The advantages and disadvantages of such a connection

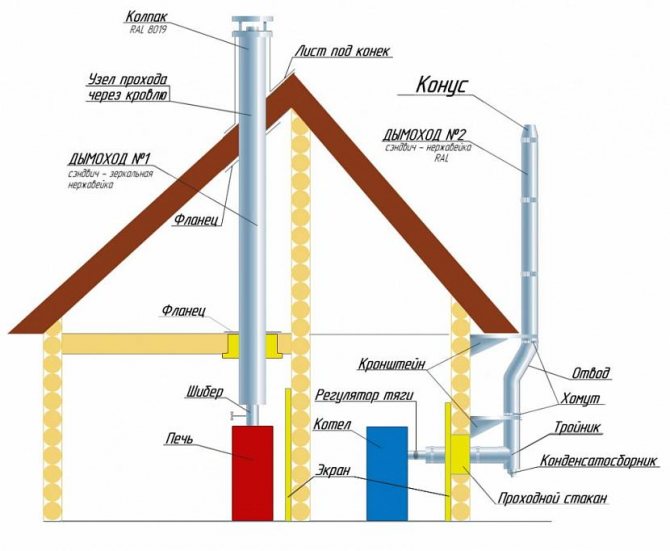

Switching to stainless steel sandwich pipes provides the following advantages:

- easier and faster installation of a new chimney;

- you can do the installation yourself;

- less expensive;

- the design is lighter in weight, smaller in size;

- soot and other combustion products do not accumulate on smooth walls;

- the device can be brought out both through the roof and through the wall;

- the presence of an insulating layer, which to a certain extent reduces the amount of condensate;

- the possibility of installation through the rafter system.

The disadvantages of sandwich chimneys are the same as for all modular smoke extraction devices:

- over time, some loss of tightness at the joints;

- significant price of the kit and its installation;

- service life limitations (15-30 years).

Pros and cons of sandwich pipes

Manufactured stainless steel chimney systems. In order to prevent the formation of condensation between the two metal layers, a basalt insulation is attached. The main disadvantage of the chimney blank is its relatively high cost. The tightness of the flue gas outlet system from the furnace may be compromised. The main advantages of sandwich pipes:

- ease;

- resistance to environmental influences;

- multilayer structure, preventing the accumulation of moisture and combustion products;

- high temperature resistance;

- quick installation;

- do not deform when exposed to chemicals;

- rarely get dirty.

A metal chimney can be installed for all types of furnaces and boilers.

Do the work yourself or call the wizard

Assembly and installation of a sandwich chimney is feasible for almost every middle-aged man, taking into account the need to work on the roof. However, it must be borne in mind that a mistake in design, choice of a kit, installation of a structure can lead to unstable operation of the stove or fireplace, the appearance of carbon monoxide in the house. As a result, to eliminate the negative consequences, additional cash costs, loss of time and nerves will be required.

In order to save them, it may be better to invite professionals with experience in installing this type of chimney.

Why the sandwich transition is attractive

It should be noted that this installation technology has a number of important advantages, moreover, it has practically no drawbacks. And the most interesting thing is that, if you wish, you can always carry out the necessary work related to the design, as well as the construction of the chimney yourself.

- It is not at all necessary to clean the chimney several times a year and it will save a lot of time.

- The material is fire resistant and you can use almost any type of fuel.

- Also, this design perfectly tolerates the aggressive environment that occurs when exhaust gases are removed, as a result of which it is durable.

- To ensure normal functioning, it is necessary to carry out preventive procedures once every few years. You must correctly assemble the communication, so that smoke and combustion products will be discharged into the atmosphere without settling in the room.

- To get a good result, it is imperative to use high quality materials, they should not let you down, so give preference to trusted brands.

The price of such a structure is not high, especially when compared with brickwork. After all, only a specialist can do this. But if you need a brick for a general design, then you can always cover the pipe with a facing brick and it will turn out to be much cheaper.

Estimated cost of work

The cost of installation work for installing a sandwich depends on:

- assembly channel length;

- the height of the house;

- type of roofing;

- roof configuration.

So the fee for the standard installation of a chimney for a private house with a roof ridge height of up to 6 m will be from 26 thousand rubles. As a rule, the price is specified by the master directly on the spot.

Often the installation price is set per running meter, on average from 1,700 rubles per running meter.

Installing the outside of the pipe

The outer can be assembled from other materials. The transition of the "sandwich" pipe to the outside is assembled taking into account the parts used. The main rule that must be observed is that each joint must be completely sealed. Smoke tends to seep into any gap, which is fraught with negative consequences.

If the combustion products are not completely removed outside the premises, then this will negatively affect the health of all residents. Smoke will also negatively affect the state of the house, exerting its destructive effect on all the elements with which it will interact.

"Sandwich" on a brick pipe is one of the most common types of joints. This is not surprising, given that such an external chimney has the best durability and is easy to design and build. The brick is well protected from destructive weathering and is adapted to work with high temperatures. Now we are talking about heat-resistant brick, which is used in the construction of fireplaces, stoves and chimneys.

