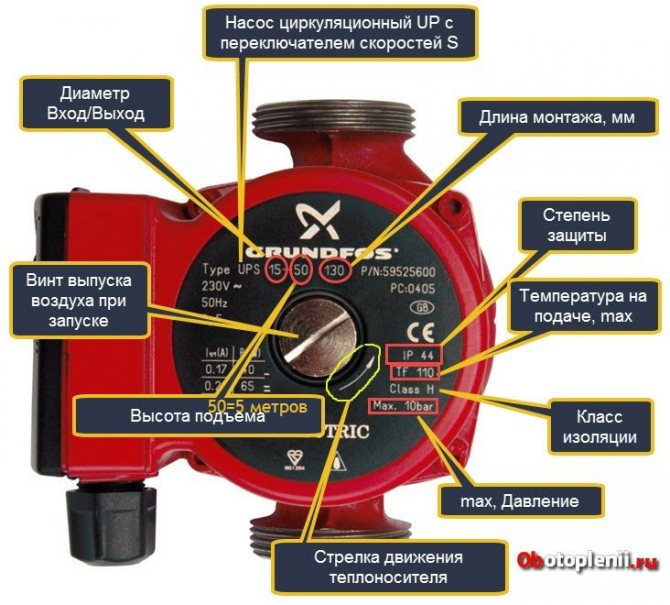

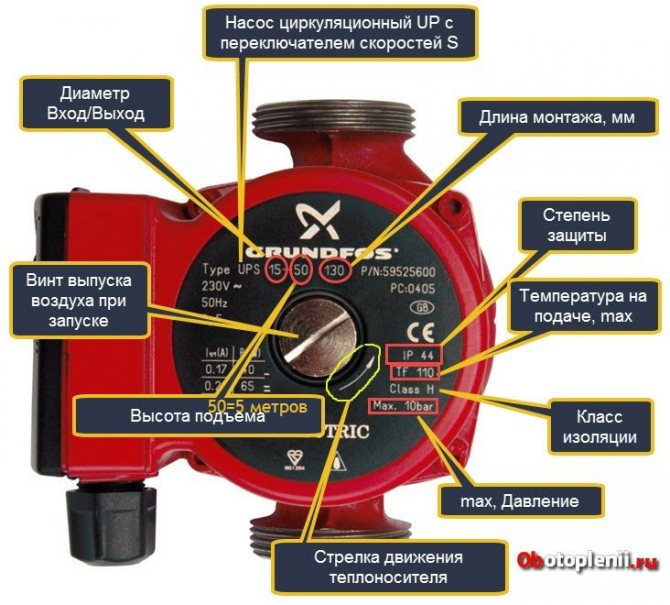

Two main characteristics of a circulation pump

With a long list of heat pump specifications, there are two main ones. These are the diameter of the connection pipes and the power of the "accelerator". These two numbers are considered defining and are indicated in the name.

Connection pipe diameter

The most important parameter for installing a pump, especially with an already installed heating system. This is a numerical value indicated in millimeters and showing the diameter of the heating pipes that can be connected to the inlet / outlet pipes.

Please note that for connection on the nozzles of the body, taps with threaded threads are made.

Power

Power in heating systems is the ability to raise water to a certain height or pump head.

In the labeling of Grundfos pumps, the power is indicated in meters multiplied by 10 or atmospheres multiplied by 100. That is, Grundfos with the ability to raise water by 5 meters (head of 5 meters) will receive the number 50 or 0.5 atm in the marking. (atmospheres).

Example: Circulation pump Wilo Star 30/2, means that the diameter of the connection pipes is 30 mm, the head is 2 meters.

In the Wilo marking, the power is indicated, simply in meters.

Example: Grundfos UPS 25 40 (130 mm), means that the diameter of the connection pipes is 25 mm (1/2 inch), the head is 4 meters. 130 is the installation length of the installation.

Operational Requirements

In order to avoid premature repair of Wilo pumps, the following should be adhered to:

- exclude idling (in the absence of water in the system);

- do not block the water flow when the pump is on;

- set the operating mode in accordance with the minimum and maximum capabilities of the equipment;

- follow the manufacturer's recommendations on the permissible pressure in the system;

- do not allow heating of the coolant suitable for the pump over 65 ° C;

- avoid long downtime;

- use filters to clean the water circulating in the system.

The range of Vilo pumps

If these rules are followed, the pump will make a uniform sound and maintain a stable head, which is evidence of its normal operation. Most pumps operate without repair for 5 years or more, until the main elements are completely worn out, provided that all operating rules have been observed.

