Siding for house cladding

This design option is not chosen by chance. This material is capable of performing not only a protective function, but also looks very interesting and aesthetically pleasing. Facade cladding provides excellent protection to walls from atmospheric agents, improves the appearance of the house, perfectly hides some imperfections, irregularities, surface defects, which is especially important in old buildings.

Externally, a siding wall looks like a planked wall.

Siding consists of strips of various widths and lengths, equipped with latches. Thanks to this, they are easy to attach to each other. The length of the siding can be up to 6 meters, and the thickness reaches 10 millimeters.

We buy material and components

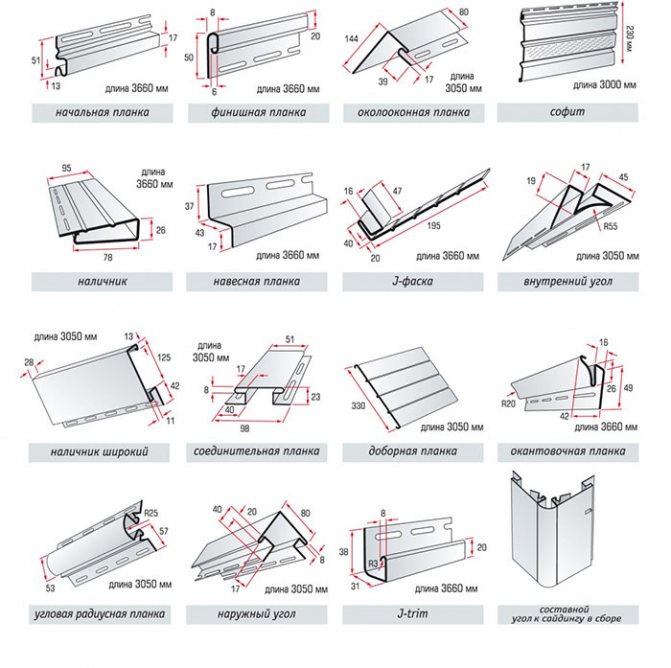

When making a purchase, pay special attention to the uniformity of the siding and the thickness of the panel. This guarantees the perfect appearance of the building. Anyone who knows how to sheathe a house with siding with their own hands will tell you that you cannot do without component parts in this matter. These include the starting and finishing profile, the outer and inner corners, the profile connecting the two panels. You cannot do without F- and J-profiles, which are used for finishing cornices.

Advantages and disadvantages

The positive qualities of siding facade decoration include:

- Long service life.

- Minimal care.

- The ability to use this material on almost any surface.

- Siding does not lend itself to decay, corrosion, microorganisms.

- Convenience and ease of installation.

- Strength.

- Attractive appearance.

- Relatively low cost.

Each type of siding has certain disadvantages:

- Metal siding is difficult to transport as the sheets do not bend. In addition, this material is not elastic, and when a dent appears, it is difficult to fix it.

- Wood siding is not resistant to environmental influences and needs protection. It is highly flammable and not suitable for use in humid environments.

The most common vinyl siding, it also has its drawbacks:

- Immunity to mechanical damage.

- Difficulty of replacement. You cannot remove the sheet separately and change it, you will have to change a large area.

- Large coefficient of expansion when changing temperatures (you have to solve the problem with the use of gaps between the sheets).

- Poor thermal insulation.

- The material melts with strong heating.

Required tools and materials

It is first necessary to determine the area of the walls and the type of roof in order to correctly calculate the amount of material.

Before starting work on cladding a house with siding, you should prepare the necessary materials and tools.

For installation you will need:

- Bulgarian.

- Metal knife.

- A hammer.

- Screwdriver.

- Drill and hammer drill (when working on concrete walls).

- Screwdriver.

- Roulette, better laser. If it is absent, you can take a level and a square.

- Ladder.

Frame installation

The technology of covering the walls of the house with siding provides for the installation of vinyl panels exclusively on pre-assembled and securely fastened to the walls of the building a crate made of metal profiles or wooden battens. Installation on bare walls is strictly prohibited - this is not only materials thrown into the wind, but also significant damage to the entire building.

Operations for fixing finishing elements on the house, necessarily preceded by the marking of a straight line of the contour of the building perimeter on the walls of the house with a tape measure and a level.Especially accurately measuring the distance from the previously drawn line to the basement at the corners of the building, the angle of reference is determined, with a minimum distance, putting it down to draw another so-called initial contour.

Further, it is from him that the installation of starting strips begins, the incorrect fixing of which during the cladding process can lead to a skew of all siding panels.

