The principle of operation of the condensing boiler

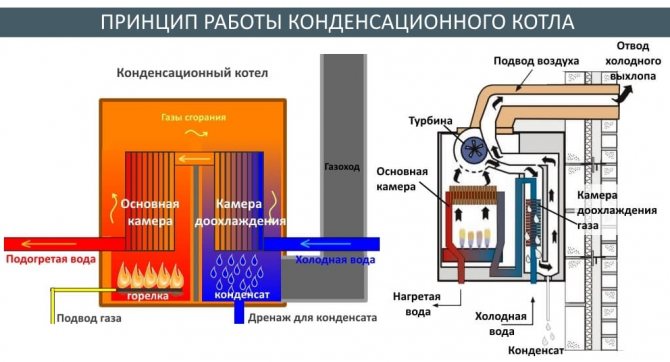

The operation of the condensing boiler is based on the principle of fuel combustion and condensation processes. When hydrocarbons are burned, water and carbon dioxide are formed during a chemical reaction. A liquid in a high-temperature environment in a short time interval turns into steam, consuming thermal energy, which can be returned by turning the steam into water.

The difficulty in creating such a system was the release of toxic substances during the combustion of gas, which created chemically active compounds that cause corrosive processes, as well as carbon dioxide. With the development of stainless steels capable of operating in this environment, these problems were no longer significant.

The operation of the condensing boiler in stages is as follows:

- Water is supplied to the boiler.

- Gas is supplied to the combustion chamber, fire is kindled.

- In the process of combustion, heat energy is released, which is transferred to the heat exchanger by a gas method and heats it and the water that circulates in it.

- Gas with a temperature above the dew point passes into a second heat exchanger, in which it is cooled by circulating water with a lower temperature.

- When the gas reaches the dew point, the released thermal energy of the vapor is transferred to the liquid.

The principle of operation of the condensing boiler

The condensing boiler heat exchanger is designed to maximize the contact area between gas and coolant for increased efficiency. Its configuration also has a significant impact on efficiency.

The dependence of the volume of condensed moisture on the operating mode of the boiler is as follows: the lower the water temperature in the return circuit, the higher the condensation. However, in this case, the temperature should be at a level up to + 500C. Otherwise, the condensing boiler will operate in the normal gas mode and thus its efficiency will decrease to 5%.

For comparison: at a liquid temperature of + 40 ° C in the direct feed circuit and + 30 ° C in the reverse, the efficiency of the condensing boiler will be 108%, and at 90 ° C and 750 ° C, respectively, 98%.

When operating boilers, it is necessary to observe the operating modes, and also when choosing a suitable model, its optimal heating power should be selected.

The device of the main components of the boiler

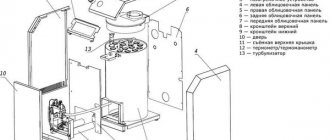

Condensing heating boilers consist of the following main components:

- a steel body in which all structural elements are located;

- a circulation pump for circulating water in the heat exchanger system;

- combustion chamber, inside which burners are located;

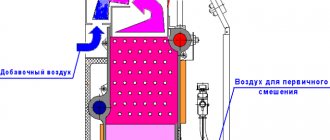

- aftercooling chambers for the vapor-gas mixture to a temperature of + 570C;

- a fan (turbine) located above the combustion chamber, designed to mix the gas and air mixture;

- two heat exchangers: for transferring heat to water from the combustion products of the chamber and for condensation of moisture and obtaining thermal energy;

- nozzles and pipes for supplying water to the circulation system;

- condensate collection tank;

- chimney for removal of combustion products;

- control panel.

Advantages and disadvantages

The advantages of condensing boilers are the main criteria for choosing this particular design for heating systems. These include:

- environmental friendliness - the minimum amount of toxic emissions, for comparison, is on average 70% lower than gas or solid fuel;

- compact size, due to which they can be installed even in small rooms;

- low noise and absence of vibrations;

- relatively low temperature of the exhaust gases, which makes it possible to equip boilers with plastic chimneys and save finances;

- the possibility of a cascade installation, which allows heating large rooms or organizing heating systems of increased reliability;

- precise regulation of heating power, thanks to which it is possible to change the efficiency of the condensing boiler and use it in economy modes.

Among the advantages of condensing boilers are their environmental friendliness and low noise.

When choosing, it is also important to take into account the disadvantages of boilers in order to avoid unnecessary fuel costs and ensure effective heating of the premises:

- high cost of equipment and spare parts for it;

- complex design of the heat exchanger, requiring periodic maintenance and condition monitoring;

- the need to dispose of condensate;

- high requirements for the cleanliness of indoor air;

- inefficiency of use at high temperature conditions.

That is, the disadvantages of condensing boilers are not so significant compared to their efficiency, durability, reliability and environmental friendliness, especially when they are used in residential premises.

