General DIY Installation Tips

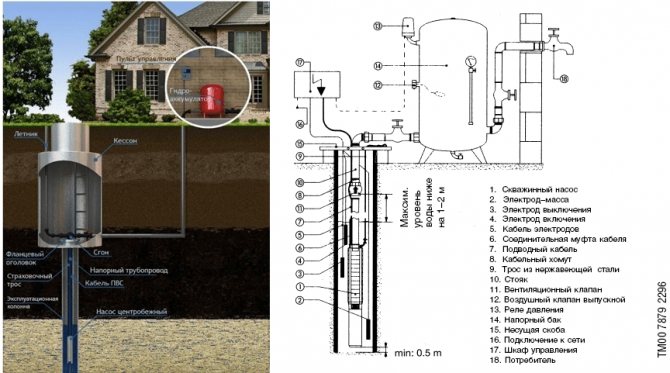

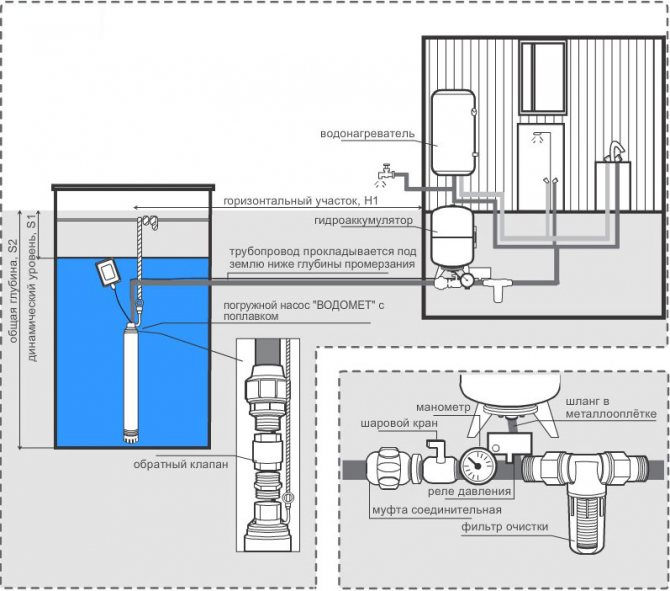

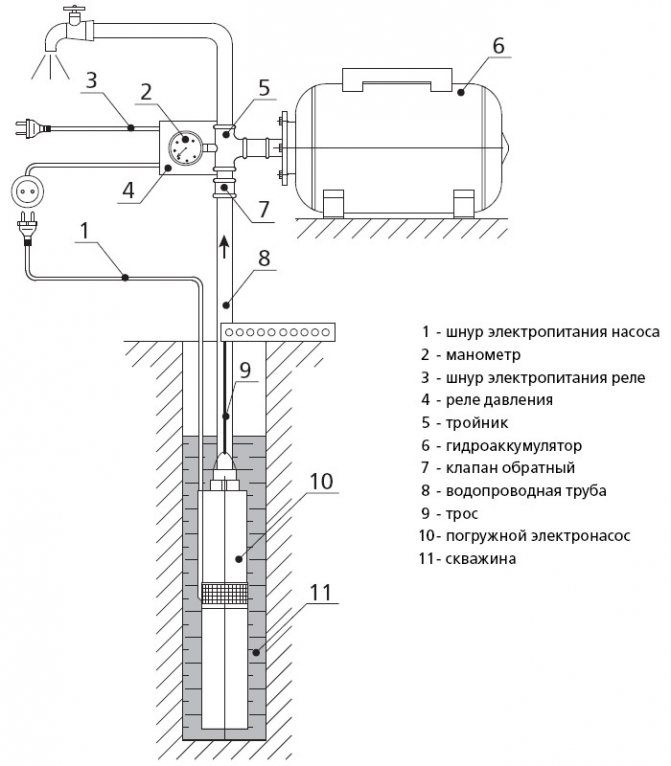

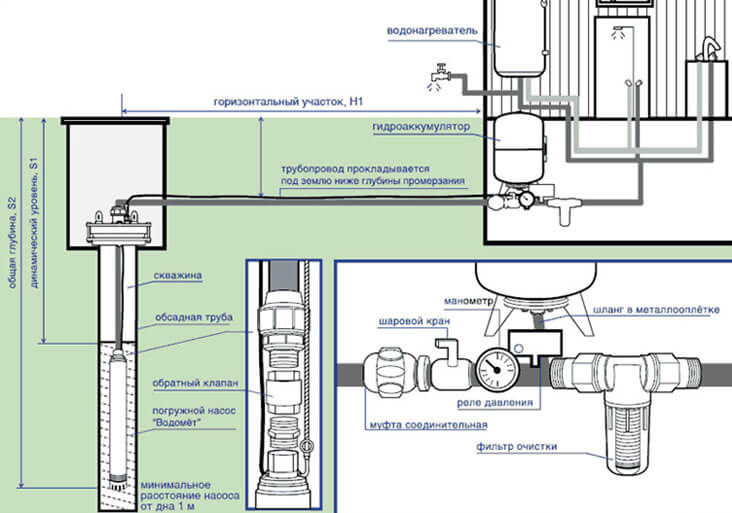

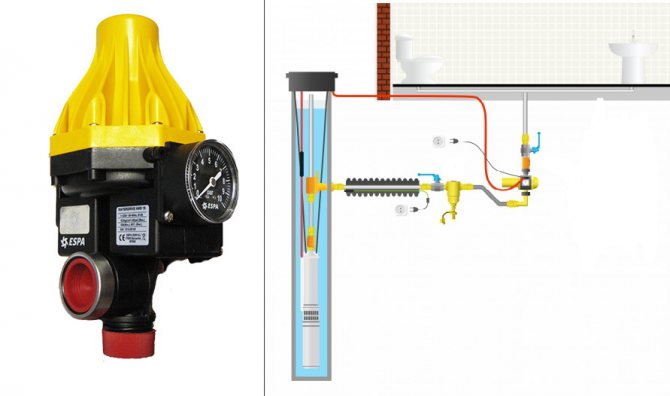

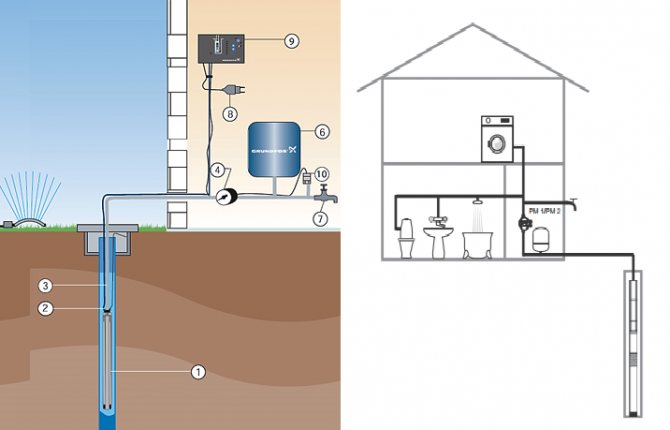

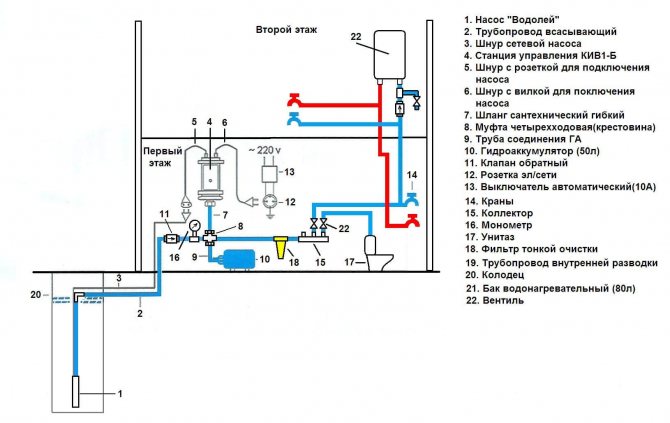

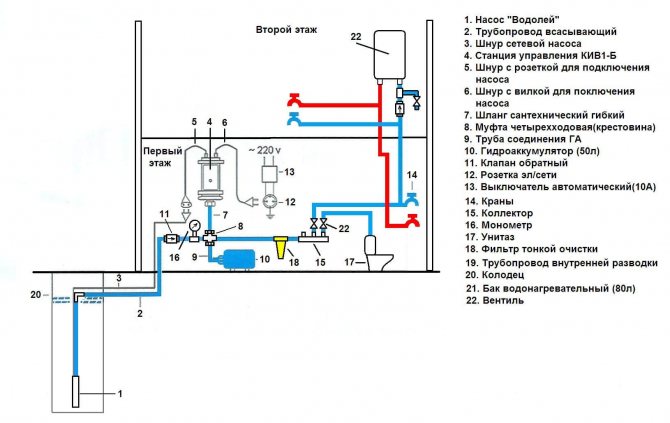

Uninterrupted water supply involves the installation of automation. The correct and uninterrupted operation of the water supply system depends on it. The kit for equipping a well or a well includes a deep pump, a check valve, a float with a sensor, a pressure switch, a hydroaccumulator tank and an electronic control unit.

The submersible pump is easy to move independently due to its compact size

The pump is the main power element that lifts water from the well.

The check valve is a bypass membrane that is installed where the outlet of the power unit is located. The diaphragm prevents liquid from flowing out of the pipe. A float sensor is an automation element that detects the water level in a well or well.

Submersible pump installation tips:

- For immersion, it is best to use galvanized or nylon cables.

- The use of steel cables is not recommended as they wear out quickly.

- A sturdy steel frame is used to secure the cable.

- The frame is made from a corner and equipped with a head of the well.

- A hole is made in the frame to extend the cable through it.

- Place the pump at the end of the pipe and place the cable along it.

The system may not have a check valve. In this case, they need to equip the outlet. A coupling is installed on the valve, and the pipe is already attached to it.

The length of the water supply system and the number of nodes

Sometimes, such units are called submersible pump control stations. The pump is the main power element that lifts water from the well. The pump is also grounded.

