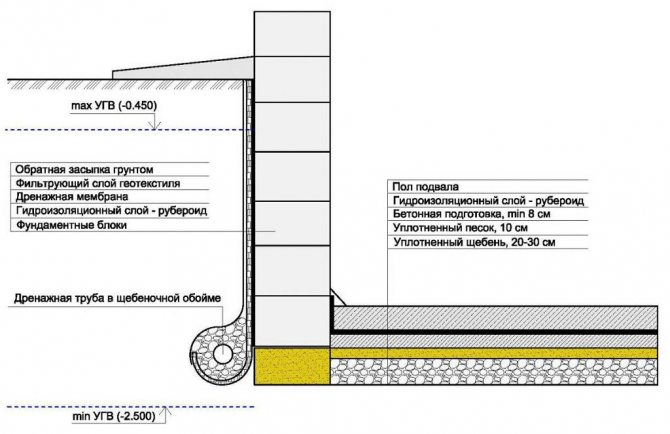

Most people always associate the basement of a house or any other building with dampness. And it is not surprising - usually this part of the structure is located below ground level and even adjacent to groundwater. However, excessive dampness or the ingress of water into the basement threatens to destroy the foundation of the house, and therefore damage the structure itself in the future. That is why, at the construction stage or later, the basement floor is waterproofed. And then the moisture will not threaten the structure, and the basement can be turned into a utility room or warehouse where anything can be stored.

Basement floor waterproofing

Insulation and vapor barrier of walls from inside a brick house

The heat transfer properties of brick walls tend to deteriorate over time. The fact is that from the inside of the masonry, between the rows of bricks, heaters are usually laid - mineral or glass wool, which, under the influence of penetrating moisture, gradually lose their properties. The insulation can be changed, but this requires disassembling the outer layer of the brick, removing the insulation from the inside and replacing it, and this is a very expensive and time-consuming measure... In addition, over time, the properties of the brick itself deteriorate.

In this case, it is necessary to produce external or internal insulation of the wall. When choosing between these two types of insulation, preference is given to external insulation. At the same time, there are situations when external wall insulation is impossible or impractical - as in the case of insulation of an apartment in an apartment building or insulation of a building of historical value, etc.

Basement wall insulation

As strange as it may sound, insulation from the basement side in a wooden house has both advantages and disadvantages.

Not only the ceiling needs thermal insulation, but also the walls of the underground storage.

- The ability to maintain a stable temperature not only in the basement, but throughout the house.

- Basement insulation significantly reduces heat loss in the interior of the house.

- When insulating the basement from the inside, it is necessary to make high-quality waterproofing.

- In addition, efficient ventilation is required.

If none of this is done, then the insulation will soon begin to collapse, because under the influence of moisture, any material will lose its performance.

We use foam

To insulate the walls of the basement from the inside, as a rule, ordinary foam is used. This heat-insulating material has a low weight and a lot of positive properties:

- Excellent performance.

- Complete safety from an environmental point of view.

- Relatively low price.

The service life of the foam will depend, first of all, on the quality of the work on the insulation of the room, as well as on the effectiveness of the created waterproofing.

Of course, you can use more expensive materials: polyurethane foam, expanded polystyrene, etc., but if there is no urgent need to make the basement as warm as possible, then they can not be used. It is possible to insulate the basement from the inside from all sides, in principle, with mineral wool.

The working process

Any heat-insulating material will not adhere well to the wall if it is glued to an ill-prepared surface. That is why, before starting work, the surface should be completely cleaned, eliminating all minor defects.

This fixing of the foam is more reliable than glue.

Fastening of polystyrene, in most cases, takes place on adhesives, but for greater reliability, many homeowners fix the material with dowels, which guarantees the most reliable fixation of the insulation.

Laying foam must start from the bottom of the basement. The basic rule in this case is that the insulation must be laid with a minimum gap between the plates. That is why special attention should be paid to the initial surface preparation. If the base has serious differences, then significant gaps will form between the plates, which will minimize all the performance characteristics of the material. It will be extremely difficult to insulate the basement in a wooden house.

Foam boards must be thoroughly impregnated with adhesive, glued to the wall and secured with dowels for reliability. Experts also strongly recommend using a reinforcing mesh at this stage (it is possible with a minimum diameter of the rods). It is immersed in insulation and covered with an abundant layer of adhesive. This approach allows the insulation to hold reliably for more than one year. As soon as the resulting surface is dry, it must be rubbed and leveled using special mixtures (primer, plaster). Optionally, you can carry out additional decorative finishing of the wall, ceiling and floor.

Cons of insulation inside a brick house

- insulation from the inside of the house does not protect the wall from destructive climatic factors;

- it is less efficient in terms of heat conservation;

- hides the useful internal volume;

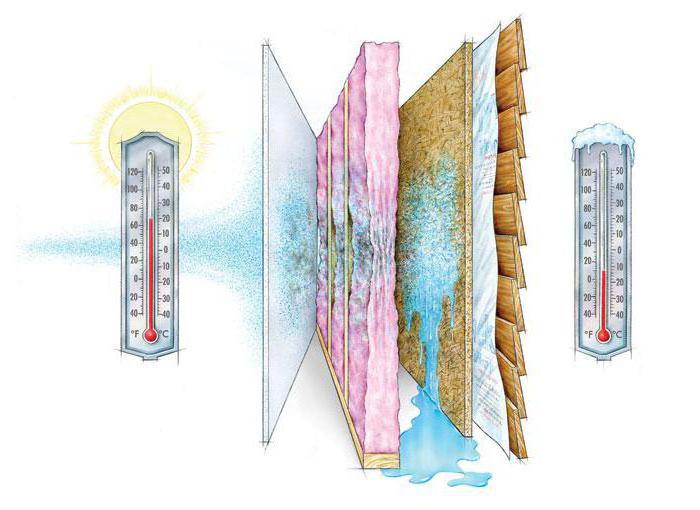

- creates high humidity between the insulation and the inside of the wall of the house. Condensation forms, which leads to the gradual destruction of the wall from the inside. In addition, this leads to the formation of a favorable environment for the reproduction of molds, which not only accelerate the process of destruction of materials, but also have allergenic properties and are simply harmful to residents.

To eliminate this type of shortcomings, builders use methods that postpone the dew point (creating an air gap), vapor barrier and special antifungal compounds.

