General characteristics of polypropylene pipes

Is polypropylene so good

Today the market is overflowing with pipes made of polymer materials from various manufacturers. For example, you can find Chinese, Turkish, Czech, Russian and German pipes. Choosing any of these can be a daunting task. Before we introduce you to the advantages of polypropylene pipes from each of the manufacturers, we will consider the general characteristics of polypropylene pipes, their positive properties:

- Polypropylene is corrosion resistant. Due to this, the pipeline maintains its original quality indicators for many years.

- The service life of polypropylene pipes exceeds the service life of metal pipes by three or even four times.

- Resistant to possible biochemical aggressive influences.

- Even under extreme weather conditions, polypropylene pipes remain extremely reliable. Fittings and pipes themselves are not subject to rupture during winter.

- No vibration and noise. The noise in the pipes is not so significant as to create inconvenience to others.

- The absence of a strong hydraulic resistance, as a result, the inner shell of the pipe does not affect the water pressure in any way.

- Unlike steel pipes, polypropylene pipes save the heat of hot water by 20%.

- Does not create problems during installation.

- Due to the large number of all kinds of fittings, it is possible to make a plumbing system of any configuration.

- Polypropylene does not affect human health in any way.

So, there is no point in doubting the quality of polypropylene pipes. Now let's start reviewing pipes from different world manufacturers.

Types of fittings and size range

Since there are several types of pipe connections, there are several varieties of connecting elements. Main types:

- Coupling is a simple hollow cylinder for joining two pipe sections of the same diameter.

- An adapter is an element designed for the same purposes as a coupling, but allowing to connect pipes of different diameters. They are also used to switch from polypropylene to metal (in this case, there is an internal thread at one end).

- Corners to form a right angle or 45⁰. Despite the relative plasticity of the material and the ability to bend the pipe after heating, this should not be done. On the outside of the bend, polypropylene will become thinner, which will negatively affect the strength of the entire structure. At the same time, folds form on the inside, impairing the throughput.

- Tees and crosses are routing elements used to create multiple branches from the main line. There are a lot of options for such fittings. Some allow the pipe to be diverted at a right angle, others at a smaller one. If there is a thread, shut-off valves can be installed on such connections.

- Curved bypass elements are designed for laying complex communications when you need to bypass one or more pipes.

- Shut-off fittings, which are valves and taps, can be either threaded or not.

- Plugs (also welded or threaded) are a necessary element to complete the pipeline line.

- "American" - a special type of fitting in the form of a coupling with a union nut, used in cases where the structure needs to be periodically disassembled.

We recommend that you familiarize yourself with: How and why is the production of PU foam insulation carried out?

It is important! The selection of connecting elements is carried out in accordance with the outer diameter of polypropylene pipes. In this case, it is advisable to purchase products from the same manufacturer.

The size range is presented in several options.For domestic needs, as a rule, fittings 16, 20, 25, 40 mm are used (this size corresponds to the outer diameter of the pipes used).

The maximum size for domestic pipelines is 50 mm, and for industrial pipes, polypropylene pipes of a larger cross section are produced. At the same time, technologies and elements for their connection are different.

Turkish quality or soap bubble?

Among the wide variety of polypropylene pipes, Turkish pipes occupy a separate place, which is justly deserved. Consider seven types of polypropylene pipes that have reliably mastered the domestic market.

Pipes and fittings TEBO

TEBO technics. TEBO technics pipes are manufactured from Ø20 to Ø160 mm. They are used for water supply and heat supply in industrial enterprises. They do an excellent job of transporting various aggressive chemical mixtures. The TEBO technics product line includes the production of PN10 and PN20 pipes. This type of polypropylene pipes is intended directly for the creation of water supply networks. The Turkish company TEBO technics produces reinforced pipes and fiberglass. According to estimates by TEBO technics, it is in the middle class of fitness. There should be no problems working with these pipes.

Pilsa

Pilsa. Unlike other polypropylene pipes, Pilsa is flexible, strong and durable. Due to this, these pipes are successfully used in cold / hot water supply systems and in heating systems. It is customary to use Pilsa PN20 for the heating system and hot water, and PN10 for cold water supply. For several years after their installation, you will not worry about their maintenance. The most important requirement is compliance with the installation technology.

Pilsa polypropylene pipes must not be hidden in the wall. To use these pipes in the heating system, a controlled boiler must be used, as otherwise a temperature of more than 95 ° C may be given.

For the sake of objectivity, one drawback of Pilsa pipes should be noted. After stripping pipes from aluminum, it can partially remain on the surface. This is because the pipes have a slight ovality.

