The main item in all the homes of our ancestors was the stove. Most often, it was erected in the very center of the room in order to warm the house as evenly as possible. In addition, food was cooked on it and colds were treated, if there was a bed. But at present, a brick oven is only a heating structure. At the same time, making it with your own hands is not so difficult. The procedure does not require expensive specialized equipment, extensive experience and the involvement of a professional stove-operator. And if you use high-quality and outwardly beautiful brick, then you will not have to deal with finishing work. But despite all the ease, basic knowledge must be present.

Additional requirements for the selection of the furnace

Since we suggest doing everything yourself, and not buying a ready-made stove in a store, when choosing the required design, we recommend paying attention to the following parameters:

- Ease of operation... The heating process should be a pleasant and uncomplicated activity that every family member can handle.

- Profitability... This point is especially important if it is planned to use only this stove to heat the house on an ongoing basis (in winter). In this case, one unit of fuel will provide maximum heat transfer.

- Simplicity of design... If a person who does not have experience in masonry takes up the construction of a complex model of the device, then difficulties may arise that will subsequently lead to incorrect operation of the furnace.

- Appearance... The design of the structure should be pleasing to the eye and create coziness in the room, so it is worth paying special attention to the quality of the brick.

- Presence of a water circuit... It is known that even a small heating stove with a built-in heat exchanger for heating the coolant is much more efficient than other models without this device.

When choosing a heating stove, you should consult with a qualified stove-operator. He will tell you which configuration to choose and what to pay special attention to.

Seat selection

Before proceeding closely with the construction, it is worth deciding where the furnace will be located. If there is only one small free area in the house, there is nothing to be done about it. But for maximum heat transfer, it is recommended to place the stove in the central part of the house or room. Thus, none of its elements will touch the street wall, respectively, warm air will not come out. In addition, in the vicinity of the supporting structure, temperature drops may occur, which negatively affects the durability of the heating device and the operation of the chimney.

