A modern home needs a high-quality ventilation system. It is a matter of health and wellness - everyone wants to breathe clean, fresh air free of pathogenic microorganisms. It so happened that the house was built in a small village far enough from the city and its main communications. Moreover, in Russian conditions, housing must also be heated for a significant part of the year.

So, we have built a frame house with an area of 200 square meters with a well-designed ventilation system, from heat sources - only electricity. The choice of the heating system seemed obvious - they decided to stay on an air-to-air heat pump compatible with ventilation.

Why not firewood?

Our neighbors mainly heat wood-burning stoves, but this option was initially not pleasant. Every year it is necessary to stock up on fuel, clean the boiler, and monitor its combustion. With electricity, everything is much simpler - I pressed the toggle switch, the heat started. The only disadvantage of this method is the high cost of electricity. At the time of the start-up of the heating system, a kilowatt-hour in the Moscow region cost 5.29 rubles.

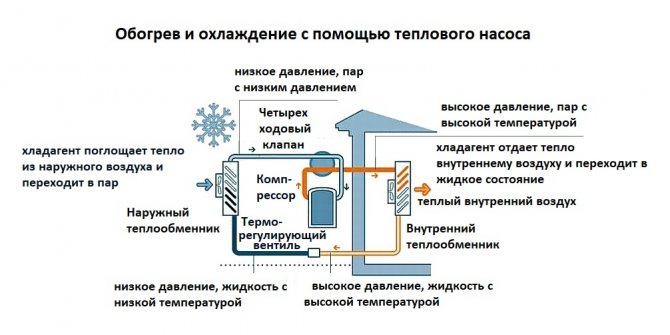

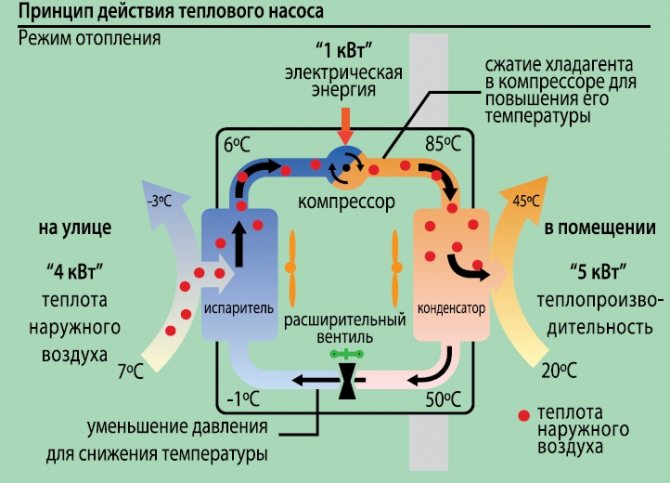

Naturally, we wanted to use such a valuable resource as economically as possible, so we settled on an air-to-air heat pump. This is the cheapest option, it works almost like an air conditioner.

Equipment operating parameters

Severe frosts in the Moscow region are rare, experience has shown that the temperature rarely drops below -25 ℃. It was calculated that in such conditions a pump that produces 15 kW of heat will be enough for the house of the available area. The system budget cost us about 150,000 rubles.

The efficiency of air pumps also changes depending on external conditions. In our case, it turned out that with the consumption of 1 kilowatt-hour of electricity, the system produced 2-2.5 kW of heat. It's minimum. If there is a light thaw outside with a temperature slightly above zero, then it gives out 3.5 kW of heat.

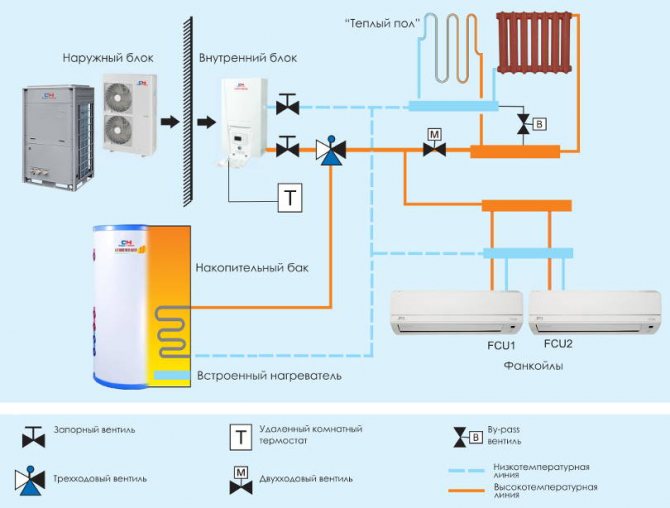

The house is evenly warmed up by the warm air, there are no radiators or warm floors. Fresh outside air is constantly added to the system through the recuperator.

