Heating systems implemented in private housing construction are presented in several options.

Only knowing how best to make heating in a private house on your own and correctly, you can get a high-quality and durable system with a minimum investment of time and money.

Read on for more details.

Principle of operation

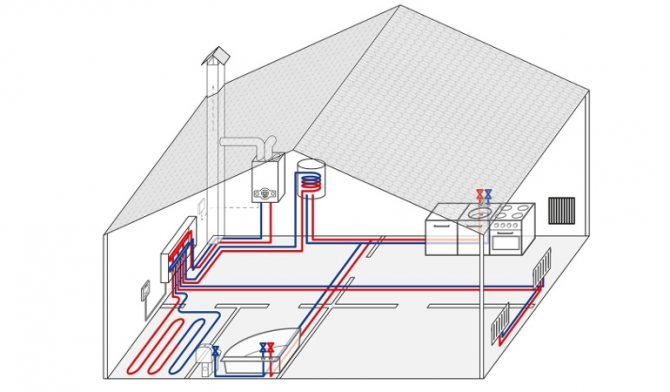

The heating system operates with the use of a heat carrier heated to certain temperature indicators. Heating is carried out inside the heat exchanger, after which, through the pipes, the coolant reaches the radiators, where it is cooled and, in compliance with the cycle of the process, returns to the boiler again.

- In open systems the squeezing out of the heated coolant from the heating unit is carried out under the influence of cold water, therefore, gravity distribution through pipes and radiators is observed. Lightweight air from the system is forced into the expansion tank, which is able to maintain a stable pressure level in the heating system.

- Closed or forced systems are distinguished by the circulation of the coolant using pumping equipment. A standard pump allows you to maintain a stable pressure in the range of one to three atmospheres.

Despite the fact that the forced operating principle is more promising and easy to maintain, today such heating circuits are used less often than the time-tested open systems.

Setting up the heating system

After filling the system, you need to go through all the radiators and bleed the air through Mayevsky's taps: open the Mayevsky's tap, first the air comes out, then the tap "spits" with air and water ... when only water has flowed out, it means that the radiator is filled with water, we close the Mayevsky's tap. And so on for all radiators.

Most likely, the pressure will drop after manipulating the radiators, so we recharge the system to the operating pressure. If there is a second floor, we bleed the air from its radiators in the same way. And - we feed the system up to working pressure.

We bleed air from the circulation pump. The pump has a screw, it needs to be slightly unscrewed with a screwdriver with a wide slot. First, as from radiators, air will come out, and then a thin stream of water. Then tighten the screw. Check pressure, top up heating fluid if necessary.

Important! Before going any further, listen to see if the pump is running. It happens that it does not work because its rotor has soured. We turn off the pump and fix it, for which it is necessary: 1) unscrew the screw in the center of the pump motor; 2) inside, at the end of the rotor, there is a slot, insert a screwdriver into it and turn the rotor; 3) screw the screw into place. Let's turn on the pump again, it just has to work now.

For 10-15 minutes. Moreover, after 1 ... 2 minutes of work, we unscrew the screw on the pump again, if there is water, everything is in order. When the pump is turned on, you will hear that air has flowed out of the air vents again, this is also normal. And the pressure will drop, and we will feed the system to the 1.5 atm we need.

While the pump is running, we go through all the Mayevsky taps and check for the absence of air in the radiators. And again we supply the system to the required pressure.

Now we believe (so far we only believe) that the system is completely filled with a coolant (but we are not very deluded, air can leave the system up to 3 weeks and even up to a month, especially if there is a water-heated floor; air will come out of the warm floors itself through the air vents on the manifolds).

Components

The main component of the heating system of a private house is a heating boiler:

- solid fuel models;

- gas models;

- electrical models;

- liquid fuel models.