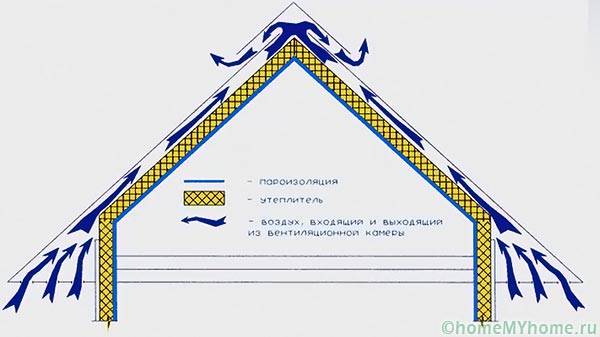

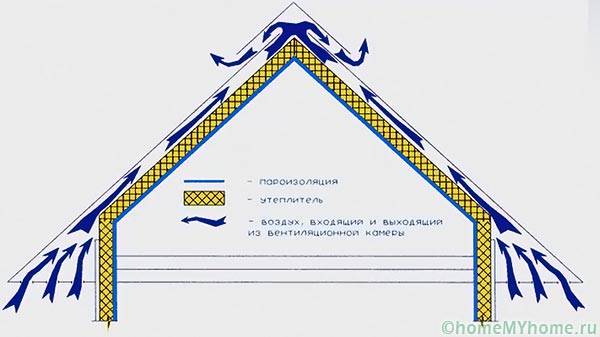

Correct vapor barrier

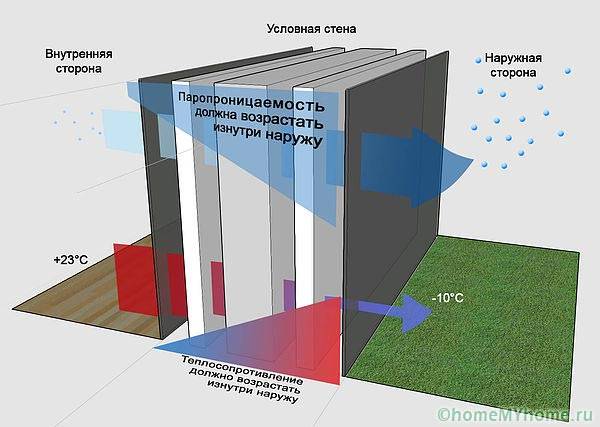

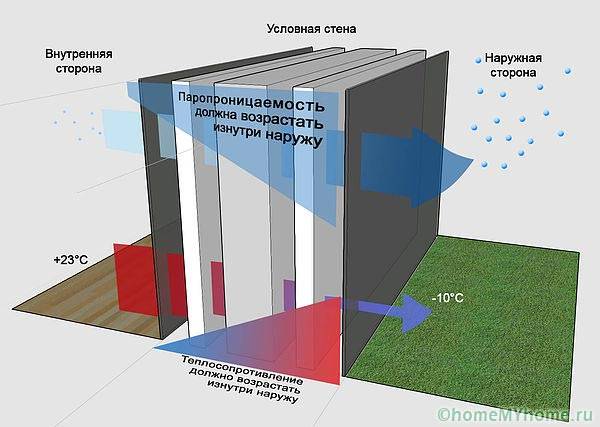

Vaporized moisture is present everywhere - it is part of the natural water cycle. Ignoring this factor when ensuring the energy efficiency of buildings and structures is unacceptable. It is known that waterlogging reduces the thermal resistance of wall materials by up to 30%. Today correct vapor barrier - an important part of the thermal protection of a construction site.

Why is it correct? Because a vapor barrier that does not comply with standards or is installed incorrectly leads to a loss of properties of the thermal insulation layer after a year. The accumulation of moisture on the surfaces of structures starts the process of their destruction. This applies to any material.

Warming methods

Warming with plaster

Features of the

This is the "dirtiest" method of insulation from the inside, coupled with the need to completely empty the room. At the same time, it is one of the most inexpensive and easy to implement. It takes a lot of time and effort.

Technology

- Wall surface preparation. Cleaning from wallpaper, paint, plaster.

- Installation of slats up to 5 mm thick on the wall (interlayer between the wall and the mesh).

- Reinforcement of the surface with mesh up to 50 mm.

- Sequential application of plaster layers with a total thickness of up to 10 cm.

Thermal insulation with foam or expanded polystyrene

Features of the

One of the best methods of insulation from the inside of the house. It allows you to significantly enhance not only thermal insulation, but also noise insulation in a brick house. Expanded polystyrene has better performance than polystyrene, but is more expensive.

Technology:

- Cleaning the wall surface from wallpaper, paint, old plaster.

- Leveling the surface of the walls.

- Application of a layer of antifungal agent, primer.

- If the wall is being prepared for drywall, then the installation of brackets.

- Fastening the panels to the wall - using glue or special mushroom-shaped dowels.

- If the wall is being prepared for wallpaper or painting, installing a reinforcing mesh followed by plastering the surface.

- If the wall is being prepared for drywall - assembly of the drywall wall, jointing, alignment.

- Next, painting or wallpapering is done.

- In case of significant humidity, a vapor barrier is installed.

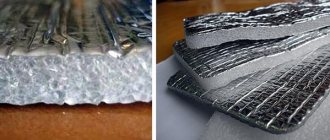

Insulation of a brick wall with penofol

Features of the

Penofol is a material consisting of several layers, including foil. It is only advisable to insulate them only for premises that are used exclusively in the warm season (cottage, barn, etc.).

In other cases, this material is used as an additional heat-insulating layer and vapor barrier (with mineral wool). Aluminum included in the composition of the material requires the implementation of increased electrical safety measures.

Technology

- Preparing the wall.

- Treatment with anti-mold compounds.

- Fastening of 20 mm bars to provide an air gap.

- With the help of a construction stapler, sheets of penofol are attached to the beams.

- Glue the joints of the sheets with aluminum tape.

- On top of the penofol, another layer of bars is strengthened.

- Drilling of sheets of gypsum board, fiberboard, chipboard or other selected material.

- Wall surface preparation, wallpapering or painting.

Penofol can be glued directly to the wall with glue. But in this case, thermal insulation and vapor protection are reduced.

