Types of fireplace stoves

The stove industry allows the use of various materials in the construction of wood-burning heaters. But basically, oven manufacturers present a wide range of models, which are divided into three types:

- metal

- brick

- combined.

It will not be difficult to make brickwork or a welded case according to the scheme with your own hands. In addition, all components are available for free sale. The main condition for a successful project is strict adherence to building codes and the construction plan.

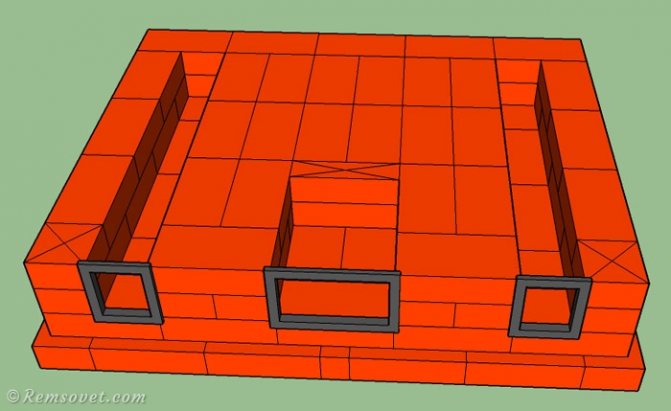

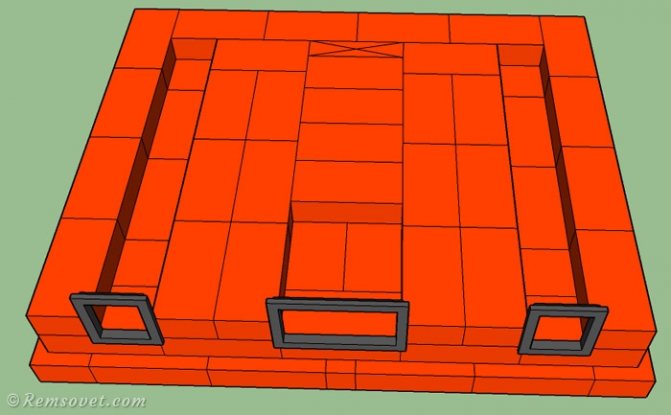

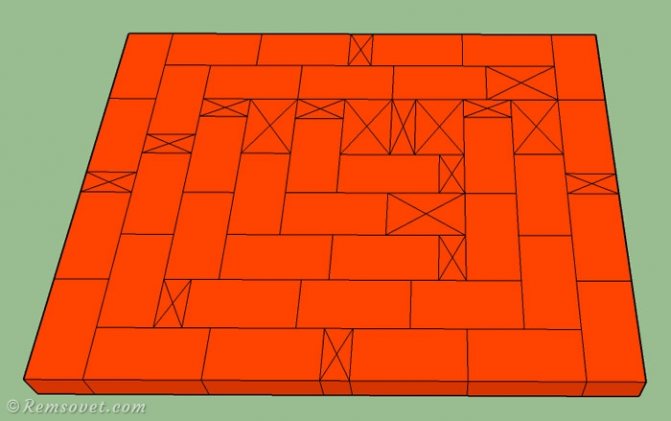

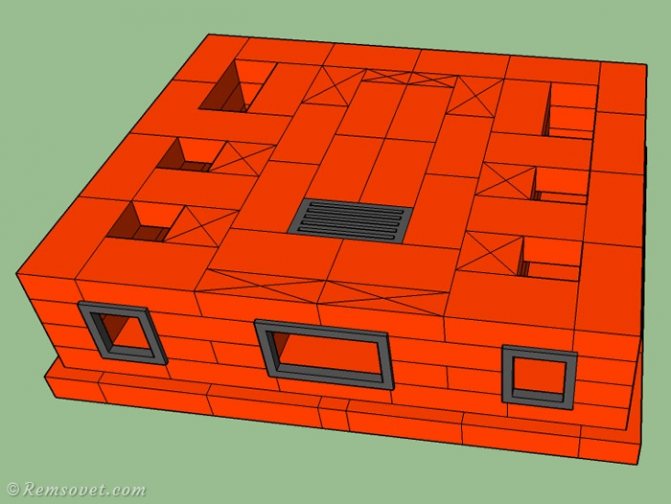

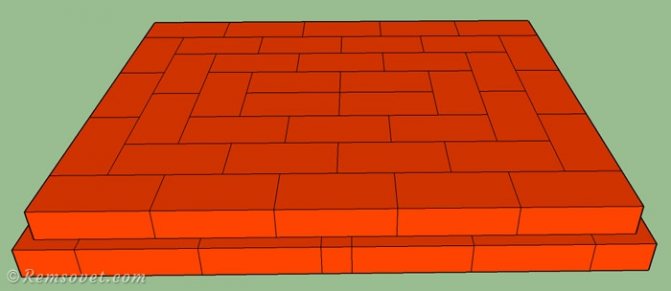

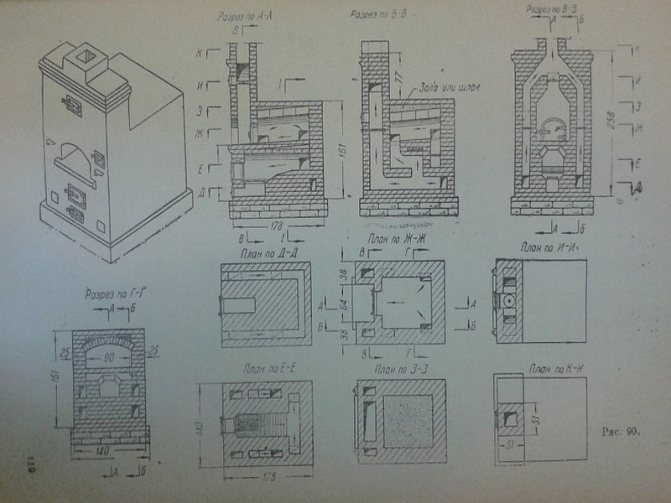

Schematic drawing of the ordinal masonry of a universal 5x2.5 brick fireplace stove.

The masonry of the furnace presented is considered to be of medium complexity and requires the performer to strictly adhere to the ordering, the thickness of the seam (5-8 mm). In addition, a high quality sorted brick is required before laying it must be soaked in water for 10-30 minutes.

As a cladding for the fireplace stove, it is best to use the jointing while they are half-dried, or grout the entire array with bricks after the oven will dry.

If you like the project of this fireplace stove, I strongly recommend that you familiarize yourself with calculation of the chimney for fireplaces and her masonry.

www.osnovaremonta.ru

Fireplace with stove

The design of this oven is a portable metal product with a hob mounted on top. The firebox door has a heat-resistant glass element, allowing others to admire the fire. Fireclay bricks or non-combustible blocks with a refractory base are used in the construction.

Metal stove-fireplace with hob

In most cases, this type of oven is of factory origin. The size of the portable fireplace stove is compact, and is designed to heat a room up to 25 sq / m. Each furnace has a capacity set by the manufacturer.

For reference! The heater for the room is selected on the basis of a simple formula: 1 kW of product power is designed for a room of 10 m².