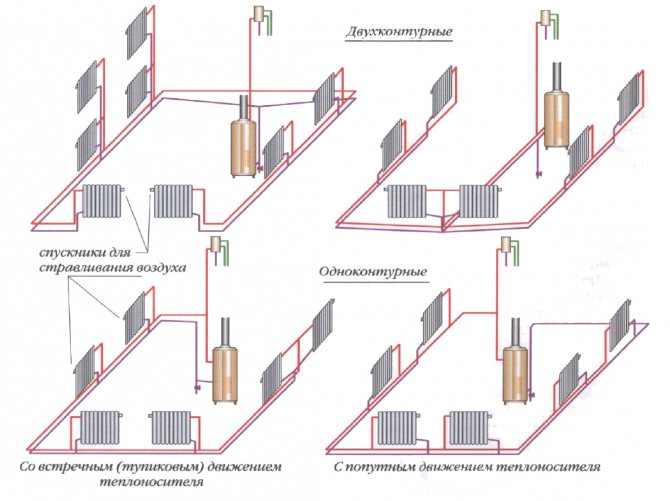

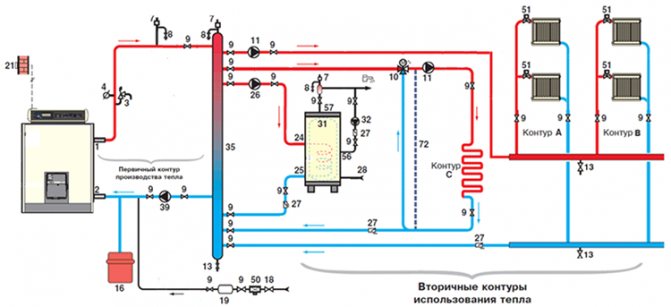

Heating system diagram

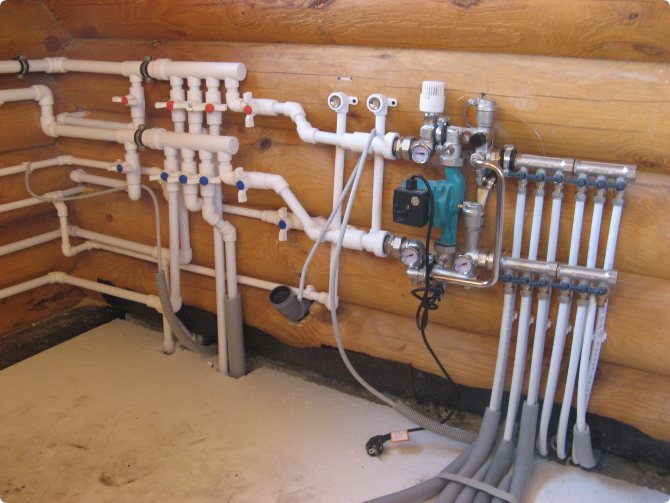

Also, for self-installation, it is necessary to purchase additional components, which can be represented by pipes and radiators, a circulation pump, an expansion tank and a coolant, an air valve and other devices.

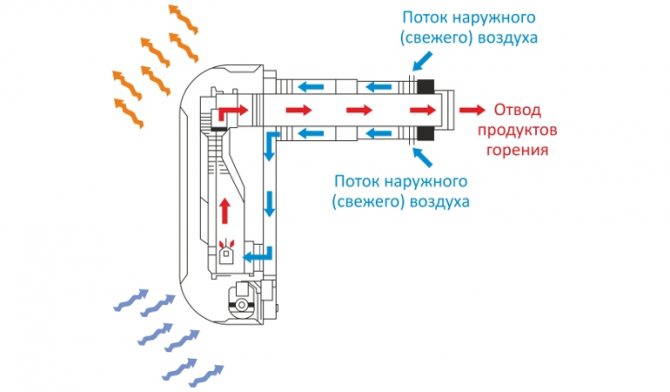

Particular attention should be paid to the choice of a heating boiler, which may differ in the place of installation, the design of the chimney, the type of fuel used, the number of circuits, as well as the materials of the heat exchanger.

Checking the elements of the heating system

Without the correct functioning of all the nodes of the heating system, it will not be possible to start it correctly. First of all, it is necessary to check the operation of measuring devices - thermometers and manometers.

It is also necessary to check the functioning of the protective elements. The system may not start up if the seats of the bleed valve or air vent do not move due to limescale or rust. For this reason, each of them is opened manually.

The air chamber pressure controls the expansion tank, it must exceed the nominal value in the system by 5-7%. If the design of the tank allows the membrane to be changed, it should be disassembled and checked in what condition it is.

The cost of the service for launching a heat supply system in a private household depends on many factors and is determined on an individual basis.

- Author: Maria Sukhorukikh

Rate the article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Liquid circulation options

Systems with a natural circulation option do not allow for fast and complete heating of large areas, which is due to the insufficient transfer rate of the heated coolant through the pipeline and radiators. The wrong location for mounting the expansion tank can cause the water to freeze, and moisture often causes corrosive changes to the metal components.

The forced circulation of the coolant allows you to equip the "warm floor" system, and is also widely used, if necessary, to install indirect heating equipment.