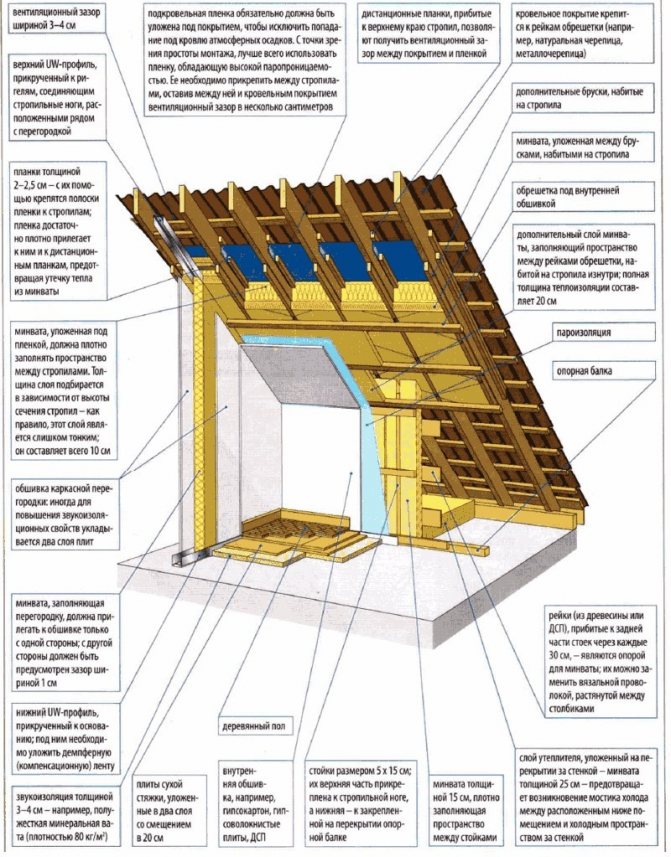

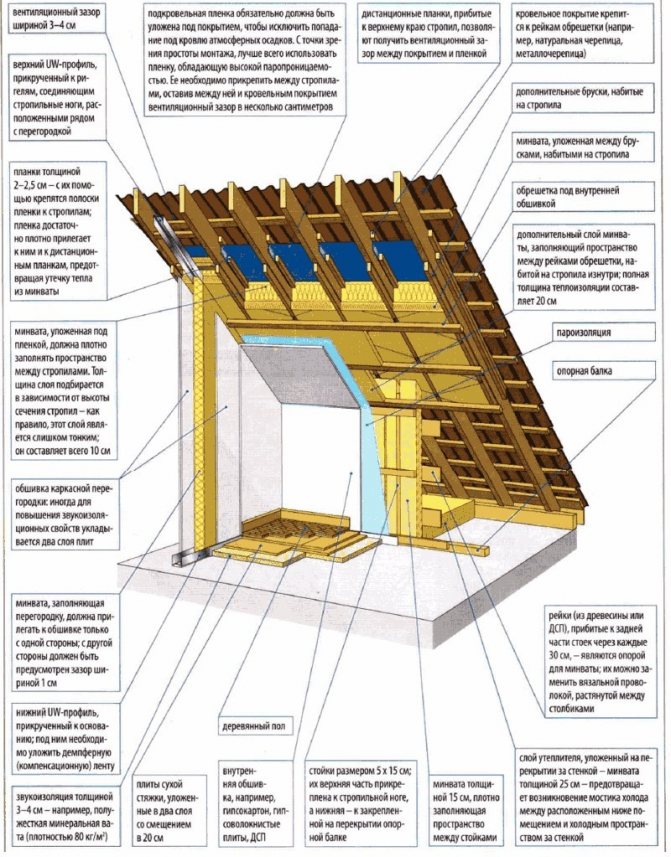

Insulation of walls from the inside with mineral wool or glass wool

Features of the

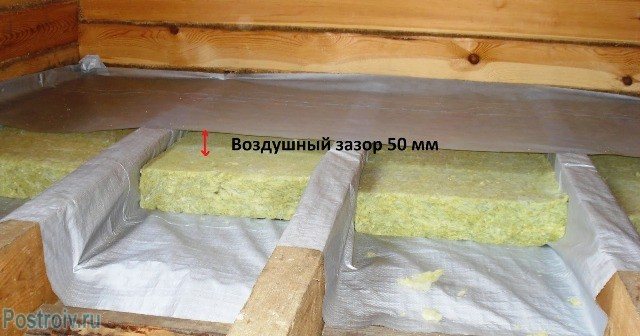

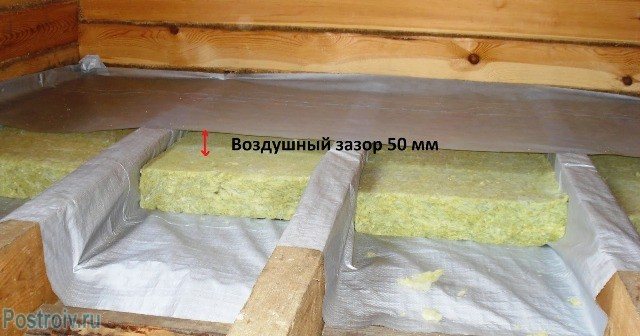

Mineral or glass wool is afraid of moisture, so special precautions must be taken with respect to moisture. It is necessary to install slats on the wall to provide an air gap and to keep the dew point away.

They have a soft surface, so it is imperative to mount some kind of rigid structure, be it drywall, fiberboard, chipboard or something else (it will not hold the plaster or wallpaper on itself).

Technology

- Cleaning the surface of the walls from old layers of paint, wallpaper, plaster.

- Priming the wall and covering it with antifungal agents.

- Installation of vertical slats to ensure clearance (the step should be narrower than the thickness of the mats).

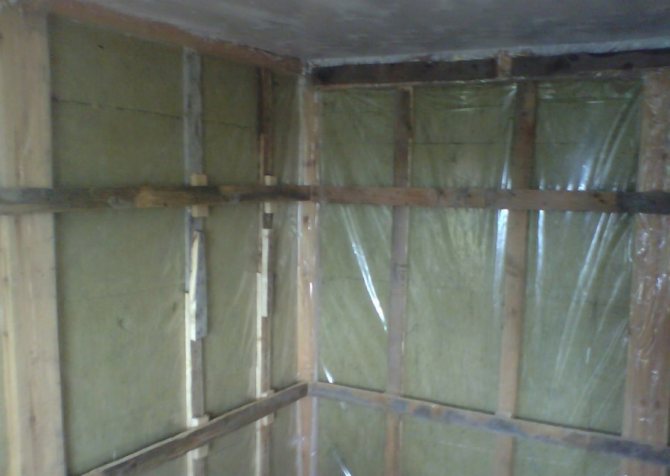

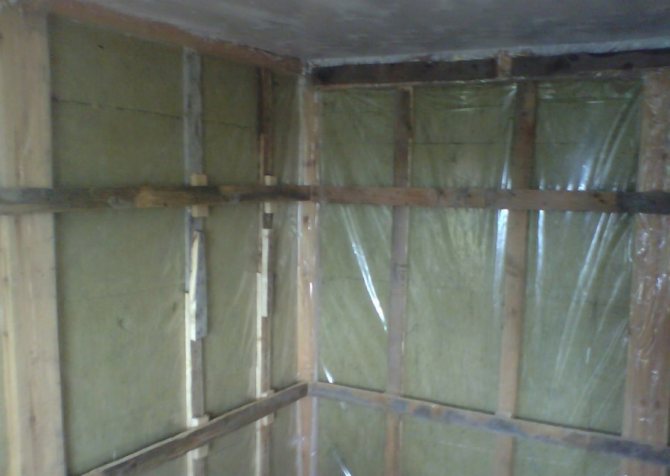

- A vapor barrier is installed on top of the rails.

- Installation of frame profiles. The dimensions of the sections should be slightly narrower than the dimensions of the mats or sheets of thermal insulation (for tight contact).

- Filling sections with sheets or mats of heat-insulating materials.

- A vapor barrier is installed on top (protection from moisture from the side of the room).

- Fastening to the profile of sheets of gypsum board or other final surfaces.

- The final stage is preparation for wallpapering or painting the wall (if necessary).

Thermal insulation with liquid products

Features of the

Thermal insulation of the wall with liquid sprayed agents is rarely used, as it requires special equipment and trained personnel.

It is the most expensive of the listed methods.

It is produced by spraying special compounds (polyurethane foam). When applying the method, a vapor barrier is usually not required.

Technology

- Surface cleaning and priming.

- Building a profile from beams or a metal profile.

- Filling the sections with polyurethane foam.

- Undercutting of spraying defects.

- Finish coating.

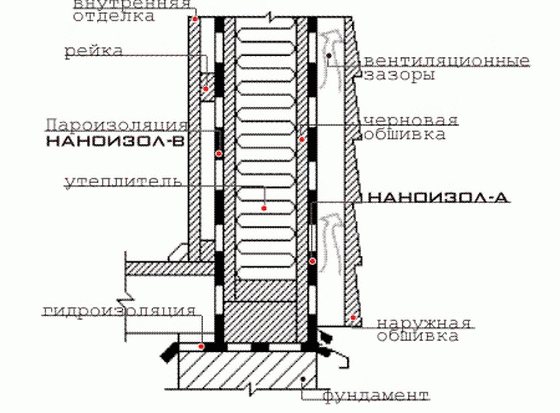

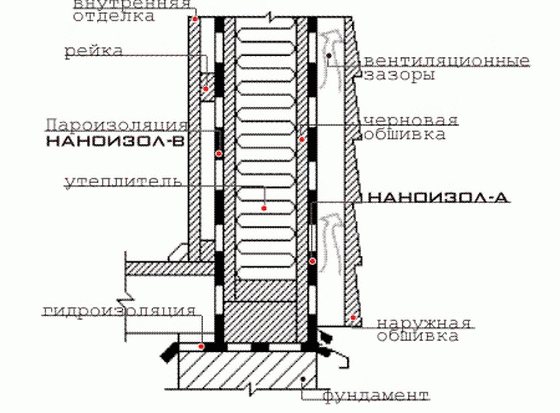

Vapor barrier for walls of a wooden, brick or frame house

When building all types of houses, various heat-preserving materials are used, but their effectiveness will noticeably decrease if they are not protected by a vapor barrier.To ensure that your house is always dry and warm, in order to exclude the slightest possibility of condensation and the appearance of mold or mildew, you need a competent and reliable vapor barrier for the walls of a wooden house, as well as houses built from other materials.