Wesbo. The Turkish Novoplast plant produces polypropylene pipes, which are known as Wesbo. Although the price of these products is low, they are of high quality. However, as for the set of shaped elements, there is a big minus, since the choice is very small. But this is perhaps the only drawback, therefore, they are also very popular in our market.

Valtec

Valtec. Valtec Turkish pipes are of the best quality. PP-R 100 fittings are manufactured here, which allows the pipes to have greater reliability and strength. The pipes are perfectly round. The location of the foil in the reinforced pipes is ideal.

Firat. Fittings and pipes of the PPRC system from the Turkish company Firat are manufactured in accordance with all existing international quality standards. For many years the company has been occupying leading positions. These pipes are easy to install and maintain. They don't rust.

The only drawback of Firat pipes is their high coefficient of expansion when they are heated. If you use them in hot water supply, then Firat pipes can lead.

Kalde. Kalde pipes are often compared to Ecoplastic. But this comparison is biased, since Kalde pipes have a solid aluminum shell. Ekoplast has a perforated shell. Inside, Kalde plastic is gray. According to reviews, Kalde polypropylene pipes are softer and more pliable, and due to the lack of perforation on the aluminum layer, pipe delamination can occur.

If you do not follow the Kalde pipe installation technology, bubbles will appear on the pipe surface. Their laying is allowed only outside the wall.

Turkish pipes

Jakko. The company produces high-quality polypropylene pipes - reinforced with fiberglass. In the process of soldering, they show their best side. Joints can only leak if the specialist who soldered them does not have experience. Although most often problems arise when soldering hot water supply and heating. For cold water, Jakko pipes are ideal. Although the manufacturer claims a minimum level of linear expansion, there is sagging on a track of more than nine meters.

Expansion joints can be installed in the pipeline to cope with the problem of sagging. On average, every four meters.

The choice of a polypropylene pipe: advantages and disadvantages

The advantages of installing polypropylene pipes generally outweigh the disadvantages of these consumables.

Among the advantages it should be noted:

- a wide range of applications for such pipes - polypropylene is neutral and does not react with most transported media, therefore, the probability of surface corrosion is extremely small;

- ease of assembly of the pipeline - polypropylene pipes are connected by welding; the process itself is quite fast, and as a result, a homogeneous surface is formed that excludes leaks;

- slight expansion in the cold - when returning to normal temperature, polypropylene pipes take on their usual sizes;

- the products are smooth inside - they usually do not deposit impurities, so such pipes can be used for a long time and for the serviceability of the pipeline, pipes with a smaller section are sufficient than for similar products made of other materials;

- a relatively low price - for the same from plastic pipes, you can build a pipeline of much longer length than from metal ones.

There are two main disadvantages of polypropylene pipes. It:

- a significant increase in dimensions during heating (about 0.05 m / 1 m) - therefore, in order to avoid fracture and deformation of pipes operating in unstable temperature conditions, it will be necessary to provide compensators (lens or any other) in the pipeline design;

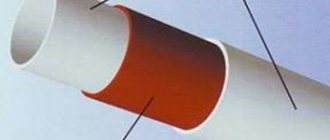

- oxygen permeability - acceptable for water pipelines, but unacceptable for heat supply systems; in this case, it is preferable to use aluminum-coated products, which have a significantly more suitable coefficient of thermal expansion, and isolation from oxygen, and a maximum operating temperature (up to 95 ° C).

Therefore, if the system is not designed to operate at high temperatures, polypropylene pipes are a perfectly suitable option for pipeline assembly.

Chinese pipes - cheap fake or good quality?

Although products from China do not always enjoy a positive reputation, good quality can be found among Chinese PP pipes. We present to your attention well-known pipe brands that can be found on the Russian market:

Blue ocean

Blue Ocean. The Chinese company Blue Ocean produces quality polyethylene fittings and pipes. As practice has shown, pipes from the manufacturer Blue Ocean are excellently soldered. For these pipes, it is customary to use soldering iron nozzles, which have small roundings that are located inside the nozzle. Thanks to this innovation, aluminum is better sealed with a layer of polypropylene. One of the disadvantages of pipes is the diameter error, which can fluctuate within small limits. Moreover, as the installers say, Blue Ocean pipes are tautly inserted into the soldering iron. And you have to solder by eye, since the red line is drawn in a spiral.