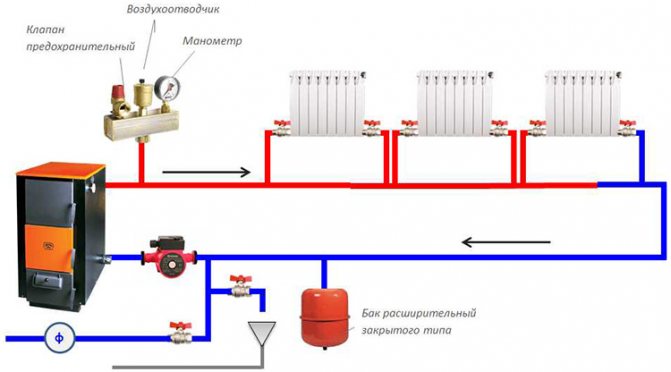

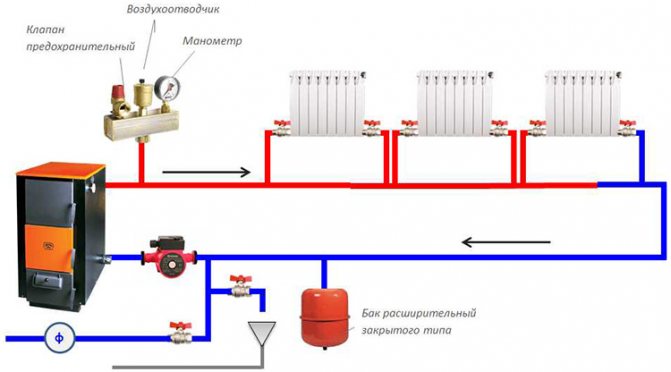

Scheme of a closed one-pipe heating system

Among other things, with a closed liquid circulation system, pumping equipment and an expansion tank can be compactly placed inside one room, which minimizes the risk of freezing of the coolant.

The forced circulation option is the most preferable, and allows not only to control the speed of fluid movement through the system, but also to regulate the heating temperature by means of thermostatic valves.

Preparatory stage

As a rule, in warm weather, the heat supply structure is not used. Therefore, before starting heating in a private house, you need to make sure of the integrity and reliability of its elements and perform a number of preparatory work. Before using a closed heating system, you need to determine the deviation of its actual indicators from the calculated parameters.

According to the rules, preparation for the heating season is carried out in a certain sequence. First of all, a visual inspection of communications and heating equipment is carried out. For a property owner, the question of how to start a radiator should not come first. First of all, he needs to make sure that there are no mechanical damages on the device case and check the reliability of its connection to the pipeline.

Also, before starting the heating system, a number of preventive measures are taken:

- Checking the condition of the flue gas system. In order to start the boiler, there must be sufficient draft force in the chimney to maintain combustion.For this reason, the internal cavities are cleaned of soot and the integrity of the pipe is inspected. In a brick structure, damaged elements are replaced if necessary. Rust is removed on galvanized pipes, if any.

- Visual inspection of pipes. Without this, it is dangerous to start the heating system. It is necessary to find out how tight the pipes are, whether there are cracks or noticeable defects.

- Battery condition monitoring. The management company, before starting heating in an apartment building, must warn the tenants about this, and they must check the integrity of the radiators. Individual devices must not be disconnected from the heating network. When filling the pipelines, make sure that there are no coolant leaks.