Vapor barrier work can be performed from the outside or from the inside of the house. The choice of the best option for each specific house depends on the area of the building, building material and building structure. So, for example, the presence of a veranda around the house can be considered as an air gap that reduces heat loss, and brick walls are known for their high heat transfer, therefore, they require more thorough protection.

Related article: How to thread a pipe near a wall

A large number of modern, easy-to-use and reliable vapor barrier materials allow you to extend the service life of the insulating layer, create an acceptable microclimate in the house, reduce heat loss and increase energy savings. It is worth noting that each type of house has its own specific features for performing this operation.

Insulation of the floor in the house from the basement side

Insulation of the floor in the house from the basement side is of great importance. With the help of high-quality thermal insulation, it is possible to significantly reduce heat loss, effectively protect against dampness and subsequent destruction of the floor, which often happens with frosty swelling of the soil.

In the event that heating of the insulated basement is not planned, the temperature in it, even in the most severe frost, is unlikely to drop below 10 degrees. The cost of modern insulation and heat-insulating materials on the market is not as high as before, so you can easily insulate the floor, floors and basement walls without serious costs.

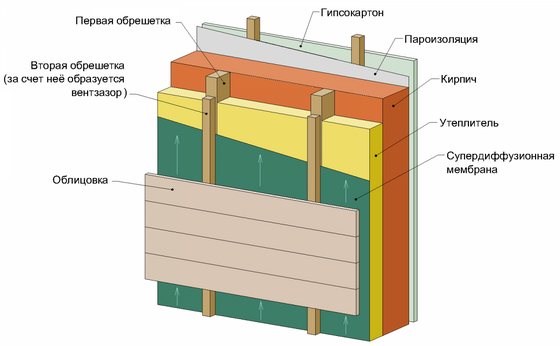

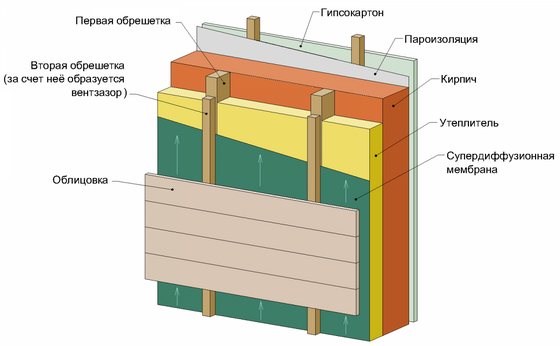

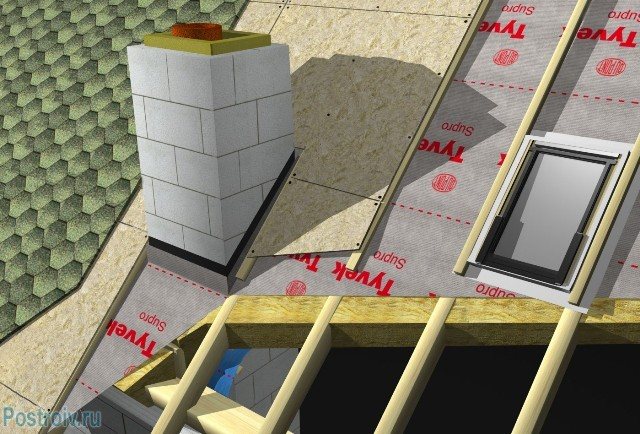

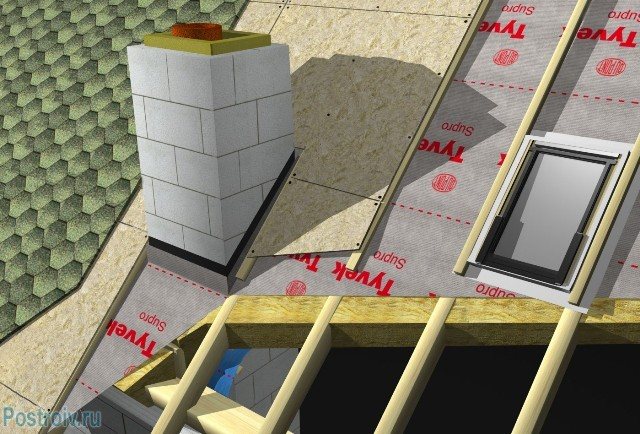

Features of the vapor barrier of the walls of a brick house

Brick continues to be the most popular material for the construction of country houses. To reduce heat loss, brick walls must be intensively insulated on the outer surface of the building or from the inside of the house.

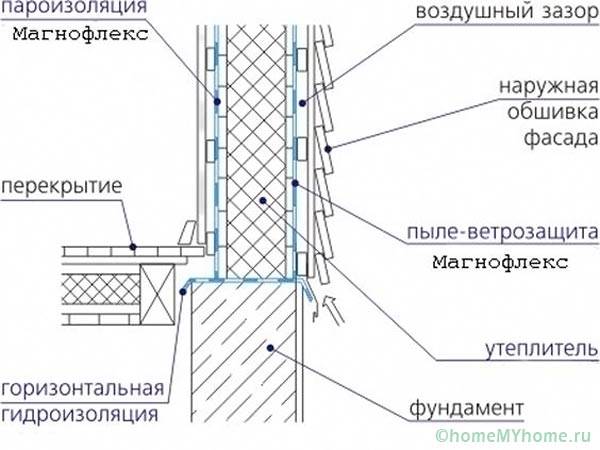

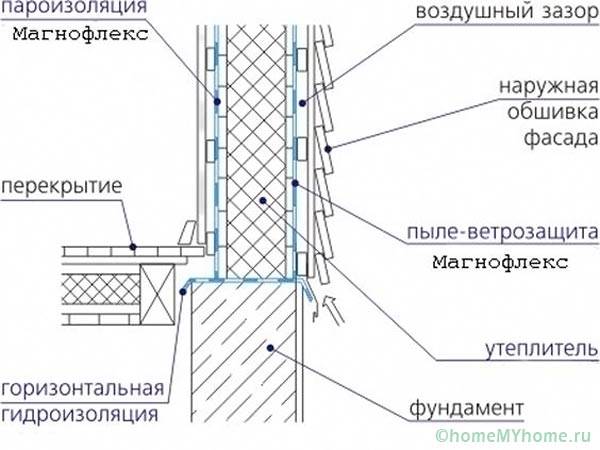

Insulation work must be accompanied by the installation of a vapor barrier layer. When insulating the outer wall of a house, it is best to lay the layer on both sides of the insulation, which will ensure complete tightness. A good vapor barrier for the walls of a brick house will create a solid barrier to rain, wind and noise. When laying a vapor barrier, it is necessary to leave gaps for ventilation, carefully connect all joints of the material.

If, for some reason, the external cladding does not cope with its functions or the walls are of a small thickness, then in order to avoid the appearance of condensation on the surface of the walls, you can additionally perform vapor barrier cladding inside the room.

Is a vapor barrier always needed for siding?

Another important question: is it possible to do without a vapor barrier? And if so, in what cases?

Vapor barrier of walls for siding is required in the presence of insulation. But do you need a vapor barrier for siding without insulation? Not. Wind protection is sufficient without it.

In addition, a vapor barrier is not required if:

- the house is insulated with expanded polystyrene (including as part of SIP panels);

- the walls of the house are very thick and retain heat well (in this case, the thickness of the insulation is minimal - no more than 50 mm, and there is no need for vapor barrier);

- the vapor barrier is installed on the inside of the house.