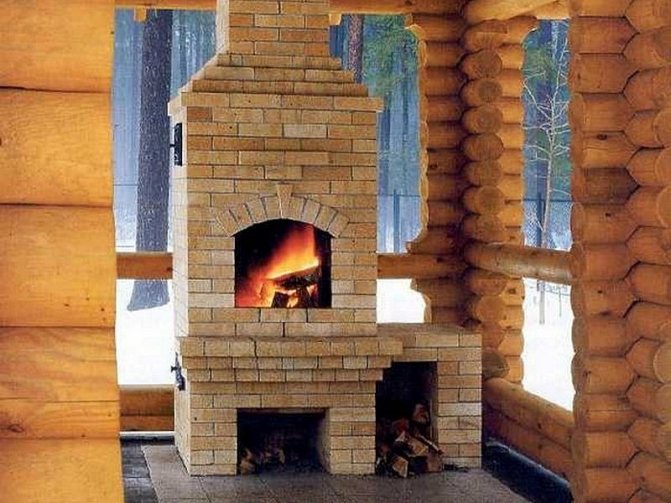

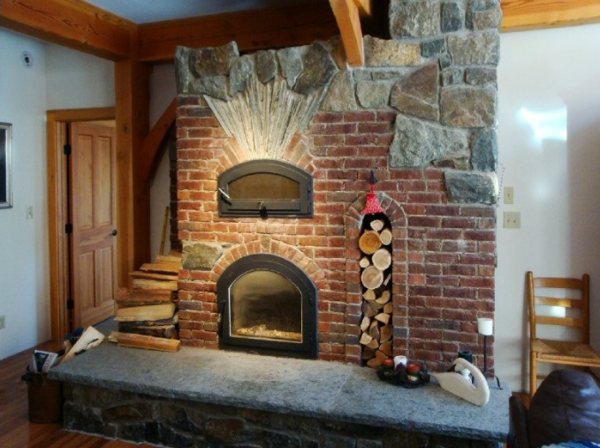

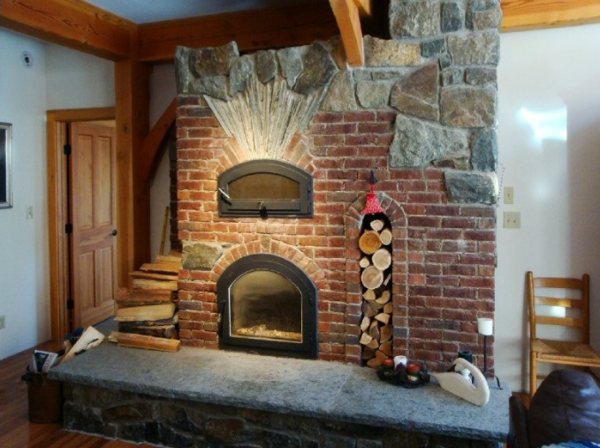

Corner fireplace stove with bread chamber

Table of contents

1. Materials for the furnace, the choice of bricks

2. Work progress

3. Construction of a red brick corner stove

4. Works on the construction of the furnace

5. Conclusions on the operation and combustion of the furnace

We present a project for self-construction of a fireplace stove. After placing on the location of the fireplace, as well as options for the size of the stove. It turned out a furnace with dimensions of 3.5x3.5 bricks - a large structure would not fit. Various options for ovens were considered - with or without a bread chamber. The corner stove was chosen because in such an arrangement the fire in the firebox was clearly visible, and the heat from it would be much less - in the case of a direct firebox on the existing territory, the stove heat would burn those sitting at the table too much.

Materials for the furnace, the choice of bricks

Materials for the construction of the furnace were selected in parts, and not in the store. For example, the author on the Internet came across Finnish molding, an SVT door with two glass panes 50x50 cm, as well as a blower and a cleaning device, a valve and a grate. In the same way, the door for the bread chamber and the cleaning door were found. The first option is priced at 6.5 thousand rubles, the second - 3.5 thousand.

After the order was placed, the author began to design the construction of the furnace, taking into account the dimensions of the purchased furnace accessories. The design of the kiln had to be done in a special program, and it became clear that the work on the erection of the kiln could take more than a month, since a large amount of bricks had to be cut. Another method was used: it was very convenient to draw on graph drawing paper.The author cut the squares and then secured them with a paper clip. You can draw one row, and the next is drawn with the glass laid or by looking at the light for the best translucency.

As for the type of brick, there were several suitable options. This is a brick of the Ilsk plant M-125 and M-150 of the Khabal plant, or with five holes - each brick turns out to have 7% of the empty space. Both variants had grooved sides. Other types of bricks were either rotten or cracked. Most often, stoves are laid in this area from Ilskiy and Khabalskiy bricks. The first option is slightly worse, since there are problems with geometry, chamfers protrude outward, and there are also small cracks. As a result, the best brick option from the available proposals was chosen - Khabal brick. The condition of the brick was excellent - out of three hundred pieces, only ten were rejected. Also, this brick has a characteristic sound - as if ceramics are ringing.

Progress

The author did not have any experience in mixing clay mortar. Five bags of "Terracotta" were purchased for brick laying, the mixture is suitable for ceramic and fireclay bricks, fireclay clay was also purchased. It was also decided to try mixing the solution with local clay - there was very little of it, it remained after drilling the well. The optimal solution was obtained empirically: then add sand, then fireclay clay, in order to "grease" it. The mortar was spread on the brick in a thin layer until it dries up, sand was added. While the casting was on the way, the author started preparing the foundation and bricks. The chamfers were removed from the brick with a grinder with a diamond grinding disc, then the surface was processed with a sandpaper with a grain size of 100.

