Please rate the quality of the article Rating:

5.00 (2 ratings)

To keep the thermometer readings at the required level, regardless of the season, various heaters are called upon. And most people associated with construction prefer mineral wool.

Building your own home is one of the most troublesome and desirable goals of every person. The primary task in the design, together with the area, the location of the rooms, the height of the ceilings, is to ensure a comfortable temperature for a person. The microclimate at home should not depend on the environment.

Due to its properties, mineral wool can be used by builders not only as insulation, but also as a good means for sound insulation. Mineral wool insulation is widely used for thermal insulation of a bath (it is also used as protection against fire).

Helpful information:

- Insulation TechnoNIKOL: technical characteristics

- Metal tile Monterrey: technical characteristics

- Pvc sewer pipes: dimensions, properties and installation

- Polystyrene concrete - characteristics and scope

- Insulation Isover: types and technical characteristics

- Knauf insulation: technical characteristics

Mineral wool properties

I want to see everything!

I want to see everything!

The main technical characteristics and properties of mineral wool include:

- Thermal conductivity. W / (m * K) is used as a unit for measuring the ability of cotton wool to retain heat. Information about the thermal insulation of mineral wool is almost always available on the packaging and is regulated by GOST (permissible value is 0.041-0.045).

- Soundproofing. This parameter "speaks" about the ability of cotton wool to damp sound waves. This indicator is indicated by the Latin symbols Aw and is also indicated by the manufacturer on the packaging. It takes on a value of 0 and 1, depending on whether the mineral wool absorbs waves or reflects them.

- Density. The density of mineral wool is a quality characteristic of the wool. It depends on the number of fibers located per 1 m3 of material. This indicator fluctuates in the range from 20 to 220 kg / m3.

- Vapor tightness. Due to the ability of mineral wool to pass steam through its fibrous structure, the material on which the wool is laid (metal, brick, wood) retains its natural appearance for a long time.

- Low flammability. Mineral wool insulation can be used at a maximum temperature of 650 degrees. above zero. The maximum value indicated by the manufacturer on its products is A1.

- The absence of organic elements in the composition of cotton wool extends its service life.

An important quality of cotton wool is the ability not to emit smoke in case of combustion, and the ability to maintain its structure - not to crack. On the packaging you can find the corresponding marks - S1 and d0.

Types and composition of mineral wool

The basis of mineral wool includes portions of slag, glass, certain rocks. In this regard, it is also classified according to the material of manufacture: glass wool, stone and slag wool.

Glass wool is especially popular due to its cheap cost. It is obtained from molten glass, as well as from rocks containing silicate. It is yellow in appearance and has a well-visible fibrous structure. Unlike other types of mineral wool, its fibers are up to 3 mm long. Thanks to this feature, a better adhesion of the fibers is achieved, and hence the required density of the insulation.

Its advantages include low thermal conductivity and anti-vibration properties. Due to its elasticity, it is convenient to transport it - it can be compressed several times.

Glass wool insulation should be used where the load (including mechanical) on the surface to be insulated will be minimal. It will be in place in the case of external walls of buildings and pipelines.

When working with this type of insulation, it is worth considering the fact that it can cause harm to health. Therefore, it is not worth giving up means of protection. It is undesirable to touch glass wool with open skin areas.

Insulating the walls of the house with foam: debunking the myths.

Slag

There is also mineral wool on the market for insulation, which is based on slag (waste from the processing of cast iron) of blast furnaces. Slag wool has a pronounced drawback - it absorbs moisture well. As a result, acids are released. It cannot boast of anti-vibration properties, as well as the necessary thermal conductivity, therefore there is no particular consumer demand for it.

The strength is small. This is due to the size of the particles from which it is made - they are smaller than that of glass wool.

It is used in enterprises, factories, in mines to insulate flat horizontal surfaces. A slight slope is allowed. To handle it, the use of personal protective equipment is mandatory.

This species was not recognized among the population due to the inconvenience of installation. People who prefer to do everything with their own hands have great difficulties when working with slag.

