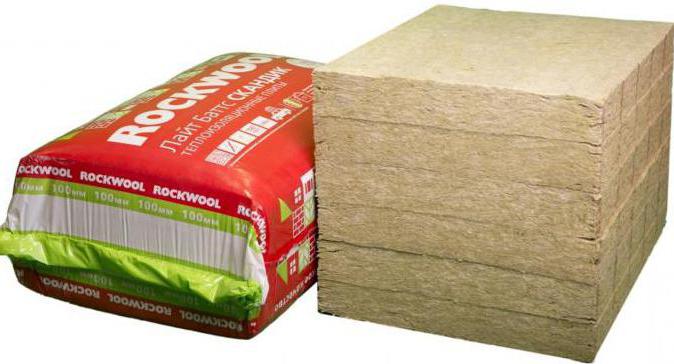

Rockwool stone wool (the original brand name is ROCKWOOL, but in Russia, according to our data, consumers are more likely to request a name in the Cyrillic spelling) - a product of natural origin. This is a natural stone in its composition. It is because of this that the material has become popular for use in all kinds of buildings. Stone wool is used for thermal insulation of any structures - both multi-storey buildings and detached premises, including those with very strict environmental and sanitary requirements, such as children's institutions or hospitals and health resorts.

Rockwool stone wool technology is sometimes compared to the process of volcanic eruption. Once at the plant, the stone is melted in furnaces at very high temperatures (up to 1500 degrees C). A lava-like substance is formed. In a special centrifuge, when processed by powerful air currents, the mass turns into separate stone fibers. A certain amount of binders is added to the fibers. This is necessary to give the desired shape to the fiber. Also, water-repellent components are added to the composition. The resulting fibers are formed into slabs, which are then left to harden.

If you do not have time to read the article, just watch the visual video, and you will get an idea of the properties of Rockwool stone wool:

Scope of application

Insulation facade Butts from Rockwool are used not only in construction, but also in the automotive industry, agriculture. In the first case, the scope of application is as follows:

- Insulation of single-storey and multi-storey residential buildings in order to preserve heat, reduce noise, and ensure fire safety. Rockwool mineral wool is mounted not only on the outer side of the walls, but also on chimneys.

- Insulation Rockwool applied for technical thermal insulation ventilation systems, smoke removal, industrial installations, as well as devices that operate at low temperatures.

- Increasing the fire resistance of building structures.

- Making mats or screens that absorb noise and vibration.

- Floor insulation on the ground.

- Finishing a flat roof, and here 1 layer of material is used.

- Facade panel production. They are distinguished by high characteristics of resistance to deformation and weathering. Such finishing materials are used for cladding all types of buildings.

Important! If the walls of the house are thick enough, then thin sheets of Bats can be used for insulation, the thickness of which is 50 mm.

Forms of issue ↑

Rockwool in the form of mats

Rockwool products are available in three main types:

mats (rolls);

cylinders;

plates.

Mats are soft materials, cylinders are hard. Rockwool slabs can be soft, hard and super hard.

Rockwool in the form of cylinders is used for thermal insulation of pipes

Application area

Rockwool in various forms is used for thermal and sound insulation of buildings and structures for various purposes, as well as for fire protection of reinforced concrete floor slabs and thermal insulation of pipelines.

Flammability group

Rockwool stone wool and, accordingly, all products from it are considered non-combustible material (GOST 30244-94).

Density

For most building materials, a direct relationship is characteristic: the more dense the material, the higher its thermal conductivity - therefore, such a material retains heat worse. As for the Rockwool thermal insulation materials, in this case there is no such direct relationship.Suffice it to say that the thermal conductivity of Rockwool materials, for example, with a density of 35 kg / cu. m and 200 kg / cu. m can only differ by 0.002 W / m ° C.

Hydrophobicity

This is the ability of the material not to absorb, but, on the contrary, to repel water. Rockwool stone wool has low water absorption. Water absorption by volume is not higher than 1.5%. It practically does not absorb water from the air. Moisture, getting on the surface of the cotton wool, does not penetrate inside and, accordingly, does not change the properties of the material.