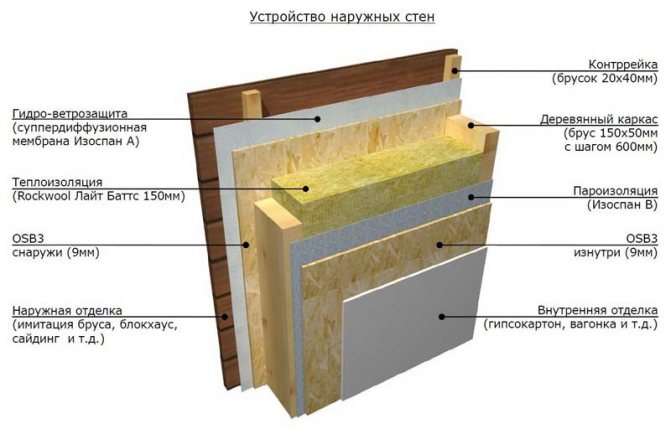

The device of a vapor barrier layer in frame houses

In the construction of frame-type houses, boards of small width are used, which requires the use of a high-quality insulation layer. So that you do not have to carry out work on its replacement soon, it is necessary to protect the layer from steam, which is oversaturated in the air of any living room.

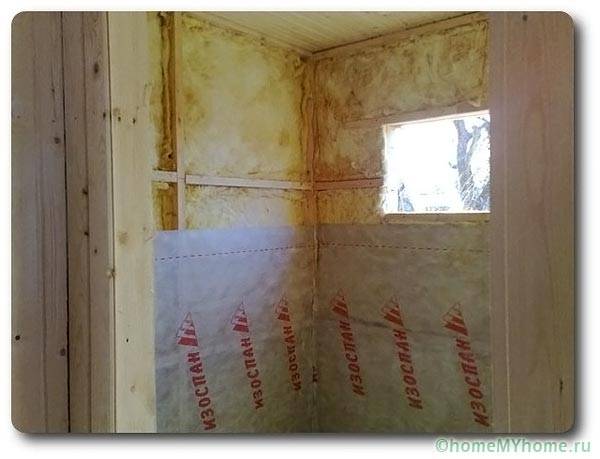

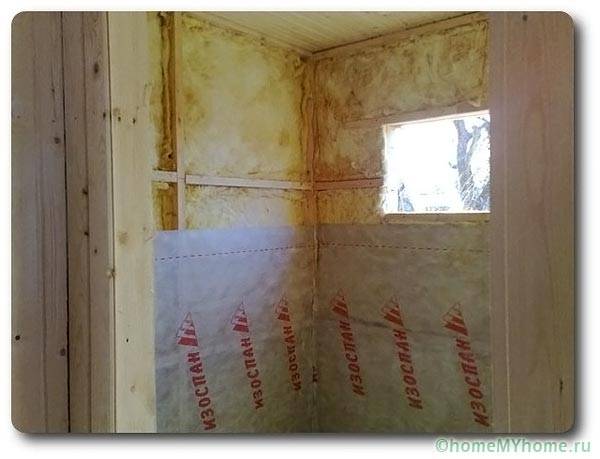

Vapor barrier for the walls of a frame house is carried out only from the inside of the building.When laying sheets of film or membrane, it is necessary to ensure that there is a ventilation gap between the heat and vapor insulating layers and absolute tightness. In places where it is necessary to make holes for sockets, switches or other elements of the engineering equipment of the house, the vapor barrier material must be glued with self-adhesive tapes or sealant. The sheets of material should be placed on the walls not vertically, but horizontally, laying each subsequent layer with an overlap of 10-15 cm and providing a slight sagging of the film.

The vapor barrier is attached to the frame posts with a stapler. The more carefully you do this work, the less likely it will be for tears and damage that will break the tightness.

Wood floor protection

Mandatory vapor barrier of a wooden floor over an unheated basement, underground, or other unheated volume. It is always arranged from the side of the heated room.

Logs are laid on the ceiling with a step of 600 mm, insulation is tightly laid between them, and already along the logs - a vapor barrier material. The finishing coat is laid on it.

Over the entire area of the room vapor barrier of a wooden floor must be holistic. For this, the material is laid with an overlap, the joints are glued with a tape that has vapor barrier properties.

When installing a wooden floor on concrete slabs, before installing the lag, the surface of the concrete floor is covered with water protection with careful sealing of the joints.

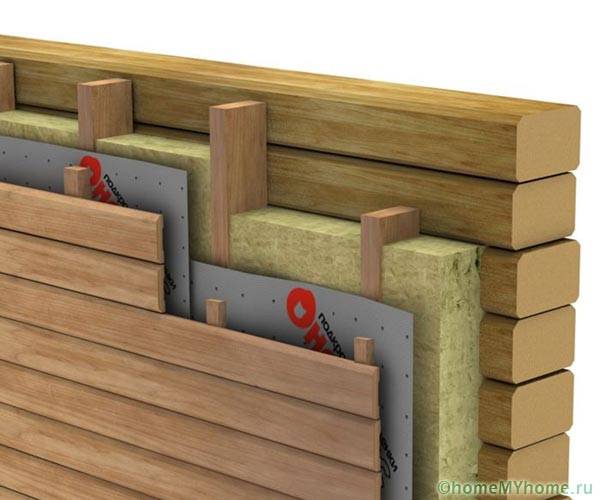

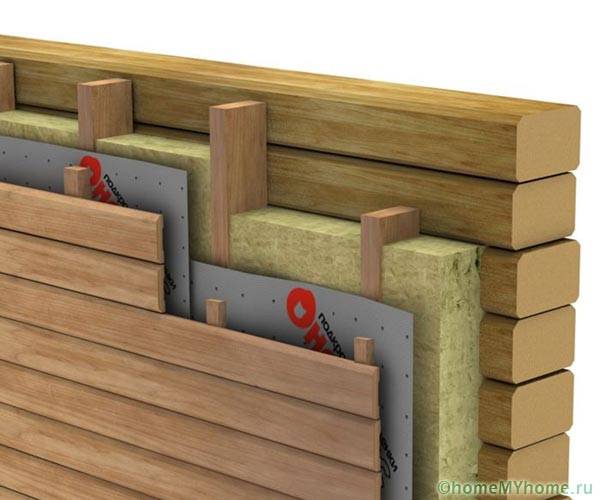

Protection of walls of wooden houses

Eco-friendly houses made from natural wood require thorough protection from moisture that causes rotting and deterioration of this material. The vapor barrier for the walls of a wooden house from the outside should not adjoin directly to the wood, because in order to create high-quality ventilation, a crate should be made on which the vapor barrier material will be attached (from above it is covered with insulation, on top of which the cladding is performed).

The vapor barrier for the walls of a wooden house from the inside works much more efficiently. Before arranging it, it is necessary to prepare the surface of the walls. Wooden walls usually have cracks that are clogged with dust and dirt. The walls must be leveled, all voids must be repaired and the surface treated with an antiseptic. Only then can you begin installation work on laying the vapor barrier material and insulation. For wooden walls, it is best to choose a film coating or a membrane-type vapor barrier, which will not adversely affect the condition of the wood.