Choosing the right equipment

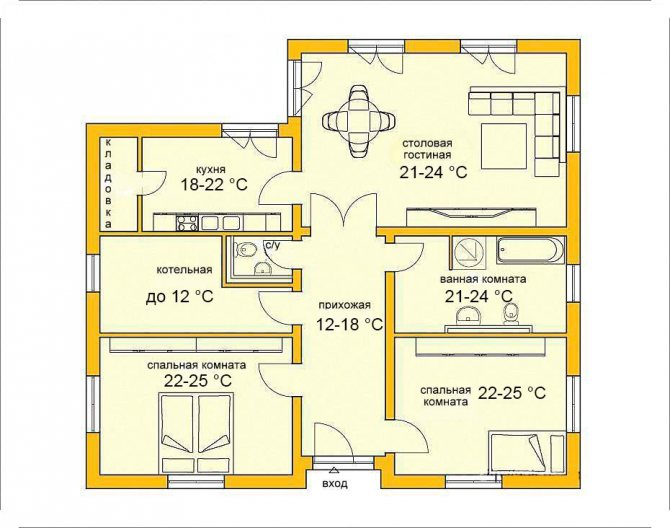

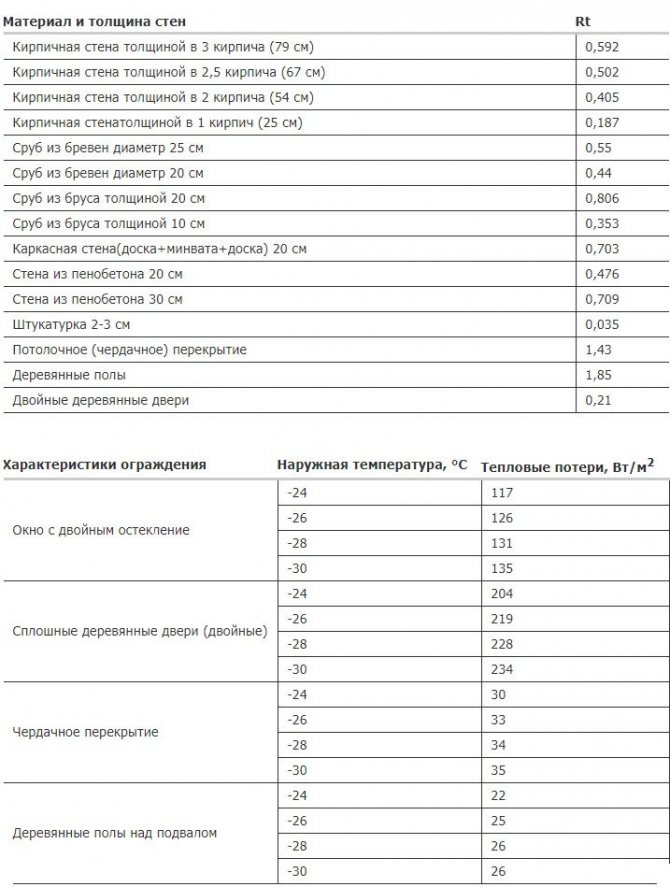

When choosing the equipment that will be used in the arrangement of the heating system, many factors must be taken into account, including the area of the room, the coefficient of thermal conductivity of the walls and the mode of operation.

Boilers

The main parameters of a heating boiler are represented by its power and the type of fuel used:

- For every 10 m2 of heated area in an insulated private house with a ceiling height of no more than three meters, 1 kW of boiler power will be required. If necessary, you can resort to the help of designers who perform the correct heat engineering calculations taking into account all environmental factors.

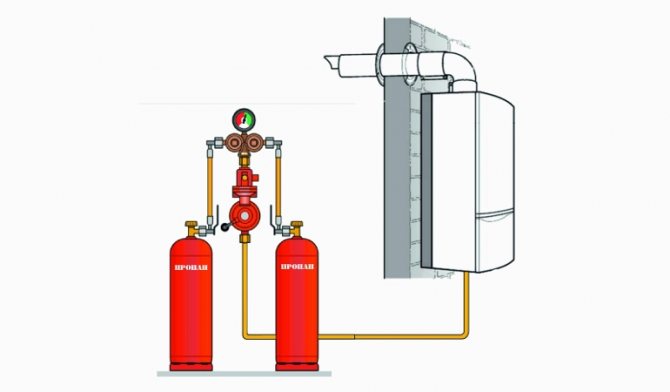

- Fuel can be liquid or diesel, as well as represented by electricity, main or bottled gas. But the most widespread are solid fuel boilers operating on coke, pellets, wood or coal.

No less important selection criteria are the material of manufacture, as well as the method of installation. Modern and very easy-to-use boilers can be wall-mounted and floor-standing, single-circuit and double-circuit, non-volatile and volatile, with forced or natural draft.

Pipeline

The decisive importance in the integrity of the heating system is given to the pipeline, which ensures the movement of the coolant and its delivery to the radiators. The pipeline must be as strong and durable as possible, and also have maintainability.

Optimal thermal conditions are determined by the tightness and quality of the pipeline system, therefore, when choosing pipes, you need to pay attention to the following parameters:

- option of laying and arrangement of pipes;

- average temperature of the coolant;

- pressure indicators inside the pipeline system;

- heating system configuration.

Heating pipelines in a private house can be metal, plastic and metal-plastic. The first option is represented by copper and steel pipes, but it is best to use galvanized products, which are less susceptible to corrosive changes. Galvanizing can be diffusion or hot.

The organization of the natural circulation heating system is most often carried out with galvanized, stainless or steel pipes, observing the necessary slopes. The most modern, convenient in operation and maintenance option is the use of pipes based on reinforced polypropylene. Such pipelines can be not only external, but also internal, due to the high quality and durability of the material.

If in the house, in addition to the standard heating system, there is also a heat accumulator, heated floors and a pool, then you cannot do without a hydraulic arrow for heating. Read more about the functions of this system.

How to convert Gcal to kW and vice versa, read on. Formulas and examples.

In the event of an emergency, the safety valve in the heating system relieves pressure to prevent a breakthrough. You will learn more about how such a valve works from this material.