Which way is better

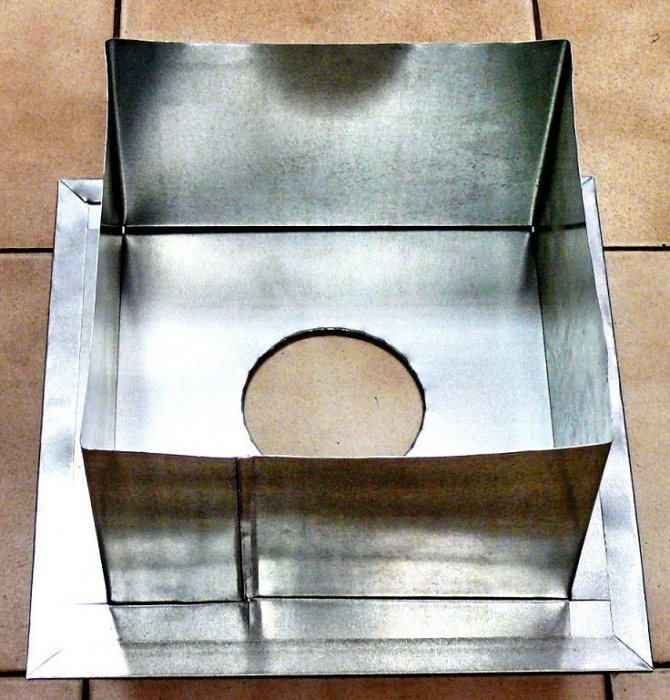

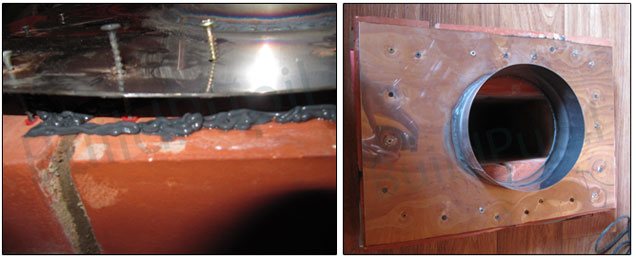

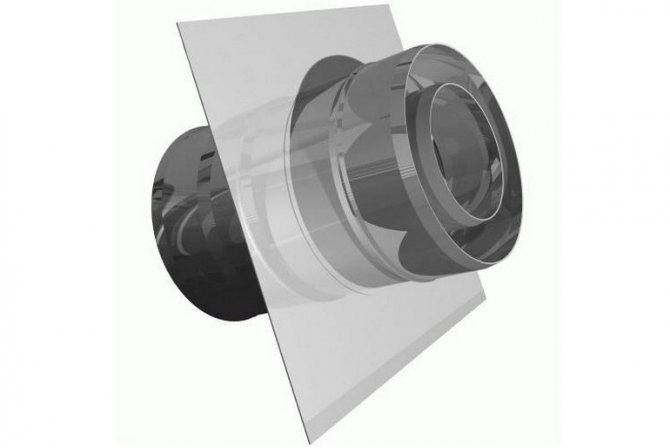

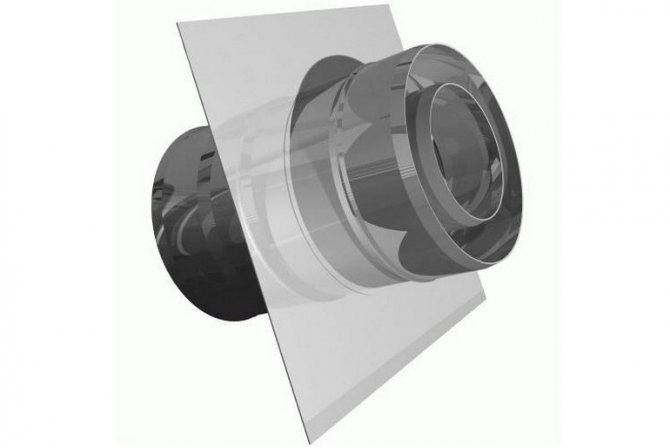

The most versatile adapter is made in the form of a metal mounting platform, with two nipples in the middle: one at the top, the other at the bottom. The site is laid on an old brick channel, sandwich pipes are inserted into the nozzles. When docking, as a rule, gaps are formed, for which sealant is used to seal. A simple adapter of this type can be ordered from a professional tinsmith. This photo shows the above adapter.

In the second method, an inner pipe of a double design is placed into the prepared hole, the gaps are closed with an oven solution. The outer pipe, resting on bricks, is coated at the joints with the same mortar.

In any case, the main requirement is to ensure the tightness of the structure. Therefore, only a special refractory sealant for chimneys is used as a hermetic composition.

Of course, the use of adapters reduces labor costs for installing the chimney and makes the connections more reliable and durable.

Design features

Modern ducts for removing smoke from sauna stoves are assembled from pipe sandwich parts. Products are popular among owners of country houses, despite the large selection of materials for creating chimneys.

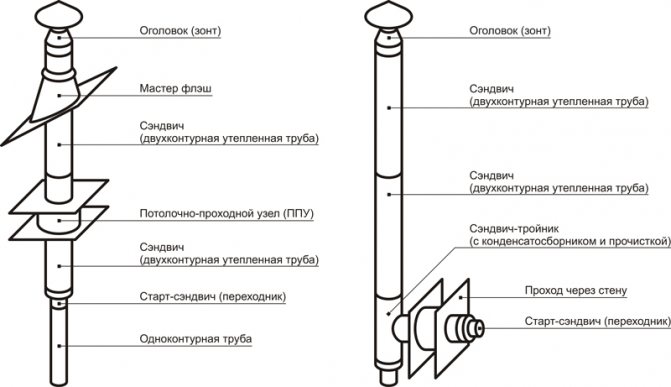

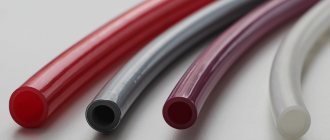

The sandwich pipe is a double-circuit design. It consists of the following main parts:

- internal chimney;

- a layer of heat-insulating material;

- protective decorative shell - an outer contour in the form of a tubular product of a larger diameter compared to the internal chimney.

