Dear boiler owner "premium

Page 3

- Picture

- Text

Premium-M B. 1.03

3

Dear owner of the premium boiler!

we are grateful to you for choosing a brand product

lemax

.

you are now the proud owner of a highly efficient boiler, which

When properly installed, operated and maintained, it will reduce heating costs for your home and will serve you for years to come.

"Lemax"

- a trade organization of the federal level in the field of heating equipment

mining, provides consumers in russia and the CIS with steel, cast iron and wall-mounted boilers, gas water heaters and other related products.

"Lemax"

- the leader of the Russian market of household gas boilers (according to independent

my British expert agency BSRIA, Russian consulting agency Amiko). the company has been operating on the market for over 20 years.

"Lemax"

- has its own modern production base, having in

a modern

plant for the production of domestic heating gas

boilers

.

"Lemax"

- the only Russian manufacturer of heating equipment

the vania on which the robots work are high-tech Italian and German machine tools. we are waiting for your feedback and suggestions on the company's website

www.lemax-kotel.ru

.

What are gas heating boilers

Gas boiler equipment is on sale in a significant variety, therefore, before choosing a parapet gas boiler, you need to consider the following parameters:

- Cost.

- Power.

- A set of functions.

- The type of heat carrier used.

- Burner type.

- Smoke extraction feature.

- Place of installation.

- The presence or absence of automatic control.

- The need for electrical energy.

The above are only the main differences that are found in different models of gas boilers. The main one is considered to be the peculiarity of the installation of a parapet boiler. Wall-mounted equipment is characterized by low power, relative cheapness and the possibility of using it in apartments.

Attention, read, Stop

Page 4

- Picture

- Text

4

Premium-M B. 1.03

Content

1.

GENERAL INSTRUCTIONS ………………………………………………………………………………………… 5

2.

COMPLETE SET ……………………………………………………………………………………………. five

3.

SPECIFICATIONS ……………………………………………………………………… 5

4.

SAFETY REQUIREMENTS ……………………………………………………………………… .. 8

5.

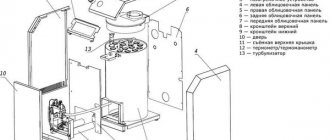

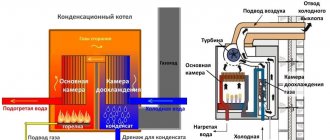

BOILER CONSTRUCTION …………………………………………………………………………………………………………………………

6.

INSTALLATION, PREPARATION FOR WORK …………………………………………………………………… 10

7.

OPERATING PROCEDURE …………………………………………………………………………………………. 14

8.

OPERATING RULES, MAINTENANCE ………………………………. 16

9.

WARRANTY …………………………………………………………………… 16

10. RULES FOR PACKING, TRANSPORTATION, STORAGE ………………………………… .. 17 11. CERTIFICATE OF ACCEPTANCE ……………………………………………………… ..................... 18 12. TROUBLESHOOTING REMEDIES .................................... .. 18 13 MARKERS OF ANNUAL TECHNICAL

AND PREVENTIVE MAINTENANCE …………………………………………………… 19

14.CHECK CARD FOR BOILER INSTALLATION ……………………………………………… .. 20 15. SERVICE CENTERS …………………………………………………… …………………………………… 22

ATTENTION, READ!

when buying a boiler, you need to make sure that its capacity meets the design for heating your premises.

Lemax premium series boiler effectively operates in open and closed heating systems, with and without a circulating pump.

when filling or replenishing the heating system, the water pressure should not exceed 2.0 kgf / cm

2

... to comply with this condition, install a relief

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm

from the point of connection of the valve for filling the heating system.

Do not install shut-off devices on the signal pipe in an open heating system.

It is forbidden to make up the heating system during operation of the main burner and when the water temperature in the heat exchanger is more than 50 ° C.

We strongly recommend that you strictly follow the requirements for the room used for the installation of the boiler and the requirements for the construction and insulation of the chimney.

It is not recommended to operate the boiler at a coolant temperature below 50 ° C.

when buying a boiler, ask the dealer to fill out a warranty repair coupon. check the completeness and presentation of the boiler.

The boiler may only be transported in an upright position.

STOP

Before using the heating boiler, read ...

Page 5

- Picture

- Text

Premium-M B. 1.03

5

1.

GENERAL INSTRUCTIONS

1.1. Read this manual before using the boiler.

estom.