Dizayn. Dizayn pipes are available in reinforced form. There is no need to strip the aluminum before soldering. Thanks to this, their installation for both cold and hot water supply is accelerated and simplified. As a result, the soldering joints have an aesthetic appearance. Chinese Dizayn pipes occupy a worthy place in the Russian market. Even non-specialists can work with them.According to some indicators, they are not inferior to the leading European brands of polypropylene pipes.

So, although China is famous for producing cheap building material, you can find quality polypropylene pipes.

Welding of polypropylene pipes

To connect polypropylene pipes and fittings, a special tool is used - a soldering iron for polypropylene pipes.

The best option is a soldering iron produced by one of the well-known respected companies, equipped with a timer and a high-quality heating element. However, a pipe soldering iron can be assembled at home or even use a regular soldering iron.

For home use, a standard soldering iron for plastic pipes with a diameter of up to 50 mm with two or three nozzles is sufficient. For commercial use or non-standard piping, more advanced and expensive options will be needed.

The procedure for working with a soldering iron for polypropylene pipes is as follows:

- Install the nozzles on the heating element of the soldering iron: for melting the inner part of the fitting - a mandrel, for heating the pipe surface - a sleeve.

- Set the heating temperature to about 260 ° C.

- Connect the device to the network. When the heater reaches the desired temperature (usually within 15 minutes), the lamp on the device lights up (or vice versa goes out).

- Start welding products.

It should be noted that welding work with PP pipes and fittings can only be carried out at a positive temperature (at least + 5 ° C).

The heating time for different environmental conditions differs, more details should be written in the instructions for use of a particular device.

It is very important to maintain the heating time as accurately as possible, because with a longer time, the pipe will melt too much and become unsuitable for assembly, and with insufficient heating, a homogeneous mass will not come out of the pipes, which will significantly worsen the strength of the structure.

We must not forget about cleanliness: after each soldering, the mandrel and the sleeve should be wiped with a cloth, removing plastic residues. This should be done carefully: the scratched surface of the product is no longer suitable for further work.

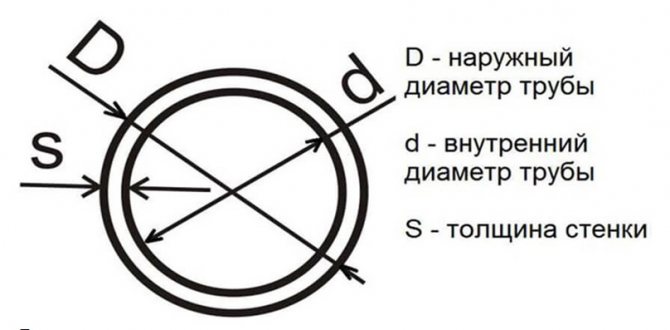

The diameters of polypropylene pipes and fittings should be related as follows: the outer diameter of the pipe should slightly exceed the inner size of the fitting. As a result, during soldering, a roll is formed - a burr, which increases the strength and insulation of the joint.

In accordance with this, it is necessary to select the fitting so that the pipe enters into it with effort, or it itself fits tightly on the mandrel of the soldering iron. If this or that condition is not met, a reliable connection will not work, and another, tighter fitting should be found.

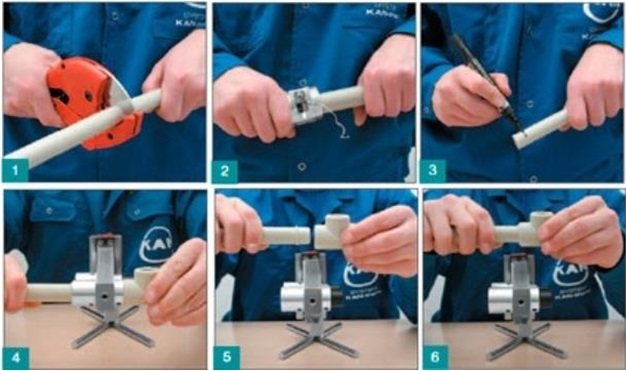

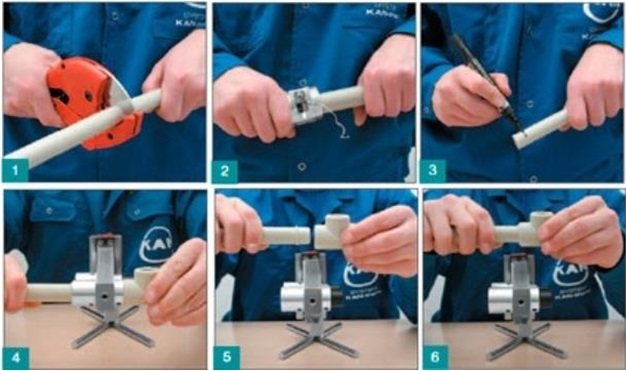

The algorithm for welding pipes is as follows:

- The required length of the section of the polypropylene pipe is cut with scissors. It is important that the scissors do not deform the pipe and that the end of the resulting cut is vertical with respect to the longitudinal axis of the pipe.