The double-circuit pipe has become commonly used by homeowners when installing chimneys. She came to replace single-circuit similar products made of steel with a thickness of 0.5 mm. After all, a steel pipe product is not suitable for installing a smoke exhaust duct outside the building. The reason for this is its design, which does not retain heat in the off-season and winter period of the year. In cold weather, condensation forms in a steel channel with one circuit due to a sharp temperature drop. Therefore, the draft effect in the chimney decreases, and even plugs appear.

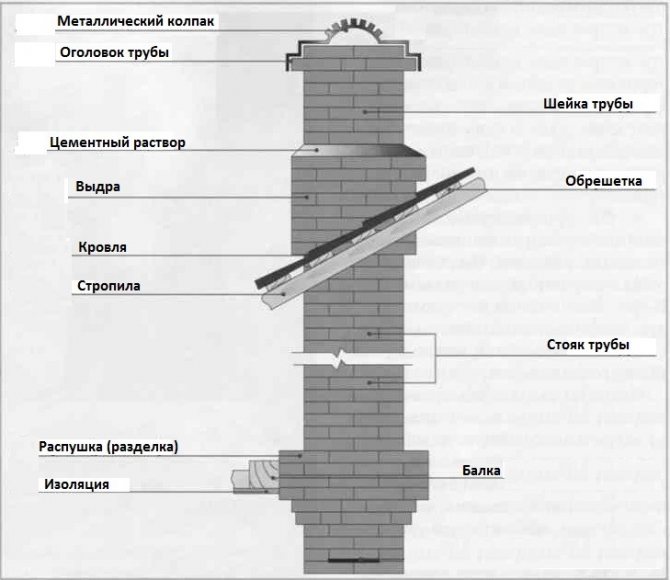

Design features of a thermal pipe with two casings Source pechnoy.guru

The inner contour of a pipe sandwich product for the removal of combustion products is made of stainless steel. Its one-piece construction is manufactured using TIG welding. It allows you to make neat, thin seams.

The outer casing is also welded from stainless steel or galvanized steel. The second type of metal allows manufacturers to produce more affordable products. In cooperation with the construction and installation organization, it is also possible to order a chimney from a sandwich pipe with an outer casing that has an enamel coating of the required color.

The thermal insulation layer in a product with two contours is created from a material that is resistant to fire. Manufacturers use high-density mineral wool from basalt raw materials. Typically, the thickness of the thermal layer is 25-100 mm. Design engineers select this parameter, taking into account the peculiarities of the installation work and the conditions for using the chimney.

Chimney with a heat-insulating layer of basalt mineral wool Source festima.ru

The ends of the sandwich parts for the flue gas duct are made in the form of sockets and tapered ends. Such an interface system simplifies the installation process and allows the elements to be tightly coupled. To increase the strength of the joints when installing the chimney, special clamps are additionally used. Depending on the design features of the smoke exhaust duct and the working conditions, parts can be used that are connected to each other and other elements of the furnace system using flanges.

Crimp Type Clamp for Sandwich Chimney Source ytimg.com

GOSTs and standards

The connection of the sandwich to the brick pipe must be carried out in accordance with the general rules and regulations established for the installation and operation of chimneys.

The total height of the brick and sandwich chimney from the fireplace or stove to the head must be at least 5 m, which provides the required draft.

The assembly joints of the segments of the double device, the transition itself, are mounted so that they do not coincide with the ceiling and rafter floors.

The inner pipe must be made of stainless steel that meets the requirements of GOST.