1.2. installation work, instruction in operation, commissioning, professional

lactic maintenance and repairs of the boiler are carried out by a specialized organization and the local administration of gas facilities in accordance with the “safety rules for gas distribution and gas consumption systems” approved by the State Technical Supervision of the Russian Federation, and building codes and regulations SNip 11-35-76; SNip 2.04.05-91 Gosstroy of the Russian Federation, according to the project for the installation of the boiler and the mandatory filling of the control card.

1.3. The assembled boiler can only be put into operation after its acceptance

by gas experts, instructing the owner and obligatory filling out of the control coupon for the installation (p. 21)

1.4. Checking and cleaning the chimney, repairing and monitoring the water heating system

are made by the owner of the boiler. When replacing an old boiler with a low efficiency with a modern one, you should pay special attention to the design of your chimney. When the boiler efficiency is below 80-85%, the flue gas temperature is about 200 ° C, which ensures good draft even with a poorly insulated chimney. With an efficiency of 90%, the temperature of the flue gases drops to 110-120 ° C, and, in the case of an outdated chimney, the draft disappears, which leads to the operation of the automation and shutdown of the boiler. Failure statistics show that 94% of problems with boilers arise from an incorrectly executed chimney.

1.5. In the room in which the boiler is installed, it is necessary to provide

natural ventilation. It is forbidden to cover the grilles of the ventilation ducts.

1.6. The use of boilers at hazardous production facilities is prohibited.

2.

SET

2.1. A heating boiler with a gas burner installed on it. 2.2. Packaging containers. 2.3. Boiler operation manual.

3.

specifications

3.1. Steel heating boilers premium series

designed for heating and

rye water supply of apartments, residential buildings, cottages, buildings of administrative and domestic purposes, equipped with a water heating system with natural or forced circulation. the boiler meets all the safety and environmental requirements established for this type of product. GOST 20548; TU 4931-011-24181354-2011.

3.2.The boilers run on natural gas GOST 5542-96 and are delivered assembled

with gas burner

3.3. Working pressure of water in the heating system is not more than 2 kgf / cm

2

, in a closed system

heating, it is necessary to install a safety system with a safety valve for a pressure of no more than 1.5-1.7 kgf / cm

2

.