- The end and edges of the fitting are degreased (with soapy water or any alcohol), cleaned of burrs and dirt, and dried.

- If PN25 foil-reinforced pipes are used, with the help of a specific device - a shaver - a layer of material is removed from the welding site before the operation starts (otherwise the pipe will not enter the fitting; sometimes, if the foil is located in the central layer of the pipe, it is necessary to remove the protruding piece of aluminum using a facing tool.

- Align the stripped end of the pipe and the fitting until it stops, making a mark at a distance of 2 mm from the edge of the fitting in the assembled state. It is possible, if available, to use a dedicated measuring tool with marks for pipes of any cross section.

- The fitting and the pipe are put on the soldering iron nozzles and start heating.

- After the due date, the elements of the future connection are removed from the nozzles and connected by inserting the end of the pipe into the fitting until the mark is made. After joining, it is impossible to change the position of the elements, otherwise the seam will collapse.

- Allow the compound to cool.

If it turns out that the elements are not neatly spliced, you can cut off a part of the pipe and weld a new fitting onto it. You can do this until the length of the segment is exhausted, without any consequences.

The whole process is repeated as many times as necessary until the pipeline is completely assembled.

Are Czech pipes a quality standard?

On the market for polypropylene pipes, Czech pipes also take their place. And to be convinced of this, we propose to consider the features of well-known brands of Czech polypropylene pipes.

Wawin

WAWIN Ecoplastik. Czech WAWIN Ecoplastik pipes are considered a quality standard in Europe and the world. From the first batch, WAWIN Ecoplastik polypropylene pipes have proven themselves only on the positive side. Due to the good quality and selection of fittings and pipes, the Ecoplastik system has become popular in many countries. Czech polypropylene pipes are used:

- for hot / cold water, air, underfloor / central heating;

- PN 10 - for underfloor heating and cold water supply;

- PN 16 - for low pressure central heating and high pressure cold water;

- PN 20 - for hot water supply and central heating.

The product range of WAWIN Ecoplastik polypropylene pipes includes:

- PP-R - all-plastic PN 10, PN 16 and PN20.

- Ecoplastik Stabi - multilayer PN 20. The pipe consists of a layer of plastic, foil and aluminum.

- Fiber polypropylene pipe.

- All-plastic and combined fittings.

WAWIN Ecoplastik manufactures fiberglass reinforced Fiber pipes. They are used in various directions: heat supply, water supply systems for any purpose. Before soldering, there is no need to strip the aluminum from the surface. Fiber pipes have high strength with 3 times linear expansion.

FV-Plast

FV-Plast. Czech FV-Plast pipes are used for heating and water supply systems. A layer of aluminum is included in the structure of the pipe. Thanks to this, the design of the pipes is more resistant to temperature extremes. Due to the presence of a large number of fittings, all kinds of water supply and heating structures can be soldered. FV-Plast is used not only for the manufacture of plumbing and heating systems. They are used in agriculture and industry. Also used for air duct wiring.

The low weight of the FV-Plast pipe makes installation simple and safe. There is a slight roughness on the inner wall of the pipe, which does not affect the water pressure in the system.

Why choose polypropylene pipes and fittings when installing engineering systems?

Many people know how long and labor-intensive the installation of heating and water supply systems in a country house can be. This process includes steps such as: developing a project, purchasing the necessary materials, and, finally, assembling all the elements according to the calculated data.

When purchasing components for a pipeline, one has to choose between metal and polypropylene.

Choosing metal pipes, you are faced with the need to find a qualified welder and ensure the delivery of massive material to the work site. Polypropylene (PP) pipes have the following advantages: short time required for the production of works; ease of transportation; service life of the water supply system.

For high-quality welding of PP pipes, you will need to purchase a compact welding machine, as well as select pipes and fittings of the required size. Let's figure out how to choose fittings for polypropylene pipes.

There are several types of fittings:

- bends and corners, the size of which is selected according to the outer radius of the pipe;

- tees for bends;

- crosses;

- adapters that allow you to connect pipes of different radii;

- couplings for joining two pipes of the same radius;

- fittings - for connecting the hose;

- plugs that are mounted at the end of the pipeline.