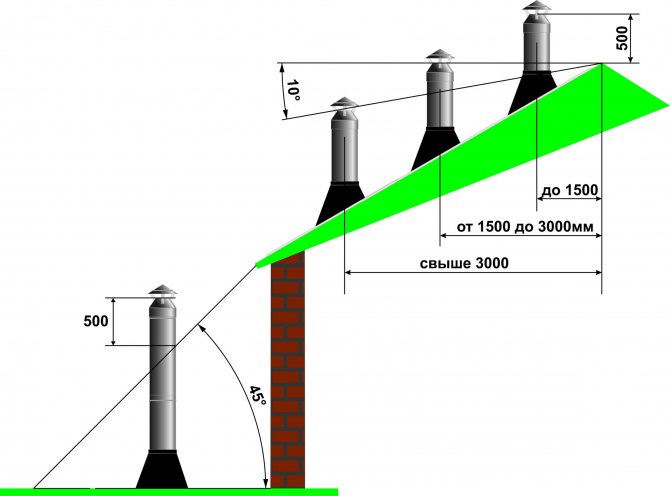

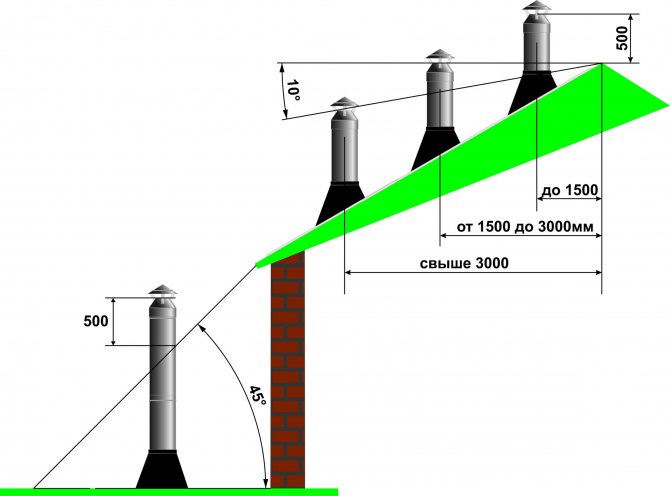

The head of the sandwich is placed 50 cm above the roof ridge and at a distance of 150 cm from it.

You need to know that wood can ignite at constant heating at 170 ° C. In this regard, compliance with fire safety standards is of particular importance. In the passages through the ceiling and roof, cutting is carried out - laying of a thermal insulation layer. The distance from the inner pipe to the edge of the ceiling in the passage must be at least 38 cm.

How to assemble a chimney correctly?

Fire safety rules when installing a chimney prescribe the observance of certain standards. For wiring a sandwich pipe through wooden structures, high-quality thermal insulation of metal parts from wood (or any other combustible) is required.

In the case of a finished metal pipe, it is possible to purchase ready-made structures that insulate the roof from the effects of heat (pass-through unit) and precipitation (oblique pad and protective corrugated flange).

Rules for assembling a sandwich part of a chimney:

- The assembly of the structure is carried out from the bottom up.

- Metal parts are inserted into one another according to the principle of socket connections. The joints are sealed with a special non-flammable compound and reinforced with clamps (special clamps).

- There should be no joints in the pipe section through the floors. This is a fundamental fire prevention rule when assembling a chimney structure.

- If the roof is made of flammable material, it is necessary to install a spark arrestor on the pipe head. In any case, a protective cap is required.

- To secure the high structure, I use tension cables.

General rules for installing the transition:

- The metal part of the pipe can be partially recessed into the brick part according to the sleeve principle.

- It is unacceptable to reduce the inner part of the channel or install mechanical barriers (protrusions, fittings) for the passage of combustion products.

- To ensure tightness, a black oven sealant with a resistance of up to 1500 degrees is used. If the pipe is not supposed to be disassembled, then the sealant passes through the inside of the pipe. If the structure will (in the future) need to be disassembled, then only the outer seam is sealed. Later, during disassembly, the sealant is removed by mechanical action (broken).

- To switch from a square shape to a circular section, a support platform (square) and a branch pipe (cylinder) are required. Better if it is a one-piece construction.

We recommend that you familiarize yourself with: HDPE pipe for laying cables in the ground

There are several options for switching from a brick chimney to a sandwich pipe. Each of them has its own advantages.

DIY step-by-step connection technique

Video: installing the adapter and the passage of the ceiling:

Let's consider how to place the correct vertical sandwich pipe on an old brick channel.

- They dismantle an unusable part of a brick chimney.

- Prepare the adapter for installation: unbend the bends, cut off the outer rim at the bottom.

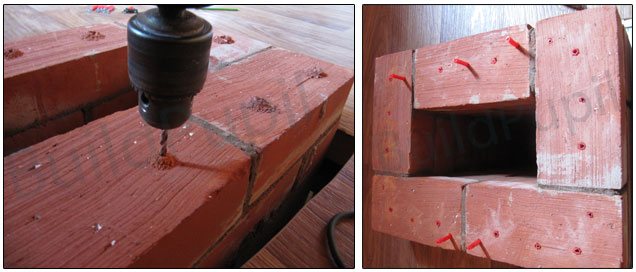

- Insert the mounting platform with the lower branch pipe into the channel of the old chimney on the oven mortar, fasten it at the corners with dowels to the bricks.

- Then the first segment is installed in the upper branch pipe and then the entire pipe in the assembly.

Required tools and materials

- For dismantling, you will need a puncher, a chisel, and a heavy hammer.

- To cut a hole in the masonry - a circular saw.

- For installation and fasteners - oven mortar, trowel, sealant, screwdriver, self-tapping screws.

Work progress

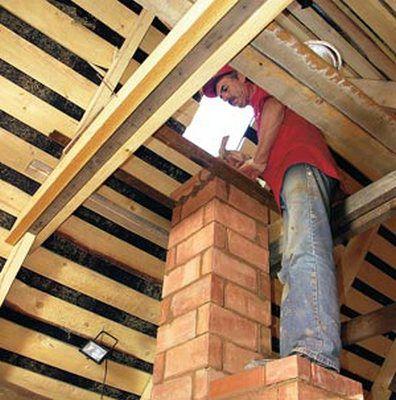

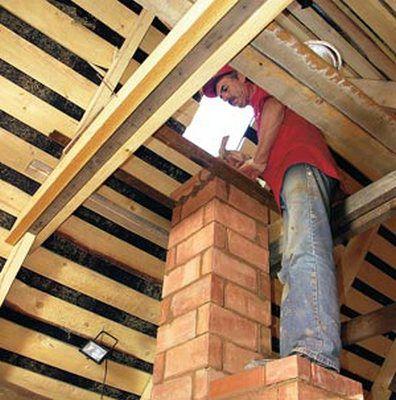

Often, the part of the old brick canal in the house is in good condition. Therefore, the output in the attic and roof is dismantled.

