Rating of the best chimney manufacturers

| A photo | Name | Rating | Price | |

| #1 |

| CRAFT | ⭐ 100 / 100 4 - voices | Find out the price |

| #2 |

| Volcano | ⭐ 99 / 100 3 - voices | Find out the price |

| #3 |

| ROSST IN | ⭐ 97 / 100 | Find out the price |

| #4 |

| Jeremias | ⭐ 97 / 100 | Find out the price |

| #5 | Thermophore | ⭐ 96 / 100 | Find out the price | |

| #6 |

| Ferrum | ⭐ 96 / 100 1 - voice | Find out the price |

| #7 |

| Elits | ⭐ 95 / 100 1 - voice | Find out the price |

| #8 |

| Inzhkomtsentr VVD | ⭐ 93 / 100 3 - voices | Find out the price |

| #9 |

| Phoenix | ⭐ 92 / 100 1 - voice | Find out the price |

| #10 |

| Baltvent | ⭐ 91 / 100 | Find out the price |

| #11 |

| Rosinox | ⭐ 90 / 100 | Find out the price |

Which chimney manufacturer would you choose or would you advise to choose?

Take a survey

Chimney manufacturers rating: TOP-11 best

Before buying a chimney, a potential buyer should familiarize himself in advance with which brands offer the best quality products today.

Below we will tell you about the best manufacturers, as well as note their pros and cons. They have proven themselves well, which is also additionally confirmed in their reviews by the people who contacted them.

Rosinox

Rosinox

The brand, which has been operating since 2001, opens the rating of the best chimney manufacturers. Rosinox uses only high quality stainless steel and other environmentally friendly materials, and all production is located in Klin. The best German technique is what helps a brand to have a good product.

The best German machines are used for manufacturing, so the products from Rosinox are quite competitive in relation to the products of other companies presented below.

The dealer network is well developed, which means that the products of this domestic company can be found in almost any city.

All employees work extremely well, which allows you not to worry about the good performance of the Rosinox chimney installed in your house.

The only drawback of this manufacturer is the problematic contact with the support service of this company.

pros

- Using fresh solutions and production technology from Germany.

- Dealerships can be found everywhere.

- The use of environmentally friendly material.

- High quality products.

Minuses

- It is quite difficult to contact the support team of this company.

chimney rosinox

Baltvent

Baltvent

This domestic company has existed for many years on the market of heating equipment and its components. The production is located in Kaliningrad, and this city, which is importantly located near Europe. It was the location that influenced the technical base of the enterprise from the very beginning.

The best equipment from Europe, excellent specialists, high-quality material - all this allowed us to become what we know it now - well-known and with great production.

Quite important in this company is that the pricing policy of this company is within the average value with high quality of the final product.

pros

- Modern European equipment with high production rates.

- Commitment to modern technological solutions that have improved the product itself.

- The price for the products of this company is within the normal range.

- Extremely high reliability of products from this company.

Minuses

- Few things can be found interesting in the assortment of this company.

Phoenix

Phoenix

Another domestic company with production in the Moscow region, whose products have high reliability and durability.The long warranty period will allow you not to worry about the state of the chimney, because for this "Phoenix" uses not only high-quality material, but also good equipment in combination with modern production technologies.

Before manufacturing the chimney, the company creates a 3D model on which everything is pre-checked, then plasma cutting and TIG welding. The result is obvious - a chimney from absolutely any shape and type with all the necessary certificates and documents confirming the high quality of the goods.

The clients who turned to them were generally satisfied with the quality of the service and product, noting only the average quality of the seam. Only a small number of people had a chimney corrosion problem.

pros

- The chimneys are manufactured using the latest technology.

- Quality equipment from Europe.

- Long warranty period - 15 years.

- It will be quite easy to install the chimney of this company.

Minuses

- The chimney of these products is easily corroded.

- Seam quality not very good.

Branch-sandwich 230х130

Inzhkomtsentr VVD

Inzhkomtsentr VVD

Another Russian company, founded in 1999 and known for the production and development of high-quality steel chimneys. Own production allows us to achieve high quality and low cost of products.