Purpose, types, characteristics

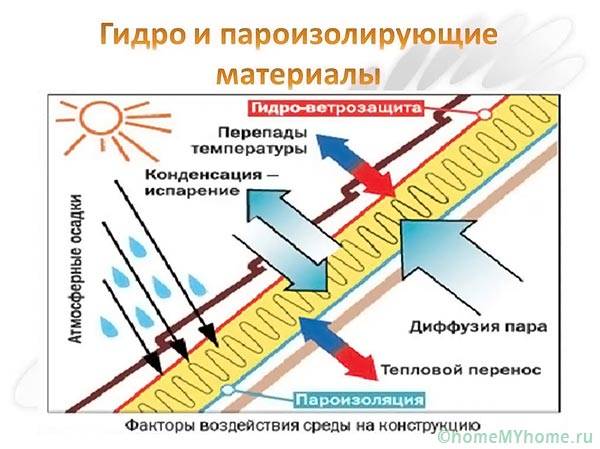

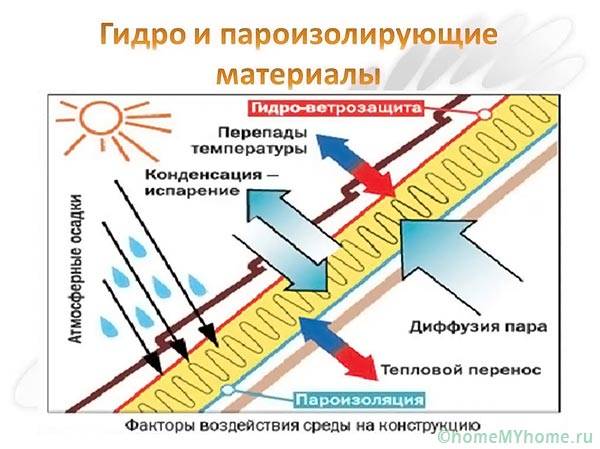

There are several types of insulation materials that individual developers usually confuse:

- waterproofing - cuts off only water, but lets in moist air;

- vapor barrier - retains moist air, preventing it from penetrating to the structural frame of the building, and, no matter what materials the building is built from;

The principle of operation of steam and waterproofing

- hydro-wind protection - used only in ventilated facade systems, roofing pies, covers external thermal insulation, prevents the destruction of expanded polystyrene, mineral, glass wool from weathering.

Hydro-vapor barrier and wind protection scheme

Vapor barrier for the walls of a wooden house is vital, since it reduces the operating budget of the cottage, increases the building resource. When humidity changes, lumber loses its geometry stability, is exposed to rotting, destruction.

Consequences of the lack of vapor barrier

The following structures are usually called wooden houses:

- log cabins - crowns made of sanded or calibrated logs, planed or glued beams;

Log house

- "Carcasses" - a timber frame sheathed with boards, OSB boards, gypsum plasterboard from the inside;

Frame house lined with clapboard

- half-timbered frames - a wooden frame, any filler can be used between the posts, including panoramic glazing;

Fachwerk

- SIP panels - expanded polystyrene or polyurethane foam between OSB boards.

House of SIP panels

Therefore, for each construction technology, various vapor barrier materials are used - films, membranes, polymer varnishes. For example, of all the above structures, only log cabins made of cylindrical construction do not have external finishing. Therefore, the crowns on the outside are often coated with polymer varnishes.

Coating a log house with varnish

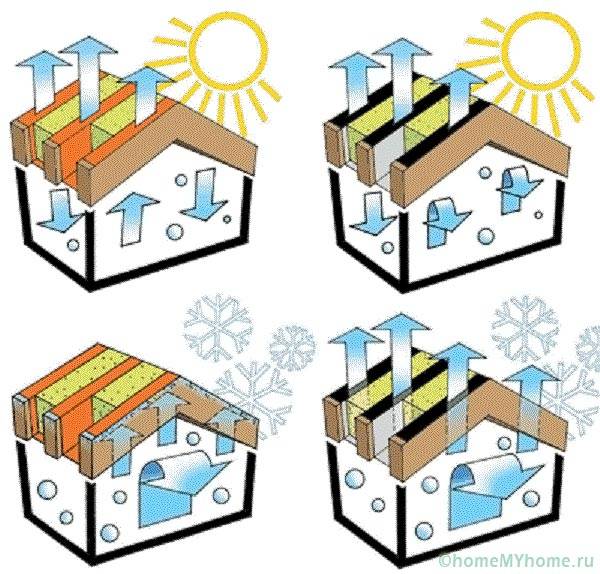

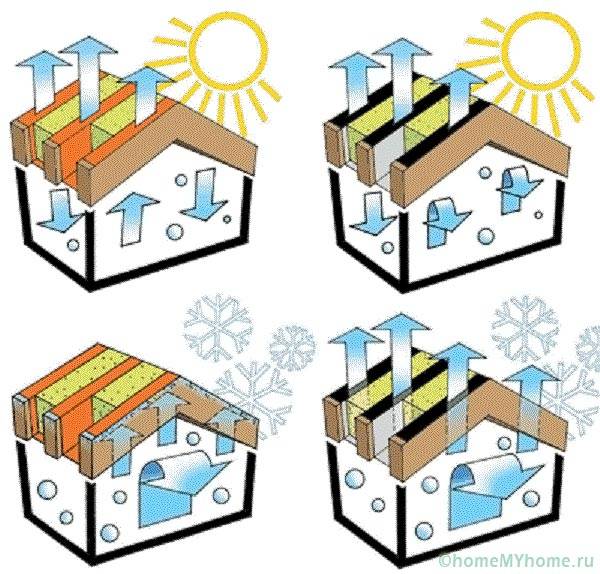

On frame, panel board, panel houses, the vapor barrier can be installed both outside and inside:

- if the dwelling is operated in a cold region, an internal vapor barrier is sufficient, which will cut off the moist air from the premises;

Internal vapor barrier

- in hot climates in summer, the outside air is often much warmer than indoors, therefore, an external vapor barrier is additionally installed;

External vapor barrier

- if the cottage is insulated from the outside with mineral wool, expanded polystyrene through the ventilation facade system, moisture is removed due to air circulation in the ventilated space, however, a hydro-wind protection of the insulation outside is required.

Ventilation facade hydro-wind protection device

When installing a vapor barrier layer, take into account:

- some interior finishes have their own vapor barrier, therefore, the layers in the building wall cake should be positioned in such a way that the vapor barrier properties increase from the inside out, otherwise the dew point will shift to the inside of the wall, condensation will form on the surfaces of the lumber;

The principle of consistency of finishing materials

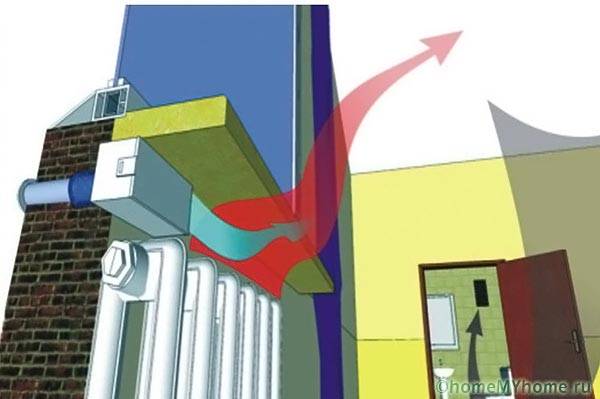

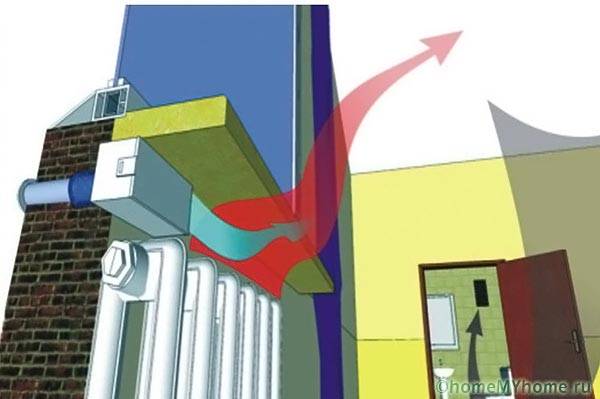

- any vapor barrier material automatically makes the walls not "breathable", therefore, it may be necessary to install forced ventilation (supply valves on the windows, fans in the walls, vents).