In this case, dismantling begins, before reaching the ceiling of 20 cm, prepare a flat surface for the adapter.

The gaps between the nozzle and the brick are sealed with a heat-resistant sealant.

In the places of passage through the attic and the roof, a fireproof platform is made.

The assembly joints of the sandwich, if provided by the manufacturer's instructions, are additionally secured with clamps.

On the roof, the pipe is fixed with a special roofing element, sealed with a silicone nozzle, and the external design of the chimney is made.

Installation features

If the brickwork has to be disassembled close to the brick oven, then the first link of the transitional chimney is better to make a thick-walled single steel pipe made of stainless steel. This area, especially in sauna ovens, is characterized by high temperatures during peak loads. The pipe with insulation will overheat and burn out quickly.

To protect the chimney from wind and rain, improve traction and smoke exhaust, a deflector is put on top of the pipe, securing it with galvanized self-tapping screws.

Basic rules for installing chimneys

The outer can be assembled from other materials. The transition of the "sandwich" pipe to the outside is assembled taking into account the parts used. The main rule that must be observed is that each joint must be completely sealed. Smoke tends to seep into any gap, which is fraught with negative consequences.

If the combustion products are not completely removed outside the premises, then this will negatively affect the health of all residents. Smoke will also negatively affect the state of the house, exerting its destructive effect on all the elements with which it will interact.

"Sandwich" on a brick pipe is one of the most common types of joints. This is not surprising, given that such an external chimney has the best durability and is easy to design and build.The brick is well protected from destructive weathering and is adapted to work with high temperatures. Now we are talking about heat-resistant brick, which is used in the construction of fireplaces, stoves and chimneys.

Before installing the chimney, it is recommended that you familiarize yourself with the following rules:

- the total height of the chimney from the point of its connection with the heating equipment to the final element of the system, which is the head, must be more than 5 m.Otherwise, the chimney will not have enough natural draft to remove harmful substances generated as a result of combustion;

- the height of the chimney on the flat roof of the building must be at least 0.5 m. For other roofs and methods of placing the chimney on it, there is a certain diagram shown in the figure;

The layout of the chimney on the roof of the building

- when arranging chimney crossings through the walls and roof of the building, all joints with the house must be insulated. For this, non-combustible materials are used that can withstand high temperatures. For example, asbestos sheets;

- before installing the chimney, you should decide on the diameter of the pipe, the required length and shape. The diameter of the chimney depends on the power of the heater and is calculated based on the requirements of GOST. For 1 kW of power, it is recommended to use a pipe with a diameter of 8 cm²;

- correct installation of the chimneys requires absolute tightness of all existing joints. Additional insulation at the joints can be provided with a heat-resistant sealant.

High temperature protection materials: asbestos sheet and heat resistant sealant

All basic rules for installing the chimney must be followed. Otherwise, the system will not work properly, which could result in a fire.

If you already have an old brick chimney, then you need to dismantle the brick chimney. This is necessary for correct installation.

We dismantle a brick high-rise pipe

Also, when conducting work, it is worth knowing the rules:

- When installing the chimney, various ledges must not be allowed;

- The pipe bend is made at an angle of at least 30 degrees;

- The cross-section of the pipe with a horizontal branch cannot be less than vertical;

- It is also necessary to provide for a spark arrestor, because it will be safe to use peat with it when burning;

- To protect from rain, it will be necessary to install a deflector;

Sandwich pipe device

| Outer cloak | It's just a casing made of fire-fighting materials. An anti-corrosion coating is also applied. There are also stainless steel pipes. They are more durable, but their price is higher. |

| Inner cloak | It is mainly made of the same material as the outside. |

| Basalt | It's just a layer of thermal insulation. It is placed between the pipes and does not allow the smoke to cool down quickly and resists the formation of condensation. |

How to make the transition without an industrial adapter

How to make a transition if there is no adapter?

- After dismantling the collapsed part, a hole slightly larger than the diameter of the inner channel of the sandwich is cut out in the brick channel.

- The inner pipe is inserted into this recess, the gaps are sealed with oven mortar.

- In this case, the outer pipe will rest on the masonry. The slots at the point of attachment are simply coated with the same oven solution.

- Collect subsequent segments by inserting them into each other.

- In the passage through the hole in the ceiling, a cutting is performed, and only then a channel is passed through it. The sandwich is brought out to the roof, fixing it with an assembly platform or simply with scraps of a metal profile.

- The pipe fitting method can be used.

- After dismantling, a superstructure with a gradual narrowing is laid out on a suitable remaining part of the brick trunk with a rectangular masonry. She will act as an adapter.

- A so-called mono-thermo transition is inserted into the resulting hole.

- The outer part of the sandwich is trimmed and the protruding inner end is inserted into the superstructure. All this is sealed with a solution.

When is such a connection necessary?

It is possible to use modern technological solutions when arranging smoke removal and heating systems at any stage of operation. When building new houses, brick chimneys are being erected less and less. In most cases, owners will prefer a round sandwich tube if it fits into the exterior of the property.

Such structures can be installed on objects of any purpose. They are used to remove combustion products of various types of fuels. The replacement of a brick chimney with a metal analogue is carried out when the first structure is destroyed, with a loss of attractiveness, for example, when the facade or roof is being renovated.