The versatility of the chimneys of this company allows them to be used in almost any heating system, which is extremely convenient.

It should be emphasized that people speak of this company only on the positive side, highlighting the reliability and ease of installation of their chimneys.

pros

- Anyone can buy the goods of this company due to the affordable cost.

- High quality products.

- The installation of such a chimney will take place quite quickly.

- Extremely reliable chimney.

Minuses

- After a while, the flue pipe may darken.

Elits

Elits

This company, judging by the name, makes only high quality chimneys. And this is so, because all the efforts of specialists and engineers are aimed at one thing - to create high-quality and at the same time inexpensive products.

The use of quality material in the form of stainless steel allows to achieve a long product life - more than ten years without a single complaint.

Elits chimneys can be found in many summer cottages, private homes, and even industrial warehouses. In addition, it should be noted the versatility of the products of this company.

Ease of installation, high-quality welding and appearance - all this is available in Elits chimneys. And as the name implies, the pipes are really of the best quality.

The only thing that people notice is the presence of insignificant flaws in the design that are easily fixable.

pros

- Acceptable pricing policy.

- Easy installation.

- High quality seams.

- Wide area of use.

Minuses

- Design flaws.

Ferrum

Ferrum

In sixth place is the domestic manufacturer Ferrum, the range of which is quite large. Everyone can find the chimney that suits their home better.

All chimneys are manufactured in Voronezh, where the main workshop is located. As a rule, the company uses high quality raw materials that undergo a series of checks before entering production and becoming a chimney. High quality material is what gives this company's products the durability that the company has long been proud of.

Customers have repeatedly noted that the quality of Ferrum products is at the highest level, although the price, in their opinion, bites a lot.

pros

- The use of quality metal.

- The presence of a large assortment.

- The ability to purchase individual components in a large range.

- Simple and convenient installation.

- Nice appearance.

Minuses

- High price.

chimney ferrum

Thermophore

Thermophore

The top five of this rating of manufacturers is a relatively fresh company founded in 2003.The brand developed so rapidly at the beginning that a year later it already had an award.

The assortment of this company contains a variety of products, among which you can find the following products:

- tanks;

- boilers;

- ovens;

- chimneys.

It should be noted the qualifications of specialists, as well as powerful modern equipment that allows you to create a high-quality product.

However, it is important to be careful - "Termofor" has a lot of fakes, the quality of which is too far from that of the original products.

pros

- The equipment and technologies are all the most modern.

- Skilled workers, thanks to whom the products are of such high quality.

- A large assortment.

- High quality product.

Minuses

- Counterfeits are common.

- Finding products from Termofor is not always easy.

Jeremias

Jeremias

The fourth place is taken by this premium brand from Germany. The Bavarian company is the only foreign representative of this rating, so it will be quite interesting to take a look at Jeremias.

The company itself was founded quite a long time ago - in 1970, but the company appeared on the territory of the Russian Federation not so long ago - in 2008, when the company opened its own representative office.

In short, the products of this company are characterized by several characteristic features at once:

- fine chimney design;

- smooth seam;

- combination of modern developments and quality raw materials.

Judging by the reviews, the chimneys of this company are installed quite easily, which pleases. In addition, high reliability and high-quality work of specialists stands out.

pros

- Excellent quality in everything - material, workmanship and even seams.

- High-tech chimney production.

- Bright and attractive product design.

- High indicators of durability.

Minuses

- The price bites.

chimney Jeremias

ROSST IN

ROSST IN

"Bronze" in our rating goes to a company whose production is located in Moscow itself. It has long been known in the market for heating equipment and their components, and there is no doubt about the quality of the products.

The chimneys of this company are considered quite versatile, because they can be installed almost anywhere and without any problems.

Rosst In products are made according to the latest developments and using modern technologies.

High quality and reliability are what made this company one of the market leaders. A high price is a payment for the fact that the chimneys will serve for a long time and with high quality.

pros

- High indicators of the durability of the products of this company.