A new corner stove was being erected next to an old small cast iron stove. When the cold weather began, it was necessary to combine the heating process with the old stove and the construction of a new one. The difficulty was also in the fact that the chimney of the old stove passed over the place of construction.

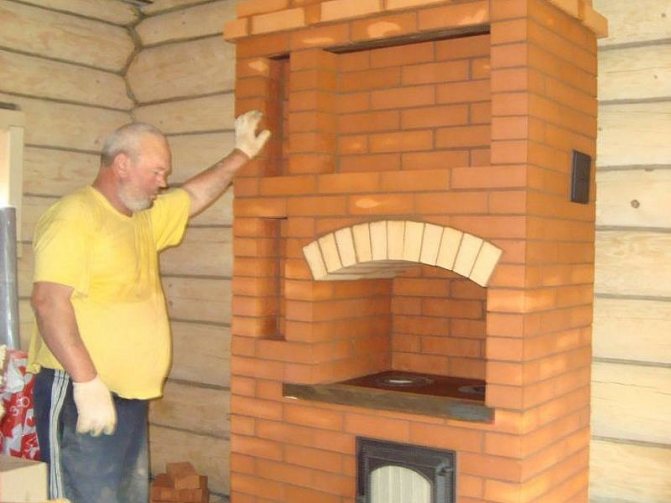

Construction of a red brick corner stove

After the first row of masonry was laid, the future chimney channel was covered with mortar. A whole bag of Terracotta mortar went to the first row. A lot of time was spent on thinking of this type: how to lay a brick on a corner ledge more beautifully. The thing is that a large door could be placed either by drowning it towards the furnace space, or by pushing it out. The second option was chosen - the firebox to the outside. It turned out that the furnace side was the tooth shown in the photo.

Fixing a brick in such a position is not easy - there are some difficulties here. If the foundation is without stock, then only 3.5x3.5 are available. The foundation of the blocks turned out to be higher than the floor level. The author also came up with the idea of putting the bottom row of the furnace side on the edge - a brick beam for ten bricks. It was also necessary to cut a place in the brick for the ledge of the foundation so that the height of the remaining brick was equal to the height of the brick, which lies flat. It was also necessary to assemble this entire beam on fiberglass reinforcement, since it does not expand much from heat like metal, it is also heat-resistant - like fiberglass. As a result, the beam was glued with Terracotta mastic. To fill the holes, the author came up with a design similar to a pastry syringe - this is a tight bag with a hole in the corner.

With the third row in place, it was time to think about casting as well as installing doors in the oven. By the third and fourth rows, the lower cleaning door in the center and two side doors were already ready. Then the time came for fireclay bricks, the brand was mainly used ShB-8. But also several bricks of the ШБ-5 brand were used. At the same time, fireclay bricks were slightly sawn off so that fine dust fell directly into the grate.A small channel was made from the side of the blower in order to organize access to the glass of the firebox - as an option for European fireplaces to clean the glass. There will be special gills on the doors just for this, but the author decided to play it safe and came up with such a solution in the form of a channel. Basalt cardboard was placed between the ceramics and fireclay.

The fourth row was completely lined with fireclay. After laying two more rows, the fifth and sixth, a place was formed for a dry seam, 1.5 cm passages were left. The chimney was cleaned from the clay and mortar. For good resistance to heat, the chimney was impregnated with liquid glass. Sawed fireclay was also impregnated, but it will still be impregnated with mastic. Ledges were made for the coals, the original shape was obtained, the installation took place on the sixth row.

The author also came up with one solution - to construct an overlap between the firebox and the baking chamber from a cast-iron hob with mugs for one burner. But in this situation, the heat from the firebox will be as hot, sharp and excessive as possible. And they will not cook with fire on the ceiling of chamotte. A 410x410 slab will fit perfectly. It was decided to build the overlap of the bread chamber from SHB-44 fireclay. At first it was assumed that only one part of the furnace would be made of this brand - the door frame.

There was a decision to make a hailo only through the bread chamber or to make small burnouts in the upper part of the firebox. It was done in both places. Thanks to the cast iron hob, the bread chamber will be warm enough. Just in case, you can make two blocks of fireclay for plugging. For ease of removal and insertion, insert and drill into them along the anchor with a ring - a bolt and a ring instead of a cap.