When work is carried out in heating systems, universal PP fittings are used to connect polypropylene and metal. Such fittings are used for the installation of pipes with radiators and boilers.

Polypropylene products have a number of advantages that have made them so popular. First of all, the price is affordable in comparison with steel pipes. Secondly, PP pipes have a long service life - more than 50 years, because the material is not afraid of corrosion. It is worth mentioning that in order to achieve such a service life, the temperature of the fluid in the system should be no more than + 70 ° C.

If these conditions are met (for example, in water supply systems), PP pipes and fittings will serve for a long time. The inner surface of polypropylene products is smooth, therefore, PP pipes do not clog up, do not harm the environment. Subject to the technology of low-temperature brazing of polypropylene pipes, the likelihood of leakage is very small.

One of the disadvantages of polypropylene is the inability to use it at temperatures above +110 ° C and high pressure. Under such conditions, polypropylene pipes are deformed or ruptured from excessive pressure.

Read the material on the topic: Fittings for metal-plastic pipes

Domestic manufacturer keeps the brand

Although our market is filled with imported materials from different countries, Russia also produces polypropylene pipes. There are several well-known manufacturers of Russian polypropylene pipes.

PRO AQVA. Polypropylene pipes PRO AQVA are used in a wide variety of areas: water supply, heating, pneumatic pipelines and process pipelines. These pipes are capable of withstanding operating temperatures up to + 95 ° C. They are resistant to corrosion. Easy to install. They are distinguished by high chemical resistance. They are harmless to the environment and to humans. Unlike Chinese pipes, PRO AQVA is 1.6 times stronger.

Only PRO AQVA can withstand a pressure of 79.5 atm, so their service life exceeds the service life of all its analogues.

RBK. Since 2007 RBK has been producing multilayer polypropylene pipes PN 25. PP-R / AI / PP-R polypropylene is used for their production. There is an aluminum reinforcement in the middle of the pipe. In reinforced pipes, the aluminum layer is located outside the walls. For objectivity, negative customer reviews should also be noted, who agree that the diameter of the pipes is walking.

Heissekraft

Heisskraft. Reinforcement of pipes takes place in Germany. Heisskraft pipes are of high quality. They have a characteristic gray color. This is due to the fact that technical soot is added to the polypropylene composition. This substance serves as a stabilizer for polypropylene pipes.

Polytec. Polytek pipes are little known in our market. Although, according to reviews, it can be concluded that these pipes have an above average rating. But, according to the installers, the walls are subject to deformation during the compression process. Soldering Polytec pipes does not create any difficulties. The only drawback is that fittings are not always available for sale, so they should be bought at the same time when buying the pipes themselves.

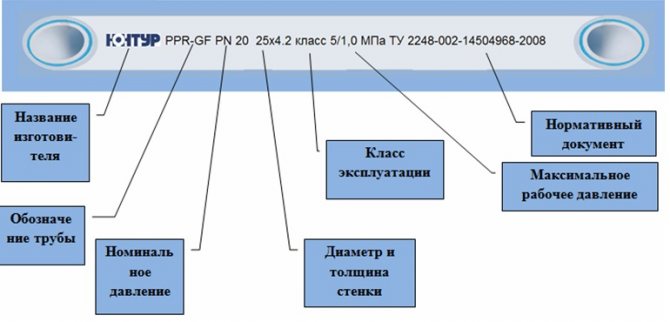

Marking of polypropylene pipes and permissible temperatures

By marking products, you can determine their main parameters, which facilitates the selection of polypropylene pipes for water supply.

- PN10 - pipes designed for a pressure of 1 MPa with an outer diameter of 20-110 mm and walls of 1.9-10 mm. They are used for transporting cold water (temperature not higher than 20 ° C) and installation of a "warm floor" (up to + 45 ° C).

- PN16 - allowable pressure 1.6 MPa. The brand is rarely used, it can be used for water up to + 60 ° C, installation of heating communications under the floor covering. Diameter - 16-110 mm, walls 2.3-15.1 mm.

- PN20 is a grade designed for pressure up to 2 MPa and temperatures up to + 80 ° C. Diameter - 16-110 mm, walls 1.6-18.4 mm

- PN25 - special pipes for heating with reinforcement, designed for pressures up to 2.5 MPa and temperatures up to + 95 ° C.Also used for hot water supply and process piping systems. Diameter - 21.2-77.9 mm, walls - 4-13.3 mm.

Labeling of polypropylene pipes for water supply will help you choose products for a specific object.

Exemplar

Polypropylene pipes made in Germany are of the highest quality. To verify this, you can view the characteristics below from well-known manufacturers.