Vapor permeability

The property of passing water vapor through the thickness of the material. It is characterized by a vapor permeability coefficient. The enclosing walls have the ability to "breathe" only when the heat-insulating layer has a high vapor permeability coefficient (above 0.25 mg / (m * h * Pa)). Competent installation and correct operation of Rockwool hydrophobic materials minimize the risk of moisture condensation in structures.

Mechanical characteristics

- Compressive strength with a deformation of 10% is not less than 20 kPa

- Peel strength - not less than 7.5 kPa

Rockwool is made from natural stone and therefore has the ability to provide high thermal and sound insulation of premises. Also, stone wool has good fire resistance, strength and durability.

Fire safety

Rockwool stone wool will prevent the spread of fire.

Rockwool fibers can withstand high temperatures up to 1000 degrees. C, thus protecting structures and structures from fire. Rockwool products do not emit smoke and do not form burning droplets in case of fires.

Acoustic comfort

Rockwool fibers are intertwined with each other in chaotically different directions, forming many small cavities that communicate with each other. Because of this, Rockwool stone wool materials provide good sound absorption and reduce vibration. Rockwool is used for acoustic ceilings, for the manufacture of noise protection screens along busy highways, for interior partitions, for ceilings and floors in order to improve acoustic comfort in rooms.

Environmental friendliness

The Rockwool brand has the right to be proud of the fact that for the first time it received the environmental safety mark - environmental standard EcoMaterial

confirmed the safety of using this material in any type of buildings and for interior decoration of structures and structures (including rooms such as bedrooms and children's rooms).

Durability

The key to the strength and, accordingly, the durability of stone wool is the special structure of the material. Its thin fibers are located chaotically - in horizontal and vertical directions, at different angles to each other. The wool fibers are intertwined with each other, which ensures the special rigidity of the material and the stability of its shape for a long time. Therefore, Rockwool materials do not undergo deformation over the years, Rockwool slabs serve without caking or compaction, and the thickness of the thermal insulation layer of thermal insulation remains practically unchanged.

Installation instructions for Rockwool insulation

The main subtleties of installing Rockwool insulation depend on the place of its installation. Consider the option of installing insulation in the attic. The recommended thickness of the insulation is 20-35 cm. To begin with, using a tape measure, you need to measure the distance between the beams in which the heat-insulating material will be laid. Next, the mineral wool is cut with a knife into the appropriate parts.

Lay the first layer of insulation, pay attention to its abutment to the edges of the beams. Next, a metal frame is installed, which will become a separator between two layers of insulation.

After the metal frame is assembled, install the pre-cut parts of the second layer of insulation. If necessary, install a vapor barrier, overlap and secure with tape.Next, the attic is finished in accordance with the individual requirements of the owner of the premises. Installation of Rockwool insulation will save on heating the attic in the cold season.

Attic insulation tips:

- the plates to be installed must have the same thickness;

- if several layers of slabs are installed, then their seams should not coincide;

- press the thermal insulation material as tightly as possible to avoid the formation of gaps;

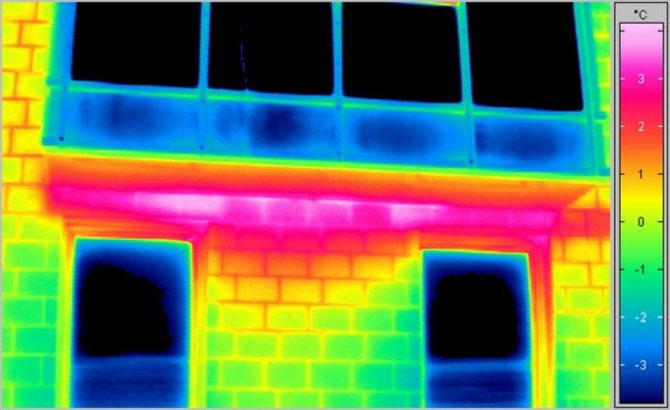

- with incorrectly installed thermal insulation, cold bridges are formed, which lead to the appearance of condensation, increase heat loss and significantly affect the duration of use of the insulation.