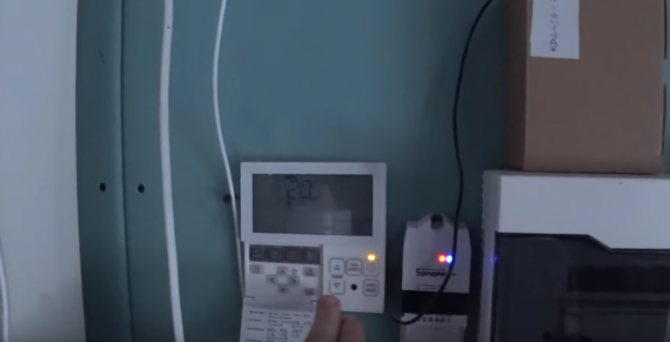

The task of the recuperator is to save additional heat. With its help, the air coming from the street is heated by the one that is forcibly thrown out of the house, for example, from the bathrooms. The desired room temperature is set on the remote control.

Automatic control, at night the temperature is reduced for greater comfort.

How to choose an air source heat pump

In order to maintain a comfortable indoor temperature in winter, a sufficient power reserve of the heat pump is required. Not all models perform well at low temperatures. There are those that have an energy efficiency factor above 1 at -30 degrees, but their cost is too high.

Another point is the service life of the heat pump. The more powerful it is, the less stress it experiences during normal operation and the higher its service life. Standard mid-range heat pumps are designed for an average of 10 years of normal operation. Cheaper little-known brands - from 5 to 7 years, more expensive, premium class - from 15 years and above.

When choosing an air heat pump, it is worth considering what time of the year you will use it and at what temperatures, how much electricity it will take to operate it and how long it will pay off. Based on this, and choose a model. As practice shows, an air-to-air heat pump is more profitable to use in addition to the main heating, and not instead of it.

Which brand of air-to-air heat pump to choose

The equipment is offered by German, Chinese and Japanese manufacturers. When choosing, you must focus on the parameters specified in the technical documentation and customer reviews.

The best brands of air-to-air pumps are made in Japan. Asian corporations were among the first to use the technology of extracting low-grade energy from the air to cool premises. Since then, their products have improved significantly:

- Daikin - the world leader in the manufacture of heating and air conditioning systems. The main feature of the products is the complete integration of the system into a residential building and the provision of autonomous climate control, adapting to the wishes of the owners. The Daikin brand offers heat pumps for residential and commercial needs, operating for heating and cooling, as well as meeting the needs of domestic hot water.

- Mitsubishi - the domestic consumer is familiar with the company's products mainly from the cars produced. But, like many other Japanese companies, in addition to cars, Mitsubishi produces several other types of equipment. The main advantage of the company is the creation of a unique ZUBADAN design, which has significantly improved operating parameters and reduced energy costs. TN Mitsubishi remain operational down to -25 ° C. For heating industrial complexes, multi-zone systems have been developed.

- Fujitsu - the main emphasis, the company makes on the production of the so-called combined systems, which have a wide additional functionality. Heat pumps work for heating and cooling. If necessary, they can be easily integrated into the liquid heating system and hot water supply. Fujitsu are compact and easy-to-use systems for heating private houses and cottages.

When choosing a suitable station, in addition to choosing a manufacturer, they pay attention to technical parameters, in particular COP and the minimum temperature at which the pump remains operational.

How much does the air-to-air heat pump cost?

The cost is influenced by technical characteristics, availability of additional functions. The Japanese are accustomed to classifying installations by performance and reliability. The consumer is offered three classes of equipment:

- Household - the estimated price is 200-350 thousand rubles. The maximum heated area is no more than 100-140 m².

- Semi-industrial - will cost 500-800 thousand rubles.

- Industrial - the most expensive and productive units, designed for long-term operation under adverse conditions. Performance up to 90 kW. Cost from 900 to 3 million rubles.

In addition, the cost of installation and production of the project, for the distribution of air flows during operation, is added to the price of the heat pump. This is especially important when heating large areas, divided into rooms by partitions.

