Characteristics of closed expansion tanks

Sealed metal containers are used, in which there is a supply of coolant in case of temperature compression of the liquid. This is how the problem of airing the pipeline is solved. If the coolant, expanding when heated, creates too much pressure, the hydraulic tank compensates for the difference.

Despite the apparent simplicity of the design, the expansion tanks are different from each other, and different models have different operating parameters. Structurally, the following types of hydraulic tanks are distinguished:

- Reservoirs for pear replacement.

- Tanks with a permanently installed membrane.

- Tanks that do not have a membrane in the design.

In the first case, the pear acts as a membrane. It is into it that air is pumped, which changes the volume of the working chamber with a thermal increase in the volume of liquid in the system. The air pressure in the expansion tank must be such as to squeeze water into the pipes when the temperature in the radiators drops.

How to remove an airlock from the cooling system?

There are several ways to expel air from the cooling system. The easiest way is to lift the front of the car up so that the air lock comes out on its own through the radiator neck. There are times when the plug does not come out by itself, as it is held by the fluid pressure in the cooling system. In this case, in order to remove the air lock, it is necessary to relieve the pressure in the system: loosen the connection on the outlet pipe of the radiator and wait until the coolant flows.

Another way to remove airlock from the cooling system will require some coolant to top up. The procedure is as follows.

- As in the first case, the car must be put upside down so that the radiator neck is at the top point.

- Pour coolant into the expansion tank to the maximum level, and open the plug on the radiator through which air is bled.

- Start the car and turn on the stove to the maximum.

- Periodically re-gas.

- Have an assistant watch the air bubbles that come out of the expansion tank.

- If hot air begins to blow from the stove, this means that the thermostat has opened the valve to the maximum.

- When liquid begins to flow out of the hole without air bubbles, the hole can be closed. After that, the required amount of coolant must be added to the expansion tank.

Setting the tank pressure in the water supply system

Initially at the time of sale, plumbing tanks have a standard pressure of 1.5 bar in the tank chamber. The instructions for use indicate the permissible range, which is not recommended to go beyond, especially in the direction of increase.

To correctly set the optimal mode for the hydraulic tank, the following recommendations are taken as a basis:

- The air pressure in the expansion vessel is adjusted after the power supply is cut off.

- The valves must be closed. The water is drained, leaving the container empty.

- The air pressure in the expansion tank is recorded using a pressure gauge.

- In case of non-conformity, the air is pumped up or vented until the values set by the manufacturer are reached.

In the production of hydraulic tanks, inert gases are used instead of air in order to eliminate the appearance of foci of corrosion. When manually adjusted, the pressure is made 10% lower than the manufacturer requires.

It should be remembered that after turning on the pump, the working chamber of the hydraulic tank will be filled with water, and only then will it reach the consumer. If the air pressure drops, the head is unstable. And when the equipment is operating normally, it is constant and does not change while using the system.

Adjustment of the hydraulic tank in the piping of the water heater

There is one peculiarity here. Such hydraulic tanks must have a slightly higher operating air pressure, namely 0.2 bar higher than written in the instructions.

So, if the pump delivers 3.5 bar, the hydraulic tank is set to 3.7 bar. The first functional check and adjustment is performed before starting the system, until the tank is filled with coolant.

No liquid in the chamber is normal operation. And it fills up only when the water in the pipes heats up. Lack of air pressure in the expansion tank leads to the fact that the coolant fills the tank, which is a violation of operational requirements. In this case, it is necessary to turn off and release the system, and then configure the hydraulic tank again.

Reasons for the appearance

There are several reasons due to which air accumulates in the channels of the cooling system. An airlock is formed due to:

- Leaks in the system. Leaks at the joints of the nozzles lead to the fact that when the fluid flow moves, a vacuum is formed, which sucks air into the system. Gradually, the amount of air increases, then it accumulates in one place, forming a plug.

- Loss of tightness in the water pump. If the gasket under the pump is damaged, the unit will suck in air during operation.

- Violation of the technology for replacing or adding antifreeze. If you immediately fill in a large amount of liquid, then the air in the nozzles will not come out and the antifreeze will push the air bubbles into the system with its own weight. After starting the motor, air will collect in one place, interrupting the flow.