Wefatherm

WEFATHERM. German WEFATHERM pipes are used for laying heating and plumbing systems. The company produces not only polypropylene pipes, but fittings and fittings. Pipes are made both with aluminum and reinforced. These pipes have a number of clear advantages over their competitors:

- The inner surface of the pipe walls is smooth. As a result, the water pressure does not drop.

- A wide range of fittings that allows you to combine WEFATHERM pipes with each other and with other systems.

- A perfectly sealed joint is formed by diffusion welding. It does not take much time to cool and process the compound.

Aquatherm GMBH. The German company Aquatherm GMBH is a leader in the production of polymer pipe materials. The products are used for underfloor heating, heating, water supply, air conditioning and fire extinguishing. Pipes Aquatherm GMBH are produced in different series and versions.

Fusiotherm

For example, Fusiotherm universal polypropylene pipes. They are made of PP-R 80 polypropylene. This pipe has found its wide application:

- Compressed air.

- Cold water.

- Hot water.

- Conditioning.

- Heating mains.

- Heat supply.

- Heating of stadiums.

- Shipbuilding.

- Cooling of ice rinks.

Fusiotherm pipes are also used for pumping more than three hundred types of chemicals.

It is customary to use Faser for heat supply. The diameter of pipes and fittings ranges from 20 to 250 mm. The pipe is composed of fiberglass and reinforcement. Faser polypropylene pipes withstand operating temperatures up to + 95 ° С with pressures up to 20 atm. The color of the product is green. Pipes are also produced in white, but Ø20–40 mm.

Stabi pipes have also proven themselves positively. These are perforated pipes with a layer of aluminum. They are recommended for use in heating systems. Stabi diameter ranges from 16mm to 110mm. The peak operating temperature is considered to be + 130 ° C with a pressure of up to 20 atm. The pipes are distinguished by the presence of perforations.

Climatherm products are used for cold water supply and air conditioning. The diameter of the pipes is 20–630 mm. The composition of polypropylene includes fiberglass and a reinforcement layer.

Banninger

BANNINGER. German BANNINGER pipes and fittings are also distinguished by their high quality and reliability. BANNINGER pipes have found their wide application in the field of heat supply, water supply systems, and various industries. BANNINGER pipes are available in different series:

BANNINGER series PN 20 and PN 16. These pipes are used for cold and hot water supply. They are made of PP-RCT polypropylene. This is a new generation material. Its structure resembles a crystal. Its technical characteristics are improved by 50% in comparison with all analogues. Numerous crystals in the structure of polypropylene are formed due to a special cooling technology. The result is a very flexible and dense product. These features make it possible to withstand pressure up to 20 bar at a temperature of + 95 ° C for a long time.

BANNINGER Stabi. The Stabi pipe series is made of multilayer composite material. They are mainly used for heating and water supply for hot and cold purposes. These pipes are made from crystal structure PP-RCT copolymer. BANNINGER Stabi are distinguished by many positive characteristics, for example: minimal thermal expansion and high mechanical strength. Before welding the pipes, it is necessary to remove the layer of polypropylene and aluminum.

BANNINGER Faser. They are similarly used for water supply and heating. The structure of the plastic resembles that of a crystal. The pipes are fiberglass reinforced.Unlike conventional polypropylene pipes, BANNINGER Faser is characterized by high strength, resistance to temperature changes and a low coefficient of linear expansion.

BANNINGER Faser pipes do not require pre-stripping of aluminum. This greatly speeds up and simplifies the installation process.

BANNINGER Climatec. The BANNINGER Climatec pipe is made of composite laminates. Used primarily for air conditioning, ventilation and industry. The inner plastic layer is reinforced with PP-fiberglass. BANNINGER Climatec, unlike Stabi, does not delaminate. They do not require preliminary stripping.

Rehau. In Russia, the most famous German polypropylene pipes from Rehau. They are used for various engineering structures in residential and public premises. The duration of operation directly depends on the skill level of the specialist.

So, we examined with you the features of the famous German polypropylene pipes. As you can see, their assortment is diverse, and the scope is wide.

The procedure for welding polypropylene pipes with fittings

Independent installation of a household polypropylene pipeline with the necessary equipment and high-quality components is not difficult. To do this, you will need a special soldering iron with a suitable size for pipes and fittings. The order of work is as follows:

- Using a roller cutter, cut off a piece of pipe of the required size strictly perpendicularly.

- Clean the cut with emery (you can additionally degrease).

- Fix the necessary tips on the soldering iron and heat it up to a temperature of about 260⁰С.