Where to begin?

First of all, it is necessary to dismantle that part of the brick chimney that has become unusable. The key point of this operation is not the method - the brickwork is broken in the usual way, but the security. It is necessary to ensure that falling bricks do not injure any of the people standing below and do not break through the roof.

Calculation of the angle of a double-circuit pipe.

Dismantling of attached external chimneys is often carried out by overturning, for which they are hooked with a cable and pulled using a vehicle or a winch.

In this case, before starting the operation, it is necessary to measure the height of the pipe and determine exactly whether there are any necessary objects at the place of its fall.

The work area must be fenced off taking into account the scattering of the fragments and make sure that there are no unauthorized persons within it.

Traditional sealing materials

When buying a chimney lining, you should focus on the type of material from which the chimney is made. Experts advise to work:

- roofing bricks. Robust boards are resistant to temperature fluctuations and the influence of aggressive environments. Solid bricks are laid on a cement mass, and the seams are treated with grout;

- clinker tiles. The tiles are lightweight, which is ideal for high chimney structures;

- plaster. The inexpensive cost of the mix makes it affordable for construction work on a small budget. The loose texture of the composition requires reinforcement with a cement screed or cement-lime paste. Additionally applied and dried mass is coated with silicone compounds;

- slabs made of cement fibers. The small plates are durable, UV and climate resistant. Eco-friendly non-flammable material with a smooth or structured texture is easy to install due to its low weight;

- slate. The natural material is suitable for roofing or chimney cladding. In addition to sealing, rectangular, flake or octagonal panels create an attractive pipe decor.

When choosing the type of material for self-sealing, give preference to steel sheets - they are characterized by strength, ductility and ease of use.

The steel apron is applied to the roofing board covered with liquid or sheet roofing material. Sealing arrangements include:

- bending the edges of the apron onto the walls of the chimney structure;

- laying of timber sheathing at the beginning and end of the pipe;

- placing tiles on top of the lathing;

- cutting a groove on the wall of the pipe - the upper part of the apron is located in it;

- fastening elements of the steel frame to the walls of the pipe. They start to work from the bottom;

- filling the grooves with the upper part of the apron with roofing silicone or special sealant.

It is recommended to seal the roof hole when installing the chimney.

Roll insulation

To seal pipes of large diameter and square shape, roll insulation reinforced with an aluminum strip is produced. It has its own nuances of editing:

- the material must be cut 30 cm larger than the diameter of the chimney in order to secure it with an overlap;

- when gluing the insulation, it is necessary to bend it so that the edge goes into the chimney to a height of about 5 cm;

- after the end of the formation of the edges of the roll insulation, it is necessary to fix it with a special silicone glue. The fasteners are reinforced with small screws.

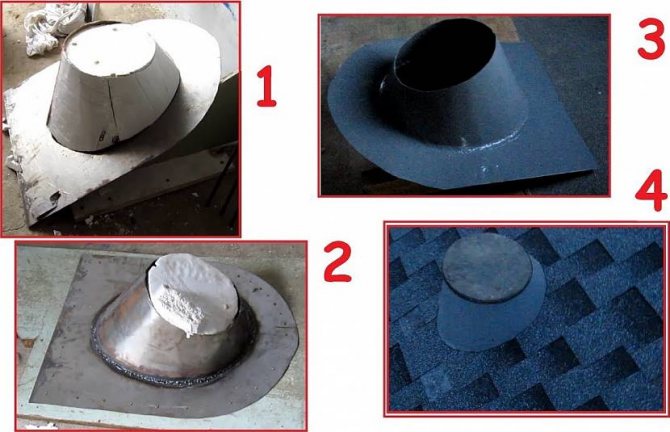

After finishing fixing the insulation, it can be painted in the color of the roofing sheet. The speed of construction is provided by an innovative material - "Master Flash". Special penetrations made of elastic rubber are characterized by a long service life and resistance to aggressive media.

"Master Flash" is an elastic seal that seals the joints of the chimney and roofing material. It is a rigid silicone or rubber base with rings of different diameters at the top. To strengthen the product, use an aluminum gasket.

The chimney cover has the shape of a cone and an angle of inclination depending on the roof slope. Cones with an angle of 90º are used for flat roofs. The pitched roof covering is sealed with a rag with a protrusion of the rings at 45-30 °. Silicone or EDPM rubber is used for the manufacture of the seal. The raw materials differ in their qualities:

- silicone cones are more elastic. When exposed to temperatures up to 315 ºС, they are destroyed under the influence of ultraviolet radiation;

- rubber melts at temperatures above 185 ºC, but is UV resistant.

The cost of the Master Flash structure is influenced by the material and the diameter of the product.

The modern design for sealing the chimney has a number of advantages:

- elasticity, which ensures a snug fit of the pipe to the material;

- resistance to temperature changes, which is especially good in regions with a harsh climate;

- fire resistance (maintaining its qualities at temperatures of 185 - 315 ºС, depending on the type of material);

- long service life - about 30 years;

- does not require special skills, efforts and specific tools for installation;

- can be installed at any time of the year.

The use of the Master Flash sealing design eliminates the need for additional use of sealing materials.

Roof placement rules

- If the head is at a distance of no more than one and a half meters from the ridge-roof bar, the chimney mini-roof should rise above the ridge by at least half a meter.