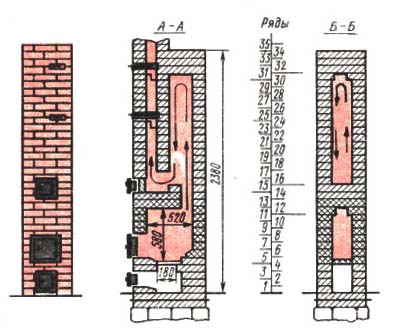

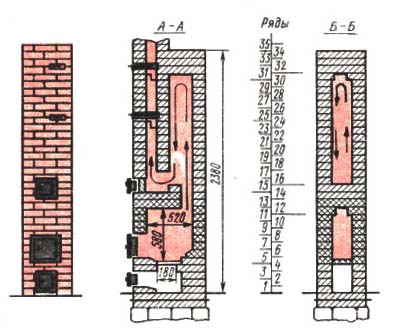

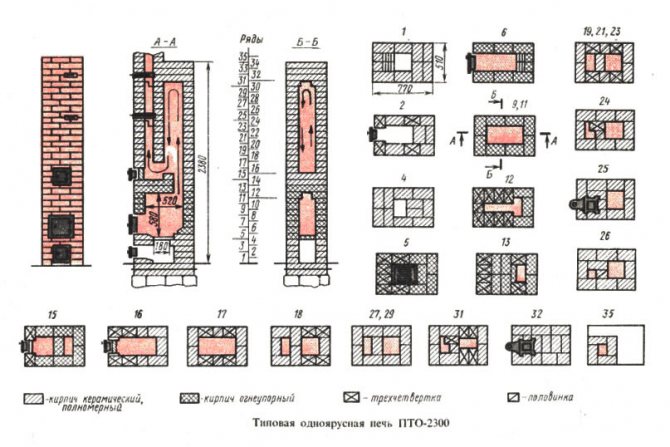

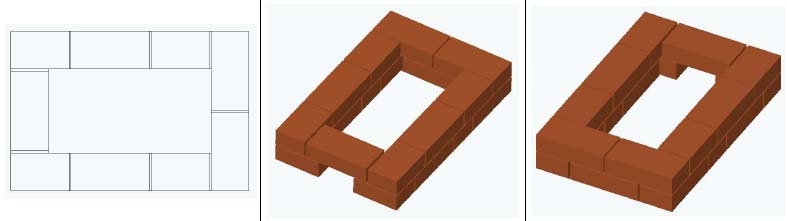

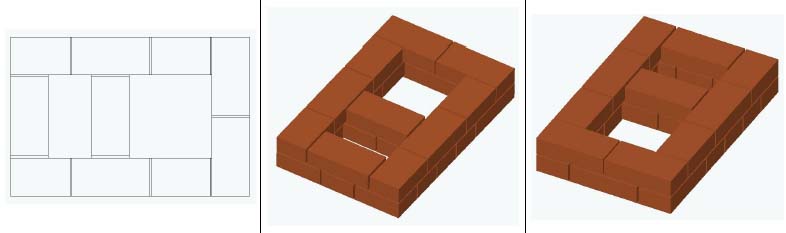

What are we going to build

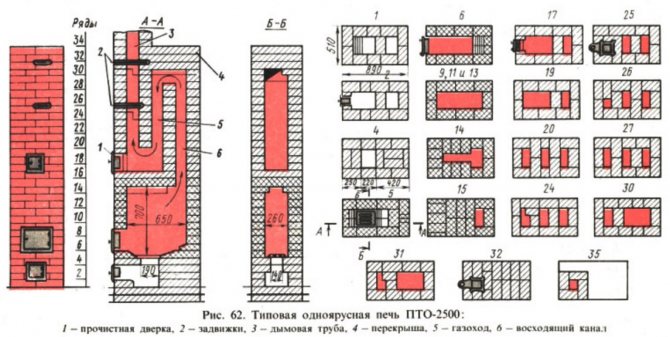

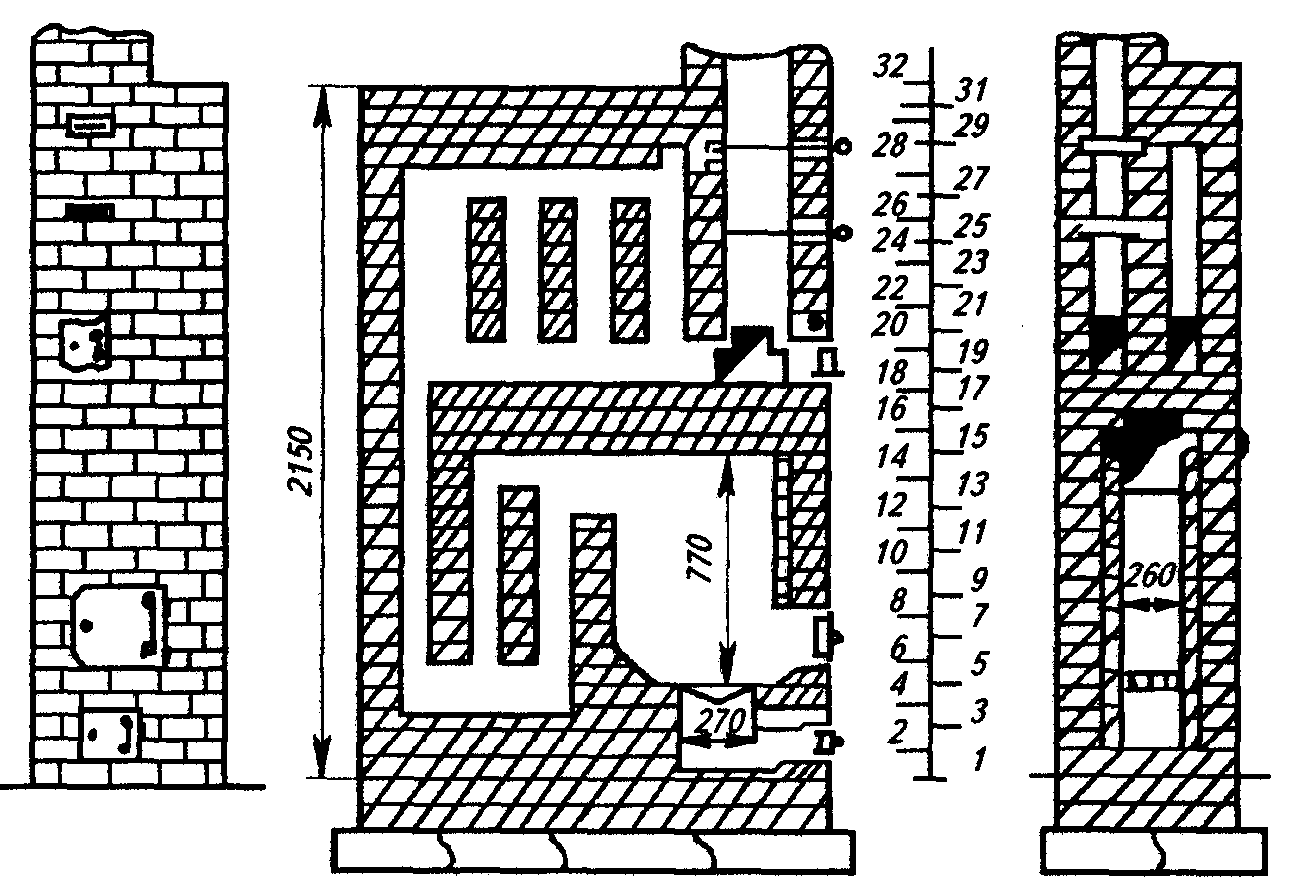

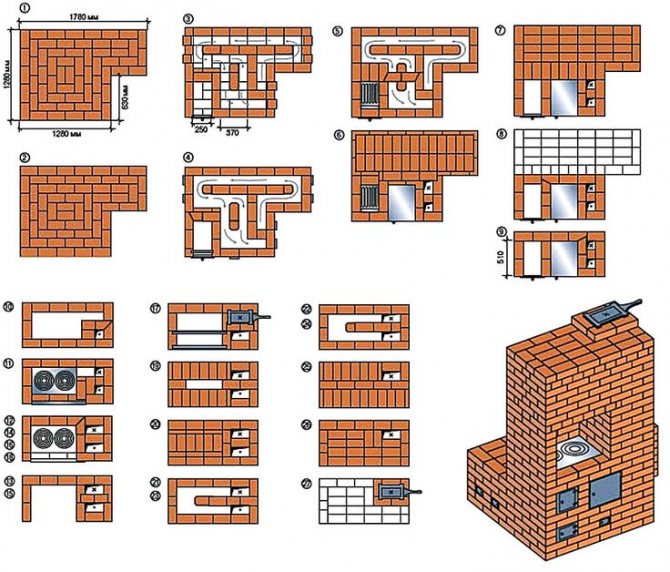

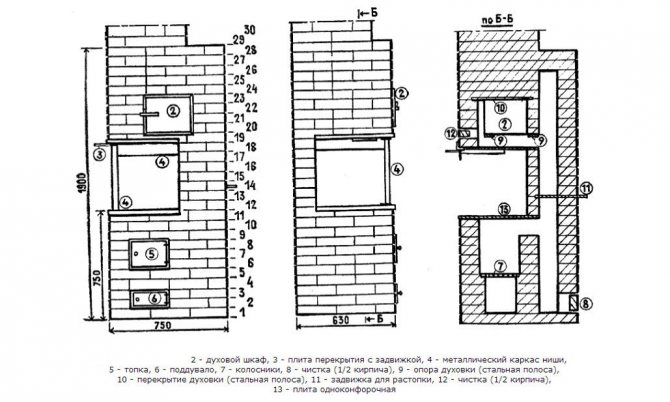

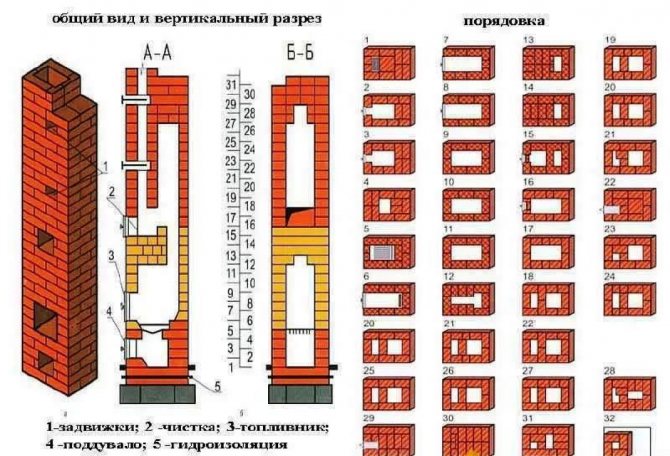

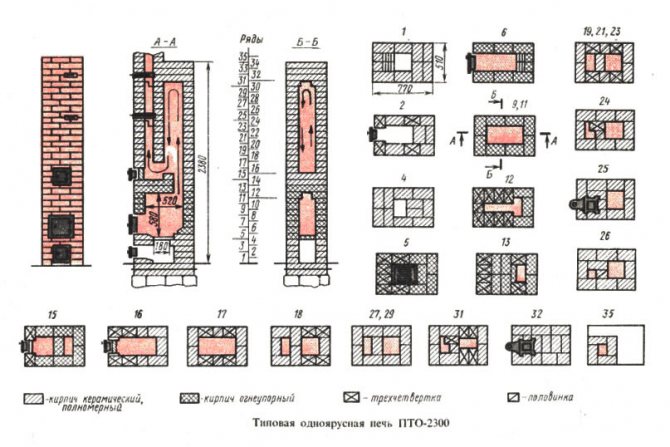

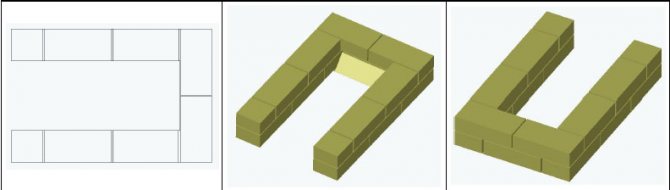

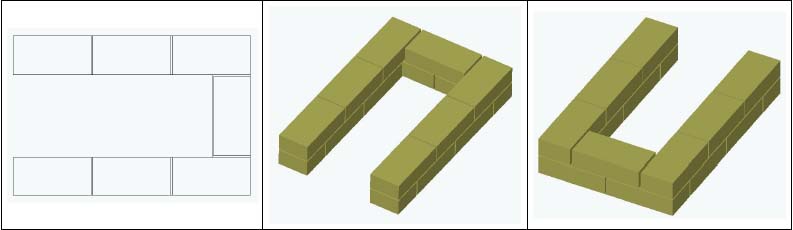

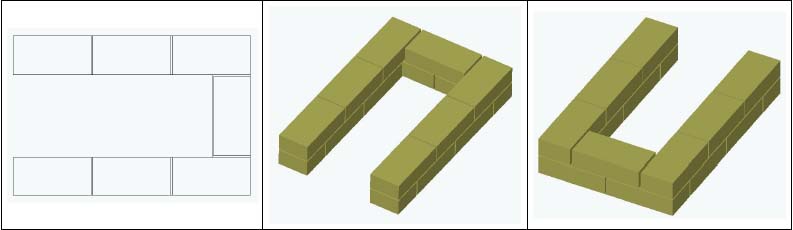

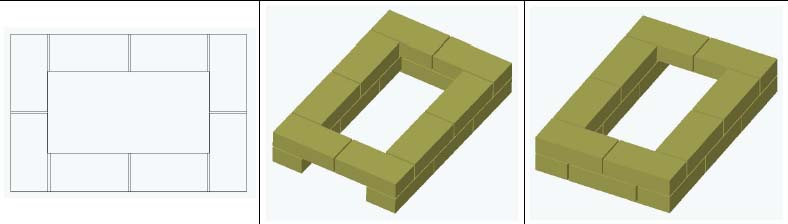

The stove, which we propose to fold with our own hands, has several names among the people: "Baby" or one-bell PTO-2300 stove. Its dimensions are 770x510x2380 mm. This design is well suited for suburban construction. The firebox is made of refractory bricks. The device can operate on almost any solid fuel, namely wood, coal, peat, anthracite.

PTO-2300 is the most compact of all thick-walled models. Below you can see a 2x3 brick oven with a fairly simple design. The name itself speaks of its power, i.e. the device can produce up to 2300 watts per hour. One firebox is enough to heat a 25 m² room or two adjacent 35 m² rooms.

Basically, a similar structure is installed in the central part of the house. Due to the shape of an elongated rectangle, it acts as a partition between rooms.

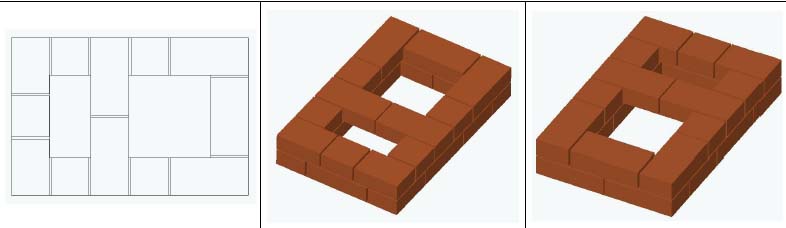

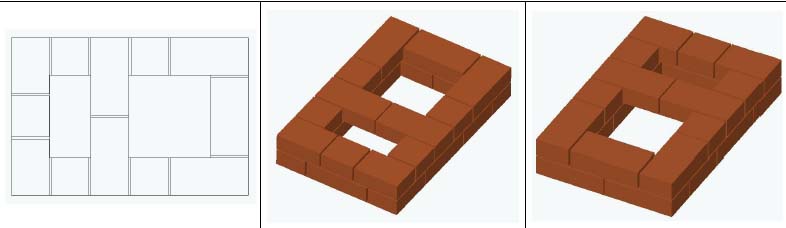

Features of the heating stove 4 by 4 bricks

Oven dimensions at the base 102x102 cm, and the height is 2 m. 10 cm. Minimum ceiling height, taking into account fire safety requirements - 2 m. 45 cm.