Furnace construction works

When kindling with an open ZLH, it will show through strongly. When closing, the thrust will decrease, but if the combustion has gone and the wood is dry, then it burns well enough. At first, during operation, there was a little smoke through the door of the bread chamber, this is because the door is not sealed and was not originally intended for the bread chamber. The door was an ordinary furnace under the arch. For this, a fiberglass pigtail was held along the door opening, and everything became normal, the smoke did not pass at all.

During construction, be sure to think over the brick vault of the firebox - in this model of the furnace, the firebox is large and it will not work to lower the bread chamber below. With what is, the bottom of the bread chamber will turn out to be low.

Minerite was attached to protect the outer ceramics from overheating. It is hard to believe that he will perform his functions there for a long time. On the 21st row, it became clear that some kind of decorative element was missing. It was decided to cut a bird out on a brick.

The project to build a corner oven with a bread chamber required a lot of brick cutting. It is convenient to draw the order of the oven on graph paper: two sheets are applied to the bottom, and the previous row is immediately visible - this is how you can check yourself.

The chimney was coated with mastic.

Conclusions on the operation and the furnace

As the oven dried and heated, a lot of salt (white stains) came out on the brick surface. It was also difficult to scrub the Terracotta clay mixture on the ribbed uneven surface. The stove keeps warm long enough. If the temperature is above freezing, then the house is heated once a day.

Fireplace with oven

These models of stoves are installed in the kitchen area or dining room, where a large number of people gather. The type of oven can be portable from metal or stationary from brick. Depending on the size of the room, custom-made construction is allowed. For information! Compliance with the basic building codes when performing the fireplace part will save the owner from smoke (SNiP III-G.11-62).

Metal stove fireplace with oven

Do-it-yourself fireplace stove: how to choose a place

When laying out the fireplace stove with his own hand, the combination of the elements that are present in the bread ovens will be performed. These elements retain heat well.

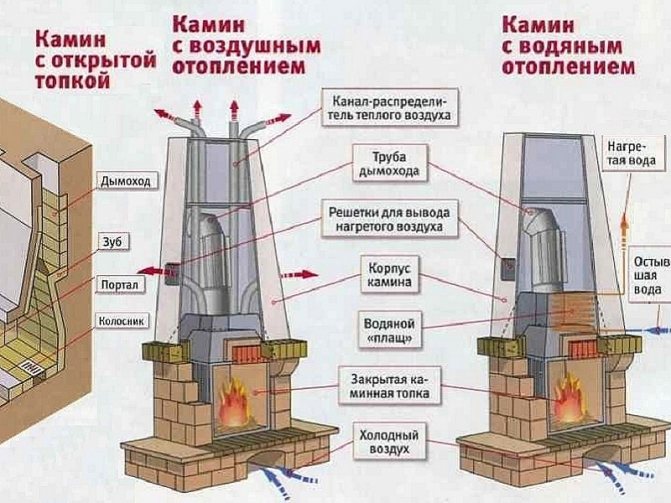

The fireplace itself has an open firebox, it is able to warm up the room almost instantly. And if you add a small stove to the fireplace, then you can cook on it. The main feature of the fireplace stove is the presence of 2 fireboxes and 2 chimneys. Based on this feature, the stove and fireplace can be heated separately.

Fireplace stoves in chimney ducts have a huge amount of smoke circulation. And with the help of this amount of smoke circulation, the heat is retained for a long time. Also, fuel consumption is reduced. For heating, you can use different fuels, for example: firewood, peat, coal and other types.

When choosing a place for a fireplace stove, you need to remember that such a structure is a solid building, but it is better to think about the place where such a stove will be installed when building the country house itself, and only in this case you will do without altering the room.

You can also install the fireplace into the walls of the house, but for this you will have to partially disassemble the floor and roof.

How to place a stove with a fireplace in the house more efficiently

Choosing a versatile oven is not the first step in setting up. Initially, the optimal location in the house should be chosen for the heater and the required power of the generated heat should be calculated.

One of the ideal places for a fireplace stove with a hob and an oven should rightfully be considered the space between the kitchen and the living room. The side of the fireplace located in the common room will warm residents on chilly evenings and create a romantic backdrop.