- From a design point of view, the chimneys of this company look pretty neat and fresh.

- Using modern technologies and only high quality materials.

Minuses

- High price.

Volcano

Volcano

The company that took the second place in this rating started the production of chimneys back in 1996. Therefore, we can say about a very rich assortment of chimneys from this brand.

Any potential buyer, whether he is a private owner or a representative of another company with his own production workshop, can find a suitable chimney model from this company.

Qualified specialists are constantly introducing new technologies. Having our own laboratory allows us to quickly test new possible options in search of the best solution.

High-quality materials and raw materials, as well as the most modern technology - what the company uses when creating its famous chimneys, which are quite capable of competing with their competitors, since such serious companies as Nissan and Toyota pay attention to them, which is extremely significant.

The products of the Vulkan company have all the necessary certificates and licenses, which confirm the high quality of the products, as well as a long warranty period, with which you can forget about the issue of replacing the chimney for a long time.

pros

- Advanced production with modern technology.

- Very long warranty period of fifty years.

- Use in the production of high quality raw materials.

- Availability of our own laboratory for testing.

Minuses

- High price.

chimney volcano

CRAFT

CRAFT

"Gold" is received by a fairly young domestic company, which, at the same time, has fairly high-quality products for the heating systems market.

It is interesting that the products of this company do not go outside the country, which means that they are sold only for the domestic market, which allows us to talk about an adequate price for most buyers.

The use of high quality materials, as well as an emphasis on modern equipment and technology, allow us to achieve the best products that will delight you with reliability and durability.

pros

- The use of very high quality materials.

- Using the best technological base.

- Modern equipment.

- Reliability of goods.

Minuses

- Not detected.

chimney Craft

Which chimney to choose?

- Chimneys Ferrum

- Which chimney to choose?

| Asbestos | Black metal | Brick | Stainless steel |

| Price | |||

| Ease of installation | |||

| Serviceability | |||

| Durability | |||

| Security | |||

| Condensate | |||

| Heat |

Asbestos chimney

During the Soviet era, asbestos-cement pipes for the chimney were used quite widely, since the low cost made such pipes made of non-combustible material the optimal solution for organizing a smoke exhaust channel. This was relevant only for old heating devices, since the AOGV installed in garden houses and dachas were rather low-power, which allowed asbestos-cement pipes to successfully discharge exhaust gases.

At the same time, the fire safety rules and SNiP state: a chimney from an asbestos-cement pipe can only be operated at temperatures not exceeding 300 °, that is, in such cases as:

-the upper segments of the flue channels, in which the exhaust gases have almost cooled down

- low-power gas heating appliances, etc.

It should be borne in mind that the asbestos chimney bursts at a high temperature, therefore it cannot be used in the initial section of the flue, in which the highest temperature is observed. In addition, such chimneys cannot be installed in chimneys that remove combustion products from solid fuel boilers.

The rules also clearly state that the use of asbestos-cement chimneys with coal-fired units is prohibited, since the combustion temperatures of wood and coal significantly exceed the combustion temperature of conventional natural gas.

Important: in this regard, asbestos has never served as a material for the manufacture of chimneys.

In addition, a significant disadvantage of asbestos cement is the porosity of the material and the absorption of condensate by it, which causes rapid destruction of the gas duct at the "dew point" - the base of the outer part of the pipe, where the roof lathing and rafters pass.

In this case, a violation of the integrity of this sandwich pipe can cause a fire in the wooden roof frame in this area.

Asbestos chimneys now.

Twenty years ago, asbestos sandwich pipes for a chimney, also called asbestos-cement and asbestos-cement pipes, were considered a fairly reliable building material with such a rather important advantage as cost effectiveness.

Longevity then did not bother anyone, especially since the level of quality control was quite low, and cheap material could be purchased with a margin.This is what led to such a widespread distribution of chimneys from asbestos pipes in rural areas, primarily in summer cottages.

And at present, almost every second country house is equipped with such an accelerated version of the chimney as an asbestos-cement pipe for the chimney, which is not due to the high quality of this material, but to the desire of the population to complete the construction of the house as quickly as possible at the lowest possible costs.