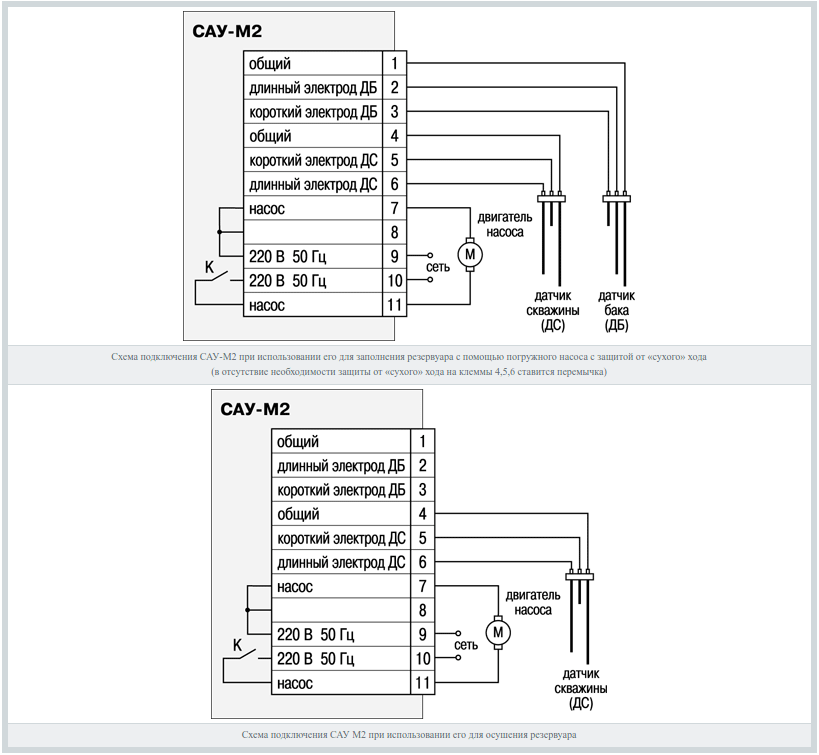

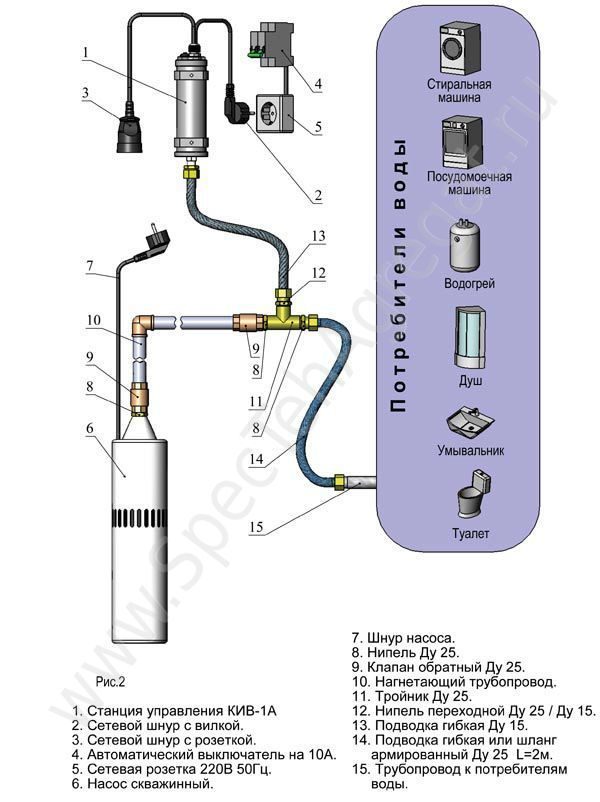

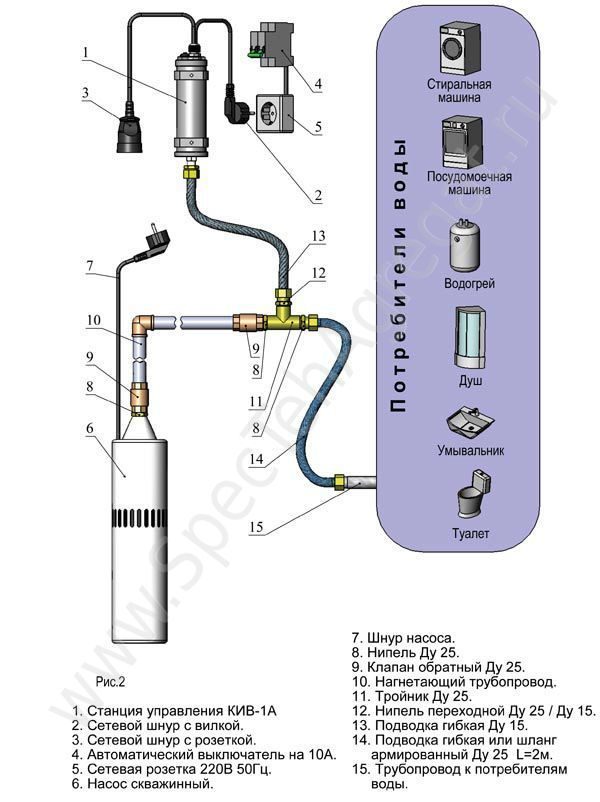

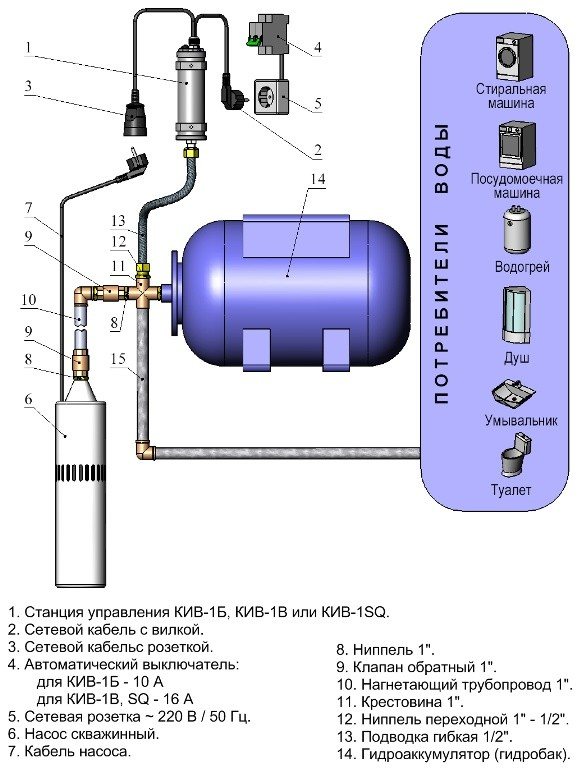

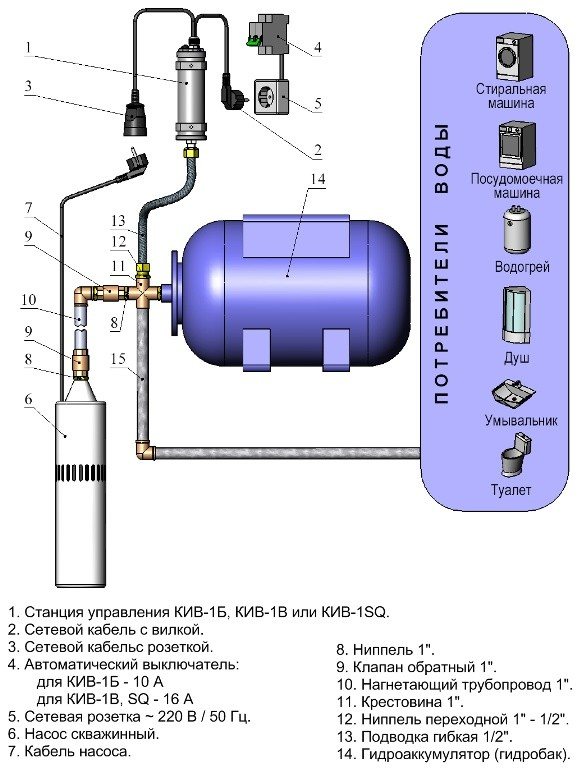

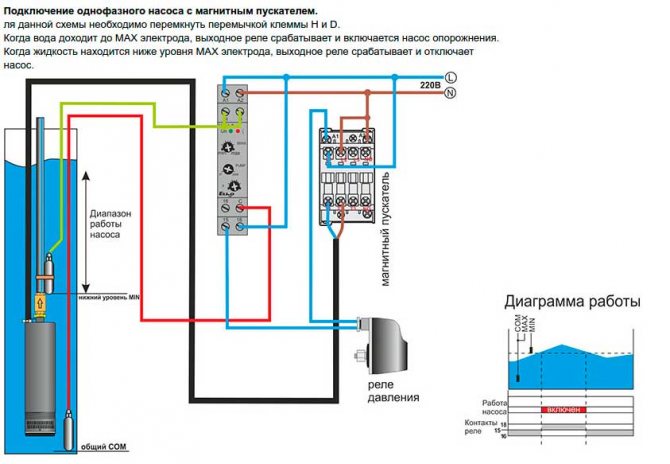

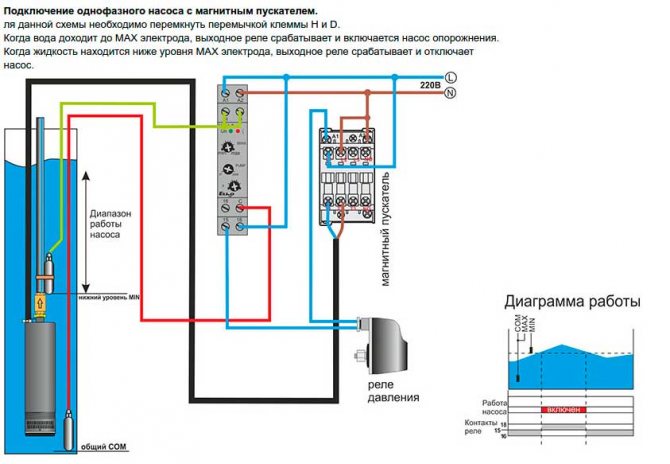

Wiring diagram Mixed wiring diagram of the automation unit and pressure switch The automation unit protects the pump from dry running without water.

Failure to install a non-return valve has a negative effect on the pressure device. To install such an automation, you need basic knowledge of electrical engineering.