Stove-fireplace in the interior of a country house

If it is necessary to heat three rooms, the option of shifting the stove to the third room is suitable. Thus, the firebox and hob will remain in the kitchen, the fireplace area will face the living room, and the side of the heater will be in the third room.

If it is required to locate the hearth in the same room, then the fireplace insert must be planned in the recreation room and provided with good visibility. The hob should be in a convenient location, which requires close proximity to the kitchen. The location of the fireplace in relation to the hob, in this case, has different designs, for example, on the side or, on the opposite side.

Wall-mounted fireplace stoves have both fireboxes on one side in most cases. This design complicates the simultaneous preparation of food and admiring the open fire, since the approach to the hob will be difficult due to the heat of an open fire.

Design selection factors

Among the many projects presented, not every one is suitable for use in certain conditions. In addition, not everyone is able to fulfill all the requirements of the residents of the house. Therefore, you should familiarize yourself with the basic technical criteria that will have to be adhered to in order to ensure the functional and safe operation of the device.

- The first factor will be the size of the furnace, since the discrepancy in size will not only lead to a violation of the basic functions, but also to the inappropriate use of free space. When deciding on the dimensions, it should be remembered that heat transfer is carried out not only due to the rear and front walls, but also due to the side walls.

- Any stove-fireplace with a stove and an oven performs several functions. The main task that the design sets itself is to ensure smooth operation in all provided modes, which means that the installation of the oven must be done so that the side walls are facing the room that requires heating, and all cooking devices are on kitchen.

- The shape of the stove is chosen in accordance with the layout of the house.For self-construction, the most suitable design will be square ovens, rectangular or made in the form of the letter "T". In some models, there are protrusions for separate placement of the oven or stove bench.

- Any model is characterized by such a parameter as power. It shows the possibility of heating a room of a certain area. When choosing a project, elementary calculations of the required power should be made.

Large fireplace and stove complex

Some indirect factors are related not to the device, but to the construction, but they will also have to be taken into account. This is the material from which the building is made, the degree of insulation of the house, the wind rose, etc.

Good to know: Cast iron fireplace stove for home and summer cottages, distinctive features

Projects of brick stoves with stove and fireplace

Universal stoves with a hob with an open or glazed fireplace insert are the best option for small country houses. Putting a universal stationary stove will not be more difficult than folding the "Swedish" or "Dutch" masonry of standard designs. The master has the opportunity to acquire the ordinal diagrams of the furnace that he is going to build.

Brick fireplace stove with oven

Fireplace stove with stove and oven for kitchen-living room

The standard model of the multifunctional oven is designed for installation in living spaces up to 30 m². However, the dimensions of the structure allow you to install this stove in a room half as much as stated in the specification. The structure of the model includes: a single-burner hob and an oven, which is in the area of moderate heating.

Operation of a fireplace stove with a stove is possible in winter and summer modes. Brick quickly absorbs heat and retains it for a long time. Also, this model range should include a fireplace stove with a stove and a heat exchanger. In this case, it is possible to heat additional rooms by circulating a hot water circuit.

According to the calculation, the construction of this modification of the furnace will require:

- bricks - 725 pieces, including refractory bricks for the furnace lining

- oven - 280 X 300 X 520 mm

- hob - 400 x 420 mm

- grate - 180 x 300 mm 2pcs

- view - 2 pcs

- firebox door

- podzolnik door

- steel sheet for the pre-furnace site.

Above the mantelpiece you can make yourself from wood or stone. If preference is given to wooden material, before it is necessary to make a gasket from an asbestos sheet.

Corner fireplace with stove for a small house

For small country houses, with a combined kitchen-living room, a corner fireplace with a stove is highly popular. The heater's key potential lies in the stove. The fireplace serves as a decorative function in this model and is not designed for long-term burning with a large amount of fuel.

These circumstances allow the use of ceramic bricks for the fireplace insert. But if the owner intends to use the fireplace insert on a regular basis, then it is necessary to make a lining of refractory bricks. To install a standard corner fireplace, 400 bricks will be enough.