These parameters are approximate and depend on the size of the bricks. To find out the exact width and depth of the oven, it is necessary to lay out the first row.

In this case, a distance is left on the seams (about 5 mm). To determine the height of the furnace, add the height of the brick and the thickness of the seam, and then multiply by the number of rows.

If necessary, the oven is made higher. For this, the rows are repeated 23 and 24.

With a two-time firebox, heat transfer will turn out not less than 4480 W... This is enough to warm 35-40 square meters with proper thermal insulation.

The model has a straight stroke for easy kindling in bad weather. It is also used in summer, as the heating is noticeably reduced.

Device

In the presented furnace, hot gases rise through the supra-furnace channel into the bell (their path is indicated by arrows in the diagram). Further, the gases descend, bend around the "curl", enter the vertical channel and rush into the chimney, where two valves are installed.

In the absence of a convective system, a solid fuel stove would not have time to heat up. The hood serves to slow down gases and increase their contact time with brick walls.

You can download the high quality drawing at this Link.

Advantages of the baby oven

Among the main advantages are the following:

- The simplest design allows even a non-professional to build a furnace on their own.

- The device covers an area of only 0.4 m². Thanks to such dimensions, this heater is popular in country houses.

- A strong foundation is not required because the weight of the structure is low.

- The efficiency of the stove allows you not to make large reserves of firewood. In addition, it can be fired with other types of fuel: coal, peat, anthracite.

- The device does not contain heating ducts. Their functions are performed by the fuel cap.

- It can heat a room up to 35 m². In spring and autumn, one firebox will be enough to heat the room, and in winter, two.

- The structure can be installed in a wall, thereby saving space and uniform heating of two rooms.

Foundation

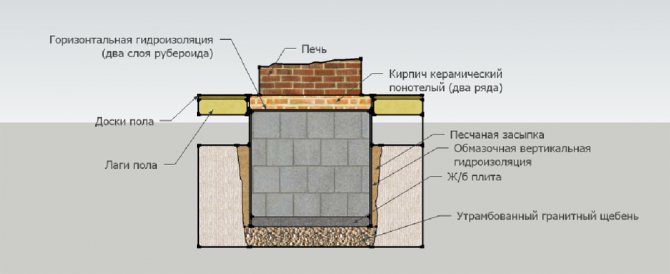

The foundation should be free-standing, not connected to the house. Depending on the material, rubble, rubble concrete and brick foundations are distinguished. Usually cement or lime-cement mortar is used.

The size of the foundation must be laid 5-7 cm larger than the dimensions of the furnace itself. In depth, it should be 15-20 cm below the floor. A cement-sand screed is arranged on top of the masonry. It is recommended to use a level and check its levelness. Then you need to lay two layers of roofing material and lay out 2-3 rows of bricks to the floor mark.

Operation of the device

After the structure is laid out, it is dried. In summer it will take 2 weeks. If the laying was carried out in the autumn-winter period, they begin to heat the stove with small chips for 30 minutes, once or twice a day. For additional ventilation, all cleaning doors and valves are opened (if it is raining, they do not open).

Photo 2. Finished furnace 3 by 3 bricks. The device is installed near a wall and has a very compact size.

When wet spots disappear from the surface, and condensation ceases to fall on the metal elements, the structure has dried out. After that, a control firebox is carried out - for several hours the stove is heated in full force at maximum draft. If there are no cracks in the masonry in the area of the firebox (small cobweb cracks are permissible), then the stove is ready for use.

Attention! You cannot immediately heat the stove strongly - this will cause cracking of the masonry and disable the structure even before the start of operation. As a result, the entire construction stage will take 1 month on average:

As a result, the entire construction stage will take 1 month on average:

- foundation preparation - 10 days;

- laying of the stove and chimney - 1-2 days;

- drying of the structure - 14-21 days, depending on the season.

After this period, if no shortcomings have been identified, you can begin to heat the stove at full strength.