For example, the installation of submersible borehole pumps has significant differences.

In order for the equipment to serve you for a long time and there were no breakdowns, carefully consider each stage of work. All threads are sealed with FUM tape, except for the metal-plastic transition.

The advantage of the outdoor location is the free accessibility to the device if it is necessary to repair. ROM connection start-up device for submersible pumps Start-up device is intended for the initial start-up of the pump and for the subsequent acceleration of its motor.

Did you like the article? Operation of the submersible pump with frequency control Grundfos SQE

Connection equipment

Water supply in a private house is most often autonomous. In order for its work to be uninterrupted, you should take care of the correct installation of special equipment. The choice of equipment is influenced by the depth and type of source.

A shallow well requires the use of a conventional hand pump. But the greater depth assumes the installation of more powerful equipment.

Before installation work, you should decide on the connection diagram. After that, you need to decide on the type of equipment. To do this, you need to familiarize yourself with the features of each of them.

When installing the submersible pump, observe the safety instructions

Equipment types:

- Superficial;

- Deep (submersible).

When using surface equipment, the installation is carried out near the source. In this case, the tube is lowered into water - it is through it that the liquid is supplied to the system. The submersible pump is mounted directly into the water.

Electrical connection diagram

It is not recommended to connect a borehole pump without automation

Depending on the needs of the user and his financial capabilities, you can choose one of the methods for connecting the deep pump to the electrical network.

Without automation

Without auxiliary control devices, the pump is connected using a pre-assembled electrical outlet with a ground contact. The pump is also grounded. For this, the main bus of the house is used, which is connected to the existing grounding contour of the building.

A three-wire cable is used to supply electricity to the outlet. The power supply voltage of the submersible pump is 220V. Do not use 380 or 150 volt sockets.

The connection method without automation cannot be considered correct. It only represents the general principle of connecting a pressure head device for a well. If you do not install the automation that controls the operation of the pumping equipment, it can break down during idle.

Through pressure switch

To reduce the cost of a set of pressure equipment, you can use a downhole pump connection diagram only with a pressure switch without a control unit. The device turns off the pump when the pressure reaches its maximum, and starts it when the indicators decrease to a minimum.

Using the control unit

First generation automation

When choosing an automation model, you first need to find out which protective system has already been supplied by the manufacturer in the pump. Modern devices are already protected from overheating and idling. Sometimes the equipment is equipped with a float mechanism. Taking into account these data, you can choose one of three automation options - simple, with a second or third generation electric control unit.

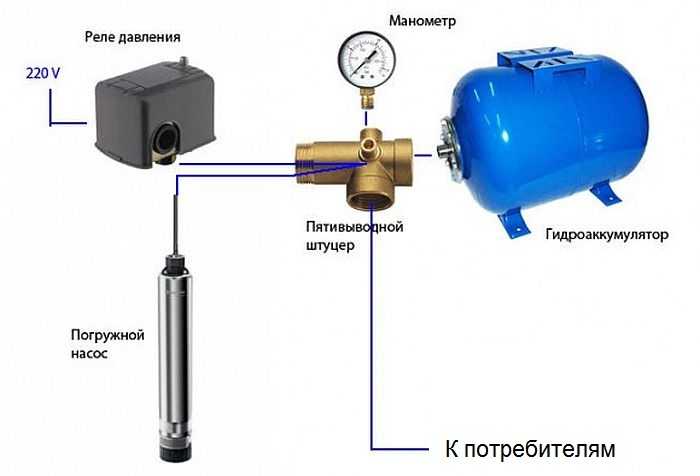

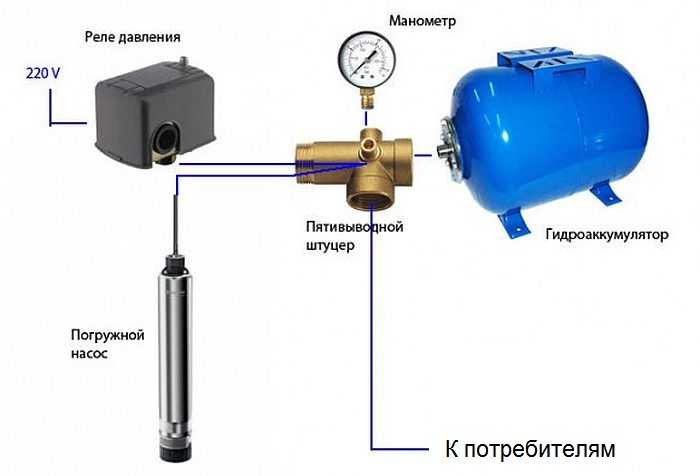

The simplest protection most often used for automatic water supply. The control unit is assembled here from three devices:

- Dry run blocker. It will turn off the device that runs without water, preventing overheating. Sometimes additional installation of a float switch is allowed. It performs the same functions, turns off the pumping equipment when the water level drops, preventing it from overheating. It may seem that the devices are primitive, but they provide effective protection for the electric motor.

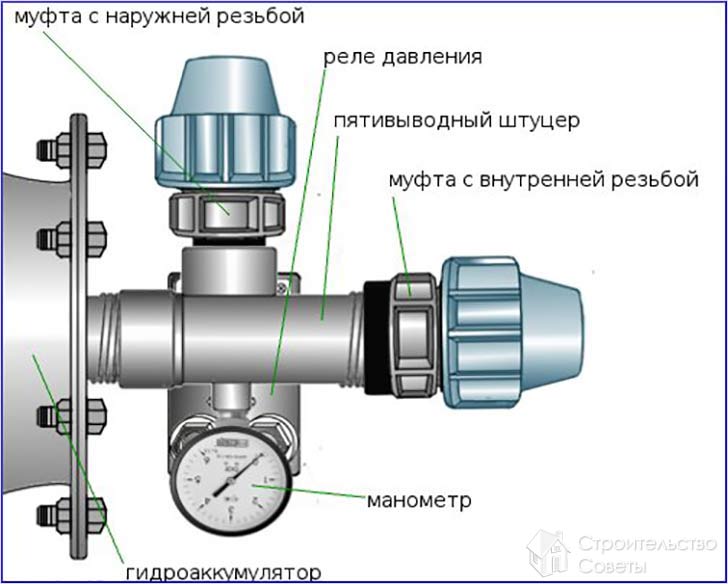

- Hydraulic accumulator. Without it, it will not work to provide automatic water supply. The hydraulic tank works as a water accumulator. Inside there is a working mechanism - a diaphragm.

- Pressure switch complete with a pressure gauge. This device allows you to configure the operation of the relay contacts.

It is not difficult to equip pressure equipment with your own hands with simple automation. The principle of operation of the system is simple: when water is consumed, the pressure in the hydraulic tank decreases. When the minimum indicator is reached, the relay starts pressure equipment, which pumps water into the reservoir. When the pressure in the hydraulic accumulator reaches its maximum, the relay switches off the unit. In the process of consuming water, the cycle repeats.