- Damage to the cylinder head gasket due to overheating. If the resulting breakdown connects the cooling system channel to the atmosphere, then the liquid will draw in air from the outside. Airing appears if the sample has connected the channel to the cylinder. In this case, the exhaust gases will break through into the cooling system, which, in addition to the appearance of an air lock, is accompanied by the bubbling of antifreeze in the expansion tank.

Open type hydraulic tank

Such designs are considered obsolete, since they do not provide absolute autonomy, and can only increase the period between services. The heated liquid evaporates, and its shortage must be eliminated by periodically adding the coolant, replenishing its volume. No diaphragms or pears are used. The pressure in the system appears due to the fact that the open hydraulic tank is mounted on a hill (in the attic, under the ceiling, etc.).

Naturally, there is no air pressure in the open-type expansion tank. When calculating, it is taken into account that one meter of water column creates a pressure of 0.1 atmospheres. However, there is a way to automate water extraction. For this, a float is installed, which, when lowered, opens the tap, and after filling the tank it rises and blocks the access of water to the tank. But in this case, you still need to control the operation of the system.

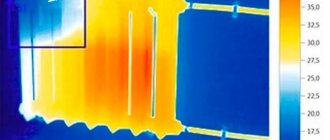

Air has entered the engine cooling system: the main signs of airing

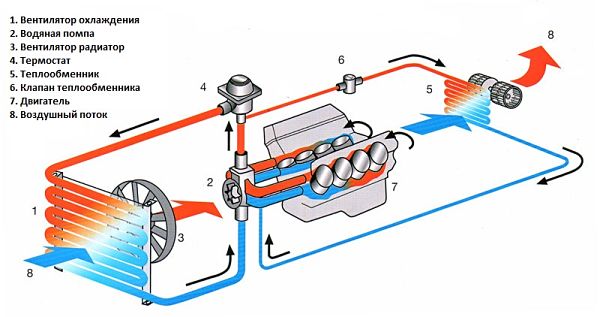

For a better understanding, let's start with the general principles of work. While the engine is cold, the liquid circulates only through the cooling jacket (special channels in the cylinder block and cylinder head), without entering the radiator. The circulation is provided by a water pump (pump).

After the coolant temperature reaches a certain value, the thermostat is triggered, which opens a large circle (the liquid passes through the radiator). If the cooling of the coolant when driving in a large circle is not enough, then the engine cooling fan (air cooling) is automatically activated.

In this case, it is important that the system works correctly, since its efficiency depends on maintaining the optimal temperature of the internal combustion engine, the normal functioning of the interior heater (stove), etc.

Please note that these malfunctions can occur for various reasons, that is, the engine begins to overheat not only due to the occurrence of air jams, but this likelihood should also not be excluded.

As with any closed loop fluid system, trapped air can cause the system to stop operating normally. In this case, the risk of motor overheating also increases significantly, the stove stops working normally.

- The main symptom of an air lock is engine overheating. In other words, the temperature rises above normal, the temperature gauge may rise to the red zone. In this case, when checking the coolant level in the expansion tank, no deviations may be detected.

- Also, in the cold season, the driver may notice that warm air practically does not enter the passenger compartment, although the engine is normally warmed up. It also indicates that there may be air in the cooling system.

One way or another, but the air lock does not allow the coolant to circulate normally through the channels of the cooling system. As a result of impaired circulation, certain malfunctions arise. As part of the diagnosis of the engine cooling system, you should check the coolant level in the expansion tank, and also carefully inspect individual sections of the system.

Leaks of antifreeze or antifreeze, any visible damage to hoses and nozzles are not allowed. You also need to check the reliability of fixing the clamps at the joints. It often happens that air enters the system precisely because of a loose or worn-out clamping clamp.

We also note that air can enter through subtle cracks in the rubber pipes, while there may not be intense leaks through these cracks. Usually, such cracks are not immediately visible, however, a detailed inspection or the introduction of air into the system under pressure for verification can identify problem areas. Also, during the check, you should pay attention to the pump, check the operation of the thermostat and the cooling fan.

If everything is normal, then there is a high probability that the stove does not work and the motor overheats precisely because of air congestion. In this case, it is necessary to take measures and "drive out" such a plug from the cooling system.