Classification of gas by-pass boilers

Double-circuit gas boiler with built-in boiler

Gas fired boilers can be classified based on the following characteristics:

- Power is the main characteristic. Naturally, the more powerful the gas boiler, the more it heats up the room. Focus on the area of your house, if it is small, then a very powerful boiler is not needed. If the heated area is large enough, then one should proceed from the formula that 1 kW of generated thermal energy heats approximately 10 square meters of the room, provided that the ceilings in the house do not exceed 3 meters.

- Second circuit. This is an important characteristic, because if the boiler is single-circuit, then this imposes certain restrictions on the use of the unit. Single-circuit units are much cheaper and cope with heating the premises no worse, especially if only this is required of him. If you want the boiler to also heat water for domestic use, then you definitely need a wall-mounted gas double-circuit boiler with a boiler. A unit with a boiler will fully satisfy your needs for hot water, in contrast to an instantaneous water heater, which, with large volumes, may not cope with its task.

- Spent fuel ejection system. This parameter is directly responsible for safety, because if the boiler burns oxygen and air in the room, then at least unpleasant side effects will appear in everyone who is in the house. Therefore, devices with a natural draft system are only suitable when there are special chimneys for exhausting gases. Otherwise, if there were no spruce ones, the best choice would be a forced gas outlet system. The essence of which is a double pipe, exhaust gases are removed through the inner one, and fresh air is drawn in through the outer one. They are more economical to install, since there is no need to build a special chimney.

- Ignition method. This is not an important aspect, but nevertheless it can help to save a little on the operation of the boiler. The main methods are with the help of a piezo element and full automation. Automation is much more economical, due to the absence of an igniter and, therefore, there is no fire burning in it either. Plus there is no need to press buttons and reignite the flame every time there are interruptions in the gas supply. In autonomous mode, everything will ignite by itself and adjust the temperature.

Various technical sensors are provided in the design of wall-mounted gas boilers. The most common ones are:

- Flame sensor. An obligatory device, since it precisely shuts off the gas supply if the flame suddenly goes out

- Thermostat.The same applies to the main sensors, since it turns off the gas boiler if the water in it reaches a critical temperature mark.

- A sensor that blocks the boiler in case of a sudden power outage.

- The sensor is a blocker that is triggered in case of gas interruptions.

- Traction control sensor. Switches off the boiler in case of lack of draft.

- Gas level sensor. In case of a small amount of incoming gas, the boiler shuts down.

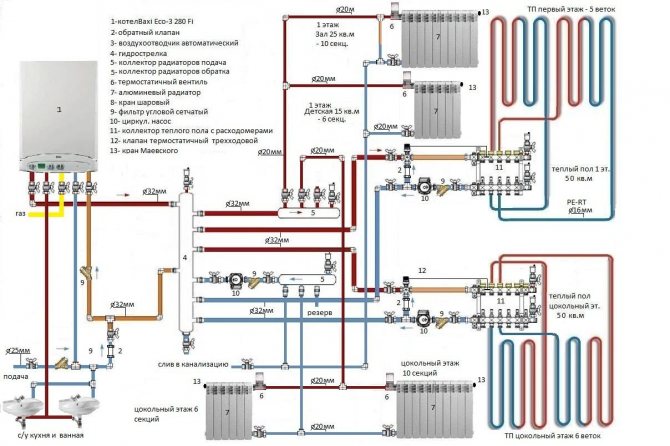

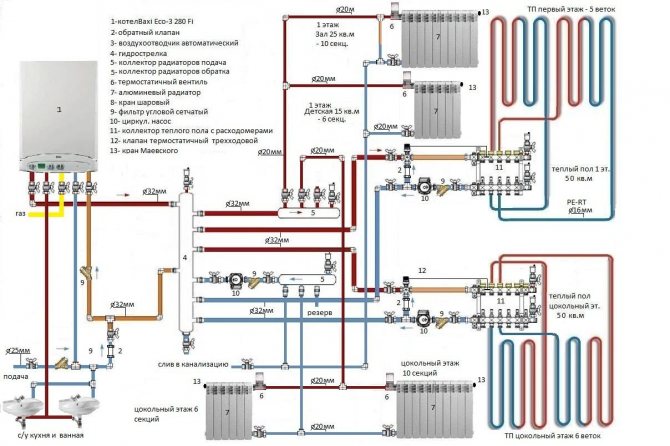

Wiring diagram for a double-circuit gas boiler

Types of condensing boilers

Condensing boilers are classified according to the following criteria:

- by type of installation: floor or wall;

- by the number of circuits: single or double circuit.

Condensing floor boilers are not only large in size, but can also be equipped with external pumps and other equipment that require a separate room for installation. They are usually single-circuit and are designed to heat large areas. Their advantages are maintainability and design simplicity.