Stone wool

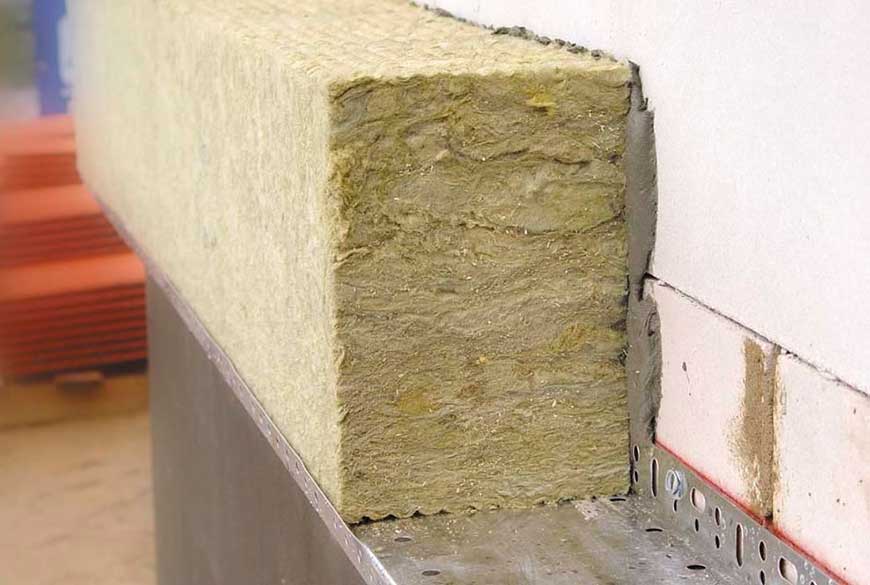

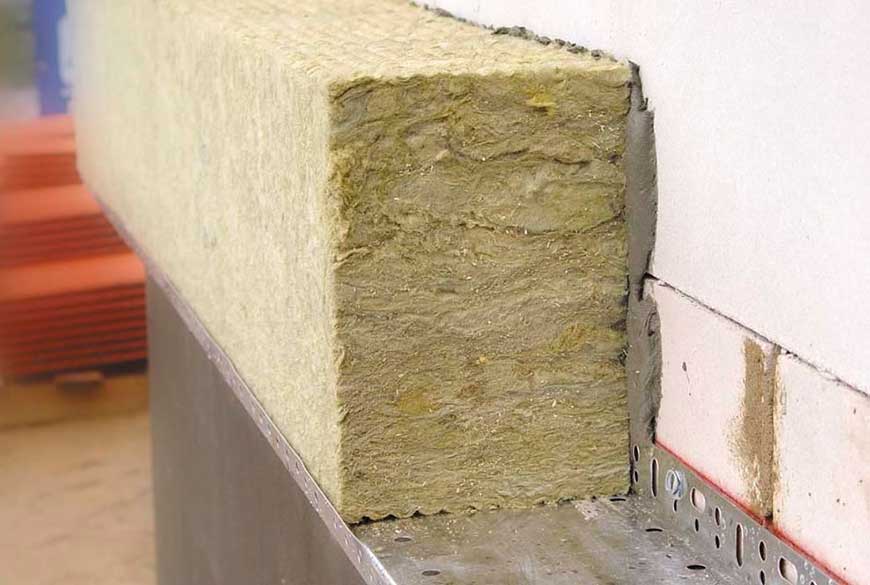

Another type of insulation is popular among the population - stone wool. It is also called basalt wool. It is made from gabbro-basalt rock. These include diabase, gabbro, and basalt. The composition also includes portions of limestone and dolomite.

Compared to slag and glass wool, this type of insulation surpasses them in many respects. The use of stone wool as a heater is more expedient - its thermal conductivity is much lower than that of the same glass wool.

Vibration and external load (including mechanical) are not an obstacle for it. The areas of application of stone wool are also different due to its resistance to fire. Moisture is not an obstacle for her either.