Hydraulic tank maintenance rules

The essence of the audit is to check the pressure in the air chamber. The pressure gauge must be in good working order and have a measurement accuracy of 0.1 bar. You can use a car tire pressure tester. Convenient when the scale contains gradation and in atmospheres. Then you do not have to recalculate if the instructions indicate the pressure in other units.

If, as a result of inflation, the air pressure in the expansion tank does not rise, this may indicate that the bulb or membrane has failed and requires replacement. During the inspection, the nipple and valves are checked. They must be sealed.

It is important that this equipment adheres to the parameters set by the manufacturer. It is not worth checking the strength, but after pumping the air should remain in the gas chamber for a long time.

How to properly pump the expansion tank in the boiler.

Today I want to talk about what a closed-type expansion tank is, how it is arranged, what it is for, how to choose the right expansion tank, what air pressure needs to be maintained in it and how to pump it up correctly. If you are interested, then listen further.

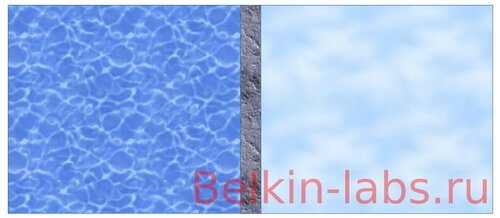

The device of a closed-type expansion tank is very simple - it is a container, most often made of steel, divided inside by an elastic diaphragm.On one side of the diaphragm, there is water in working order, on the other side there is air. Instead of a diaphragm, something like a rubber bulb or "balloon" placed inside a steel container can be used. In the part that is filled with water, a connecting nipple with a thread with a diameter of 3/8, ½, ¾ or 1 inch and others is welded. In the part where the air is located, there is a built-in fitting with a conventional automobile nipple for filling with air. The shape of the tank can be different - cylindrical in the form of a small barrel, it can be rectangular or round. It depends on where you want to install this expansion tank. There are tanks with feet for installation on the floor, there are for hanging fasteners to the wall or inside the boiler or other equipment.

Now let's figure out what the expansion tank is for and where they are installed. They are installed in heating and water supply systems.

AT heating system an expansion tank is needed to compensate for the thermal expansion of water or other coolant poured into the system. As we all know, a liquid is an incompressible medium that tends to change its volume depending on temperature. Simply put, the same amount of liquid at different temperatures occupies a different volume. Most modern heating systems are closed, that is, they have no connection with the atmosphere, and have a certain volume that does not change. If an expansion tank is not installed in the system, or it is selected incorrectly, then when the heating heats up, the liquid will not expand where and the pressure will rise to a critical value, after which the coolant will be discharged through the emergency relief valve in the system. After turning off the boiler and cooling down, the pressure, on the contrary, will drop to zero, the pressure sensor will work and to start the boiler into operation, you will have to refill the system with water again.

What does "airlock" mean?

By a conventional plug, we mean an object that prevents the flow or leakage of liquid. Antifreeze is generally understood as a liquid in the cooling system. If air is used as a plug, this is called an airlock. In addition to cars, this definition can be found in water and heat supply systems.

It is easy to explain this phenomenon physically. Air has a high volumetric compression ratio. In the antifreeze circulation system of the car, a maximum pressure of 2 - 3 atmospheres is maintained. Such a relatively low pressure often cannot "push through" the airlock.

The most that the water pump can do is move the plug to the highest point of the cooling system, and then if the radiator valve plug is working. Some engine CO components may be located above the upper level of the radiator, for example, the interior heater radiator. In this case, the airlock will be "eternal" until you take steps to remove it.

The worst option is to move the plug towards the water pump. Once in the area of its blades, the plug will lead to zero pump performance. That is, there is antifreeze in the system, but its movement is absent. The engine can overheat in a few seconds. In medicine, this effect is called air embolism.

Water pressure and air pressure

In this article, I first look at the problem from a theoretical point of view. I don't even take the tank itself, but an ideal model and see what processes take place in it. And only towards the end of the article I indicate how our ideal model differs from a real tank

These, as they say in Odessa, are two big differences. Water is incompressible, therefore, it is impossible in principle to create pressure in the water supply system by compressing water. And at the expense of what it is possible? Due to just two things. By stretching everything that can be stretched with water. For example pipes or hoses.