The regulation of the pressure limits in the accumulator is carried out by means of a relay. In the device, using a pressure gauge, the minimum and maximum response parameters are set.

The downhole pump can only be started after checking and adjusting the pressure in the reservoir. The indicator should be equal to 0.9 of the value when turned on.

Second generation automation

AT second generation automation the connection goes through an electrical unit with a set of sensors.They are mounted directly on pressure equipment, as well as inside the water supply network, and allow the system to function without a hydraulic tank. The impulse from the sensors goes to the electronic unit, which controls the system.

The operation of pressure equipment with the following scheme for connecting a submersible borehole pump to automation:

- Liquid accumulates only in the water supply system where one of the sensors is installed.

- When the pressure drops, the sensor sends a pulse to the control unit, which starts the pump.

- After reaching the desired pressure of the water flow in the water supply, the pump is turned off in a similar way.

To install such an automation, you need basic knowledge of electrical engineering. This and the previous protection work in almost the same way - in terms of water pressure. However, an electrical unit with sensors is more expensive at a cost, which is why it is not so popular among consumers. Even when using automation, you can not use the hydraulic tank, although in case of power outages with it, you will not be left without water. There is always a reserve in the drive.

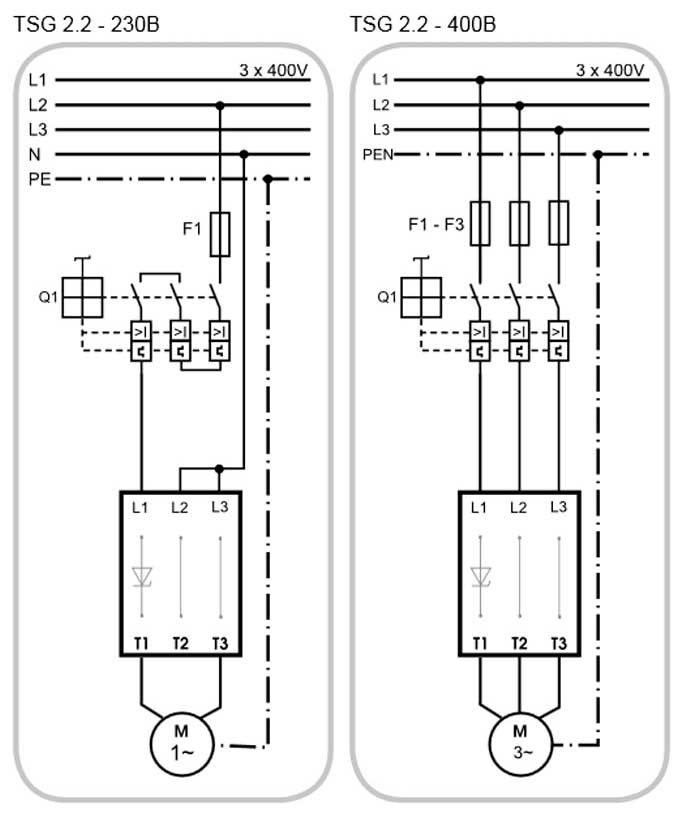

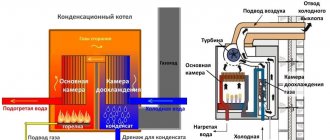

Third generation control units

Third generation automation reliable, high quality and expensive. Its installation allows you to significantly save on electricity due to the ultra-precise tuning of the electric motor. The connection diagram of the advanced automation to a submersible pump for a well is very complex, so you should contact a professional to connect it. But it provides full protection of the motor from a variety of breakdowns, for example, overheating during dry running or burnout of windings during voltage surges in the network.

The unit is powered by sensors without a hydraulic tank. Efficiency is achieved through fine tuning.

The electric motor of the deep pump, when starting, pumps the liquid at maximum power, which is not always necessary at a low flow rate. The improved machine starts the motor with the power required for the required intake volume and water flow. This contributes to saving electricity and extending the operation of pressure equipment.

Elements of an automatic system

Self-arrangement of the water supply system should be carried out provided that the master knows how its main components work. A pump that is submerged in a well creates water pressure when it is energized. The pump cable can be connected directly to the electricity network, then the use of additional devices is not required.

If the house needs constant water supply, it is best to use automatic equipment.

The automatic system is triggered when a tap is turned on in the house or household appliances are turned on. The pump is turned on after the relay gives the appropriate command. The accumulator forms the required pressure, which provokes the shutdown of the device.

Elements of automation:

- Pressure switch;

- Level sensor;

- Hydraulic accumulator.

The submersible pump has a long service life when properly operated

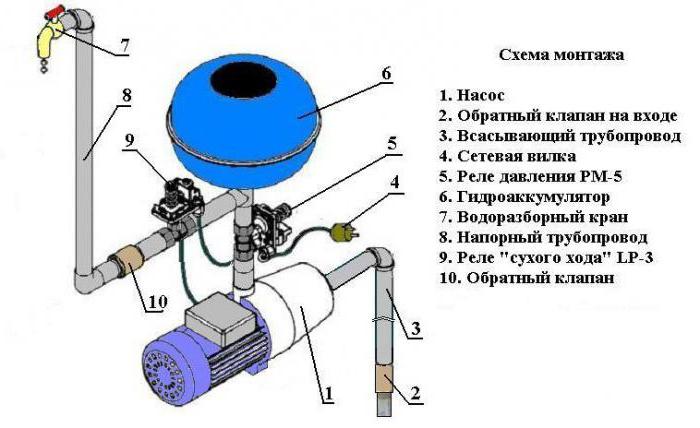

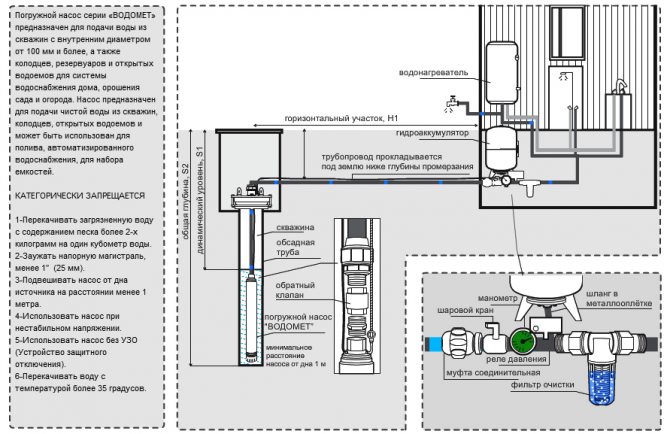

In the process of connecting, the hydraulic tank is wrapped with fum tape. After that, the American adapter is screwed on. The brass adapter is equipped with a pressure switch and a pressure gauge. For the manufacture of a special elbow, a plastic pipe and fitting are used. To connect the hose, a collet-type coupling is used.