On the market, this type of insulation is presented in several options, depending on the strength and thickness.

Due to the ability to vary with the density of the insulation, building material from gabr-basalt rock is in great demand. Such material can be used to insulate cottages, summer cottages, baths.

Advantages and disadvantages

We recommend reading our other articles

- Types of laminate

- Using bathroom tiles - the right approach to renovation

- Inventory Tasks in Clothing Stores

- Where do you buy interior doors today?

Experts note both the advantages and disadvantages of stone wool, so before buying it for insulation, it is necessary to weigh the pros and cons. What are the advantages of stone wool?

- The material is lightweight, which allows it to be easily carried and laid during the insulation of the room.

- This is a time-tested insulation.

- High insulating properties.

- Stone wool is not afraid of temperature extremes. Regardless of the weather, it does not expand or contract, it keeps its shape and retains its properties.

- The basic characteristics are the same regardless of the manufacturer. So, for example, insulation from Rockwool and Isobox have similar parameters and qualities, but differ in terms of price, additional raw materials used for production and other parts. Hence the price difference.

- The material is not flammable.

- Depending on the quality of the insulation, vapor permeability can range from 0.3 to 0.55 mg / m hPa.The higher the indicator, the better this property is expressed.

- Laying stone wool is pretty easy, even without practice.

Now about the disadvantages of stone wool.

- Contrary to misconceptions, it does not scare away rodents. Mice and rats are not afraid of it and can live peacefully in it.

- The sustainability of stone wool is often questioned due to the fact that the fibers are held together with resins during production. Manufacturers rarely explain what these resins are, their exact composition and whether they are harmful, so the question remains open.

- During the laying of stone wool, dust appears, which is strongly recommended not to inhale. Therefore, you can work with it only in a respirator.

Photo of stone wool Technonikol and Rockwool

The shape and thickness of the insulation

Mineral insulation is produced in the form of rolls, plates or cylinders. Basically, the shape of the material is determined by the scope of application.

- Rolls... Mineral wool in the form of a roll is used by builders where there is no significant load on the surface to be insulated. This includes walls, attics, floors between floors. This kind of cotton wool cannot boast of high density.

- Slabs... They are used on those objects where density comes first. It is advisable to apply mineral wool slabs to a concrete screed.

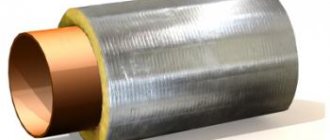

- Cylinders... Heat-insulating mineral wool cylinders are used to insulate pipe surfaces. The density of cylindrical mineral wool is average.

Plates, in comparison with cylinders and rolls, have a number of advantages: they do not cause hassle during transportation, are convenient for installation and work (they are easy to cut), they can be installed on uneven surfaces.

Rolls, plates and cylinders differ from each other not only in shape, but also in size. The dimensions of one slab are 60x100 cm, and the thickness can be different and varies from 5 to 20 cm.

The dimensions of the rolls differ significantly from the dimensions of the slab, since they are intended for insulation of large areas. Dimensions of one roll: length - 9 m, width 60-120 cm and thickness 50-150 cm.

The diameter of one cylinder can vary from 2-27 cm. The length of the insulation of this shape is 1 m, and the thickness is 2-10 cm.

The origin of stone wool

The highest quality stone wool is produced from basalt type rock

Volcanic rock - basalt - is thrown to the surface of the earth in the form of lava, then it solidifies and turns into stone. For some time now it has been used in construction. Due to the fact that basalt is easy to mine and there is a lot of it in nature, the cost of building materials based on it is available to everyone.

There are entire groups of volcanoes that provide the greatest amount of rock suitable for further processing. They are located in Kamchatka and the Kuril Islands. There are more dormant volcanoes on earth, near which basalt layers have already formed - they are the main sources of the rock.

Many islands are of volcanic origin and are entirely formed from basalt rock, such as the Hawaiian ones.