Organization of air flow through the ventilation valve

Related article:

Why do plastic windows in the house sweat? From this publication you will learn about all the reasons for this unpleasant phenomenon and how to get rid of it.

The main installation errors are the incorrect placement of the vapor barrier inside the cake of the walls, the inverted sides of the membrane, or the lack of continuity of the contours. The films on the walls should be joined with the materials on the ceilings and floors.

Continuity of the vapor barrier circuit

Films

The industry produces smooth polymer films without perforation, with maximum vapor barrier. For baths, saunas with specific operating modes (rapid heating to extreme temperatures), aluminum foil is glued to one or both sides. It reflects heat back to save energy.

Film vapor barrier materials

The most popular are polyethylene, PVC films, which are mounted either under the wall cladding or over the outer insulation. If, in violation of the standards of the joint venture, there is no internal vapor barrier of the dwelling, the film is installed outside under the basalt wool.

Film vapor barrier device

Membranes

Diffusion membranes, in contrast to classic films, have a different design. The molecules inside them are arranged in a labyrinthine order, which makes it possible to condense moisture from the air on their surface, not to let it pass to the lumber from which the frame is assembled.

Membrane vapor barrier materials

At the same time, it is necessary to install a vapor barrier for the walls of a wooden house using the following technology:

- under the inner wall cladding;

- with a mandatory ventilation gap between the decor and the film.

With an increase in moisture from the outside, vapors penetrate into the walls, however, they can freely pass through the pores of the film, condensing on its inner surface.Thus, if you change sides during installation, the effect of the vapor barrier layer will be exactly the opposite:

- all moist air will pass inside the wall;

- condensation forms on wooden structures.

It is very important to install the vapor barrier on the correct side.

Manufacturers mark each side of the membrane, provide products with detailed instructions that must be followed during installation.

Roll materials

Individual developers should not confuse roll materials with film materials. The last category is listed above, the following products belong to the roll-on vapor barrier:

- roofing felt - based on fiberglass or fiberglass with one layer of bituminous material;

- roofing felt - tar-soaked cardboard;

- glassine - bitumen-impregnated cardboard.

Rolled vapor barrier materials

Attention! The vapor permeability of these materials is 50 times higher than that of polymer films and membranes, therefore their use in wooden housing construction is not recommended.

Polymer varnishes

Most often, varnishes with the VD-AAK-001D index are used to protect the decorative layer of log cabins. The material is ready to use, applied in several layers, retains the texture of wood, forms a protective film. Semi-matt, glossy, colorless varnishes are usually used, drying in 4-7 hours. Average consumption is 1 liter per 8 - 14 squares of surface.

Polymer varnishes for vapor barrier

If it is planned to decorate the interior walls with decorative materials in a log house, cheaper polymer films are used instead of varnish.

The process of vapor barrier walls from the inside

The main task in the construction of any building is to protect the entire structure from the direct effects of moisture. It is so destructive that it can destroy any building material. In addition to moisture, another serious enemy is known, it is steam.

When building houses, it is important to vapor barrier the house from the inside. This is due to the fact that moisture destroys any material over time.

If you neglect the protection from the resulting steam, mold, fungus will appear on the surface of the walls, and dampness will appear. That is why every house requires a vapor barrier from the inside.

The choice of material for the vapor barrier of a wooden house

Main types:

- Anti-condensation film - a means of additional protection, prevents the dripping of condensate drops, which contributes to their rapid drying.

- Diffuse membranes. A special building material that allows steam accumulated inside the room to escape.

- SBS-Bitumen are polymeric materials of new technologies. Due to their elasticity, they seal the surface well.

Materials:

- Polyethylene film.

- Polypropylene film.

- Diffuse membrane.

- Liquid rubber.

- Hot bitumen.

- Penofol. It has protective functions against cold, water and steam. Multilayer material equipped with aluminum foil. The filler is polyethylene foam.

- Armofol. Made of glass mesh. Resistant to high humidity and temperature.

- Alucraft. Consists of polyethylene foil and kraft paper.

Some features

It is simply necessary in damp and at the same time warm rooms. A prime example would be a sauna, possibly a heated basement. Such rooms are located underground, they are most exposed to attacks of dampness.

Due to the fact that steam and humidity are present in huge quantities in the sauna, this room must be vaporized.

In such rooms, steam is always generated in the form of warm air, with a huge amount of the smallest droplets of water. The resulting steam simply needs to find a way out of such a room. He looks for ways and finds them in the form of the walls of the building, its ceiling.

In this case, the formation of steam becomes permanent, the destruction of building structures occurs, the building becomes emergency.To protect the walls of the building, a special vapor barrier is made, which prevents steam from entering from the inside, as a result, the life of the walls and partitions is extended.

Installation of vapor barrier is not limited only to baths and basements. It is also necessary to install vapor barrier of internal walls in buildings that have external insulation, when the walls have a homogeneous material.

I must say that there is no special vapor barrier material that is suitable for all rooms in the same way. The type of vapor barrier depends on the existing structural component of the internal wall structures.

The need for vapor protection

There is one more question: is vapor protection necessary at all? It depends on many factors. The calculation itself is carried out using SNiP 23-02-2003, dedicated to the thermal protection of buildings. The main data for it are the construction of a wall, floor, floor or other surface, as well as the climatic conditions of the region.

This calculation is also important because foreign manufacturers of vapor barrier materials calculate its permeability and strength for warm - compared to ours - winters. And since the vapor barrier works only in the cold season, the most severe frost will be the exam for the material.

And only materials certified for our conditions can withstand it. Yes, do it yourself vapor barrier allows you to significantly reduce the cost of this process, but not at the expense of the quality of the materials.

For example, cheap Asian films contain plasticizers that significantly reduce its adhesion to the adhesive backing of the tapes. This means that after a while, such a pseudo vapor barrier will consist of separate fragments of this material.

Situations when it is necessary to install an internal wall vapor barrier?

The vapor barrier of the walls must be done in several cases.

Mineral wool is a breathable material, however, with this type of insulation, a vapor barrier is simply necessary.

- If the walls have installed internal insulation. Moreover, mineral wool was used as a material for thermal insulation. Excellent thermal insulation properties are shown by mineral wool from the group of "breathable materials". But it has one negative property, mineral wool is not friendly with moisture. It gets wet quickly, gradually its properties deteriorate, it begins to deteriorate quickly. To prevent such cases from happening, vapor barrier of the walls is used from the inside of the building. Frame houses with wall structures consisting of several layers must certainly include a vapor barrier material. This also applies to structures with internal insulation.

- A powerful windproof function for buildings with a ventilated facade is performed by the laid vapor barrier layer. It measures and softens the air flow. As a result, the outer insulation is less overloaded, it acquires free "breathing". For example, a wall made of bricks, which has external insulation, made of mineral wool heat insulator and upholstered with siding. In this case, the vapor barrier becomes a kind of wind barrier, it reliably protects the walls of the building from powerful blowing. The existing ventilation gap removes excess moisture from the installed windbreak.

- In order to provide a good microclimate in the room, it is necessary, together with the vapor barrier, to install effective and reliable ventilation operating in a constant mode.

Related article: How to demolish a concrete wall in an apartment

What materials do builders use today for laying a vapor barrier?