Based on materials from the site: fb.ru, strport.ru

Thermal conductivity ↑

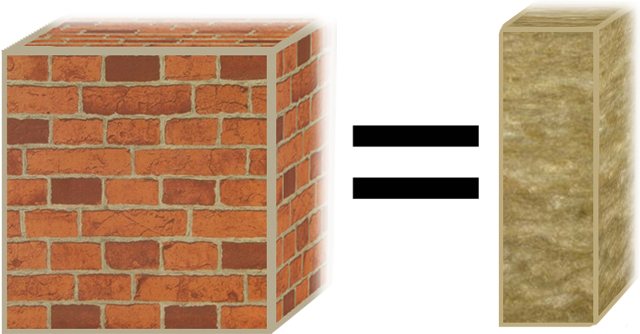

Rockwool stone wool has a very low thermal conductivity coefficient (from 0.041 to 0.045 W / mK). This is achieved to a large extent by the fine-fiber structure of the material. The figure clearly shows the difference in the thermal conductivity of brick and rockwool. Brickwork (left) 96 cm thick against the rockwool slab (right) 5 cm thick

The effectiveness of thermal insulation is shown by the coefficient of thermal conductivity. Based on the specific value, the required thickness is calculated. The values of the thermal conductivity coefficient of ROCKWOOL materials are considered one of the best in their class (0.036–0.038 W / m K). In terms of thermal insulation parameters, Rockwool slabs of the LITE BATTS brand, for example, with a thickness of 5 cm, can be compared with a brickwork with a total thickness of almost 1 meter.

All ROCKWOOL stone wool products have a low coefficient of thermal conductivity, because they do not conduct heat well. Almost the same amount of heat passes through the 1 meter thick Rockwool stone wool insulation as through a 196 cm brickwork or a 44 cm thick timber wall.

The technology of insulating the walls of the frame

The basis of the house is a wooden frame, sheathed on both sides with sheet material. Between them are thermal insulation boards. Rockwool Light Butts, Rockwool Light Butts Santik are optimal for work.

Useful: Terrace at home: planning, progress of work

Wall cake laying scheme:

- installation of a vapor barrier membrane from the inside of the room;

- placement of insulation;

- fastening the windscreen;

- external cladding.

The whole process consists of the four stages indicated above. Detailed instruction:

- Vapor barrier. On the inside of the frame racks, stick adhesive tape, remove the protective film and attach the membrane with an overlap of 10 cm.In addition, fix the canvases with a stapler, glue the joints with tape.

- Laying mineral wool. Cut the insulation according to the size of the cells between the frame posts. Install heat-insulating mats, if necessary, install a second layer of mineral wool.

- Installation of a wind barrier. The membrane is attached by analogy with a vapor barrier - on adhesive tape fixed with a stapler.

- Sheathing. To install sheet material, it is necessary to fill the crate of 20 * 30 mm laths. Attach OSB sheets over the strips, leaving a gap between the canvases of 3-5 mm.

Reviews about cotton wool "Rockwool Light Butts"

On sale today you can find hydrophobized lightweight insulation boards, which are made on the basis of basalt rocks. This product is unique, and it is intended for private housing construction. The main feature is the revolutionary quality of the fibers, which allow the plates to be compressed up to 70%.

Engineers worked for a long time to create this material, in the end they managed to obtain a structure that is capable of maintaining outstanding performance in all respects. In addition, the material has excellent recoverability. Mineral wool "Rockwool Light Butts" has, according to consumers, many other advantages, among them the ability to compressibility should be highlighted.

The material is springy, thanks to which the installation is facilitated, which is true in conjunction with a metal or wooden frame. The springy edge, according to users, is located on the long side, while the edge width is 50 mm. By looking at the end of the slab, you can see the flexed edge that is marked.