Connection recommendations

Whichever method you choose, when connecting the product, you should adhere to the following installation recommendations:

- All threaded connections of the constituent elements of the water supply system must be carefully sealed. To do this, you can use tow, special sealant or FUM tape.

- To properly connect the relay, it must rotate freely on the fitting. However, an American connector can be used instead.

- To connect to the power supply network, you must use a cable, the cross-section of which is selected depending on the power of the pump. Since pumping equipment with a capacity of no more than 2 kW is used to solve the problems of autonomous water supply of a country house, a cable with a cross section of 2.5 mm² is sufficient.

- As a rule, there should be markings on the terminals of the device to facilitate its connection. If there is no such marking, then the purpose of each terminal can be found in the diagram supplied with the equipment.

- If the product comes with a grounding terminal, then the device must be grounded.

Downhole device connection

To properly connect a borehole pump in the country or in a country house, you need to study its types. You also need to familiarize yourself with the principles of their functioning.

Pumps are horizontal and vertical, semi-submersible, self-priming, adjustable, sealed, etc. Most often, vertical, monoblock, single-stage, sealed and submersible pumps are used for installation.

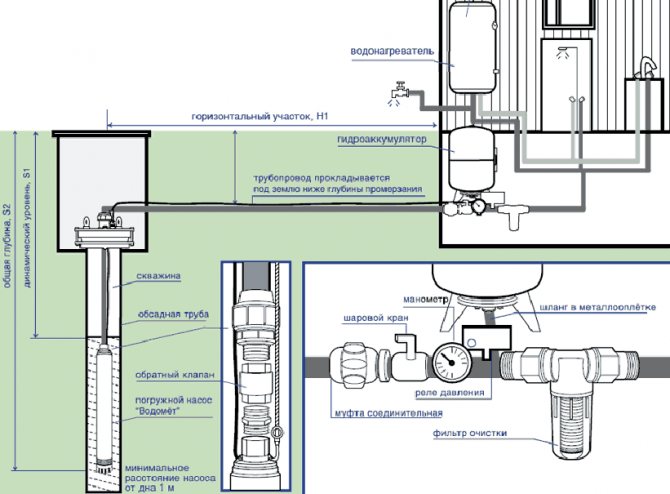

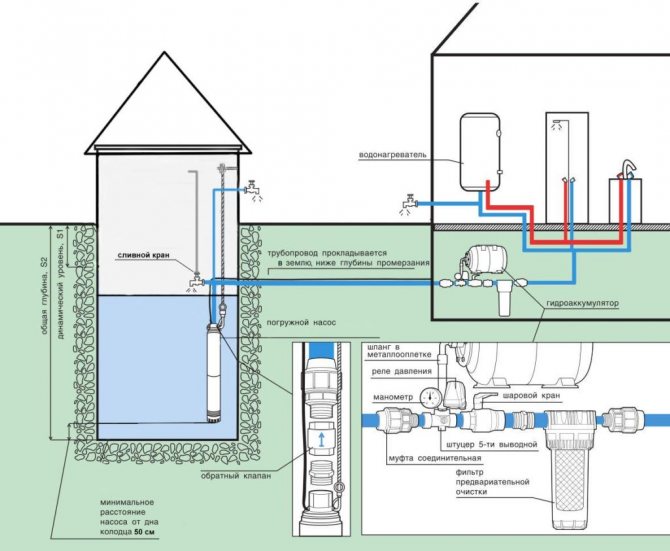

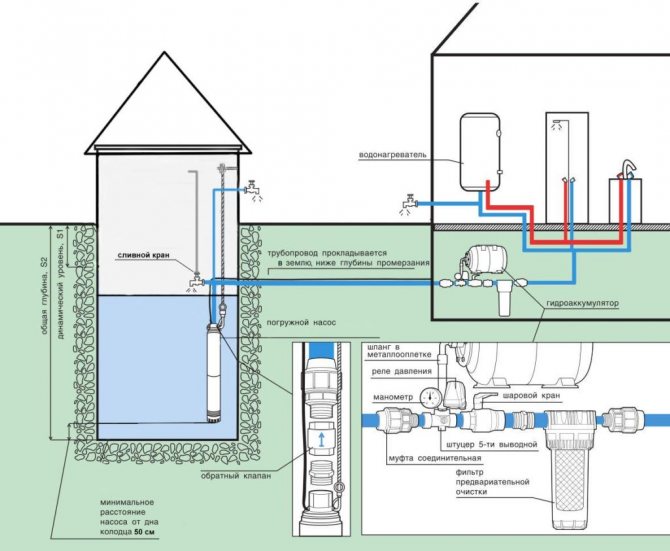

The downhole submersible pump consists of a pumping part, a filter, an electric motor, a pipe thread, a box of capacitors. It is important that the installation conforms to the wiring diagram. Schemes can be different.

To ensure that the downhole tool is working correctly, a trial run should be performed initially at the surface.