Condensing wall-hung boilers differ from floor-standing boilers in their compact size and relatively low weight. All units and assemblies are located inside the body, there are no external elements. They are produced in one- and two-circuit design, are easy to connect, unpretentious in operation.

Floor standing single-circuit condensing boiler

Single-circuit heating boilers for space heating can be used not only in heating systems, but also for hot water supply, provided there is a boiler. They are distinguished by simplicity of design, low cost compared to a double-circuit boiler, high efficiency and heating power, economical fuel consumption.

The double-circuit condensing gas boiler is produced with a storage boiler or with a flow-through heat exchanger. It can be used for heating or heating water without the need to purchase a separate boiler. Compact, easy to install and maintain, floor or wall mounting.

Boilers with a built-in boiler - when size matters.

In this article, we will try to describe in detail the representatives of a rather peculiar class of boiler equipment - wall-mounted boilers with a built-in boiler. This is why:

- The size of the built-in boiler rarely exceeds 60 liters. A subclass of such boilers can be called wall-mounted boilers, which are designed to install a boiler directly under them. Such an installation looks like a refrigerator. - The power of wall-hung boilers with a boiler inside does not exceed 35 kW. This means that the niche for using such equipment is not the largest, and more on this later.

Where it makes sense to install wall-mounted boilers with a built-in boiler?

To begin with, let's outline the appearance of this equipment. This is a wall-mounted boiler with a 40-60 liter boiler (maximum 80 - but this is already a variant of a boiler placed under the boiler). Boiler power does not exceed 35 kW.

From what has been described, the following possible options for the installation of such equipment follow:

1) Apartment heating. In cases where the boiler is placed in the kitchen of an apartment, the main requirements for it are relatively modest dimensions. A boiler with a built-in boiler will definitely take up a little more space than a traditional wall mount with a secondary heat exchanger. BUT! Anyone who at least once in his life used a boiler with a secondary heat exchanger and changed it to a boiler with a boiler will never come back. The fact is that a boiler with a built-in boiler does not have such "sores" (characteristic of the secondary heat exchanger) as: - temperature drop when the pressure in the hot water tap changes; - the need to clean the secondary plate heat exchanger (about once every 1-2 years - depending on the hardness of the water); - inaccuracy of maintaining the set temperature (it is often caused by the instability of the pressure). For a boiler with a boiler, this "ailment" is not typical.

2) Small private houses (up to 150 m2) + Townhouses (small). A boiler with a built-in 60 liter boiler will be enough if such a house has 1 bathroom, and the number of residents is 2-3 people.If the house is small, then the size of the budget for the organization of the boiler room can be modest. When using a boiler with a built-in boiler and its power up to 35 kW, such equipment can be safely located in the kitchen, without organizing a separate combustion room. With the niche of objects for such equipment, everything is now clear. Let's take a closer look at the boiler design.

Boiler device with built-in boiler

At its core, a boiler with a built-in boiler is a traditional wall-mounted single-circuit boiler, the body of which has been enlarged to accommodate the boiler. That is, by and large, the layout of the hydraulic units of such a boiler does not differ from conventional single-circuit models. Most often it is a copper heat exchanger (in the condensation version, stainless steel or silumin can be used as the heat exchanger material), a three-way valve and hydraulic units at the "supply" and "return". A detailed diagram using the example of the Viessmann Vitodens 111-W boiler is presented below.

BUT - stainless steel heat exchanger (Vitodesn 111-W is a condensing boiler, therefore the heat exchanger is made of stainless steel. In conventional boilers, copper is usually used as a heat exchanger) B - DHW boiler. Available in stainless steel (Vitodens 111-W) or conventional carbon steel with enamel lining. C - modulating burner. D - modulating fan E - expansion vessel F - built-in pump G - digital controller with touch display

This arrangement is typical for most boilers with a built-in boiler. The differences are the types of burners and heat exchangers (traditional / condensing), the presence or absence of an expansion tank of the built-in boiler and its capacity (40-60 liters) and automation. Boilers with a dummy boiler differ slightly in layout. In such models, the following layout is used: in the upper part there is a single-circuit boiler (conventional or condensing), a boiler is located under it. In this case, the structure rests on the floor, and not on the wall. In terms of dimensions, such equipment is comparable to a two-compartment refrigerator. Due to the floor installation and dimensions, the boiler capacity in such boilers is slightly increased compared to their wall-mounted classmates and is 80 liters. An example of such equipment is the Luna 3 (Comfort) Combi boilers from BAXI.

What to choose?

On the market, the segment of boilers with a built-in boiler does not shine with a variety of models. Still, the niche is quite specific. Nevertheless, even here there is a choice. Among manufacturers, similar models are offered to their users: Viessmann, BAXI, Vaillant, ACV. The choice is quite decent.