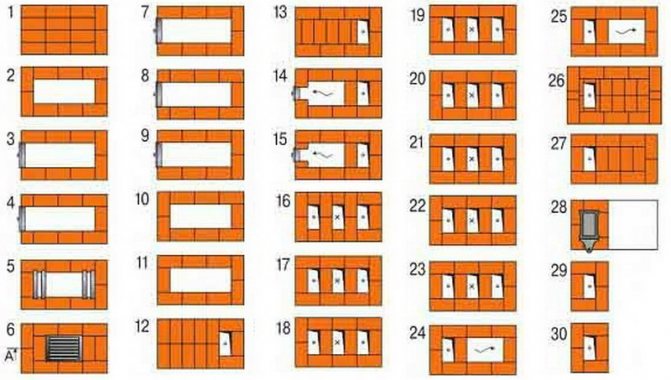

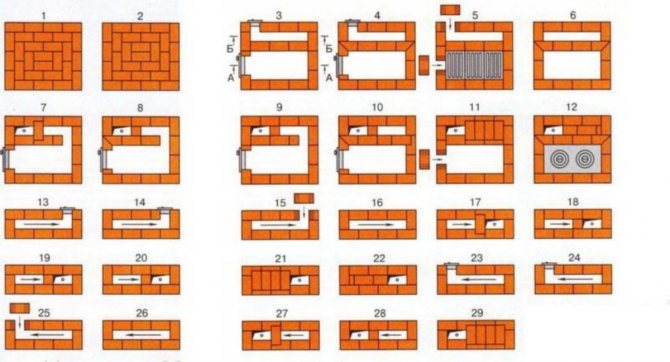

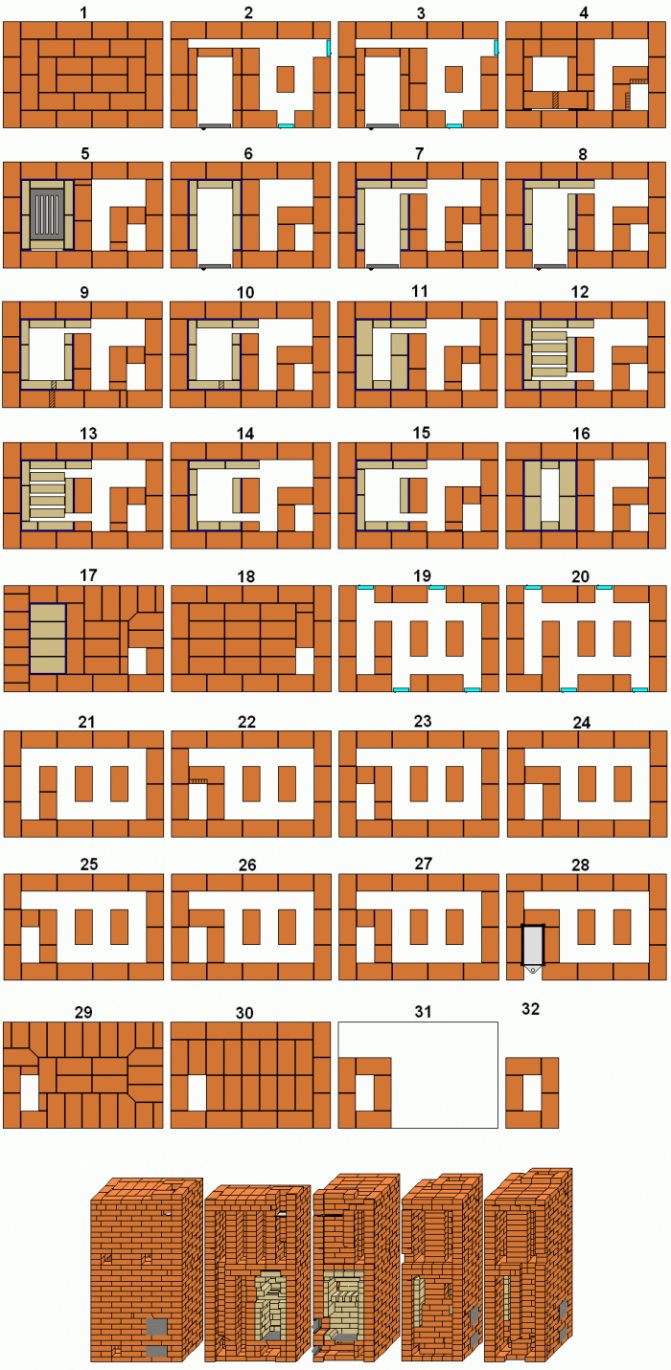

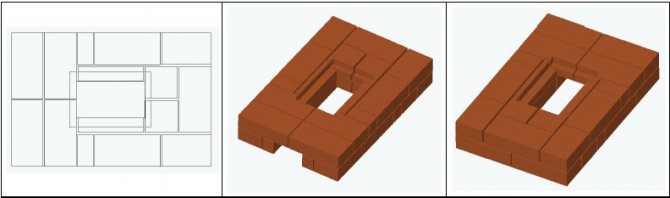

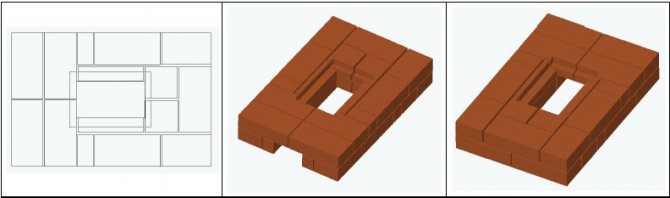

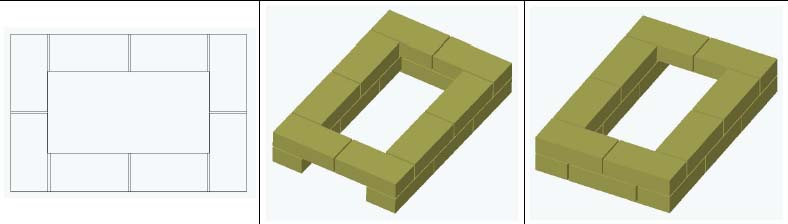

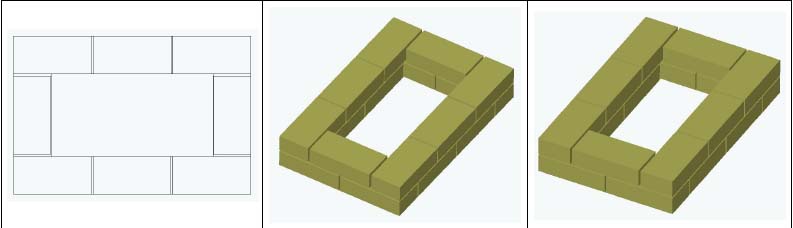

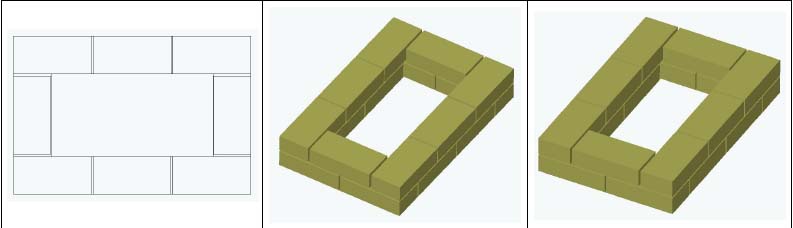

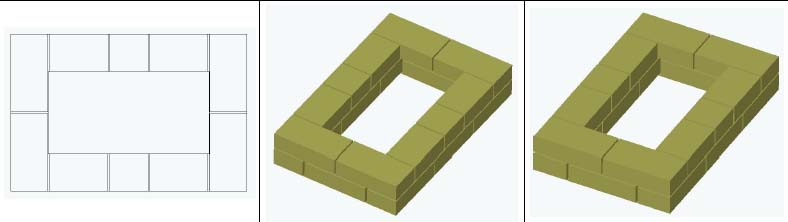

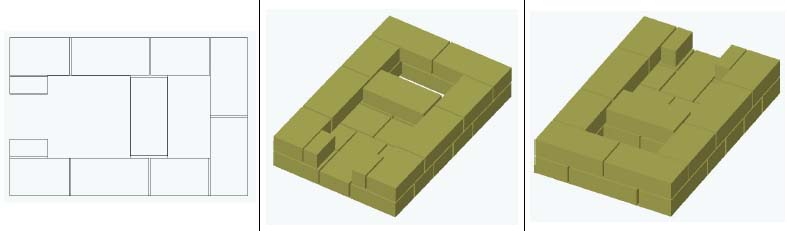

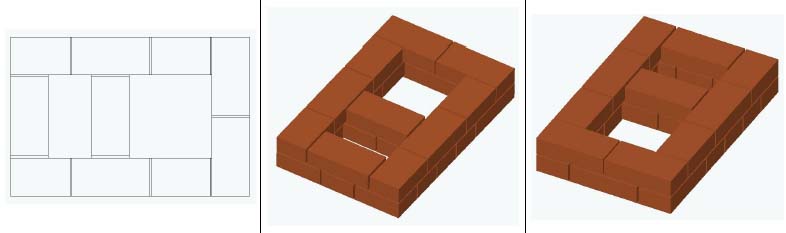

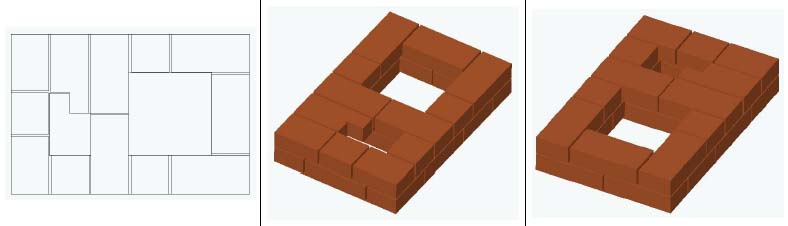

Furnace ordering

Below we will consider in detail the order of the heating furnace.

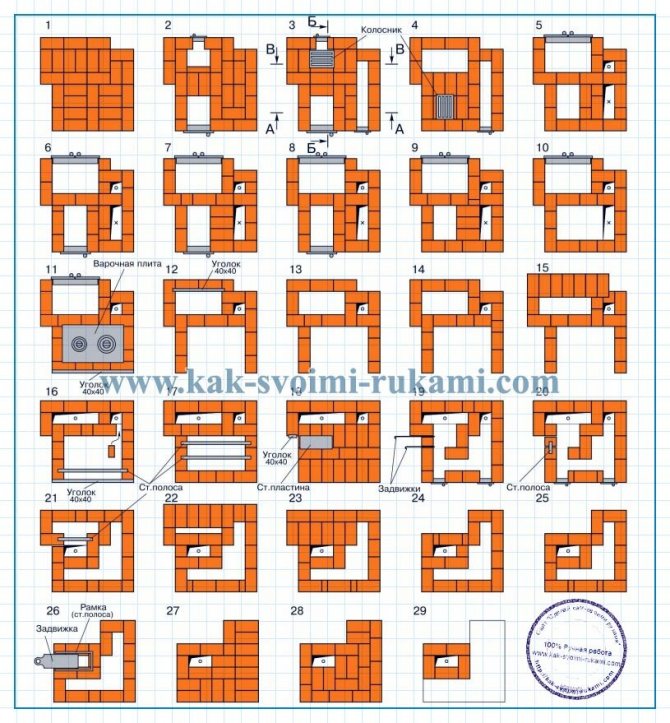

Row 0. As described above, you first need to lay out two levels up to the floor mark. They are placed on the waterproofing layer of the foundation. For this, roofing material is used.

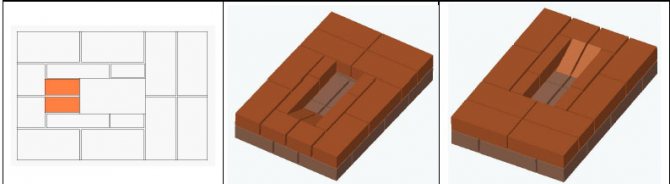

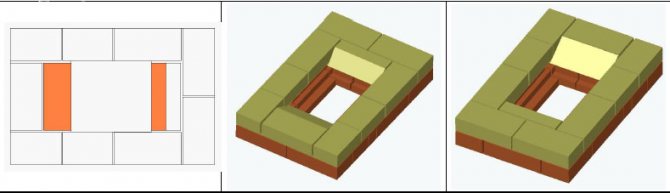

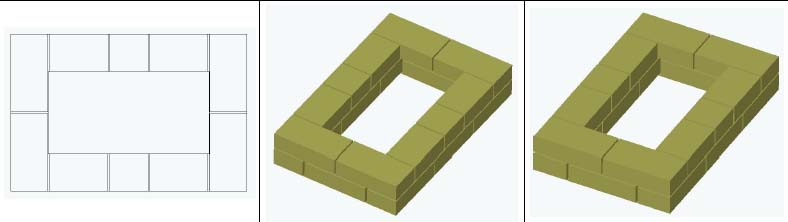

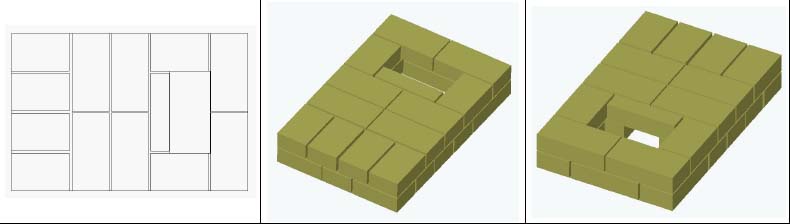

0 (1) row - solid. The number of bricks in a row is 12 (red).