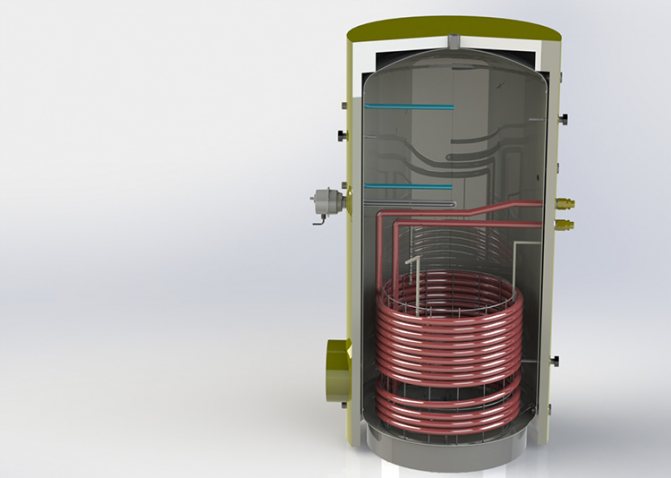

Heat storage devices

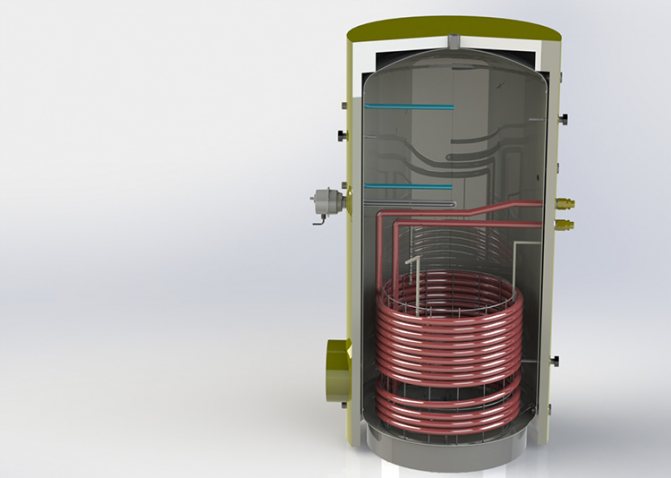

Heat accumulators provide the accumulation of thermal energy in the process of its excess generation by the source, as well as further use if necessary. It should be noted that devices for the accumulation of thermal energy are necessary only for boilers that operate in a periodic mode..

These appliances include coal or wood-fired boilers. Uninterruptedly operating equipment, represented by gas or electric models, has continuous fuel supply systems, so they do not need heat accumulation.

Heat storage from the inside

The coolant can be represented not only by water, but also by antifreeze. To preserve heat, the battery capacity must be additionally insulated with layers of high-quality heat insulator and installed on a warm base. The sealed tank should have a pair of holes for piping connections.

The heat accumulator is connected to the heating system in parallel to the boiler with supply and return connections. A prerequisite for proper organization is the use of high-quality valves.

The air option is an old proven way

It should be noted that it belongs to the oldest heating methods and was popular even before our era. Of course, during this period, a lot has changed and improved, but the essence of the method remains the same. In this case, warm air is used for heating, which is supplied to the house. Air heaters act as heating devices.

Heaters for supplying warm air to the house

The heating temperature is very easily regulated, and you can make it minimal, for example, during the day or if you are going to leave for a few days, and when you come back, increase it to the required limits. This system is optimal for areas with high humidity, since it dries the air, but if there is no such need, then you should simply use it in conjunction with humidifiers. In addition, more sophisticated systems are equipped with ionizers, purifying filters and can supply chilled air in hot summer, thereby providing the most favorable microclimate all year round. You can also combine this view with a wood-burning stove, it is so easy to heat the house, even if there was a failure with the central system. And the installation of heating of this kind will not cause any particular difficulties.

The disadvantages are as follows. Due to the forced draft, dust from the street can penetrate into the room, and the filters quickly become clogged and need to be replaced. So this heating is not suitable for residents of industrial areas. Prepare for the fact that if the fan fails, the house will quickly cool down. And if carbon monoxide gets into the system, it spreads very quickly throughout the home.

Execution of works

The level of complexity of self-installation of a heating system in a private house directly depends on many factors, including the type of pipeline and boiler installation, as well as the way of circulation of the coolant.

Boiler installation

First, the heating boiler is installed. For this purpose, a concrete or asbestos cement substrate must be installed. The easiest way to mount gas and electric hinged models. As a rule, such devices are equipped with special fasteners designed for the weight and dimensions of the installed heating equipment.

Oil-fired boiler in the heating system

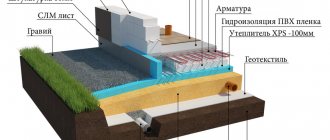

It is somewhat more difficult to install a floor-standing solid fuel boiler on your own. The place reserved for the installation of such a heating boiler is necessarily filled with a layer of standard concrete screed with a thickness of at least a centimeter.