We eliminate possible malfunctions of the Lemax Patriot boiler

_______________________________________________________________________________

_______________________________________________________________________________

Tell me how you can fix this problem. A parapet gas boiler Lemax Patriot 20 with an automatic unit Eurosit 630 was mounted. If you ignite, the main burner ignites well, but dies out within 10-20 seconds. The new launch does not change the situation. What could be? Pre-check the thermocouple and the draft sensor. Check the circuit contacts. Carefully dismantle the stationary ignition burner and clean. Set the burner to a lower gas pressure. We assume that the draft has deteriorated, as a result of this, the pilot burner has a small amount of air during the ignition of the main burner. The fire began to smoke thoroughly and the burner burned non-stop, not extinguished. The temperature does not rise above the set temperature while the flame is on. There is a lot of soot on the parts of the unit. The gas service says there is insufficient traction. How do I fix the problem? Probably, the air flow has decreased. Maintenance required. Remove the burner assembly, clean and wash the burner and nozzles. The heat exchanger must be cleaned from the outside. Please tell us what is the problem if the appliance smokes? What should be done to resolve this issue? We assume that there is a weakening of thrust in the combustion chamber. We can advise you to clean the chimney. What to do, tell us if the Lemax Patriot 10 floor boiler cannot ignite? I try to hold down the control handle, click the ignition button, then hold it for about five minutes, squeeze it, and the apparatus dies out. The ignition tube is most likely dirty. In such a situation, we recommend that you do maintenance. There may also be an oxide on the clamps of the draft sensor. Disconnect the clamps and clean them from oxidation. Malfunction of the Patriot 12.5 boiler with the 630 Eurosit automatic device. When pressing the ignition button, there is no gas supply to the burner mechanism. What could be the reason? In the case when you press the button, fuel is supplied only to the igniter; its supply to the main gas burner device is not allowed. We installed this unit. I don't like the pilot to main burner cycle. Two claps are heard all the time. It should be? Most likely, it is required to adjust the automation for gas pressure. A similar unit with a Eurosit 630 gas valve was put into operation, which does not want to function when the temperature rises to about 65 degrees. Am I asking for help to fix this problem? Most likely, the traction sensor starts to work. We recommend that you inspect the chimney. The same device has been in operation for five years. He had a heating failure at fifty degrees that week, although the fire continues to burn vigorously. What happened? It looks like there is a blockage in the gas supply pipe from the automation unit on the gas burner device, and besides that, the burner jet. A gas boiler Lemax Patriot 16 with Eurosit 630 automatic equipment operates at home. Two days ago, he had a problem. It goes out when the wind blows on the igniter. Recently I replaced a thermocouple, but the result is zero. How to fix it? When the main burner turns on, this leads to a decrease in the gas supply to the ignition mechanism, which means that the automation unit should turn on. You need to increase the gas supply to the igniter. This usually happens due to the weak pressure in the system. In another case, there was a decrease in the chimney draft if it was installed with errors.Explain to me why this model periodically stops working, mainly when outside there are strong gusts of wind and bad weather. How should the issue be resolved? At the moment of starting the ignition device, the solenoid valve should operate in about 20 seconds. When the igniter goes out, the EMC function is interrupted within ten seconds, at which time you will hear a click. Four years ago, I installed a Lemax Patriot 12.5 parapet boiler at my dacha. The building is small, the area is no more than thirty square meters. You might think that the consumption is not too high, and the water does not heat up more than sixty-five degrees. The house has 2 radiators in ten sections. I don't understand how to increase the heating temperature? To fix the problem, you need to install a circulation pump. There is often a drop in pressure in the gas pipeline. What are the reasons for overheating of the boiler during operation? An essential factor is that the circulation in the heating circuit has disappeared. A clogged filter or a large accumulation of air in the heating system is also likely. I got into trouble. When we close the tap for cold water and open the tap for hot water, then all the water leaves the heating circuit. Explain why this is so? The heating circuit make-up valve appears to be malfunctioning. It passes water through both pipelines. If there is coolant pressure in the system, then movement in the opposite direction cannot occur. Why does the device make noise, gurgles, and occasionally howl and clap loudly? The water in the system is thoroughly oxygenated. When heated, the air evaporates, from which you can hear noise. If the unit is set incorrectly, a gas valve or a bypass may leak. Pops during start-up indicate a malfunction of the ignition mechanism. Performed independently at the end of 2014, the launch of the Lemax Patriot 12.5 boiler. After about a few months, there was a failure. I set the temperature regime, but he does not hold it. Tell me what is the reason? Apparently, there were some problems with the automation, and at the moment the temperature rises by 60 degrees, the nozzles are turned off. It is necessary to configure the automation for the correct performance of the functions. Also, the reason may be that the selected unmatched capacity of the unit in relation to the areas that need to be heated. I carried out the installation of this unit myself in the middle of this year. We made a changeover to liquefied gas. For several months, almost 10 cubic meters were consumed. At the moment, there is a large amount of soot inside the unit, and the burner also began to smoke. What does this mean? Too much soot build-up in the firebox indicates that the burner is poorly adjusted and does not completely burn the fuel. A low-quality gas mixture is also likely. In order not to smoke the burner, it is recommended to periodically wet clean. He commissioned this unit. On start-up, the burner ignites and goes out immediately. It seems to me that the ignition device is defective. How do I fix this problem? You need to check if the sound of an ignition spark is heard when the cable is removed for ignition. If not, the ignition transformer must be replaced. If a sound appears, replace the ignition electrode or the burner itself. Recently there was a problem with the Patriot 20 boiler. Water began to flow. It worked properly for a total of 3 months. Maybe someone will explain why the water is dripping? It may drip due to high pressure in the heating system. Still, probably, the destruction of the walls of the heat exchange device. Water hammer can also cause leakage in boilers. In a private house, I am thinking of connecting this unit. Interested in how much the standard gas supply pressure / methane / propane / for such devices should be? In this type of boiler device, the standard gas supply pressure (natural / liquefied) is 150/300 Pa. They installed the same device for me. The other day I noticed a malfunction of his work.The boiler starts up, but the heating does not heat up. What is the problem? Perhaps there is air accumulation inside the radiators or there is a lot of scale in the heat exchanger. Try washing it. We use this unit in the apartment. Worked smoothly until tonight. It is currently in trouble. The device overheats daily. Can you help fix such a breakdown? Scale may have built up and the duct is clogged. You need to clean the device. The other day we had a problem with a heating boiler. The unit only operated for 3 weeks. After that, he suddenly stopped picking up the set temperature. Maybe someone can tell you why this happened? The gas pressure in the heating system is less than recommended. It is necessary to inspect the gas valve. Most likely, there is an excess of lubricant inside. You want to remove the extra. Explain how to properly pump up the expansion tank? The expansion tank is pumped up with any pump at hand to the pressure recommended in the passport. Basically the average volume is 1-1.5bar. To pump up the expander, according to the regulations, you need to drain the coolant from the boiler. It is possible to drain through the drain fitting or through the water parsing valve, drowning the flow of hot water supply. The Lemax Patriot 7.5 parapet gas boiler does not start. If you keep the start button pressed, the burner operates normally. But do not fix the button, the device turns off. Tell me the reason for the breakdown? Most likely, the thermocouple is damaged or the gas valve is broken. There is also a decrease in gas pressure in the supply pipeline. Sometimes there is a lack of voltage on the control board. Please tell us what steps should be taken to change the type of gas? For this, it is recommended to change the nozzles of the main burner. Next, change the supply voltage of the modulator. And at the end, adjust the pressure parameter at the maximum and minimum. What is the operating principle of the heating safety valve? This valve, adjusted to the operating pressure, serves the heating system. It is not allowed to use a safety valve to drain water from the system. The pressure of the heating system increases periodically. In the expansion tank, the pressure is reduced to 2.2-2.4 atmospheres. Could it be that the heating water comes from the hot water pipes? The rise in pressure in the heating system is formed by the following main factors. Expansion vessel pressure not set. The make-up valve is leaking. There was a problem. The start is very bad. The igniter is on, but there is no fire on the main burner. Please tell me what is the reason? It looks like a malfunction of the ignition device. You need to check the boiler and clean the ignition mechanism. Please help clarify the situation with the chimney? For two days now, there has been a return thrust, while the smoke began to pour immediately into the kitchen. I took care of the chimney myself. It is a steel pipe. Probably a mistake was made in some way. The main factor may be an incorrectly manufactured chimney design. Contamination with soot is possible, which markedly reduces its efficiency. It is also advisable to check the exhaust openings in living areas.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared.He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler is turned off with an E35 error (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3.The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a malfunction?