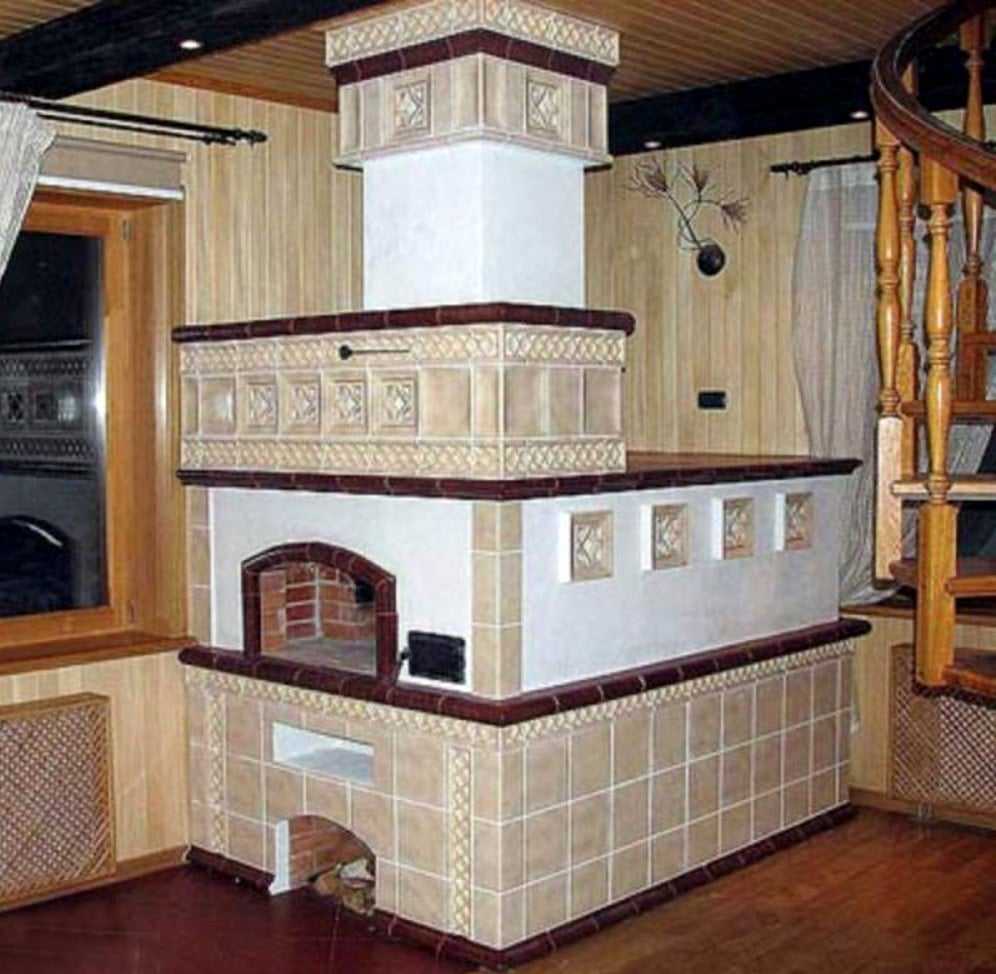

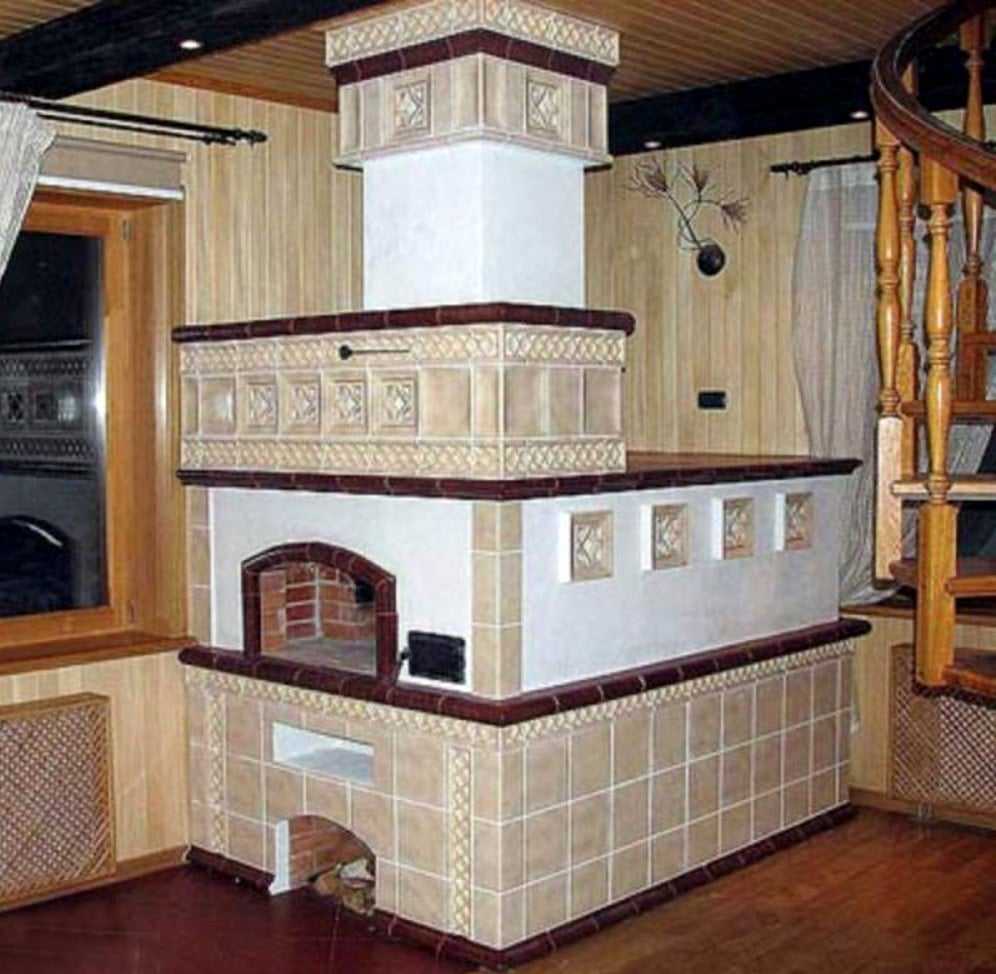

Corner fireplace decorated with tiles

Compact metal fireplace stoves

Most people have a dream of a fireplace in their own home. However, not everyone has the opportunity for this venture due to various circumstances. The construction in the house of a massive, full-fledged brick fireplace stove with a hob requires certain technical conditions. It is worth adding to this that the brickwork of the stove is a very expensive task, amounting to tens and even hundreds of thousands of rubles.

Compact fireplace stove with stove

But thanks to the stove industry, consumers are presented with a wide range of compact metal fireplace stoves with hobs and ovens.The process of operation of these devices is designed for convection and does not require complex designs of smoke ducts. In addition, the chimney can be led out through a hole in the wall.

Another undoubted plus is that some portable models of fireplace stoves are equipped with a heat exchanger. They are designed for rooms where there is not enough heat output from the heater. With a heat exchanger, it is possible to connect a section of water radiators, which will be heated due to the circulation of a hot water circuit.

At first glance, installing a portable fireplace stove may not seem like a complicated undertaking. However, the simple construction of the flue pipe and the connection to the heater can cause difficulties for the user. Therefore, it is better to consult a specialist before installation. Violation of the laws of physics will entail a lack of traction and lead to smoke in the room.

Popular models of multifunctional ovens