A more working idea is to create water pressure with air.Air, in fact, is compressed very well and can simply act like a spring. That is why it is used in closed expansion tanks. Let's refer to the following diagram. On it, I depicted an expansion tank. But conditionally, so that you can understand how it works from the point of view of a principle, and not a real device. Everything is very simplified here. We have a cylinder in which a piston runs. There is water on one side of the piston and air on the other. The main physical law that will interest us is that with a decrease in the volume of gas at a constant weight of the gas and temperature, the pressure increases. The relationship is linear. We reduced the volume by 2 times - the pressure increased by 2 times.

Filling platform (clip) for pumping cartridges universal

RUB 383.00 Buy

The disadvantage of this method is the high consumption of ink, because not all colors are filled evenly.

Photo 7

How to bleed CISS in Canon printers, where the print head is separate from the cartridges

I do it the same way in two ways:

1. As in the previous case, I fill the cartridges, fill the ink loop with ink, connect one to the other, put it back into the printer.

2. The second method is probably for the lazy, but you need to get used to it, the point is that you raise the containers with ink above the cartridges by about 20 cm. and the ink begins to flow by gravity into the cartridge. But since the cartridges are not always filled evenly, then you have to cover the outlet openings of the cartridges with something, often your fingers :)

In conclusion, I note that the CISS works stably with fresh ink and when it is sealed, if this is not the case, then there will be constant air in the tubes, and any other problems with the print quality.

Approach any business with reason and you will succeed!

In this article, I tried to share the maximum of my knowledge in this area with the hope that someone will be able to help in this delicate and sometimes not easy matter. The article, most likely, will still be supplemented with pictures and videos, so come back more often :)

I will be glad to comments, and also do not be lazy to share an article in social. networks by clicking the special buttons below!

You can repair or update your printer in Simferopol at the service center on the street. Starozenitnaya, 9 (entrance from the side of the fence). Please contact us during working hours from 9.00-18.00 at +7 (978) 797-66-90

Do not forget to rate the entry and share it with your friends on social networks by clicking the special buttons below. Don't forget to leave a comment and subscribe to our channel Youtube

Save

Save

Rate the article:

(

27 estimates, average: 4,30 out of 5)

Share with your friends:

Related entries:

Refilling instructions for Canon PG-37, PG-40, PG-50, PG-510, PG-512, CL- ...

A selection of test sheets for checking color printers and MFPs

Samsung ML-2160, ML-2164, ML-2165, ML-2165W, ML-2167, ML-2168 - Print Co ...

Instructions for refilling Canon cartridges. PG-440, CL-441 cartridges.

What is a nozzle test and how to print it.

Recommended products:

- In stock

We have created air pressure, but the water is not connected

Suppose we pumped our tank on the right with air to a pressure of 1 bar on the pressure gauge. In this case, it is quite obvious that the piston under air pressure will be pressed against the left end of our cylinder. Suppose we put some negligible amount of water on the left. Well, 1 gram, or 1 thimble, or 1 cc. never mind. Question. What pressure will this drop of water be under? Under pressure 1 atmosphere. In fact, a little more, because this drop has moved our piston by some micron, the gas volume has decreased and the pressure has increased. But since the amount of water is negligible, we will not consider the increase in pressure either. What else is important here? The fact that we could place this drop in the left side of the tank only using a device (pump) that creates a pressure greater than the air pressure, because we act with water against air. In our case, this is more than one bar.

We start filling the tank with water

What happens if we fill the tank with water to half its volume? The air volume will decrease by 2 times. The pressure in the empty tank was 1 bar. In half filled with water, there were 2 bars. The pressure in the water supply also became 2 bar. Everything is very logical.Can we drive another quarter of the water tank on the left? Let's assume that yes. We can. In this case, the volume occupied by the air will decrease by 2 times and we will get an air pressure of 4 atmospheres. The water pressure in the system will also be 4 atmospheres.

How much can we compress the air to the right? In an ideal circuit, I think it is very strong. Until the air is liquid, I suppose. In real conditions, we, nevertheless, have not a piston, but a rubber bulb, and I have not seen anywhere in the characteristics of real tanks an indication of the maximum volume of water in them (more information is available below). I suppose everything is governed by common sense, namely, reasonable limits for turning the pump on and off. And let's finally move from ideal schemes to real questions.