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When it works on a unit, it beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently started showing error 14. How can you fix the breakage?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?

INSTALLATION, PREPARATION FOR OPERATION ...

Page 10

- Picture

- Text

10

Premium-M B. 1.03

6.

INSTALLATION, PREPARATION FOR OPERATION

6.1. The volume of the room in which the boiler is installed must be at least 8 m

3

... Ras-

the distance between the boiler lining and the walls must be at least: - 150 mm behind; - 100 mm right and left; - 1000 mm at the front.

6.2. In the room in which the boiler is installed, it is necessary to provide for natural

proper ventilation.

6.3. When installing the boiler to the heating network, it is necessary to lay a non-combustible sheet on the floor

insulating material, on top - a sheet of iron, install a boiler on it.

6.4. The connections between the boiler and the heating system and the gas main must be threaded.

secondary, allowing, if necessary, to disconnect the boiler. If the boiler is installed instead of an old boiler, it is imperative to flush the pipelines and radiators of the heating system to remove rust, scale and sludge deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer from the boiler. In this case, claims regarding the temperature indicators of the heat carrier during the operation of the boiler are not accepted by the manufacturer.

With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the heat carrier is significantly exceeded - the number of radiators, pipes) from the established standards, temperature the heat carrier may not reach 80 ° C, which does not mean that the boiler is defective.

6.5. The capacity of the coolant in the heating system should not exceed: Premium 10 - 150

liters, Premium 12.5 - 180

liters, Premium 16 -

240

liters, Premium 20 -

300

liters, Premium 25 -

375

liters, Premium 30 -

450

liters, Premium 40 -

600

liters.

6.6. For correct filling and replenishment of the system, be sure to install a waste

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm from the place

valve connection for filling the heating system.

6.7. The expansion tank is installed at the top of the main riser, preferably

in a heated room. Do not install a valve on the signal pipe (see Fig. 2, 3).

6.8. Horizontal sections of pipelines of the heating system must be performed with

with a slope of at least 10 mm per 1 m towards the heating radiators and from them to the boiler. This is done in order to ensure free air outlet when filling the system with water and eliminates the formation of air pockets.

6.9. Pipelines, heating radiators and their joints must be sealed

no water leaks are allowed.

6.10. For a closed heating system, it is necessary to install a security system with

safety valve for pressure no more than 1.5-1.7 kgf / cm

2

.

6.11. The chimney device to which the boiler is connected must comply with SP42-

101-2003 "General provisions for the design and construction of gas distribution systems" (see Fig. 4).

6.12. After connecting the boiler to the gas supply system and filling with a coolant

heating system, employees of a specialized service center or local gas administration must adjust and check for operation of the safety automation and temperature control, as well as check the tightness of all threaded connections on the boiler gas pipeline and before it.

6.13. Before igniting the gas burner, check the presence of draft according to item 4.3. With absence

draft, it is prohibited to ignite the gas burner device.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

If you don’t want it in an amicable way, you will follow the instructions!

Manualza! Manualza.ru