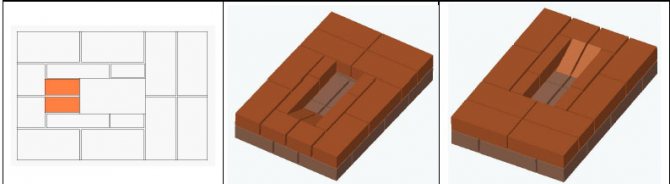

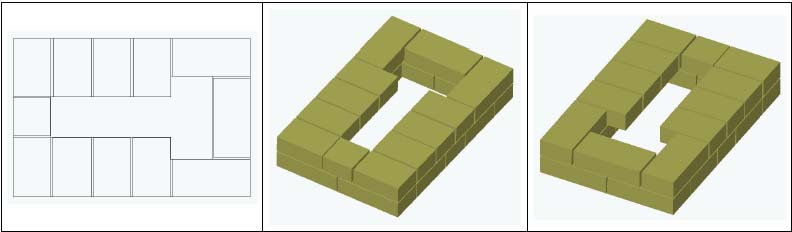

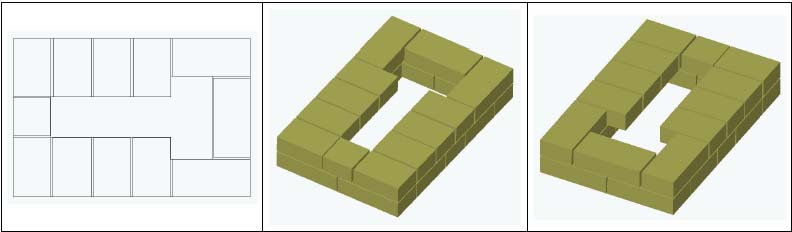

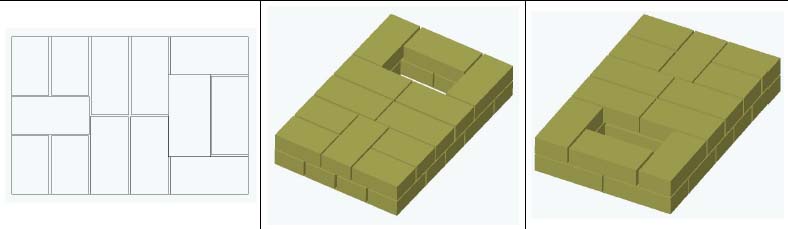

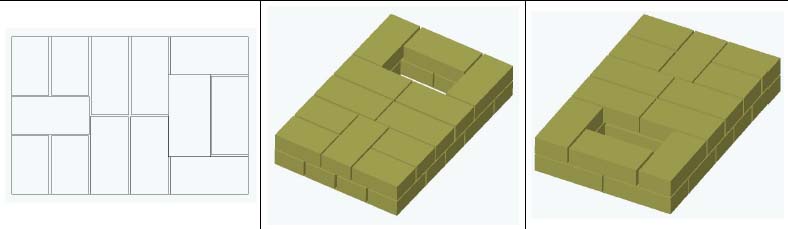

Row 1. An ash chamber is formed, where ash from products burnt in the oven will be collected. To make it easier to remove the residue from the combustion, two bricks are cut in the front part to the middle.

1 row. The number of bricks is 11 and ½ (red).

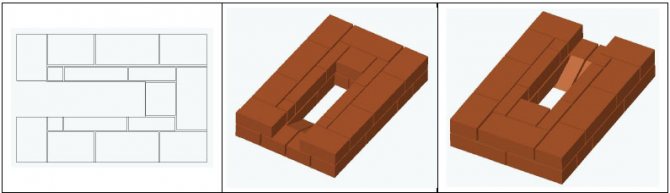

Row 2. We continue to form the ash chamber, for access to which a hole for the door is installed. Its size is 140x140 mm.

2 row. The number of bricks is 12 (red).

Row 3. Identical to the previous row and continues to form the ash chamber.

3 row. The number of bricks in a row is 10 and ½ (red).

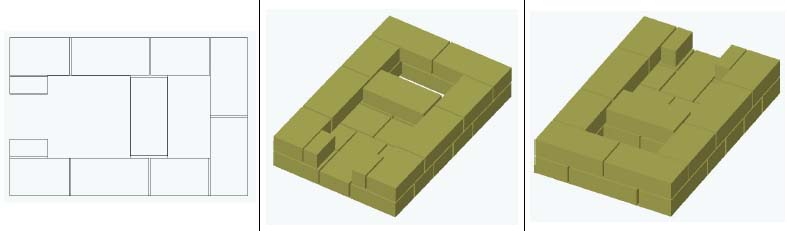

Row 4. Here the ash chamber is overlapped and grooves are cut in the bricks for the installation of a grate with a size of 200x300 mm. It is recommended to do this as follows: the existing grate is applied to the row without mortar, it is outlined along the contour with a margin (usually about 5 mm is left, which is necessary for thermal deformation of the metal). Next, each brick needs to be processed and cut. Then an estimate is made and everything is put on the solution. After that, the grate is immediately placed.

4 row. The number of bricks is 11 and ½ (red).

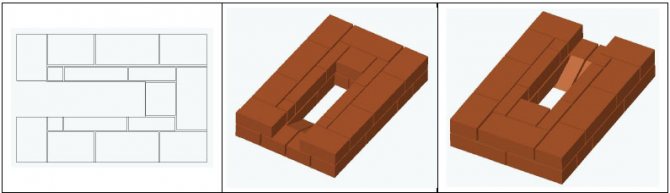

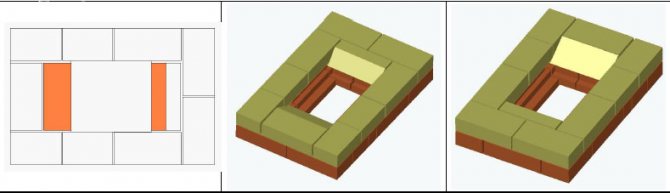

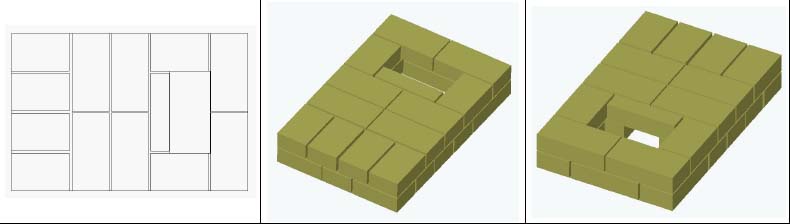

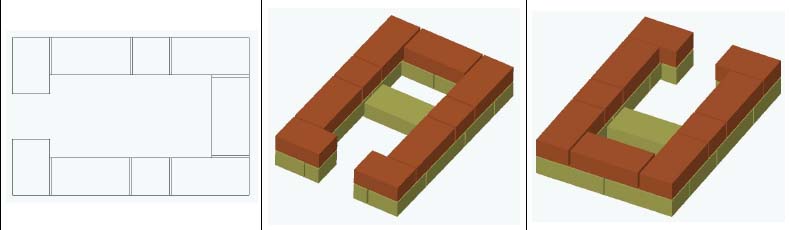

Row 5. Refractory bricks are laid, a fuel chamber is formed. Front and rear, it contains bevels of the inner surface towards the grate. This is necessary so that the combustion products can roll down to where there is sufficient air access.

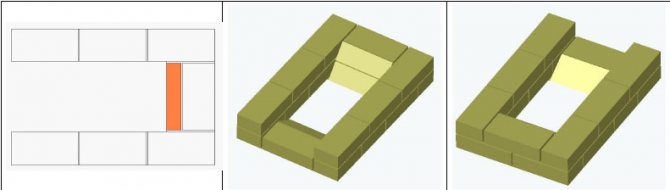

5 row. Bricks set at the front and back of the chamber are cut at a 45 degree angle. The number of bricks is 11 (fireclay).

Row 6. Continuation of the fuel chamber. Here the door for the combustion chamber begins to form. Its size is 250x210 mm. It should be noted that the rear brick has a slight bevel towards the burning area.

6 row. Cut the brick of the back wall of the chamber at an angle of 45 degrees. The number of bricks is 8 (fireclay).

Rows 7 and 8. Continuation of the fuel chamber.

7 row. The number of bricks is 7 (fireclay).

8 row. The number of bricks is 7 (fireclay).

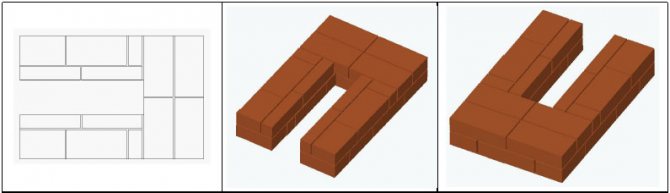

Row 9. The door of the fuel chamber is closed and its height continues to increase.

9 row. The number of bricks is 8 (fireclay).