As building materials, asbestos and cement are quite popular due to their strength and quality, and are widely used in various construction works, for example, when laying sewer communications, when covering a roof with slate, etc.

At the same time, everyone knows that slate, which is essentially the same asbestos cement, bursts in a fire, but this does not stop folk craftsmen who use asbestos pipes for chimneys.

Unreliable and unable to withstand high temperatures, asbestos-cement chimneys are recognized as not meeting fire safety requirements, and therefore their use with solid fuel boilers is strictly prohibited.

Black metal chimney

For the manufacture of the device, welded pipes made of ferrous metal are used. The main advantage of chimneys is their low cost. On average, such a pipe costs the owner 80% cheaper than a brick one. However, there are many disadvantages of such pipes: The fragility of the structure, provided by the corrosive instability of the material. Increased fire hazard due to the rather fast burning out of the walls of the flue duct. Large weight of the structure. Increased condensation formation during operation of the heater.

For the manufacture of the device, welded pipes made of ferrous metal are used. The main advantage of such a chimney is its cheapness, but at first glance, in the end the mean pays twice... On average, such a pipe costs the owner 80% cheaper than a brick one. However, there are many disadvantages of such pipes:

-fire hazard, the walls of the flue duct burn out rather quickly due to the unsuitability of this metal as a chimney.

- lack of corrosion resistance,due to the lack of chromium in the alloy in the amount of 17 percent, which gives the corrosion resistance of the alloys

- large weight of the structure, at high temperatures, the crystal lattice of the metal changes, as a result of which it loses its strength, and under its weight the chimney begins to change its shape, gaps appear at the joints of the elements, which leads to the smoke of the room with combustion products

Firstly, such a pipe rusts rather quickly. Secondly, its walls burn out no less quickly, exacerbating the fire hazard. Thirdly, the water in the chimney condenses in huge quantities. In addition, it weighs decently and needs a brick fur coat and additional processing (both outside and inside).

In general, the system has more disadvantages than advantages. It is installed when they want to save money. However, trying to save money, you will get a chimney for one season at best, you will have to pay extra for dismantling, a new chimney and installation. And most importantly, this type of chimney is dangerous for the health of you and your loved ones, not to mention your property.

Brick chimney

The traditional version of the chimney. Its peculiarity is in the construction during the construction phase of the building, while it can be quadrangular, it is an easier-to-execute option, or rounded. Disadvantages of the system: Rapid accumulation of soot on the rough walls of the brick chimney. Large weight, as a result of which the installation of a foundation for the structure is required. The gradual destruction of bricks under the influence of acid and condensate, which is especially abundant in case of improper arrangement of the system. Quite high cost. In rectangular structures, vortex currents form in the corners, which impede the movement of smoke.

The undoubted advantages of the design include:

—beautiful aesthetic appearance

-high fire resistance

-additional heat dissipation

Among the disadvantages are:

- the need to erect a foundation to the furnace

-fire hazard (with improper installation or operation)

- the chimney structure is not too stabledue to its mass and the destruction of the brick due to the strong formation of condensation

-fast accumulation of soot on the rough walls of the brick chimneydue to the unevenness of the masonry and the brick itself, cleaning the chimney from brick is not a very simple matter

-brick may crack over time

-increased formation of condensation

-expensive material

A brick chimney is a fairly good option, but not everyone will be satisfied with the expensive material and the need to build a foundation.