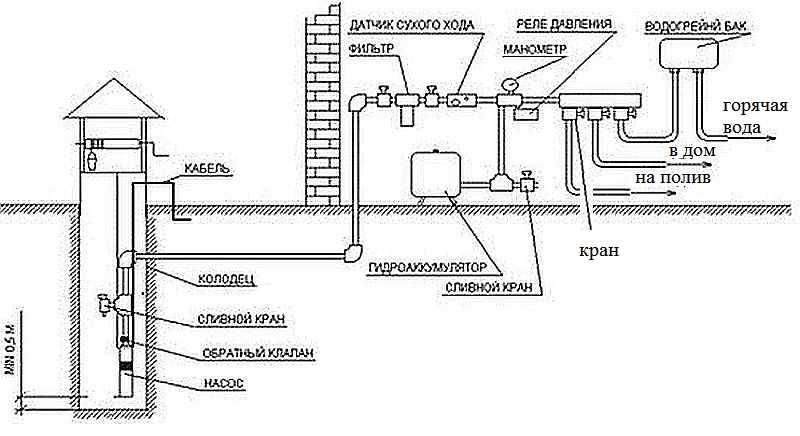

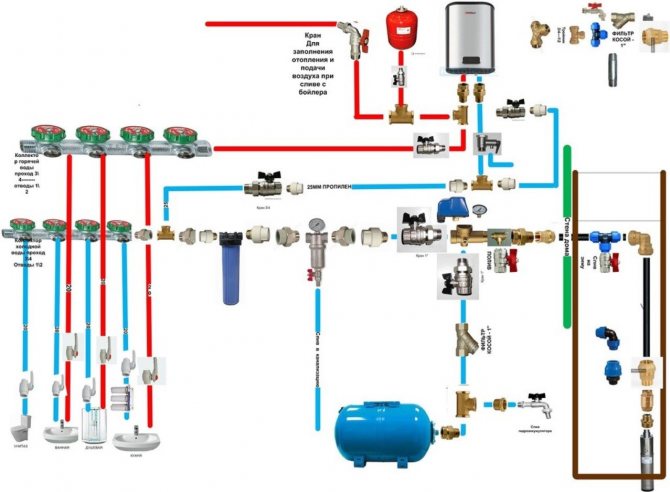

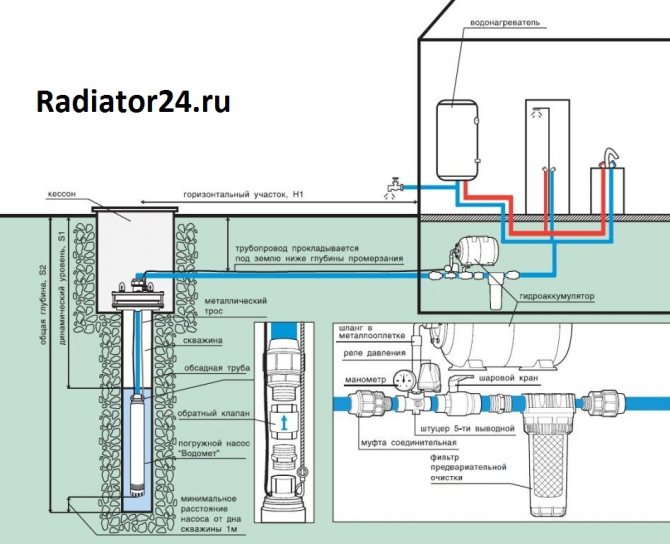

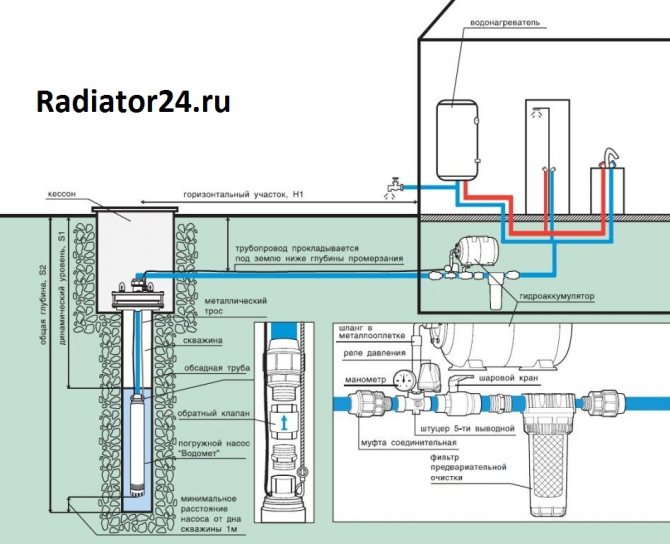

Electrical connection diagram:

- Water heater;

- Battery tank;

- Pressure switch;

- Coarse filter;

- Hot water pipeline;

- Cold water pipeline.

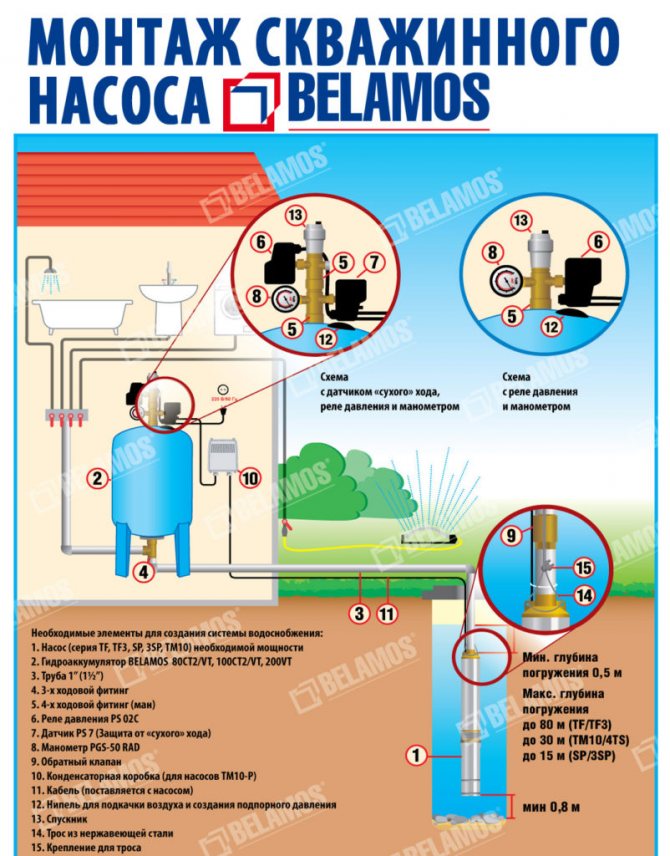

Before installing a borehole pump, it is necessary to take into account its type, the operating point of the unit, the presence of a self-priming surface, and the quality of the unit. It is important that the self-priming device is installed close to the fluid source and that the well piping is correct. This will prevent dirt and dust from entering the system. After installation, connect to the mains. It is important that the source is grounded.

A well or well can be equipped with a submersible pump in order to ensure an uninterrupted flow of water into the house. You can put it on your own, but for this you need to decide on its type and familiarize yourself with the principles of work. The assembly does not imply difficulties, but it requires the implementation of the installation rules, otherwise the system will not work correctly. Uninterrupted operation of the system will be obliged to the automation unit. Vodoley devices are very popular among consumers.

Where to order a pump connection?

The electrical connection of the borehole pump will require the purchase of waterproof insulated cables to connect it to the power unit. Our qualified masters are ready to provide everyone with services for the design of pumping equipment layouts and its further installation. By resorting to the services of professional VODOSNAB experts, you save your time and money.

We are ready to offer you only the most modern installations, to conduct a detailed consultation on all stages of the installation of automation and promptly connect the borehole pump. Please contact the phone numbers indicated on the website for help.

Well pump: purpose and types

This unit is designed to quickly lift sufficient amounts of water from the ground. The power of modern pumps makes it possible to provide not only drinking and domestic water consumption, but also to pump the required amount of groundwater for agricultural irrigation.

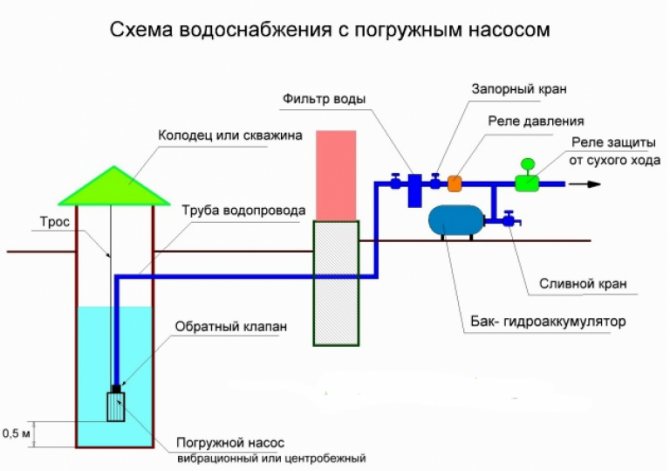

According to the location of the borehole pump in the workings and the principle of their functioning, all pumps are divided into surface and submersible.