Starting from the corners, vertical guides are fixed on the U-type mounts. It is necessary to mount them in the most tight contact with the wall, to achieve which it is allowed to shove chips or foam trimmings under them. The guides are fixed so that the distance between them is from 30 to 40 cm.

In areas of the sheathing, with an increased load of siding on it, which, for example, can be installed street lighting, as well as in areas close to corners, window and door openings, it is necessary to increase the frequency of the guides so that their number adequately corresponds to the load.

No connections are allowed between the vertically fixed ribs of the battens, in order to avoid restricting ventilation, since stagnant air quickly leads to the formation of mold.

Preparatory work

Preparation for house cladding includes the following types of work:

- Dismantling of protruding parts (door frames and window openings, ventilation grilles).

- Possible cracks in the walls in the area of windows and doors are sealed. For this, you can use cement mortar or polyurethane foam.

- If an old house is being cladding, all of the old cladding should be removed. Prepare the surface: clean it from dirt and dust, chipped plaster, remove mold, replace possible rotten areas and treat them. Houses made of wood should be pre-treated with antiseptic agents, and the foam blocks should be coated with a primer.

The surface must be flat and clean. Although the siding can hide small defects.

It is very convenient to build a special assembly table for work, it is installed under a canopy. A circular saw is attached to it. Here, the material itself can be stored on pallets.

How to sheathe a house

Siding installation is carried out in several stages:

- Surface preparation.

- Frame or lathing device.

- Creation of a steam, hydro and thermal insulation layer.

- Installation of siding sheets to the crate.

Many are trying to replace the frame with a crate, it is extremely undesirable to do this for the following reasons:

- The frame allows you to hide the unevenness of the surface of the house.

- Thanks to him, you can make a thermal insulation layer, since the siding does not have sufficient thermal insulation.

- There is space between the material and the wall of the house, so that air can pass freely. This will provide protection against mold and mildew.

Warming and waterproofing

For walls made of wood, or aerated concrete blocks, the installation of waterproofing is a prerequisite, but insulation is not critical. However, in the conditions of our country, it is unlikely to be superfluous, since a comfortable microclimate in the house, when the temperature "overboard" drops below minus 30, it is also significantly lower heating costs.

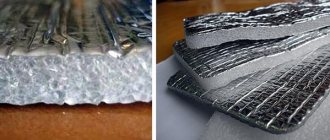

Most often, a layer of mineral insulation or basalt slabs is laid between the load-bearing walls of the structure and the crate, which, due to their vapor-permeable properties, do not harm the main structure.

To protect the insulation from vapors and moisture condensing due to the temperature difference, it is covered on both sides with hydro and vapor barrier materials. In the role of a moisture-proof coating, a membrane-type film is quite suitable. In the absence of insulation, it is fixed directly to the walls of the house, thus not occupying the empty space intended for ventilation.

Step-by-step instruction

- The choice of material for the frame. The material for the lathing is selected depending on the material from which the walls are made. For a house made of wood, you should take wooden blocks, and on concrete walls or made of foam blocks, it is more advisable to purchase a metal profile with galvanization. It will allow you to secure the siding with high quality and ensure a long service life.

- Wireframe creation. A starting profile is installed at the basement, and a finishing profile should be placed at the top of the wall, at the roof. They must be connected to the longitudinal profiles using larger self-tapping screws - 9.5 millimeters. In this case, it is better to purchase self-tapping screws in the form of a drill, and not just with a pointed end. The battens should be fixed directly to the wall surface. For this, dowels are used, they are inserted into previously prepared holes, which are drilled with a perforator. The longitudinal profile should be fastened in 35-40 centimeters increments. In the area of window openings, window strips are attached, and doorways are edged with J-profiles. The vertical elements are not fixed close to the basement and the roof; it is necessary to leave gaps of up to 6 millimeters so that the guides do not bend when the temperature changes.

- Creation of a waterproofing layer and lining of insulation. Waterproofing is required for walls made of wood and aerated concrete blocks. It is advisable to use a moisture and windproof membrane that can be attached directly to the wall of the house if no thermal insulation layer is created. Then there is space between this layer and the siding for ventilation. If thermal insulation is created, then the waterproofing is attached to this layer. And then an additional crate is created to provide ventilation of the sheathing.