Stone wool insulation goes through the following processing stages:

- Melting and grinding.

- Fiber production.

- Resin bonding.

- Treatment with water-repellent oils.

- Formation of layers of the desired shape.

The layers are made of different thicknesses and areas. Sold in rolls with one-sided foil application or in the form of slabs.

Characteristics of stone wool

Stone wool has a layered structure with a chaotic arrangement of fibers, therefore, many air pores are formed

The material retains heat thanks to the air bubbles stationary inside it. The more there are, the stronger the beneficial properties. The characteristics of the finished insulation are almost the same for all manufacturers, so there is no point in overpaying for the brand.The service life of this material is unlimited compared to other similar building materials.

On sale you can find various modifications of stone wool. A layer of foil can be applied to one side to improve the thermal reflective properties of the material. Such rolls are used to insulate attic or mansard rooms. The foil is laid in the direction of the room, which keeps the heat.

Rolled cotton wool without foil is used for laying on floors under laminate, parquet or tiles.

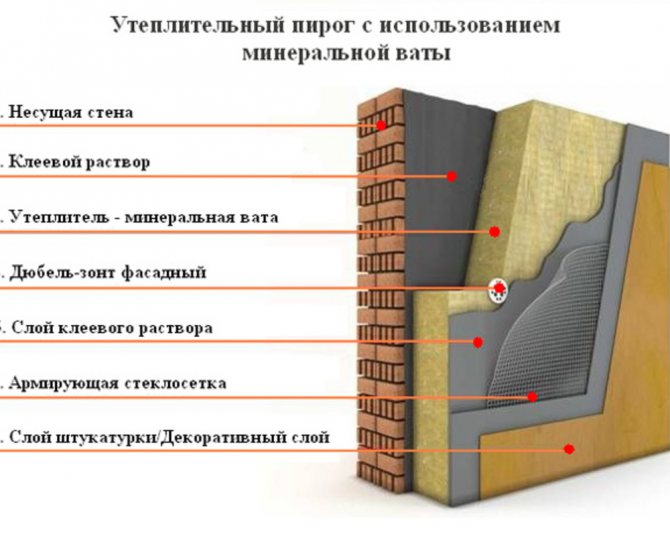

Conventional slabs are used to insulate the facade. A layer of external plaster is applied on top of them. There is also a shaped variety, which is two halves of a circle. They are used to insulate water, gas, sewer pipes in the ground above the freezing level.

Advantages and disadvantages

Due to its qualities, mineral wool withstands worthy competition in the insulation market. The advantages of this type of insulation include:

- Climatic conditions are not a hindrance for her, so installation can be carried out everywhere. No additional insulation is required.

- Using mineral wool, you can forget about such a concept as dampness. Mineral wool, as a heater, with proper processing, does not collect moisture, and also does not let steam in, so conditions for the formation of dampness are excluded.

- Such material does not interfere with the circulation of air in the room, but on the contrary, there is no need to use devices for air ventilation.

- Mineral insulation does not interact with acids and alkalis, therefore, you should not be afraid of breaking the strength of structures (laboratories are often sheathed with such material).

- Very good soundproofing. If you insulate an apartment or house with it, the sounds from the street will not bother you.

- As already noted, mineral wool does not lend itself to combustion, and also does not emit any harmful substances into the atmosphere when interacting with fire.

- Long service life of the material. Thermal insulation of buildings and pipelines with mineral wool is also beneficial from an economic point of view, due to the durability of the material. Such insulation not only burns badly or absorbs moisture, but also rodents and microorganisms do not spoil it. In addition, over time, it does not lose its shape, does not "shrink".

- Easy installation. Even an amateur builder is capable of insulating a room with mineral wool.

- Environmentally friendly material that does not cause any allergic reactions in people in the room.