And we remind you that you can get advice on the choice of equipment and ask questions you are interested in on the topic of the article and not only in the customer service department of the HOGART company

Criterias of choice

Condensing gas boiler, due to its high cost, must be chosen most carefully based on the following criteria:

- it is recommended to purchase certified equipment from well-known brands that can guarantee full compliance with the declared characteristics, as well as provide a guarantee and service;

- heating power should be enough to heat a certain area of the room, taking into account the temperature difference inside and outside the buildings, as well as the length of communications with the coolant;

- installation method, depending on the amount of space and technical conditions for the operation of the boiler;

- a complete set, which may not include expensive accessories or components, without which it is impossible to connect and operate the boiler;

- functionality, methods and ease of management;

- the possibility of connecting an additional heating circuit;

- the level of gas and water consumption.

Areas of use

The areas of application of condensing boilers are as follows:

- for heating apartments and private houses;

- for industrial purposes: heating of workshops or hot water supply;

- heating of office premises, public places.

The condensing boiler is often used to heat apartments and private houses.

Areas of use

The areas of use of condensing boilers are:

- for heating apartments and privatized houses;

- for industrial purposes: heat supply of workshops or hot water supply;

- heating office premises, public places.

Boiler

condensing type is often used for heating apartments and privatized houses

Condensing boiler installation rules and common installation errors

The installation of the condensing boiler must be carried out taking into account the following rules and requirements:

- it is recommended to choose a well-ventilated room for installing the boiler that meets all fire safety requirements: ceiling height not less than 2.2 m, room volume - from 7.5 m3, ventilation window area 0.025 m2;

- the location of the boiler must be strictly vertical;

- before mounting, it is important to mark the installation site in order to bring the necessary communications in advance and think over the installation steps;

- you need to mount the boiler on a special frame that is included in the delivery set (only for the highest class of equipment), or on a mounting plate;

- the chimney must be made of heat-resistant plastic or corrosion-resistant steel;

- the horizontal part of the chimney from the boiler should go with a slight slope towards the room;

- Condensate drainage can be organized in the following ways: to a centralized sewer system or to a separate container with subsequent disposal.

Connecting a condensing boiler without experience in carrying out such work can lead to the following errors:

- Condensate drainage is made outside the heated space. In the cold period of the year, this can be fraught with the formation of an ice plug in the tube, as a result of which the probability of failure of the boiler will increase.

- Condensate drainage is carried out into a container not intended for these purposes or is not organized at all. This is a big mistake, as the condensate can contain toxic or corrosive substances that require special disposal.

- The structure touches the heated part of easily flammable or combustible substances, which leads to a violation of fire safety rules.

- The gas connection is made without the use of special sealing gaskets, gas filters are not installed. The consequences can be as follows: gas leakage or clogging of the burner inside the combustion chamber, respectively. Operation with such errors is prohibited, as the level of explosion in the room increases.

- The angle of inclination of the boiler, which is specified in the installation requirements by the manufacturer, has not been observed. This will lead to a violation of the condensation and circulation modes, may cause an increased gas consumption or a decrease in heating power.

- Installation of a gas meter that does not correspond to the power characteristics of the boiler. In such cases, either the gas flow will be insufficient, or the meter itself will fail with the likelihood of leaks.

Organization of a chimney for a floor-standing condensing single-circuit gas boiler

Before buying a condensing single-circuit boiler in Moscow for a private house, you should first think over how the flue gas removal will be organized. In view of the peculiarities of the operation of the type of boilers under consideration, for their maximum efficient operation, only polymer coaxial pipes should be used. The use of classic aluminum or stainless steel can negatively affect performance and lead to a quick failure due to the acidity of the condensate formed.

The installation of coaxial chimneys must be carried out based on the following requirements:

- if the capacity of the condensing single-circuit boiler does not exceed 40 kW, then it is allowed to install a coaxial pipe with a diameter of 100/60 mm;

- the slope towards the boiler must be at least 50 mm per meter of pipe length;

- the length of the distance between the ceiling of the room where the boiler is installed and the first outlet bend of the chimney must be at least 20 cm;

- from the street, the exit of the pipe should be located at a height of 2-2.5 m from the ground;

- the chimney should be placed in such a way that the distance between its end and the wall of the house is at least 30 cm.

Features of operation

Some basic nuances of the operation of condensing boilers:

- it is forbidden to reduce the burner power below 10% of the total power, since due to constant switching on and off, it will fail much earlier than the calculated period;

- it is not recommended to increase the heating temperature at the outlet of the boiler above + 500С, as the gas consumption will significantly increase;

- condensate can be discharged into the sewer, subject to dilution in a ratio of 10: 1, as well as into a septic tank, if it is neutralized.