The completed screed and the installed lower part of the boiler should be in contact as tightly as possible, and any gaps should be eliminated using a special heat-resistant sealant.

Installation of heating radiators

Before installation, you need to make sure that the purchased models comply with the requirements for the safe operation of devices:

- bimetallic radiators are designed for 35 atm .;

- steel radiators are designed for 6-9 atmospheres;

- cast iron radiators are designed for 10-15 atm .;

- aluminum radiators are designed for 16 atm.

It is necessary to start installing heating radiators by installing brackets, which are fixed with dowels to the wall. The best option for the location of the heater is installation in the window sill, taking into account the following basic requirements:

- the distance of the radiator battery from the vertical surface represented by the wall is 2 cm or slightly more;

- the distance from the window sill and the lower horizontal surface represented by the floor is within 10-20 cm.

The surface is pre-marked for fasteners in compliance with the level vertically and horizontally. Then, in accordance with the markings already made, radiators are installed, and the absence of any slopes that can impede the movement of the heat carrier is checked.

It is important to remember that for arranging a heating system in a private house, a pressure of two or three atmospheres is considered normal, so the mounted radiator should easily withstand such loads.

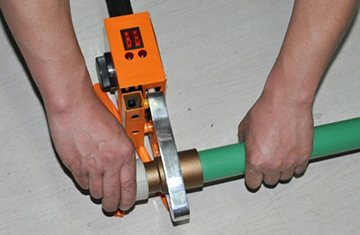

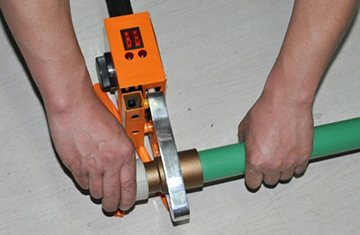

Welding of polypropylene pipes

Polypropylene pipelines are great for self-implementation of a heating system in a private house.

They are distinguished by a long service life, are not subject to the formation of rust and rot, are lightweight, and can also be installed by hand, without the involvement of specialists.

To create a heating system based on reinforced polypropylene, you will need to purchase fittings represented by corners, tees, bypasses, adapters and couplings.

It is necessary to weld polypropylene pipelines with a special device called a soldering iron or a welding machine. A pair of elements is heated by the tool to the melting temperature, after which it is combined in a hot state.

For high-quality heating of the inner part, a mandrel is used, and the outer surface is heated using a sleeve. If welding or brazing is done correctly, then the resulting joint is characterized by solidity and high reliability.

The heating temperature required for soldering is set on the regulator of the welding machine. Reinforced polypropylene pipes are welded at a temperature of 260 ° C.

Even if you want to entrust the installation of heating systems to a specialist, you need to know about some of the nuances of the heating system device.

You will find step-by-step instructions for making a thermostat for a heating system at the link.

If the radiator does not heat up.

If water comes out of the radiator, but the radiator still does not heat - what is the reason? In case of inaccurate installation, debris can get inside the pipes and accumulate in thin places, for example, in valves. We'll have to clean it up. We close both valves on a cold radiator. We release the union nuts on the valves. We carefully drain the water from the radiator.

If the pressure in the system is working, then you can abruptly open the valve on the supply pipe, while the debris should be taken out with a stream of water. We put the radiator in place, open both valves, again we poison the air through Mayevsky's tap ... well, I guess everything is already clear enough. After such manipulations, two positive results should appear:

1) warm all radiators;

2) you have a habit of working carefully, not allowing debris to fall into the pipes.

Also: the difference between supply and return for a normally operating system is 15-20 degrees. Not more. But it also depends on the ambient temperature during the launch period. In the cold season, the system will need to "accelerate", so to speak.And it makes sense to observe the difference between supply and return when the temperature is established in the room.

That's all, nothing complicated. If the heating system is assembled correctly, then there should be no other problems, and the heating system should be started without any problems.

Even a minor repair of one of the radiators or heating pipes is inevitably associated with a complete drain of the coolant from the heating system. After finishing the work, you will have to fill the circuit with water. The question arises - how to start the heating correctly? What temperature should the water be, at what speed should the liquid be filled? How to prepare and flush a home heating network? It is better if the work is done by the masters - many factors will have to be taken into account.

Launch

At the first stage, it is imperative to carry out a visual inspection of the pipeline system and heating radiators, as well as check the chimney. Then the system is filled with a coolant through a special sub-unit, which is located at the lowest point.

To remove air bubbles from the system, Mayevsky's taps are opened.

When filling the system with a coolant, pressure testing is carried out.