Some models equipped with a hob have a rather complex device. And the difficulty lies not in adding an additional option, but in the arrangement of the chimney duct. You should immediately assess your capabilities and choose the project in which the route for the removal of combustion products will be the simplest.

The stoves, with which many masters began their activity, are known among consumers as "Swede" and "Dutch". Their ordering is simplified as much as possible, and the functionality is at the proper level. In addition, there are known developments named after their creators. For example, Bykov's oven, Porfiriev's oven. All of them are made of bricks and differ in the configuration of the main elements, their relative position and the route of the chimney ducts.

- The “T” shaped oven is usually used as an island option. It is located in the center of the room, dividing the space into zones and at the same time heating them. This model is rather large, therefore it is used in large areas. Naturally, in the large volume of the oven, several devices can be placed, including those for cooking.

T-shaped design

- For a small house or summer cottage, a narrow oven has been developed, in which there is a protruding hob. This model is not equipped with an oven, but it is compact in size and has excellent technical characteristics.

Narrow option

- The traditions of Russian craftsmen were not lost in history, but were passed on to us through generations. Of course, modern stoves only remotely resemble the Russian stove from folk tales, but they retained all the necessary functions. These options are complemented by a heated stove bench, oven or brazier in which you can bake pies. There are various niches for drying clothes in the body of the oven. In such a complex, you can cook several different dishes at the same time.

Classic building