- Put a fitting and a piece of pipe on the heated device, wait for the allotted time (it depends on the diameter and ranges from 3 to 10 minutes).

- Remove the parts and insert the pipe into the fitting to the maximum depth (all the way) without rotating.

Then you need to leave the connection until it solidifies completely at room temperature. Sagging from it, as well as the remnants of polypropylene from the nozzles are removed with a rag.

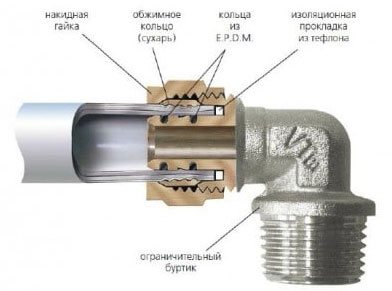

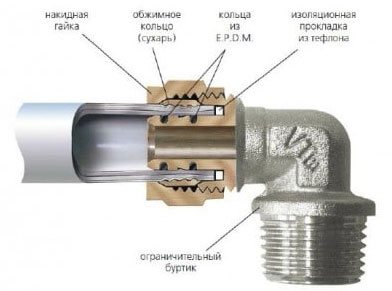

Compression and press fittings

These types of connecting elements are used more often for reinforced PP pipes and are made of brass (body). Each of them has features of installation and operation, and the advantage of both over a welded joint is the absence of sagging inside the pipe that reduces the throughput of the system.

Compression

The element consists of a brass body, o-rings, union and compression nut. The tightness of the joint is ensured by squeezing the sealing material when crimping the pipe.

From tools, you will need a regular open-end or adjustable wrench. This type of connection withstands a pressure of 35 bar and is designed for a service life of 30 years, periodically tightening the nuts is required.

Press

They consist of a body and a union with a crimp sleeve. This design provides the most tight connection, however, special pliers will be required for work.

The cost of this tool varies between 3-10 thousand rubles. Since the withstanding pressure and service life of the press fittings is higher (75 bar and 50 years, respectively), the pipeline can be located inside monolithic structures.

We recommend that you familiarize yourself with: Which fittings are best for drip irrigation

Drip Irrigation Fittings

The connecting fittings used in the installation of drip irrigation systems are called start connectors. They are intended for attaching drip tapes - branches from the main line. The delivery port of the start connector has a standard 16 mm diameter. Installation is carried out as follows:

- A hole is made in the main pipe with a conventional or special 17 mm drill.

- First, the seal attached to the connector is inserted into it, and then the fitting itself.

- The drip tape is attached to the fitting and then secured with a crimp nut.

There are several types of start connectors: there are crosses and tees for diverting several tapes, couplings for repair, as well as fittings with taps that regulate the water supply to the tape.

Polypropylene pipes: manufacturers and product quality

Among the manufacturers of PPR pipes, it should be noted such companies as:

- Valtec (Italy)... The pipes are produced in three variations: with thin walls, reinforced with fiberglass or aluminum foil (99.4% aluminum). In production, American and Japanese adhesives are used to join the layers, therefore the pipes are characterized by increased strength (70 N / 10 mm at a rate of 15 N / 10 mm). Used in production. The manufacturer uses tapered sockets to facilitate connection. In addition, mixed (threaded) fittings are available in octagonal shapes so that standard wrenches can be used for operation.

- Banninger Kunststoff-Produkte, GmbH (Germany)... The production uses high quality plastic (random copolymer brand) with increased strength and chemical resistance. The products can be used for the installation of drinking water pipelines. Such pipes are more expensive than analogues.

- Wavin Ecoplastic (Czech Republic). As the name of the brand suggests, a chemically neutral polymer is also used in the production, suitable for the transfer of drinking water. Pipes of the Stabi series are reinforced with aluminum foil, Fiber and Basalt + - with basalt fiber.

- Kalde (Turkey)... Pipes of acceptable quality at the same prices. Simple products are available, reinforced with fiberglass (Fiber) and perforated foil (Superpipe), so there is no need to clean and trim the pipe during welding. The pipes have a typical service life (50 years) at temperatures up to 70 ° C.

- Tebo (Turkey)... The pipes are made of random copolymer polypropylene with increased durability. The company has GOST, DIN, TSE certificates. Product diameter - 20-160 mm, pipe grades - PN10, PN20, PN25.

- SPK (Turkey)... Raw materials from the Netherlands and equipment from Germany are used, the price of products is lower than that of a European manufacturer. The pipes are quite resistant and can be used in Siberian conditions.