After the system is completely filled with coolant, a number of measures are performed:

- the valve at the bottom of the heating boiler opens;

- pressure values are checked, which should not exceed three atmospheres;

- after heating the coolant, the make-up valve opens and air locks are removed with the help of the Mayevsky valve.

Heating radiators are actually launched twice: during the filling of the system with a heat carrier and when the heating boiler is turned on. It is necessary to control the operation of the heating system during operation by periodically checking the values on the dashboard or by visual inspection of all nodes.

Procedure before starting the heating system

Open the valve on the expansion tank.

Open the taps that shut off the heating agent in the supply and return from the boiler.

Important! The listed taps should always be open; after starting the system, it is best to remove the handwheels from them completely and remove them "in a conspicuous place."

There should be no cranes on the safety block at all.

Open the valves on all radiators. And close Mayevsky's taps.

If the heating system is with collectors, then open the taps on the collectors as well (on the supply and return, and not those for making up and draining the system).

If there are automatic air vents, check if they are open: there is a black cap on top of them, it must be unscrewed so that air can escape.

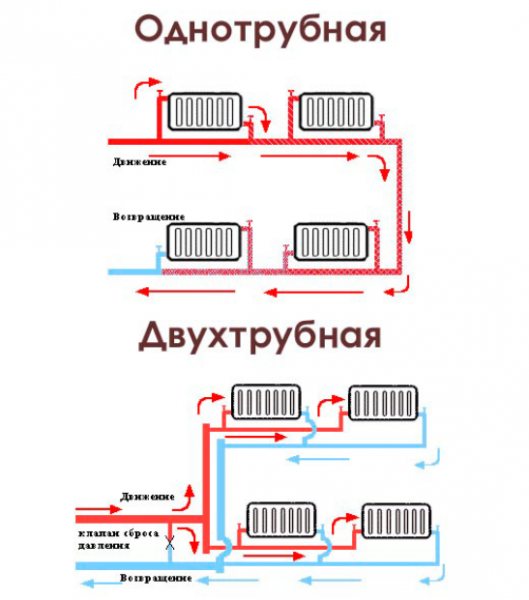

Features of water heating

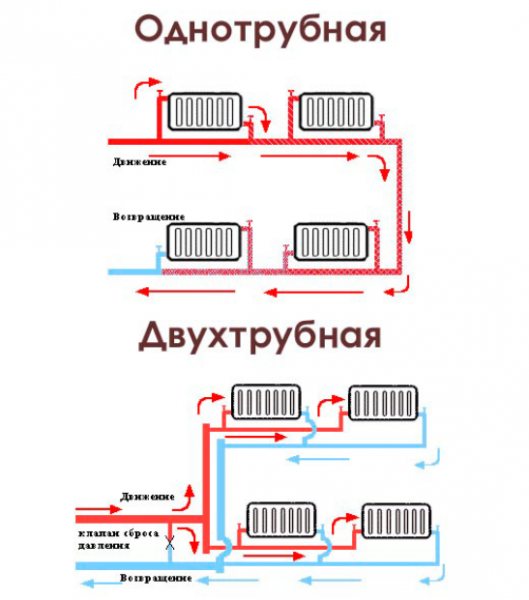

Today, two large groups of hot water heating can be distinguished, these are two-pipe and one-pipe designs. In the case of the second option, it should be noted that it is cheaper and simpler. A fairly good solution would be to install this in a one-story house, but in the case of rather large areas, in particular several floors, a two-pipe heating system would be the most suitable option.

Depending on the choice of the heating system, the heating of the batteries depends

How to choose the right heating radiators for a private house?

Batteries are of the following types:

- cast iron;

- aluminum;

- steel;

- bimetallic.

Cast iron, due to their high weight and small heating area, are gradually being replaced by bimetallic radiators, the service life of which is 50 years. They consist of an inner steel and an outer aluminum filling.

One section can heat 2 m2 of space in a room. Thus, for a room with an area of 20 m2, you need to buy 10 sections. The number of aluminum steel or cast iron radiators is calculated according to the same principle.

In order to calculate the number of pipes for a private heating system, you need to draw a scale diagram. Apply all batteries and pipelines to it.So it is easier to count the number of tees, corners, check valves, thermostats, valves.

Heating a private house with your own hands

Long gone are the days when only a stove could heat a private house. The lack of large amounts of hot water, the need to heat the stove and keep the fire going did little to contribute to life outside the city. Actually, therefore, many sought to move to comfortable high-rise buildings, where heating and hot water supply were centralized.