How does this ideal diagram differ from a real expansion tank?

To many. We have no piston. Instead of a piston, we have a rubber bag that crumples under pressure. No means are provided for neatly folding the bag. The bag will wrinkle as it wants. Obviously forms all sorts of folds. When water rushes into the bag, it straightens these folds. Again, this bag has a seam.

Rubber itself also stretches, which introduces some nonlinearities in the described process.

And in general, all the laws about the dependence of pressure and volume (Boyle Mariotte) were written for an ideal gas and ideal conditions. In practice, only molecules were considered and that was all. With real gas, especially with air, which is a mixture of gases, everything is more complicated, of course.

In a real system, there are attendant factors. Such as the quality of rubber, the quality of the tank, the adjustment of the equipment on which the tank was produced, the team of workers who made these tanks. I am sure that the tanks made by the workers from Albania will differ from the tanks made by the workers from Serbia. I’m not saying who will do better - I don’t know. But what will be different is absolutely certain.

Pump on and off pressure

What happens if all the water from the tank is gone and the pump does not turn on? In our tank, pumped empty to 1 bar, the minimum water pressure is 1 bar. That is, our water flows out, the pressure decreases and after the 1st bar it should simply collapse to zero. Simply because there is no water. It's over. The motor starts running and the entire system is under unexpected stress. Water shoots out of the pump, hits the pipes and is extinguished by the tank membrane, which takes the entire blow. This is all not very comfortable and rather dangerous. It is much better if the pump turns on while there is still water in the tank! But not too many. In our case, the pump should turn on when the water pressure is more than 1 bar. How much more? If it is much more, then we will reduce the amount of accumulated water and increase the frequency of switching on the pump (it will turn on more often and for a shorter time), which is not good. Now we are beginning to understand why we were advised to pump the tank 2 tenths of a bar less than the pump activation pressure. In this case, at the moment the pump is turned on, there will be a reasonable water level in the tank. Reasonable means reasonable by the manufacturer.

Why are very large expansion tanks good for the farm?

Here's an abstract example. We have a tank of 100 liters of full volume. We pump it up with one bar. We put the pump on at 3 bars, and off at 4. At the same time, the minimum remaining water in the tank will be more than half a tank (more than 50 liters). Our tank will work on a range of about 12 liters. That is, the pump turns on every one and a half minutes. I think that the pump will maintain such a rhythm, but on the other hand, we get a super comfortable water supply system, in which hot water in the shower does not "walk" with us due to pressure changes. I mean a fairly common case when hot water cools down with a decrease in pressure in the water supply system, and then heats up again as the pump operates to increase the pressure.

And if we assume that we are standing in the shower with a soapy head and the lights are turned off.What do we think? With a tank that is adjusted to almost complete drainage, we don't know how much water we have left in the tank, even if the tank is one liter. It is quite possible that the power outage caught us when the tank was completely running out! And in my scheme proposed above, the non-draining residue is as much as 50 liters. I will definitely have enough water to finish washing my head and torso even. There's nothing to even think about! You just need to shout to your wife to bring a candle.

But how, after all, to pump up the tank with water?

We may have only two tank faults, which are related to air pressure. If the pressure is too high (the tank is over-pumped), or too low (the tank is deflated).

If the tank is pumped over, then we experience the drop of the needle of the water pressure gauge to zero, and, only then, the pump is turned on. For example, the switch-on pressure is 2 bar, the air pressure is 3. The arrow goes down to three bar, then drops sharply to zero, the pump turns on.

The tank is under-pumped. You know, in this case, it should somehow work until it is completely deflated. If our tank is deflated, then we get an increase in the remaining water in the tank. The pump runs for a shorter and shorter time. After all, he needs to pump less and less! And by the way, the time before switching on is reduced. As a result, the air pressure in the tank disappears. It is completely filled with water and begins to "blink", that is, feverishly switch on and off.

Thus, in a pressurized system it is not at all easy to determine if there is a problem!

If the tank is over-pumped, then the pressure must be relieved through the nipple. If the tank is under-pumped, it is necessary to measure how much water it accumulates. Then, knowing the switch-on pressure and the switch-off pressure of the pump, it is possible to determine, at least approximately, how much water it should pump in one session.