Rows 10 and 11. A fuel chamber is being formed. It turns out to be quite voluminous. It is necessary to pay attention to the different arrangement of bricks at 10 and 11 levels.

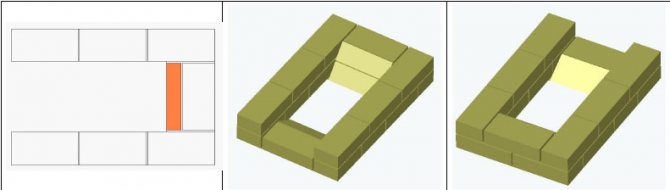

10 row. The number of bricks is 8 (fireclay).

11 row. The number of bricks is 9 (fireclay).

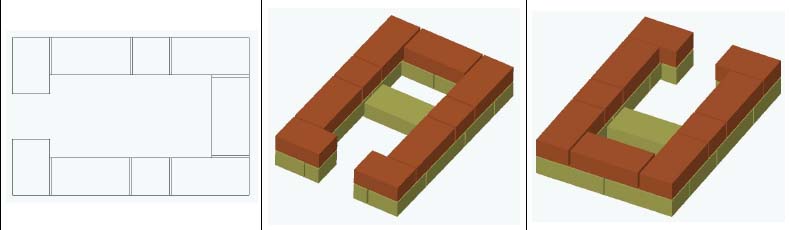

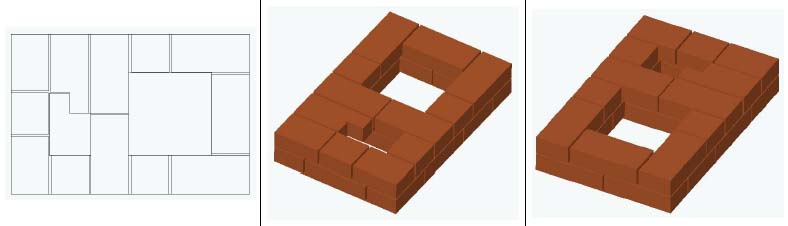

Row 12. The camera starts to overlap. Three-quarter bricks with an edge are installed, while leaving a vertical channel that will be used for the exit of gases.

12 row. The number of bricks is 11 and ½ (fireclay).

Row 13. The complete overlap of the fuel chamber continues, leaving only the vertical channel. Its size is similar to that of a whole brick.

13 row. The number of bricks is 13 (fireclay).

Row 14. The formation of the vertical channel continues. The chamber is covered by another level of fireclay bricks.

Row 14. The number of bricks is 12 (fireclay).

Row 15. A new vertical channel and a hole for installing the cleaning door begins to form. Its size is 140x140 mm.

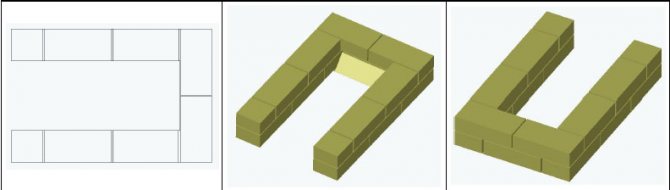

15 row. The number of bricks is 9 (fireclay).

Row 16. It uses ordinary brick. It should be noted that it is not placed in the center, since a connection is formed there between the first and second channels to ensure the passage of hot gases.

16 row. The number of bricks is 8 (red).

Row 17. The opening of the cleaning door is blocked. The channels are still connected to each other in the center, no brick is placed.

17 row. The number of bricks is 9 (red).

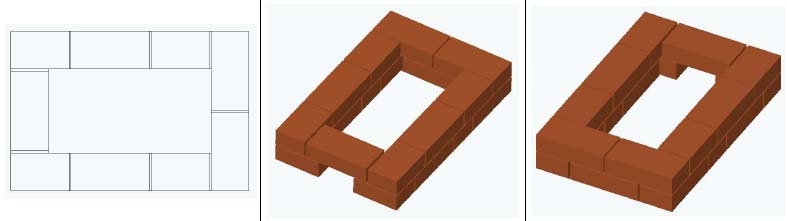

Row 18. The formation of the cap begins, which will continue to the very top. Subsequently, the front channel will go into the pipe.

Row 18. The number of bricks is 9 and ½ (red).

Rows 19, 20, 21, 22, 23. The configuration completely repeats the previous level.

19 row. The number of bricks is 10 (red).

Row 24. The opening of the vertical channel narrows in the shape of the letter G. A hole is formed for the valve.

24 row. The number of bricks is 10 (red).

Row 25. A hole is left equal to half the brick, and a seat for the smoke damper is cut out.

Masonry methods and order

We do the masonry

Stoves can be laid in various ways. This can be masonry with empty seams or undercut masonry.

Attention: These methods are fundamentally different. When laying in undercutting, the seams are completely filled, and such a stove is not plastered

The thickness of the walls of the furnace can be made in brick or half brick.

Only red solid bricks should be used for laying stoves. In this case, you cannot use bricks, second-hand, slotted bricks or other building materials that are not intended for this.

Masonry technology consists of several stages:

We cover the foundation with a layer of waterproofing. It can be a simple roofing material. We make the basement part. Its height is determined individually. Just don't make it too high. It is made by continuous masonry without voids.

We lay out the stove base

- The first row can be lined with bricks, without the use of mortar. After that, the bricks are aligned and the location of the front wall and the location of all doors are determined. After that, the laying is continued, but using a solution. As a rule, ordinary clay mortar is used for laying stoves.

- You can then install vertical beacons using plumb lines and ropes or fishing line.

- Furnace elements such as a blower, ash pan or combustion chamber are located depending on the design of the furnace. As a rule, the blower is located after the third row of masonry, and one row after it - the ash pan.

- Then the firebox is laid out. Fastening the door of the firebox and the blower is carried out using soft wire.

- The next in turn is the stove vault, which is formed after the second row of bricks laid above the firebox.

We make the combustion chamber only from refractory bricks

The combustion chamber is laid out with refractory bricks. To increase the efficiency of the furnace, it must be equipped with various valves that regulate the flow of heated gases.

Technological order of masonry

The order of laying out the oven is as follows:

- The first row is laid out without mortar and leveled using a building level.

- Bricks are laid out at the corners with mortar and strictly horizontally. After that, the space is filled with bricks, using mortar. This will be the first row.

- After laying out the first row, the evenness of the sides of the oven is checked using a tape measure. If there is a gap, then they are corrected with a mallet, knocking out one or another corner brick.

- After that, you can start laying out the second row. Laying begins from the corners and continues along the entire perimeter. After the perimeter is laid, the middle of the second row is laid.

- Then, at the corners, between the first and second row, nails 80 mm long are hammered in and using a plumb line they project an angle to the ceiling.

In the place of the projection of the corner, a nail is hammered and the rope is pulled from the bottom to the ceiling. This operation is done with all angles.

- The stretched cords will serve as a guide for further work. Subsequent rows, relative to the vertical, will be controlled by stretched cords that define the contour of the future furnace.

- All subsequent rows are laid out in the same way, controlling the horizontal with the help of a building level.During laying, you need to ensure that there is no excess solution, and the walls of the chimney should be wiped with a wet rag every 4-5 rows. In this case, you need to ensure that the solution in these places completely fills the seams.

- The brickwork for the oven is made as thin as possible and the joint is 100% filled. Masonry with thick seams is less durable, as they may partially fall out.

- The laying of the stove is carried out with the binding of bricks, otherwise it will not hold. The meaning of the dressing is that the vertical seam of the next row is somewhere in the middle of the brick of the previous row. It does not always come out and the vertical seam "walks" from the center of the brick to the left, then to the right. This should be constantly monitored and adjusted in such a way that the center of the vertical row does not go beyond ¼ of the brick.

- The cut brick lies outside the chimney, since the cut surface is considered weaker and can collapse under the influence of temperature.

Using fireclay bricks

Fireclay bricks have excellent resistance to high temperatures and are therefore used to form a combustion chamber.

- Due to the different coefficients of thermal expansion, the bricks of the combustion chamber are not tied up with the bricks of the furnace. There should be a gap of about 5 mm between them.

- When laying out a fireclay brick firebox, you can lay out a full row or, after laying out, lining the firebox with fireclay bricks.

Frequently asked Questions

Question: Is there enough chimney section 14x14 in this project? Answer: The power of the device is 1760 watts. With this parameter, the cross-section of the chimney is quite sufficient.

AT: On which solution is it better to put fireclay bricks? ABOUT: It is recommended to use a ready-mixed refractory masonry, which is sold in any specialty store. As a rule, the packaging contains instructions for its use. You can use a regular mortar, but it is recommended to add a refractory mortar to it in the amount indicated on the package. Pieces may come across in it, so you should either sift or additionally grind.

AT: The capacity of such a furnace will not be enough for a 6x6 m house, consisting of three rooms? The walls are made of adobe blocks or frame-panel. In winter, the average temperature is -10 ° C, however, there are frosts and up to 35-40 degrees below zero. ABOUT: For such conditions, this will not be enough. You need to use something the size of the Swede.