Prophylaxis

In order not to require repair of the Vilo pump, it is necessary to carry out periodic preventive maintenance. Simple maintenance of the device can be done with your own hands, without resorting to the services of specialists. To do this, inspect the pump at least 4 times a year and, if necessary, clean the pump. As practice shows, cleaning is necessary after 2-3 years of operation, depending on the quality of the coolant and the general conditions under which the heating and water supply systems operate.

Checking the rotor water jacket

When inspecting the equipment, be sure to pay attention to the following points:

- no leaks at the joints;

- efficiency of grounding;

- absence of extraneous sounds during device operation (clanking, knocking);

- lack of vibration;

- system pressure in accordance with technical standards;

- dry and clean body of the device.

Wilo pumps, in most models, are reliable and do not require regular repairs. But prophylaxis, provided that the warranty period has expired, can be carried out independently.

This will require:

- spanner key;

- Phillips screwdriver;

- flat screwdriver;

- cleaning brush.

Before dismantling the pump, water is drained from the system or the area is closed off for dry disconnection of the device. Then the pump is removed, and the following actions are performed:

- A spanner wrench is used to unscrew the bolts (4-6 pieces) connecting the electric motor housing and the shell of the pumping part.

- Removing the shell will open access to the drain holes and the impeller will remain on the engine rotor.

- A narrow flat-bladed screwdriver pushes on the jacket separating the engine compartment and the impeller, as a result of which the rotor shaft and impeller will come out of the stator glass.

Dismantling the circulation pump

After completing these steps, the main disassembly is completed and the inner surfaces of the shell, impeller and rotor are cleaned from scale or mud.

The surfaces are cleaned with a hard polymer brush with a small amount of cleaning agent containing hydrochloric acid.

In case of strong (stuck) dirt, it is permissible to use zero sandpaper.

The main malfunctions of Wilo pumps are the wear of the thrust bearings. If such a factor is identified, it is difficult to replace them with your own hands, so it is better to contact a service center.

All gaskets and seals are inspected for cracks or breaks prior to reassembly. But since the pump has already been disassembled, it is advisable to replace them with new ones.

What is BP / BP connection

The BP / BP detachable connection of the heating system is a set of adapters that allows you to connect the pipe to the pump casing.

- BP / BP stands for nut / nut;

- BP / HP stands for nut / thread.

BP / BP adapters are used to connect circulation pumps. Here is an example: Photo of an adapter for connecting a BP / BP pump (1 1/2 ″ - 1 ″). This means that the nut for the pump has a diameter of one and a half inches (32 mm), and the nut for connecting the pipe is an inch (25 mm).

On the pump nameplate and in its description, the diameter G is often indicated, this is the diameter of the union nut for the pump. Pumps are sold, which include connection adapters.

Note: Threaded connection of circulation pumps is typical for low-power domestic pumps. More powerful pumps are connected via flange connections.

Connection methods

Electrical connection with plug and socket... This method involves installing an electrical outlet in close proximity to the place where the circulation pump is installed. Sometimes they can come with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within the reach of the cable. You just need to make sure that there is a third, grounding contact in the outlet.

In the absence of a cord with a plug, they must be purchased in addition, or removed from an unused electrical appliance. Pay attention to the cross-section of the conductors of the cord. It should be between 1.5 mm 2 and 2.5 mm 2. The wires should be copper stranded to resist multiple bends. A cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the grounding pin of the plug. This can be done with an ohmmeter, while checking the integrity of the remaining wires.

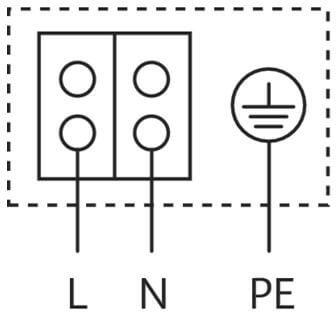

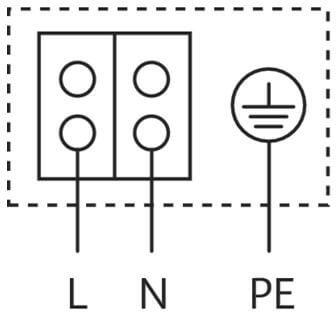

Open the terminal box cover. There are three terminals inside the box, designed to connect the device to the network, with the designation as in the picture:

We unscrew the clamp of the cable box (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, put the cord into the box. If there is a cable clamp inside the box, thread the cord through it. We connect the ends of the wires of the cord pre-stripped from insulation with the terminals.