Distribution of heat to rooms

Each room needs its own amount of heat. For example, in corner rooms, more of it is always required, because they have two cold walls. We solved the distribution problem with the help of gate valves.

In other places, the flow is regulated by valves on the grates. They stand not only in the ceiling, but also in the floor. This is very important for uniform heating and comfort - everyone knows that warm air rises up. The air intake for exhaust from the premises is arranged in a similar way - it is produced both from the ceiling and from the floor.

It has already been mentioned how the air is removed from the bathrooms: to the street through the recuperator, so the spread of odors throughout the house does not occur.

Homemade from an old refrigerator

It is quite difficult to assemble an air-to-air heat pump from individual compressors and condensers with your own hands without specialized engineering knowledge. But for a small room or greenhouse, you can use an old refrigerator.

The simplest air heat pump can be made from a refrigerator by extending an air duct from the street into it and hanging a fan on the rear grill of the heat exchanger

To do this, make two holes in the front door of the refrigerator. Through the first, street air will enter the freezer, and through the second lower one, it will be removed back to the street.

At the same time, during the passage through the inner chamber, it will give off part of the heat available in it to freon.

You can also simply build the refrigeration machine into the wall with the open door to the outside, and with the heat exchanger at the back - into the room. But it should be borne in mind that the power of such a heater will be small, and it consumes a lot of electricity.

The room air is heated from the heat exchanger at the back of the refrigerator. However, such a heat pump is capable of operating only at outdoor temperatures not lower than plus five Celsius.

This home appliance is intended for indoor use only.

In a large cottage, the air heating system will have to be supplemented with air ducts that distribute warm air evenly throughout all rooms.

Installation of an air-to-air heat pump is extremely simple. It is necessary to install the external and internal blocks, and then connect them together with a circuit with a coolant.

The first part of the system is installed outdoors: directly on the facade, roof or next to the building. The second in the house can be placed on the ceiling or wall.

It is recommended to install the outdoor unit a few meters from the entrance to the cottage and away from the windows; do not forget about the noise produced by the fan.

And the inner one is installed so that the flow of warm air from it spreads evenly throughout the room.

If it is planned to heat a house with several rooms on different floors with an air-to-air heat pump, then it will be necessary to equip a system of ventilation ducts with forced injection.

In this case, it is better to order a project from a competent engineer, otherwise the power of the heat pump may not be enough for all premises.

The electricity meter and protective device must be able to withstand the peak loads generated by the heat pump. With a sharp cold snap outside the window, the compressor starts to consume electricity many times more than usual.

It is best to lay a separate supply line from the distribution board for such an air heater.

Particular attention should be paid to the installation of tubes for freon. Even the slightest swarf inside can damage the compressor equipment.

Here you cannot do without copper soldering skills. In general, you should entrust the refueling of the refrigerant to a professional in order to avoid problems with its leaks later.

Step-by-step instructions for making a heat pump from a refrigerator are described in this article.

Outer part

The outdoor unit of the heat pump is located behind the air-transparent louvers. It is large enough and looks like an industrial air conditioner. In winter, the pump body freezes over and is covered with a dense snow coat. This is a process provided for in its work - according to its internal algorithms, the equipment regularly goes to defrost and completely thaws. After that, everything is repeated.

Advantages of air-to-air heat pumps

- Installing such equipment is not much more difficult than connecting a refrigerator or air conditioner.

- Installation does not require laying a large heat exchanger in ground or water.

- The air-to-air heat pump is ready for operation as soon as it is connected.

- The installation does not require regular maintenance, it has few moving parts, so it has a long service life.

- There is no need to arrange a heating system.

- Low cost compared to ground and water heat pumps.

- Lack of storage tank and other auxiliary units.

Conclusions based on the results of use

The entire turnkey ventilation and heating system cost about 280,000 rubles.Here it is necessary to take into account that the work was carried out on our own, and when purchasing equipment and materials, the talents of "knocking out" discounts were used to the maximum.

Many do not believe that in our latitudes it is possible to heat the air heated by electricity. From our own experience, we can say that this is real. Such systems work and even save money. The average monthly amount for heating in our country is 6000-8000 rubles. From the experience of neighbors with houses of a similar size, we know that they pay both 20,000 and 25,000 rubles a month. It turns out that all our costs for installing an air-to-air heat pump will fully pay off in about 2 years.