- Installation of panels. The panels should be started to be mounted only after all the elements of the lathing and guides are fixed in their places, heat and waterproofing have been created. The first row of panels is attached to the starting strip. From below, you need to install the element until the lock clicks, and from above it is fixed on the guide using self-tapping screws. Fastening is carried out strictly in the center of the grooves on the siding, with a step of about 40 centimeters. The remaining panels are also fixed in the bottom-up direction, from the plinth to the roof or window opening. They should not be rigidly fixed, the panels should "walk" a little from side to side. The top row should be attached to the finish bar.

What is important to know before starting work

- If you are unsure how much siding you need to cover your home, contact a consultant. Write down the dimensions of the walls, their area, the number of windows and doors, and the type of cover. Come to the OMA store with these data. The consultant will calculate the amount of siding and additional panels for you.

- Each end of the siding must be closed, otherwise the design will be ugly. To do this, use the outside corner. Its standard length is 3 meters. It is better to use a solid corner instead of cropping.

- The cornice is trimmed with a wind board or soffits. They are made of the same material as siding, and you can choose the color of the elements to your taste.

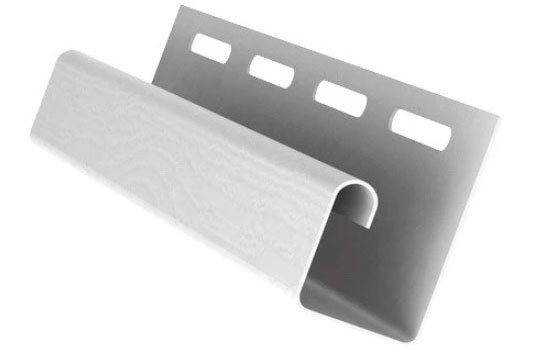

- Use a J-profile for cladding if you have a height difference on the roof. The H-profile comes in handy when you need to glue two pieces of siding together. This usually happens if the wall of the house is longer than the standard siding panel (3.66 meters).

J profile

H-profile

Check with a consultant to buy the exact amount of siding. The formula will help you. To do this, subtract the total area of windows and doors (S windows and doors) from the total area of the walls outside (S walls). Divide the result by the area of one siding panel (S panels) and then multiply by 1.10. The last value is the stock for scrap and excess expense.

The formula looks like this:

((S walls - S windows and doors) ÷ S panels) × 1.10.

How to sheathe a house with insulated siding

Thermal insulation should be done in wooden and concrete houses, as well as when creating a ventilated facade.Correctly install the insulation between the longitudinal guides.

This layer is done as follows:

- A vapor barrier is laid on the wall.

- Next comes the thermal insulation material.

- A waterproof membrane is attached on top.

To fasten the material, one more crate should be created, the guides in it are fixed horizontally. Or there is an option to make a recessed crate, the width of the guides should exceed the layer of thermal insulation.

Tips

When installing panels, the following points should be taken into account:

- It is advisable to start sheathing not immediately after the construction of the house, especially if the structure is made of wood.

- Ideal for fixing panels are aluminum nails. They should be placed strictly in the center of the elements.

- It is better to cut the panels with an electric saw or a hacksaw.

- Be sure to use a level for a smoother device.

- It is not necessary to tightly fasten the elements of the cladding material to the frame; it is necessary to leave gaps between the nails and the material, at least 1 millimeter.

- The fixing holes on the panels are made in an elongated shape. This allows the siding to move freely with changes in temperature.

Blitz Tips

- Siding panels cannot be fixed "tightly", strongly pulling them to the crate with self-tapping screws. Vinyl, which serves as a material for such elements, is very sensitive to changes in ambient temperature and, depending on the season, winter or summer, contracts or expands, so much that a change in one panel can reach up to 1% of its length. For fastening in such parts, non-circular, but oblong holes are provided to ensure their mobility. That is why it is impossible not to pull the screw head close to the vinyl, not to fix the panels by making arbitrary holes in them. According to the technology, a screw, self-tapping screw or any other type of fastener is screwed exactly into the center of the oval hole, not close to the material, but with a gap between it and the fastener head of 1 mm. Violation of this technology can lead to the fact that with strong heating in the summer heat, the panels will expand and, having no freedom of movement, begin to burst in the places of attachment.

- When installing vinyl strips in the guides, it is necessary to provide a gap of about 1 cm, so that when expanding in the heat, the panels do not bend, resting against them. In the case of installation in the summer, when the material has already expanded, this value may be lower, however, do not allow the still loose material to heat up strongly in the sun.

- Installation of siding panels can be carried out regardless of the season, but you need to know that temperatures below 10 degrees Celsius violate the plasticity of vinyl, which under these conditions is prone to cracking during cutting. Therefore, in the cold, it is advisable to carry out such an operation very carefully, preferably with a grinder.