The scheme of the vapor barrier.

However, the expression "vapor barrier walls" does not mean that such a protective barrier does not allow any vapor to pass through. Membrane materials used by builders today are endowed with the ability to pass a certain amount of air flow. This is done for one purpose only.

There should be no “greenhouse effect” in the room. The installed membrane retains excess moisture that has passed through it; it will not be able to negatively affect the internal walls of the house and the installed insulation material. When the insulation has an inner "coat", then the flow of the wet mass through the exhaust ventilation takes place.

Varieties of vapor barrier materials

Polyethylene is a classic vapor barrier material. This material requires careful handling, because if the film is pulled tightly, it can break at the time of changing climatic conditions. But there is one very important condition. Polyethylene must be perforated, otherwise it will not allow air to pass in addition to steam. It will not be possible to get a comfortable microclimate in the building with such a film. If this polyethylene is used as a membrane, it will interfere with the flow of air mass, it cannot be used for vapor barrier.

The scheme of the vapor barrier of the walls from the inside.

You can make the perforation of the plastic film with a special device. Take a roller with hammered nails. Such a "modernization" of the polyethylene film will not be able to provide reliable vapor barrier for internal walls. Of course, membrane materials are very similar to plastic wrap, but they differ greatly from it in their multilayer structure.

Builders often use special mastics as vapor barrier materials. After application, such a mastic is capable of allowing air to pass through, while retaining moisture. Surface treatment with such mastic begins to be done before finishing.

Membrane films have become a modern material that is used today for laying a vapor barrier.

This material is able to prevent the ingress of moisture, while simultaneously allowing air to pass through. Such membranes have a certain vapor permeability, which ensures the normal operation of the insulation. When such a vapor barrier is installed, the cotton insulation does not get wet, the walls "breathe", there is no freezing.

Materials used

Vapor barrier can be installed using various materials. Full air circulation is not blocked. It is redirected to the hood. Prevention of the greenhouse effect, minimum air flow with retention of excess moisture - these are the most important tasks solved by the correct vapor barrier of walls.

The following materials are used for protective work:

Polyethylene film. We fasten it carefully, without too much tension. We do not create conditions for its damage. Poetryne does not let through not only steam, but also air. Hinders ventilation. A comfortable microclimate with this kind of protection is hardly achievable. Modern construction rarely uses it.

Use of mastic. Inexpensive, easy to use. Perfectly breathable, retains moisture. Surfaces are treated before finishing work, together with waterproofing works.

Membrane vapor barrier film. A modern way of protection. Provides normal air exchange of porous insulation. Does not allow them to be impregnated. It is used to insulate frame, wooden walls. When the membrane film is stretched, it makes no sense to establish air gaps.

Nuances of vapor barrier walls installed from the inside in a wooden house

When freezing of the wall is detected, the wall is insulated around the entire perimeter, from the inside. If wet spots are formed due to freezing, the wall is insulated with so-called warm plaster from the inside.

The vapor barrier is placed on a woven mesh.

- Usually the layer laid does not exceed 30 mm. It is placed on a special woven mesh. As a result, a reliable adhesion of a special heat-insulating plaster to the wall is provided. Craftsmen recommend insulating the interior walls entirely in one room.

- As a result of such actions, moisture will not be able to spread beyond the boundaries of the damaged surface. When insulating the walls inside the building, it is necessary to make such a vapor barrier, which will reliably isolate the repaired area from wet vapors of air flows.

- Before you start to insulate the walls with a special solution, you must first remove the previously applied plaster. If you do not do this and put a new layer on the remaining plaster, then in order to obtain reliable adhesion of the plaster to the surface, you need to mount the reinforcement cage and fix it. Pull the mesh onto the frame and only then plaster the wall with the prepared heat-insulating mortar.

In recent years, builders have been using woven mesh. This material adheres tightly to the surface, the adhesion to the partitions and the wall of the room increases, the required roughness is formed.

Plastering the surface is carried out in several steps. First, a spray is made, having a continuous layer with a thickness of 9 mm. Spraying is performed with a liquid solution that has the ability to flow into any pores of the surface. It adheres firmly to the surface. Then the surface is primed to level out the remaining irregularities.

Wall vapor barrier: purpose, application, types and methods of their installation

No matter how dry the air inside the room may seem, it contains a considerable amount of moisture vapor. And no one would have paid attention to them if energy-saving technologies had not been used in modern construction. Insulation (or rather the heaters themselves) turned out to be defenseless against moisture and vapors, since getting wet, they lose their ability to retain heat inside the premises. To protect them, a hydro and vapor barrier is used - the first is installed outside (in most cases it is used to protect insulation from street moisture), and the second from inside the room. The task of the latter is to protect the insulation from water vapor contained in the indoor air of the premises. It is about him that will be discussed in this article, in which, together with the site stroisovety.org, we will deal with the purpose of this material, the types and methods of their use.

Why do you need vapor barrier walls

Laying the vapor barrier

Before buying a vapor barrier material, you need to clearly understand which structures need protection. There are many types of it on the market, so it is important to accurately determine the required one. Only in this case it will be clear how to properly lay a vapor barrier and provide maximum protection.

In most cases, it should prevent moisture from penetrating to the insulation, so special attention should be paid to the joints. Reliable fastening of the film to the base provides fasteners with a wide head or furniture staples.

Wall vapor barrier: what is it for and when it is impossible to do without it

There is only one correct answer to the question of why wall vapor barrier is needed, which we partially touched upon a little above - at least, this is how it looks in brief. If we consider it more extensively, then we should also touch upon the topic of moisture exchange in rooms, which occurs, regardless of our desire, in an invisible way to us. The moisture in the air, or rather its excess, is absorbed into the walls of a house or apartment, and if there is a lack of water in the air, moisture returns back from the walls. Now judge for yourself - where do you think the excess water vapor will go if you install a heater between them and the wall? Naturally, they will accumulate in it, and then, as described above, fill all the empty space between its fibers and displace air from them, which, in fact, is a heater. It's no secret that water in all its manifestations is by no means such.

Related article: Which expanded polystyrene is better for wall insulation

Vapor barrier of walls from the inside

Installation of vapor barrier walls is not necessary in all cases - an important condition for the absorption of moisture vapor by the insulation is the temperature difference, which is largely noticeable on the outer walls. Moisture simply condenses inside the insulation, turning into water droplets - they are the ones that are dangerous for the insulation. If this does not happen, then there is no need to install a vapor barrier - for example, there is no such effect on the inner walls of the house.

In this regard, a number of rules can be formulated when it is impossible to do without the use of vapor barriers.

- Vapor barrier is necessary for thermal insulation of building walls with direct contact with the street with mineral materials.

- Multilayer wall structures, which include mineral, basalt or any other wool, must be covered with a vapor barrier on the inside. The device for vapor barrier of frame walls is no exception - they are also a multilayer structure.

- Ventilated facades. During their installation, mineral wool insulation is generally placed between two protective layers - a hydro-barrier and a vapor barrier. The first, outer layer, protects the insulation on one side, and the inner layer, located from the building wall, plays the role of a vapor barrier. Also, the vapor barrier in such structures additionally performs the function of wind protection. A striking representative of such facades is a house sheathed with siding, with mineral wool insulation placed behind it.

How to attach a vapor barrier to a wall

A very important point accompanying the vapor barrier of walls from the inside and outside is the availability of high-quality ventilation. If we talk about internal vapor barrier, then the internal rooms should be ventilated, if about external vapor barrier, as in the case of siding, then a ventilation gap is needed here. Air passing through it removes excess moisture that settles on the vapor barrier.