Density of different types of bricks

If before the shortcomings could be given a whole list, today many manufacturers have eliminated most of them in their products. But some of the problems still remain:

- Dust harmful to health - this concerns glass wool, the work with which must be carried out in overalls and with the help of protective equipment. A damaged part of the mineral wool can be easily injured. Moreover, damaged fibers of the material can negatively affect the respiratory tract. It is quite simple to avoid this - it is enough to put on a protective suit, goggles, respirator and gloves when installing mineral wool.

- When heated, such material can release a dangerous toxin - phenol (arises from the oxidation of formaldehyde resin, which is part of the cotton wool). Some manufacturers claim that their amount of formaldehyde resins is so small that they cannot harm the human body. In any case, it is not worth the risk, and the installation must be carried out taking precautions.

- There is a problem of deterioration of heat-conducting properties as a result of the interaction of the insulation with water. Manufacturers are working to solve this problem by adding special hydrophobic formulations to their products. Additionally, during installation, it is necessary to apply waterproofing.

Insulation errors

Often the reason for negative reviews about mineral wool as a heater on the part of builders is installation errors:

- Insufficient amount of insulation. The optimal thickness in most cases is 10 cm.

- If the insulation was done from the inside (wall insulation in the apartment), then you should not dwell on this. When choosing between indoor and outdoor work, the latter should be preferred.

- You can not save on fasteners, and also use unsuitable fasteners where they are inappropriate. It is important to remember that amateur performance is not always justified and can go sideways.

- If the house has a basement, then it is imperative to pay attention to it, otherwise the proper effect of insulation will not work.

- Accuracy in work is essential. It is worth laying the layer as evenly and tightly as possible.

- It is important to pay special attention to the preparation of the base. Do not ignore cleaning the surface from debris and sanding it, in case of unevenness. In the worst case, the insulation will simply fall off the wall.

- It is necessary to avoid getting glue into the joints of the boards. In this case, it is here that the cold will come inside.

- Insulation work must be carried out in warm, dry weather. It must be remembered - no moisture.

- When attaching the mesh, one important rule should be taken into account - we use only glue, we hold the putty for other work.

- It is necessary to insulate at least 60% of the surface in order to achieve the proper result.

Do-it-yourself plastic window adjustment

Areas of use and production of mineral wool

Insulation is made in the form of rigid plates, semi-rigid mats. For professional insulation, granular insulation is often used, which is applied to the surface to be insulated.

Mineral wool, it is better to insulate such surfaces:

- Internal walls made of wood;

- Thermal insulation of bath rooms;

- Roof thermal insulation;

- House made of wood;

- Pipelines and communications;

- Foundation;

- Before pouring the screed;

- Thermal insulation of rooms with high humidity;

- Thermal insulation of external walls for further decorative plastering.

If you compare mineral wool with expanded polystyrene, then you can easily determine for which surface both materials are suitable.

What we pay attention to when buying insulation

It will be useful to know what to look for when choosing and buying insulation.

- An important condition for any purchased product is that it must comply with the State Standard.

- In addition to information from sellers, you should make sure of the purpose of this or that insulation yourself. Most manufacturers have taken care of this - the packaging contains enough information (including the value of the thermal conductivity of the material).

- Preference should be given to foil-coated mineral wool. This combination will help avoid heat loss.

- It is important to determine the maximum load that will be applied to the coating with insulation (what density mineral wool will be more appropriate to use).

- When choosing products, it is necessary to pay attention to the fibers on the insulation, their location - if it is chaotic, then the mineral wool is strong and capable of experiencing heavy loads.

- Insulation with its main function will cope without problems.

- In no case should you buy cotton wool that has gotten wet for some reason. After it dries, all of its inherent properties will be minimized at best.

- Cotton wool must be supplied and stored in its original packaging.

- The manufacturer is allowed to use different types of insulation together. In this case, the condition of equal density must be taken into account. An exception is when cotton wool is used as a sound insulator.

The date of manufacture does not play a role in the purchase of mineral wool, because.such material has no expiration date.

If the question of cost is not worth it, then you should give preference to basalt (stone) wool. Besides higher heat absorption and low noise insulation, slag wool or glass wool can be easily damaged during installation.