Without knowing how much water is in the tank, we cannot accurately determine the air pressure. We can only act approximately.

How air enters the vehicle

The vehicle of a modern car is a unit that stores and supplies fuel to the cylinders of the power unit. Most engines are designed so that the unit draws in air, which is mixed at this time with the fuel injected by the vehicle, directly near the cylinders or directly into them (direct injection).

The first symptoms of air entering the vehicle are associated with the difficulties in starting the internal combustion engine. A system in which there is air can no longer function normally, which leads to difficulties.

Of course, a malfunction of the power unit itself is possible. Therefore, it is recommended to check the engine thoroughly first. If he does not start at all, then there is a reason to believe that the problems are in him. However, if unstable operation is observed - normal start-up, then failure, then normal again, this is definitely air.

Another sign of airing the system is the response of the gas pedal. You press it, but it does not work in any way, because there is air in the system, no fuel is supplied to the cylinders.

It is for this reason that the exhaust test method exists to test if fuel is going into the cylinders. The driver should ask the assistant to hold the starter for about 40 seconds (provided that the car will not start). He himself must observe the exhaust - is there smoke from the muffler. If yes, then fuel enters the cylinders and there is no air in the system. The reason for the difficult start must be looked for in something else.

Air enters the fuel line for various reasons. Basically, this happens on used, old cars, the service life of which is more than three or five years.

The reason is that the seals that are responsible for the tightness of the entire system are aging. We are talking about clamps, connections, oil seals. There are plenty of them in the vehicle. In addition, the lines themselves, through which the fuel flows, become obsolete over time, rust, and break. In a word, a whole series of circumstances turns out that determine the violation of the fuel supply.

Of course, the designers have foreseen something.If the seals are damaged, fuel will start flowing back into the tank. Some part of the fuel remains in the pump, it is enough for the next engine start, no more.

What to do with the heating tank?

But for this I, to be honest, wrote an article. It is easy and pleasant to drain the water supply. Draining heating is a problem. Especially when you consider that it is frosty outside, and after pouring there will be, as always, problems with air in the pipes.

What are the features of the expansion tank installed in the heating system? Features are! There may be no rubber bulb in the heating tank. Heating tanks come without flanges. Then, instead of a rubber bulb, there really is a membrane in the tank. And she is in the middle. And it stretches. Is there a pear analogy? It is difficult to say, but we will assume that yes.

The maximum pressure in the heating system is tiny. Only one and a half atmospheres. There should be as much water in the tank as possible. Thus, the minimum air pressure should also be minimum. In my opinion, the main thing is to keep it simple. And we must remember that there is always pressure in the heating system with water! Simply because there is a natural drop in elevation, and a significant one.

Thus, the air pressure in an empty heating expansion tank should seem to be somewhere around 0.5 bar. Then, under the maximum water pressure, the tank will hold three quarters of its water volume. With a 25-liter tank, 18 liters. And this seems to be a super-maximum.

You can act with the tank in the same way as the described completely deflated tank from the water supply system.

Have you checked if there is air in the tank? To do this, they pressed with a fingernail or something suitable on the nipple button. If it does not hiss, then we connect the pump and pump up the air, while draining the water. A quarter of the tank was drained and left under a pressure of 1.5 atmospheres. Checked the nipple. Then they let down a little water so that the pressure was not maximum and that's it. We believe that we are ready.

Dmitry Belkin, an amateur to solve problems that have no solution.

Remove the airlock from the vehicle Priora

Priora air from the fuel system

Here's how to do it:

- the VAZ 2107 tank is checked to make sure there is fuel in it;

- the air outlet on the fuel filter opens;

- fuel is pumped up with a hand pump until fuel without air bubbles flows through the fitting;

- without stopping pumping, close the air outlet;

- continue pumping until resistance is felt.

Related article: How to set the distributor skillfully and without problems

Now you need to try to start the engine. If it does not work out, it means that air has entered the vehicle, and it must be expelled from there. On the Priora, this is done like this:

- the union nuts on the injection nozzles are loosened;

- the starter turns until the fuel comes out;

- the nuts are now tightened and the engine can be started, as the air will escape along with the fuel.

Thus, the airing system of the Priora car takes place.