Today, a lot has changed - the abundance and choice of modern heating equipment are allowed to do homemade heating

on their own, even without the involvement of professionals. Now, on the contrary, living in cottages is considered a priority, since hot water is available all year round, and heat supply can always be turned on, without waiting for the decision of housing and communal services.

In total, 3 main energy carriers are emitted - gas, solid fuel and electricity. We will tell you about each of them, as well as how to properly pip the boiler and ensure the supply of heat to various nodes, in this publication.

It will not be possible to buy a completely heating system in any store. You can pick up some parts and assemble them into a system, you can buy materials and make the boiler and piping completely with your own hands. It doesn't matter which way you decide to go, you need to first decide on the following parameters:

- what type of fuel is supposed to be used;

- which fuel is economically more reasonable.

Pipe materials

The hot water heating system uses pipes made of various materials: metal, galvanized, from of stainless steel, copper, polymer (metal-plastic, polyethylene, polypropylene reinforced with aluminum). Let's talk about the main categories in more detail.

Metals

Metal pipes are not devoid of essential lack Is poor corrosion resistance. On the other hand, stainless and galvanized materials are very resistant to rust formation, and they are mounted on threaded connections.

When laying a pipeline made of steel, you will need qualifications and work experience... But now, with the advent of metal-plastic and polypropylene products, obsolete ones are no longer used so often.

Copper

Copper pipes work at very high temperatures and high pressure, they are durable and reliable.

Copper pipes are mounted high temperature brazing, solder with silver content. They can be camouflaged in the walls of the building when carrying out finishing work. Handling materials requires high professionalism... Copper is generally used in high-end construction because it is expensive.

Polymers

Polymer (polypropylene, polyethylene) pipes are convenient and easy to install. They are durable, resistant to corrosion, have a smooth inner surface, so no mineral salt deposits are deposited on it.

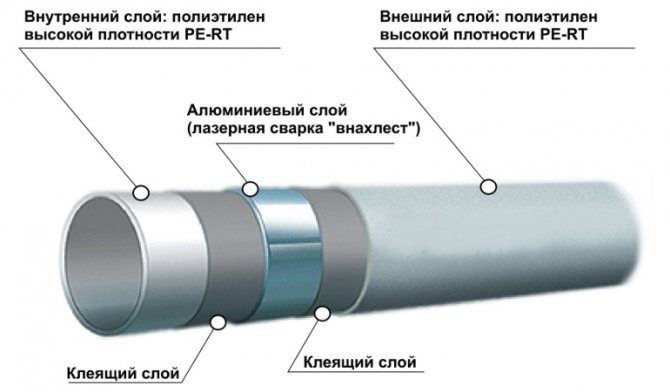

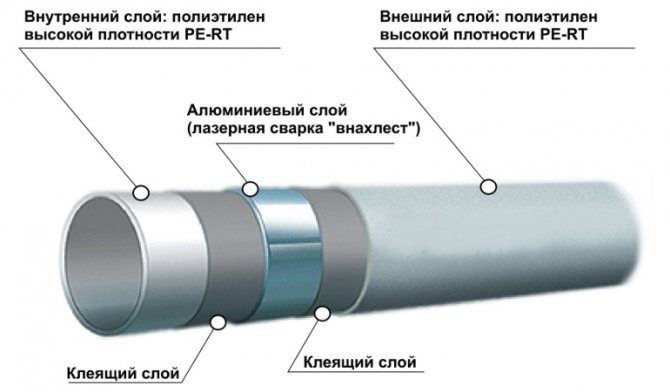

Metal-plastic

Reinforced-plastic pipes consist of a layer of aluminum and two layers of plastic - inner and outer. They are mounted using threaded connections without welding, or on press connections, which greatly reduces the cost of installation. But there is a significant disadvantage - high coefficient of thermal expansion.

In simple words - if you have been in the pipe for a long time only hot waterand then connected cold, then connections can flow.

therefore undesirable even temporarily shut down the boiler during the heating season and defrost the heating system, as this may damage the piping. Another one cause of leak - when the pipe is bent at an acute or even right angle, the aluminum layer can crack.

Choosing a heating boiler installation

The choice of boiler also plays a key role.You have to choose among electric, gas boilers, structures operating on liquid or solid fuels.

Most often, gas boilers are installed. First of all, in order to save money and due to ease of use.

It happens that they make electric heating with their own hands. Funds, in this case, will have to be spent much more, but the benefit is seen in the uninterrupted supply of electricity and in the absence of the need to constantly supply fuel.

Installation of heating pipes: wiring methods and rules for placing the heating system (125 photos)

Heating in a two-story house: do-it-yourself projects, schemes and heating systems (125 photos and videos)

Homemade heating boilers - the best projects and a step-by-step master class for building heating boilers with your own hands (135 photos)