You need to connect the wires connected to the plugs to the L and N terminals (do not be afraid to mix them up, this is not critical), to the PE terminal you should connect the wire of the grounding contact of the plug (but you cannot be mistaken here). The instructions supplied with the product prohibit using it without protective grounding. Next, tighten the clamp (if available), tighten the cable gland clamp tightly, and close the terminal box cover. The pump is ready to be connected to the mains.

Fixed connection. The diagram for connecting the circulation pump to the mains with grounding is provided below:

The requirements for the cross-section of the wires are the same as in the previous version. With this installation, the cable can be used both flexible and inflexible, copper, VVG, or aluminum, AVVG. If the cable is not flexible, the installation must ensure its stability. For this, the cable is secured with clamps along the entire route.

In this version, a residual current device (differential circuit breaker) is used. Instead, you can use a conventional single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. In the absence of such a bus, the PE terminal should be connected to the grounding device. This connection can be made with a separate wire.

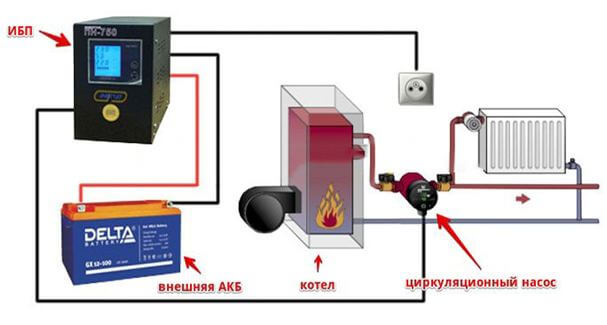

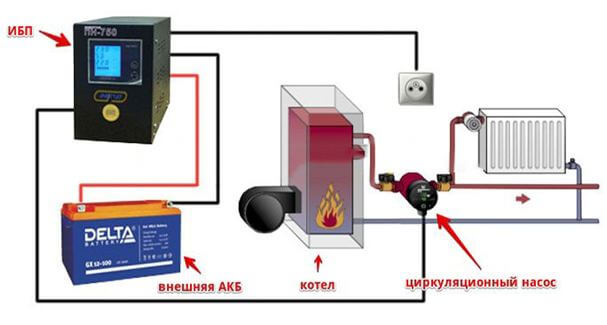

Separately, I would like to consider such an installation option as connecting a pump to a UPS. It is the most preferred and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power rating of the UPS should be selected based on the power of the pump motor. The capacity of the storage battery is determined by the estimated autonomous power supply time of the circulation pump, that is, the time when the power grid is disconnected. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as for the presence of protective earth, apply to all connection options.

Finally, we recommend watching the video instructions for connecting various pump models to the electrical network:

So we examined how the circulation pump is connected to the mains correctly. The diagram and video examples helped to consolidate the material and clearly see the nuances of the installation!

It will be helpful to read:

Circulation pumps are installed in heating systems with forced or natural circulation. They are needed to increase heat transfer and to be able to adjust the temperature in the room. Installing a circulation pump is not the most difficult task; if you have a minimum of skills, you can do it yourself, with your own hands.

Grundfos circulating pumps markings

Explanation of the brand (Type) of the grundfos pump:

- UP - circulating;

- S - there is switching of power (speed);

- D - paired;

- 30 - diameter (mm dn) of the suction branch pipe and the pressure branch pipe;

- 60 - max. head (meters × 10);

- F - connection of pipes through a flange (the letter is absent for a thread);

- N - body material (cast iron body - no letters, letter N - stainless steel body);

- B - bronze body;

- A - the case has an air outlet;

- K - case for work with antifreeze (special version).

Types and advantages of well pumps

Concern Grundfos (Denmark) produces pumping equipment for domestic and industrial water supply systems. The pumps of this company are widely used in various areas of management - in summer cottages for irrigating plantations, increasing the pressure in the supply pipelines, for creating effective fire extinguishing systems in public and industrial buildings.

The main groups of manufactured equipment:

- submersible systems (SP);

- circulating (UP);

- centrifugal (CR).

The submersible borehole pump is able to ensure uninterrupted delivery of water to the house from underground sources 8-300 m deep.Surface installations are designed to service wells up to 10 m.

Well pump Grubdfos.

All Grundfos pumping equipment is equipped with tracking equipment, allowing in automatic mode to start and stop pumping devices, as well as maintain a constant pressure in the water supply system.

Benefits:

- favorable price-quality ratio;

- ease of maintenance;

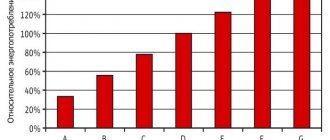

- high rate of energy efficiency;

- maximum equipment efficiency;

- durability;

- manufacturer's technical support;

- increased hydraulic performance;

- bearings are designed to protect parts from abrasive wear.