AT: If the stove is lengthened by four meters by extending the hood higher, will it function normally?

ABOUT: In practice, it has not been seen that the furnace was extended up to four meters. The design, of course, provides for a change in height due to the upper dome, but 4 m - this should be tried.

AT: Can a stove be made without a foundation by placing it on the floor? ABOUT: The weight of the structure, excluding the pipe, is almost 1.5 tons. Whether the floor can withstand this, see for yourself.

AT: Can the height be reduced? ABOUT: This can be done using rows 19-22 and 27-30. If you remove any two consecutive levels from the presented range, the construction will not be broken.

AT: Tell me, will this stove be enough to warm up two rooms (20 m² and 15 m²)? ABOUT: It all depends on how well the house is insulated and at what outside temperature you will heat it. If you intend to live in this house in the winter, it is better to choose a larger oven.

AT: What is the advantage of 2 dampers? Is it possible to leave only the top to simplify the design? ABOUT: The two valves keep the heat better. It is allowed to put one, but at the same time it must be tightly closed.

AT: Can these furnaces be made entirely of refractory? Will it be possible to underestimate the firebox and what will this affect? ABOUT: Refractory brick laying of the furnace is possible. The firebox should not be made lower. In this case, the fuel may not completely burn, soot will form.

AT: How is the issue with the difference in the sizes of ordinary and fireclay bricks solved? ABOUT: Due to the better geometry of the refractory material, the joints are thinner when laying. This hides the difference in brick size.

Fireplace stoves

| ANGARA fireplace stoves |

| Stoves fireplaces BAVARIA |

| Stoves fireplaces BAIKAL |

| Stoves fireplaces VARTA |

| Varyag fireplace stoves |

| Stoves fireplaces VIKING |

| Stoves fireplaces YENISEI |

| KOMANDOR fireplace stove |

| Stoves fireplaces LUARA |

| Stoves fireplaces MARSEL |

| Stoves fireplaces MOSCOW |

| Stoves fireplaces NARVA |

| Stoves fireplaces NEVA |

| NEMAN fireplace stoves |

| Oka fireplaces |

| Stoves fireplaces ОХТА |

| Fireplace stoves PEKHORKA |

| Stoves fireplaces PECHORA |

| Rein fireplace stoves |

| Caminetti RANGER |

| Stoves fireplaces SELENGA |

| Fireplace stoves ALMA MONS |

| Stoves fireplaces ASTOR |

| Stoves fireplaces BRUNO |

| BELLA THALIA stoves |

| Fireplace stoves CAROBNA |

| Stoves fireplaces CHAMANE |

| Stoves fireplaces CUCINA |

| Stoves fireplaces DACHA |

| Stoves fireplaces DIANA |

| Fireplace stove GRANDI |

| Fireplace stove GUNTER |

| ERIK fireplace stoves |

| EWA fireplace stoves |

| KLEMENS fireplace stoves |

| Stoves fireplaces LEDERATA |

| Stoves fireplaces MAGIC STOVE |

| Stoves fireplaces MARKUS |

| Stoves fireplaces NIKA |

| Stoves fireplaces NORTH |

| Stoves fireplaces OKTA |

| Stoves fireplaces PAUL |

| Stoves fireplaces PELLA |

| Fireplace stoves TS |

| Stoves fireplaces ZEIGE |

| By manufacturer: |

| Stoves fireplaces META |

| Stoves fireplaces ECOKAMIN |

| Fireplace stoves FIREWAY |

| Stoves fireplaces BELLA THALIA (BELLA TALIA) |

| Stoves fireplaces TIM SISTEM |

How to choose?

How to choose the right stove fireplaces

Every person wants to have his own home, the house needs strong walls, a reliable roof, warmth and comfort. There is hardly an alternative to the living, kind warmth of a stove or fireplace.

You can heat with gas (if there is a gas pipeline), you can use electricity, but the joy of communicating with wildlife, the joy of power over fire can only be given to you by a stove or fireplace in the house.

The hearth in which fire lives is a timeless thing.

Climate

When choosing heating in a house, do not forget about the climatic conditions. A normal winter in the middle lane lasts about six months. During this time, frosts are repeatedly replaced by thaws. Even the last month of spring, May, can bring a surprise in the form of frost or snow. However, for the owner of a house with a stove or fireplace, neither the whims of nature, nor interruptions in electricity or gas supply are terrible.

Today there is a large selection of different designs of stoves and fireplaces - from traditional Russian stoves and Dutch stoves to ultramodern fireplaces.

Operating mode

First of all, when choosing a particular model, the owner of the house determines the mode of operation of his home; based on this, you need to choose a stove, fireplace or a combined system. Our ancestors began to design their home with a stove. And this is a very important condition for a technically competent installation of the heater. At the stage of development of a house project, it is much easier to take into account all the conditions necessary for the construction of the foundation "for centuries", calculating the height and width of the chimneys. At the stage of starting the construction of a house, it is easy to fit into the interior a combined stove - a fireplace that heats two rooms at once (for example, a fireplace goes into the living room, and a stove with an oven - into the kitchen). With this arrangement, the owner of the house can not be afraid of any frost, as well as power outages. It is enough to take care of the stock of firewood in time - and you are not afraid of cold or hunger.

Style

The following fact is also important: a beautiful, neatly folded stove or fireplace is a wonderful decoration for the interior of your home.

In fact, there are not so many selection criteria: if the design and design (i.e. the choice of a portal or cladding) entirely depend on your imagination and the depth of your wallet, then only the right choice of oven power will not allow you to be disappointed in your choice.

Fireplace stove power

It is determined by the volume of the room that will be heated by the stove: an approximate, rough, but quite sufficient calculation is as follows: 1 kW per 14 cubic meters.

Firewood for fireplace stove

The rated capacity of the stoves is given for the conditions of using high-quality fuel, in the case of firewood it is firewood with a moisture content of 20 percent (these are firewood that was prepared in winter, stored in a dry place and put into operation next winter). How important this is can be seen from the example: 1 kg of firewood with 0% moisture will give 5 kW of heat, normal firewood (20% moisture) - 3.8 kW, and freshly prepared (60% moisture) only 1.5 kW. (for firewood of different breeds, specific kilowatts vary insignificantly, but the ratio for different humidity remains practically unchanged).

Which modes are better

In the mode of maximum power, the furnaces cannot work for a long time, 2-3 hours - no more, otherwise the furnace will overheat with many unpleasant consequences, therefore it is more important to turn to the nominal (average) power - this is the operating power of the furnace, at this power the furnace can work for a very long time (of course, with a report of firewood). But the minimum is just the power at which the stove will heat the maximum number of hours on one tab of firewood.

Manufacturers

On the Russian market there are fireplace stoves from both domestic manufacturers and firms from near and far abroad. The main domestic ones (now renamed into JSC "LAOTHERM") are the Neman fireplaces and a new model with an enlarged view of the Munich fire; group - fireplaces Angara, Volga, Ladoga, Neva, Onega, etc. (some models have modifications with ceramic inserts on the sides of the fireplace). Similar products are produced by the Belarusian-German joint venture "Vitep". And also presents cooking stoves fireplaces Bavaria. The models differ among themselves in the place of installation (corner and wall), the shape of doors and glass (straight, semicircular, bay window), dimensions, power and the presence of a stove or oven. One of the leading directions of the BELLA THALIA group is the production of fireplace stoves. Fireplace stoves are made using imported components in accordance with German technological standards, adapted to climatic conditions in Russia. The guaranteed quality is harmoniously complemented by an affordable price.

BELLA THALIA Group

She began her activity in the design, manufacture and sale of fireplace stoves more than ten years ago. The production workshops of the company employ professional craftsmen who use their experience, the latest developments and technologies for the manufacture of fireplace stoves.

Also, the BELLA THALIA group has its own production, which assembles fireplace inserts under the brands BELLA THALIA ™, EUROKAMIN ™ and ARDENNES ™. All furnaces are certified and have a guarantee subject to the requirements for installation and operation. In 2006, two unique products developed and manufactured on the basis of BELLA THALIA ™ fireboxes appeared on the market. This is a DUET fireplace set - a combination of a firebox with a cladding, in the decor of which an artificial stone is used, which has a high heat resistance and heat capacity. Another novelty is a fireplace stove that does not require additional cladding - VIKING.

Fireplace stove installation

To protect the glass from contamination, firewood must be placed so that the cut surface looks to the side. The fireplace stove must be installed in rooms with a sufficient supply of air for combustion. The chimney must be high enough (at least 5 m). It is permissible to bind only one more oven in the same pipe. The diameter of the smoke channel must be equal to or greater than the diameter of the smoke outlet of the OHTA fireplace stove. The dimensions of indents and cuts when installing a fireplace stove must comply with the requirements of SNiP 2.04.05-91. The floor on which the fireplace is placed must be flat and horizontal, made of non-combustible and hardly combustible materials under the door of the combustion chamber and the tray for collecting and removing ash must be protected by a steel sheet with a size of at least 700 × 500 mm. Not less than 0.5mm thick. The installation of the fireplace stove must be carried out in such a way that the temperature of the surrounding combustible materials, during the operation of the device, does not exceed 50 ° C. It is forbidden to install fireplace stoves in industrial premises of categories A, B, C, as well as in garages and other premises with available fuel and lubricants.