- At a greater distance from the ridge ledge (1.5-3 m), the highest point of the “cap” protecting the chimney should be aligned horizontally with the edge of the roof.

- When the distance from the deflector to the roofing girder exceeds 3 m, its top cannot be lowered below the conditional straight line forming an angle of 10 ° with the slope platform.

Head with a hip cover near and on the roof of the mansion - With any shape of the gable roof and the remoteness of the chimney device from the edge, the cap should be at least half a meter above its plane.

- If the height of the visible chimney masonry exceeds 1.2 m, without installing roof braces, the “chimney-head” set will be unstable and therefore dangerous.

- Above the ridge plank of a building made of fire hazardous building materials, even a fire-resistant smoke exhaust system should rise by a meter and a half.

Metal chimney for stove

The fairly large amount of work in the manufacture of a brick chimney, especially the upper parts of the structure, makes the owners look for alternative options, for example, from a metal or asbestos-cement pipe. Despite the visual appeal of the idea, in practice, metal or asbestos is used to install the upper part of the chimney.On the lower part of the riser, transition sections made of alloy steel from the furnace to the channel of the flue pipe can be installed.

Alloy cast iron pipes are distinguished by excellent performance characteristics. Unlike brickwork, a cast iron chimney is not susceptible to shrinkage or cracking of the material.

It absorbs heat well and, due to the high thermal conductivity of the material, provides a very even and stable traction in the channel. For a bath or a cooking stove, such a chimney is more interesting than heavy brickwork. The service life of such a pipe can easily reach several tens of years.

But a cast-iron channel with a diameter of 150 mm and a length of 4-5 m is very sensitive to the correct setting of thermal gaps on the chimney mount. Due to the high coefficient of thermal expansion with rigid pinching of the pipe surface, the metal can crack at the very first attempt to warm up the furnace.

A freshly folded brick chimney requires no less careful and careful handling during drying and sedimentary processes in masonry.

During the first week, only paper and wood chips are burned in the canal. After a couple of weeks, after the mortar has set, the temperature is slowly raised to the working temperature and, having closed all the holes and dampers, they are also slowly cooled. If no problems arise, you can proceed to normal use.

Transition from a brick chimney to a metal one

In order to switch from a rectangular brick chimney to a round metal chimney, you will need a flat steel platform with a branch pipe, the diameter of which corresponds to the diameter of the steel pipe.

The outer dimensions (perimeter) of the brick chimney are 500 x 370 mm.

I purchased a 500 x 500 mm stainless steel platform with a 200 mm diameter pipe in the center. (that is, with a cross-section equal to that of the stainless steel pipe).

Now the platform with the branch pipe must be fixed somehow.

We will fix the platform with dowels and screws.

| The transition from a brick chimney to a metal one should be not only reliable, but also airtight, that is, there should be no gaps and cracks between the bricks and the stainless steel platform. To achieve the required tightness, we will use a special fireplace sealant. I used TYTAN fire-resistant silicate sealant for stoves and fireplaces. It is intended for long-term repairs, filling joints, cracks, cracks in fireplaces, stoves, furnaces, chimneys and is characterized by: - good adhesion (adhesion of surfaces of dissimilar solids and / or liquids) to many building materials: metal, brick, concrete; - high temperature resistance - up to + 1250 ° C and good resistance to frost and moisture; - does not crumble or crack after hardening, does not contain asbestos. In general, TYTAN fire-resistant silicate sealant is what we need in our case. |

Installation of a steel platform with a pipe |

| Now let's in order about the installation of a steel chimney ... What we have to do in order to move from a brick chimney to a metal one: We cut out the site in such a way that it would correspond to the dimensions of the brick chimney: 500 x 370 mm. (or did not exceed them). We estimate the attachment points of the platform to the brick chimney. Be careful: the attachment points should not line up with the masonry joint or fall into the edge of the brick Now is the time to remind you that in order to strengthen and give strength to the masonry, I laid out the last two rows of the brick chimney on a complex one. After the attachment points of the steel platform with the branch pipe are determined, we drill holes in it for self-tapping screws, and drill holes for dowels in the bricks. We insert the dowels into the prepared holes.

We install a metal platform on a brick base, on which we first apply a fire-resistant sealant. We evenly pull the platform with self-tapping screws along its entire perimeter.

Although the pad is well tightened with self-tapping screws (I spent a lot of them), I decided to wait for the sealant to dry. And only after that you can proceed directly to the installation of the chimney from stainless steel pipes. |

Operation and care

Diagnostics of correct operation and cleaning of the inner surface of the flue duct are obligatory works, especially during the year-round operation of the chimney. This allows you to maintain a constant ventilation effect inside the structure, reduces the risk of its burning out and smoke emission through the combustion chamber.

Soot removal

Ruff with a load for cleaning the chimney

Soot removal is performed every six months. With frequent use of conifers, preventive cleaning every three months is desirable. A special tool and chemicals are used to clean the smoke channel.

A steel line with a sinker is used as a tool, at the end of which a metal or plastic ruff with a hard nap is fixed. The diameter of the hedgehog is selected according to the internal section of the channel. The ruff is progressively lowered into the chimney along the entire length of the channel, thereby removing carbon deposits and soot from the walls of the chimney.

Salt chemicals help maintain and remove soot naturally. The product is poured onto hot coals. During combustion, it releases salts that soften the resinous build-up inside the chimney.