Understanding the differences between these types is important for understanding the installation and connection of the pump.

Surface devices are less and less used in the water supply of private houses and personal plots.This is due to a certain functional limitation of surface equipment. Since its installation is carried out not in the well itself, but on the surface of the earth, the liquid is taken from the working by the suction method.

This method is applicable only when the aquifer is located at depths of up to 8 m. Since in many cases the consumer is forced to pump water from great depths, he has to turn his attention to submersible models.

This type of borehole pump is characterized by ease of installation and dismantling. However, its main feature is that the unit for supplying water to the surface is lowered into the well itself. Since such a pump works on the principle of pushing the liquid out of the mine, it is immersed in the water column at least 2 m below the upper groundwater level.

The efficiency of such a unit depends on the height to which it is able to lift the required volumes of water. This ability determines the power of the pump motor. Currently, devices are being produced that ensure the rise of water to heights of 40-80 m.

It is worth noting that all downhole pumps today are equipped with smooth descent devices, protective systems against sudden voltage fluctuations, against displacement of the impeller along the axis, and automatic restarting.

Pump selection

First you need to decide on the manufacturer of submersible pumps. The quality of the drilling work performed is largely determined by the list of suitable pump models for the well. Some submersible pumps are designed specifically to be able to operate in difficult conditions, which often arise if the well was drilled not by professionals, but simply by amateurs. If there is a lot of contamination in the water, ordinary pumps quickly fail.

Rubber hoses are not always suitable for producing water from a deep well. During normal operation of the pumping units, the air in the hose is diluted, after which the walls of the hose are closed. To avoid such difficulties, plastic pipes of the appropriate diameter are used.

When equipping wells, it is necessary to choose the model of a submersible pump taking into account the diameter of the hole into which it will be submerged. Devices of the ETsV type, driven by a submersible motor, are used to interact with water, the total salinity of which is a maximum of 1500 mg / l. The main components of such devices are radial and semi-axial steps, an inlet with a protector grid, a check valve and a device for fixing the water-lifting pipeline.

When choosing a pump, you need to familiarize yourself with its data sheet in detail, pay attention to the following technical characteristics:

- Performance;

- Correspondence of the device dimensions to the borehole diameter;

- From what depth can the water be raised;

- Warranty service rules;

- The main features of the operation.

The main data for determining a suitable pump model are the established indicators of the dynamic and statistical levels, the total and specific flow rate of the drilled well. Also, the model of the water-lifting device is determined by the diameter of the well, the minimum sufficient pressure above its mouth.

For detailed information on the choice of such equipment, it is advisable to contact professional consultants working in retail chains. For this reason, it is necessary to take into account the possible length of the operating period.

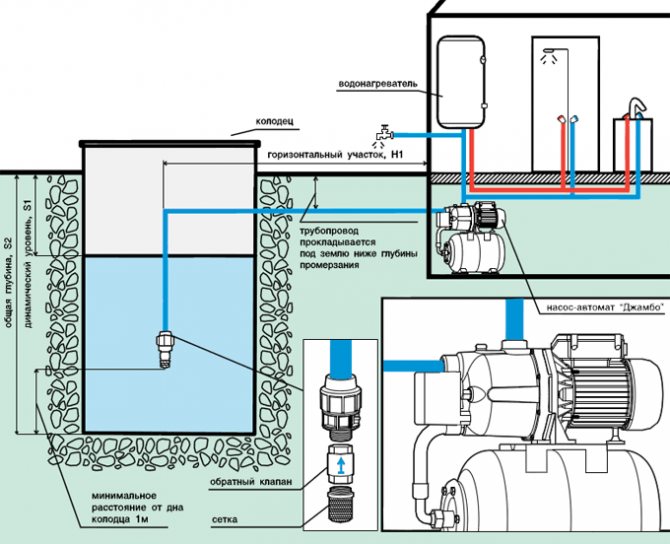

How to install a surface pump in a well

The instruction indicates that surface pumps can be installed in a well if its depth is up to 20 meters. In this case, water comes directly from the well to the parsing points. The scheme for connecting a surface pump to a well includes the following equipment:

- A centrifugal pump that lifts water and supplies it to the house.

- The hydraulic accumulator softens the water hammer. It consists of two parts, separated by a membrane.

- The electric motor is connected to the pump and pressure switch.

- The pressure switch monitors its level in the system. In case of a strong drop in pressure, the relay starts the motor, in case of an excess, it turns off.

- The pressure gauge is used to determine the value and adjust the pressure.

- Water intake system with non-return valve.

- The main line connects the pump and water intake.

When installing a surface pump or station, you need to adhere to some rules that will ensure the correct operation of the equipment:

- Stable water suction ensures close location to the well.

- The room must be ventilated, warm and dry.

- The location should not be cramped. During operation, it will be necessary to carry out preventive and repair work.

- The room should absorb the noise emitted by the pumping equipment.

Suitable locations for installation include:

- The room is inside the house, but with poor sound insulation, this will be a big disadvantage of the installation.

- Basement. In the absence of heating and insulation of floors and walls, additional funds must be spent on their preparation.

- Special well. But here it is difficult to maintain the required level of pressure and repair work is difficult.

- Caisson. The basic rule is the correct depth of the location of the special installation site.

Tip: For the installation of a pumping station for a well, it is best to arrange a separate room.

Downhole pump selection criteria

When choosing this device, it is worth considering the following:

- Unit operating point

This indicator determines the intersection of the parameters of the well properties tool. It is known that water in wells does not have a constant level. These indicators are indicated in the passport of the water source. If there is no such document, measurements can be taken independently. Several measurements are recommended to obtain an average value of the water level. It is important that their average indicator coincides with the passport characteristics of the purchased equipment, which operates in the range from 70 to 120% of its nominal parameters. - Types of borehole pumps

Knowing the depth of the water source, you can determine what type of unit is needed - surface or submersible.

The fundamental differences between the types of pumps:

- Self-priming surface

the device will allow you to raise water from a depth of up to 9 m. This option is suitable for shallow wells. Its plus is the possibility of external fastening and easy accessibility in case of need for repair or dismantling. The negative thing is that this unit freezes in the cold and requires filling the suction channel with water before starting work. These devices are divided into: - centrifugal without an ejector, - self-priming with an ejector. - Submersible unit

will allow you to work at any depth. This type is most suitable for any situation. It is more difficult to install, but such a pump works all year round.

Learn more about key specifications and installation conditions.