As you can see, there are many manufacturers and brands of pipes, and each craftsman will have something to choose from. After all, the main thing is not the cost of the product or the country of origin, but the correct calculation and accurate work during the installation of the pipeline.

Fitting installation diagram

A detailed diagram of the installation of polypropylene fittings depends on the type of connecting element.

Weld Fitting Installation

The installation of the pipe connector by welding is carried out in the following sequence:

- the pipe is cut using a special pipe cutter or scissors (hacksaw) in accordance with the dimensions established by the pipeline diagram;

- the end of the pipe to be connected to the fitting is cleaned of burrs;

- the area that needs to be warmed up is marked. Typically, this area corresponds to the depth of the mating connector;

- a prepared pipe cut and a fitting are inserted into the heated welding machine. The duration of heating of the elements to be joined depends on such parameters as the diameter of the pipe and the depth of the weld;

Determination of the heating and cooling period of the weld

- the heated elements are connected. In this case, distortions and deformation should be avoided, since they affect the quality of the weld and, accordingly, the tightness of the connection;

- the finished joint is held in a predetermined position until it cools. The cooling period is also indicated in the table in the photo from point 4.

Weld Fitting Installation Process

The technology for mounting welded fittings is shown in the video.

Connection type

When the plan of the future system of polypropylene pipes has already been drawn and the number of various components has been calculated, the question arises of which fitting is needed.

There are 3 main types of fittings, differing in both material and type of connection:

- compression, including Eurocon;

- crimp press fittings;

- directly polypropylene.

Now let's look at each of them in more detail.

Compression fitting

It can be made of various materials:

- plastic,

- brass,

- chromium.

What matters here is not so much what it is made of, but how the pipes are connected and how they are sealed.

In general, a fitting consists of two large sleeves that are fastened together using a threaded connection. Inside them there are special crimping rings, which, when the bushings are connected, compress the pipe, as if flattening it. Rubber gaskets, also inside, provide additional sealing of the connection.

The main advantage of this type of fittings is the ability to disassemble them several times. Even if the first time it was not possible to connect the pipes together, you can correct the error by removing the fitting and planting it a second time. In addition, the threaded type of connection allows you to completely disassemble the pipe system and assemble it in a new place.

Another advantage is that when installing household plumbing, no other tools are required, only the muscular strength of the person himself is enough.

But there are also disadvantages: if you tighten the nut too much, then the pipe is deformed, it can crack and leak. During long-term operation, it is necessary to tighten all connections every few years in order to avoid skipping of the transported liquid.

Compression fitting

Outwardly, such fittings for polypropylene pipes practically do not differ from compression ones. But to seal the joint between the fitting and the pipe, a special device is used - crimping press tongs. A crimping sleeve is put on the pipe, which is crimped with these pliers.

This type of connection of plastic pipes is much better than compression, so the applied force seals the joint much better.

But if a leak occurs, the fitting will have to be completely replaced, since it is non-separable. Another disadvantage is that you need a special tool, the cost of which starts from 10 thousand rubles.

Polypropylene fitting

Perhaps the most common type of fittings for connecting polypropylene pipes. When they say the word "fitting", they usually mean just this kind of it.

The connection principle is quite simple:

- The pipe and fitting are heated to a certain temperature at which they soften.

- The pipe is inserted into the fitting.

- After cooling, the joint is ready.

Here are solid pluses compared to other types of fittings:

- Brazing provides a perfect seal as the joint is integral with other parts of the pipeline.

- No additional control required, brewed - forgot.

- The soldering machine itself is relatively inexpensive and easy to operate.

- The absence of forceful action minimizes the possibility of damage to individual parts.

Another important point is not to overexpose the product in the soldering iron. There is a direct relationship between the pipe diameter and the heating time. The table below shows data for the most popular diameters.

| D, mm | Heating time, seconds | Welding time, seconds | Cooling time, minutes |

| 20 | 5 | 4 | 2 |

| 25 | 7 | 4 | 2 |

| 32 | 8 | 6 | 4 |

| 40 | 12 | 6 | 4 |

| 50 | 16 | 6 | 4 |

| 63 | 24 | 8 | 6 |

| 75 | 30 | 8 | 6 |

| 90 | 40 | 8 | 6 |

| 110 | 50 | 10 | 8 |

What type of connection to choose

While compression and compression fittings have many benefits, they are not recommended for polypropylene pipes. Leaving aside the possibility of leaks, we can say that their main drawback is that during installation there is a high probability of damaging the pipe itself, and this is fraught with its complete replacement in the future.

Therefore, the best option for a polypropylene pipeline is a soldered fitting.