Features of the

Stoves fireplaces AMUR.

Corner fireplaces are in demand precisely because of their shape, because. when installing a fireplace stove in a corner, a lot of space is saved and, if necessary, it is easier to heat as many as three adjacent rooms with one fireplace.

ANGARA fireplace stoves

... Hangar - all glazing is enclosed in one door, which gives the visual effect of much larger glazing.And also with WATER CIRCUIT AQUA series.

Stoves fireplaces BAVARIA.

All variants have hobs, and some have ovens. At the same time, observation windows allow you to admire the flame and assess the readiness of the food.

Stoves fireplaces BAIKAL.

The manufacturer pampered with the presence of different colors and styles, and also did not forget about large houses. BAIKAL has everything.

Stoves fireplaces VARTA.

Stoves fireplaces Warta Stoves fireplaces with arched sight glass with and without stove. Tiled side cladding. Large sight glass, excellent heating performance. Now also with WATER CIRCUIT AQUA series.

Stoves fireplaces VARYAG.

The design of the Meta Varyag furnace resembles the legendary Armored Cruiser of the same name. Varyag controls are made of stainless steel. The glass air control (clean glass system) is made in the form of a large gear, which emphasizes the industrial style of the Metafire oven.

Stoves fireplaces VIKING.

Viking fireplace stoves will perfectly fit into a small room and will complement the interior favorably due to their laconic design. Solid with a large sight glass.

Stoves fireplaces VOLGA.

Volga fireplace stoves - one central door and two fixed side windows.

Stoves fireplaces YENISEI.

Stoves fireplaces Yenisei The most powerful fireplace stove from the BELLA THALIA family.

Stoves fireplaces KOMANDOR.

The Commander fireplace stoves are another most powerful fireplace stove from the BELLA THALIA family.

Stoves fireplaces LENA

... Ladoga stoves LENA - both will warm up and heat food. The LENA fireplace stove is a great find for an average summer cottage, having unique shapes, a unique design of curved lines to the base.

Stoves fireplaces LUARA.

Stoves fireplaces Loire The steel stove fireplace LOIRA is a modern design find, which, perhaps, has no equal. Small, compact, its feature can also be called installation freedom.

Stoves fireplaces MARSEL.

An elongated shape can rightfully be considered an unusual find of such a fireplace stove. This shape will allow you to fit a fairly powerful fireplace even into a space limited by the wall.

Stoves, fireplaces MOSCOW.

Stoves fireplaces MOSCOW Steel stove fireplace MOSCOW has a wall position and stunning heat-resistant panoramic glass on three sides. The possibility of connecting the chimney from the back or from the top

Stoves fireplaces NARVA.

Fireplace stoves Narva NARVA is a small and very popular fireplace stove - as a rule, it is taken to heat small summer cottages, or to heat a room in the attic and very often to heat a rest room in a bathhouse in winter. And now with the stove.

Stoves fireplaces NEVA.

Neva fireplace stoves are in demand precisely because of their shape, tk. when installing a fireplace in a corner, a lot of space is saved and, if necessary, it is easier to heat as many as three adjacent rooms with one fireplace.

Stoves fireplaces NEMAN.

Neman fireplace stoves save space due to their elongated shape and decorate, visually increasing the height of the room.

Furnaces fireplaces OKA.

Oka fireplace stoves are a slightly smaller and, accordingly, slightly less powerful clone of their brothers, with a lower price.

Stoves fireplaces OKHTA.

Stoves fireplaces Okhta are intended for installation in premises with temporary stay of people and are not intended for continuous operation. The fireplace stove has a hob.

Stoves fireplaces PECHORA.

Pechora fireplace stoves are in great demand. Now also with WATER CIRCUIT AQUA series.

Furnaces fireplaces PEKHORKA.

An interesting design find, pay attention - an original stylish handle and a comb on the glass, which definitely puts it above its analogues in terms of uniqueness and relevance in modern design solutions! In addition, the fireplace stove has all the modern advantages of wood-burning steel stoves.

Rein fireplace stoves.

The Rhine fireplace stoves have an excellent 360-degree view of the burning flame, creating frontal and high windows and doors.

Stoves fireplaces SELENGA.

Stoves fireplaces Selenga are convenient for heating a summer cottage, a garden house, a small cottage.

Stoves fireplaces BELLA THALIA (BELLA TALIA).

Made in original brutal design. The stove is available in various colors.

Stoves fireplaces CAROBNA (CAROBNA).

The fireplace stove is made in an original design.The most budgetary oven from TIM SISTEM.

Stoves fireplaces CUCINA (KASINA).

The fireplace stove CUCINA (KASINA) has a nice design. The upper plate and the door of the firebox are made of cast iron. An oven is located in the upper part of the model. The CUCINA fireplace stove (KASINA) is available in different colors of the side parts.

Stoves fireplaces GRANDI (GRANDI).

The GRANDI fireplace stoves are distinguished not only by their spectacular appearance, but also by their versatility - an oven is located in the upper part of the model.

Stoves fireplaces EWA (EVA).

EWA fireplace stoves (EVA) are ideal if you want to maximize the usable area of a small room. The top plate, doors and ash pan are made of cast iron. You can cook or reheat food on the top plate. The material for the manufacture of the model body and other elements is heat-resistant steel.

Stoves fireplaces NORTH (NORT).

NORTH fireplace stoves are a dream and a true property of the hostess! A very beautiful wood-fired kitchen stove designed for cooking various dishes on the stove or in the oven.

Stoves fireplaces OCTA (OCTA).

The OCTA stove is compact, convenient and available in various colors.

Stoves fireplaces PELLA (PELLA).

Fireplace stoves PELLA (PELLA) have two types of materials: cast iron - for the door of the combustion chamber and the top plate, which can be used to heat food; structural steel - all other elements. The side surfaces of the product are elegantly lined with white panels. Available in different colors.

Stoves fireplaces TS (TS).

Fireplace stoves TS (TC) are compact fireplace stoves that are easy to transport and install. The model is installed directly on the floor surface on the stable legs included in the kit.

Cast iron stoves fireplaces PAUL (PAUL).

Cast iron stoves PAUL fireplaces - the optimum between size, price and power, yes, plus a versatile and great design! The main feature characteristic of the FireWay fireplace stove is its low weight and high power. Moreover, each fireplace stove can be used for cooking as well.

Cast iron stoves and fireplaces BRUNO (BRUNO).

If you need to emphasize the entire texture of the cast iron fireplace stove, then this is what you need! The main feature characteristic of the FireWay fireplace stove is its low weight at high power, the fireplace stove can also be used for cooking.

Pig-iron stoves fireplaces DACHA (DACHA).

Cast iron stoves fireplaces DACHA (DACHA) Successful coincidence of the name. The stove fireplace DACHA is just ideal for giving! The main feature characteristic of the FireWay fireplace stove is its low weight with high heating power and for cooking.

Cast iron stoves fireplaces GUNTER (GÜNTER).

Cast iron stoves fireplaces GUNTER (GÜNTER) are the widest and most powerful of all cast iron stoves of this manufacturer. You can cook.

Cast iron stoves and fireplaces MARKUS.

Austere, solid and small stove fireplace MARKUS ... You can cook! Beloved fireplaces MARKUS (MARKUS) have already been nicknamed - "the best alternative to a stove."

Cast iron stoves fireplaces KLEMENS (KLEMENS).

Cast iron stoves and fireplaces KLEMENS are amazing for white designs. Looks great in contrast, and even drowns excellently!

Cast iron stoves fireplaces ZEIGE (ZEYGE).

The smallest cast iron fireplaces with excellent performance and an inexpensive price for excellent cast iron! Customers have already affectionately called her "the new old stove." Combines cooking functions.

Price lists

Quick access to prices for the entire range of Pechki-Lavochki products:

:: fireplace stoves. :: sauna stoves. :: heating stoves. :: fireplace inserts. :: fireplace linings. :: chimneys. :: chimneys, wholesale. :: tanks. :: tanks, wholesale. :: stove elements. :: related products.

Our shop

You can purchase all the products presented on the site in our store, for wholesalers and large buyers special favorable conditions:

Score: MKAD, 43 km

.

Clarification of the assortment and orders with home delivery:

For Moscow and the region: (499) 391-94-28,

Free calls to all regions of the country: 8(800) 234-21-47.

Installation of stoves, installation of fireplaces, installation of a chimney: (499) 391-94-28, (910) 478-54-29, (925) 065-48-01.

We are in social networks