As a prevention of blockages, it is recommended to fire the stove with aspen wood or potato peelings. Aspen wood gives a good heat, which leads to burnout of the blockages themselves and the combustion of soot. This method can be used only if the design and materials of the chimney are designed to operate at temperatures above 1000 ° C.

Potato peelings release starch when burned, which also helps to soften soot and soot. By itself, this method is ineffective, but if you heat the oven with cleanings before mechanical cleaning, then the cleaning process will be easier.

Chimney repair

Handheld thermal imager for diagnosing the technical condition of the chimney

Repair work on a chimney of any design consists of three stages:

- cleaning the smoke channel;

- diagnostics using special equipment;

- replacement of the problematic item.

As mentioned above, the cleaning of the flue duct is performed at regular intervals. This eliminates overheating of the chimney and maintains a constant level of draft inside the flue duct. If after cleaning the draft level has not recovered, then the chimney is diagnosed using video inspection equipment and a thermal imager. At this stage, the inner surface of the smoke channel and the junction of the individual elements are examined.

If problems are found, the burned out and damaged area is replaced. For this, a certain section of the chimney is dismantled, and the damaged element is replaced with a new sandwich pipe.

Self-assembly of a chimney from steel and sandwich pipes does not cause any particular difficulties, but it requires a careful study of the technology of work and accuracy

When working at height, be sure to be careful and watch the quality of the joints.

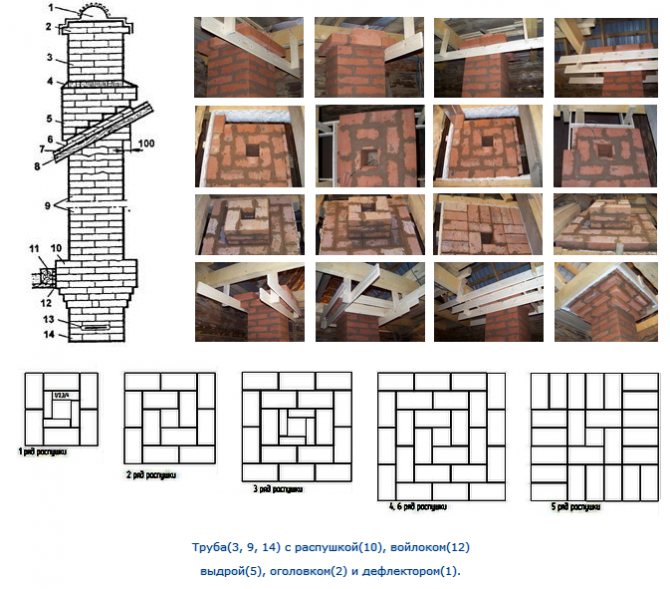

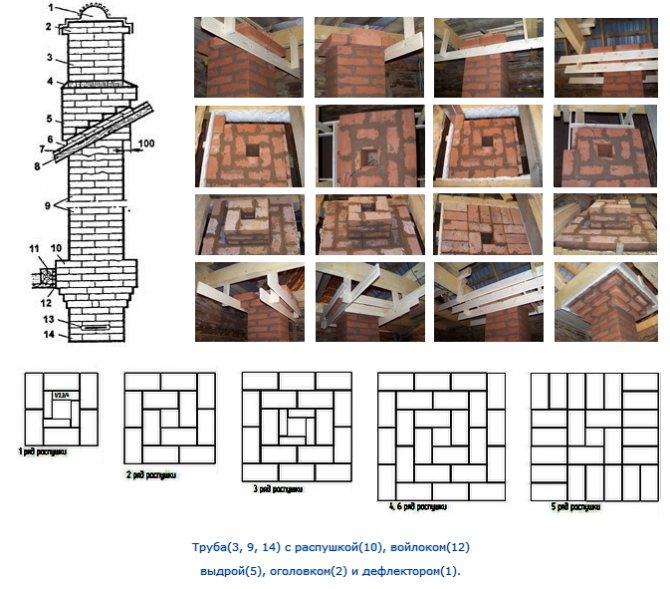

Brick chimney design

The power of the stove is directly related to the size of the chimney section:

For small stoves, a square section with an edge of 120-150 mm will be sufficient.

Most often this is a channel with four bricks in a row, therefore, the size of such a section is often called a four; For a bath of 15-20 cubic meters or a fireplace, a chimney with a cross section of "five" or 125x250 mm is required.When laying in a row, five bricks are placed; For Russian stoves and large sauna heaters, use the "sixth" size with a channel of 250x250 mm. This is a very large cross-section, and should only be used for low-sitting pipes or a very large furnace.

Structurally, the laying of the chimney is no different from the laying of the stove itself.The only area that requires the hands and skill of a professional is the overhead pipe. At this point, you need to correctly bandage the brick to be laid. For a simple chimney tower structure, the pipe can be made of alloy metal and connected to the main brick duct, as shown in the figure.

What happens if you do it poorly?

Poor assembly and installation of a chimney sandwich can lead to poor or reverse draft, when the combustion gases do not escape into the atmosphere, but are concentrated in the room. The most common reasons for changing thrust direction are:

- Incorrectly executed calculation of pipe parameters depending on the boiler power.

- The configuration of the flue duct is too complex with a lot of narrow sections and bends.

- Low position of the head in relation to the ridge or nearby tall buildings.