Stainless steel chimney

Made of special alloy steel, it is resistant to corrosion in the atmosphere and in almost any corrosive environment. Has many advantages:

-beautiful aesthetic appearance

-minimum condensation when installed correctly

- ease of installation

-allow to install chimneys of any design

- cheaper than bricks

-durability

-high fire safety

- there is no need to build a foundation

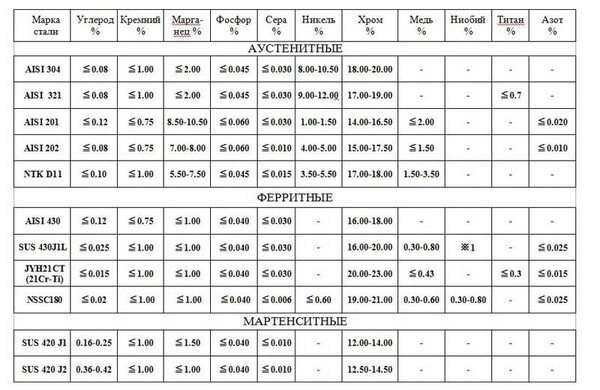

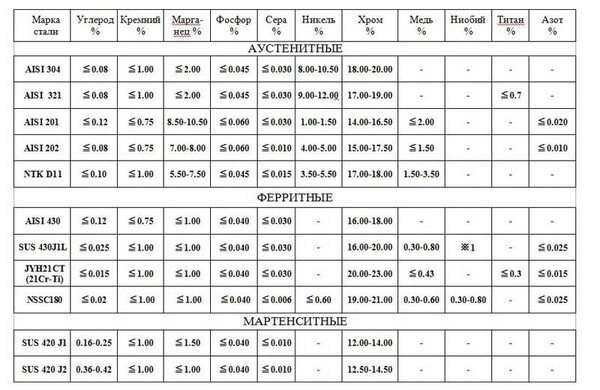

Stainless steel grade

Before you start making a chimney, you need to find the material. In this case, it will be stainless steel. Interestingly, it can be completely different, even if its types differ from each other will not be too much.

The main differences that they will have are in their composition, which will determine their resistance to high temperatures and acid. The higher it is, the longer the material will remain in its original state.

To date, manufacturers use only one series - the three hundredth, which is an example of quality. Here we will consider it below and consider the example of several representatives of this series.

A brand can decide a lot in the production of a chimney

AISI-304

- Austenitic stainless steel. It is an admixture of steel, chromium (18-20%), nickel (8-12%) and carbon (up to 0.08%).

- Steel with high resistance to acid and high temperatures (up to 400 ℃, taking into account the average level of acidity of the environment), therefore it is recommended for gas, solid fuel boilers.

Important! It is widely used in food production.

AISI-316

- The composition is the same as that of AISI-304, but in addition molybdenum is mixed (2-3%).

- Even greater resistance to negative external effects (up to 750 ℃ without deformation).

A chimney made of such material can be used in almost any type of boiler, no matter what the heat source will be.

AISI-309, AISI-321

- Refractory stainless steel. It is an admixture of steel, chromium (19-21%), nickel (11-13%) and carbon (up to 0.2%).

- High resistance to high temperatures (up to 1050 ℃), as well as to acids.

Chimneys are made from such material, which will work in places with the most difficult conditions.

- Bath.

- Sauna.

- Solid fuel boiler.

Each brand has its own properties, suitable for a particular task

Heating equipment type and chimney: what you need to know

When installing a stainless steel chimney, it is imperative to take into account not only the material itself and its brand, but also the thickness of the chimney wall. But, in addition to this, you need to consider what equipment is at home.

Below is an example of what heating equipment is available and what requirements it may have:

- stove or fireplace - AISI 321 (wall thickness - 0.5-1.0 mm);

- diesel boiler - AISI 316L (wall thickness - 0.5 mm);

- gas boiler - AISI 304 (L) and 321 (wall thickness - 0.5 mm);

- solid fuel boiler - AISI 309, 310 and 321 (wall thickness - 1.0 mm).

Conclusion number 1: solid fuel boilers need to have a chimney with a wall thickness of 1 mm. This chimney is made of heat-resistant steel, since the temperature inside the chimney can reach up to 500-700 ° C.

Conclusion number 2: oil and gas boilers emit acid, which means that you need to install a chimney with high resistance to temperature and acid, the wall thickness of which is 0.5 mm.

| Heating installation | Temperature inside the active installation, ° С | Stainless steel brand, AISI | Wall thickness of the inner pipe, mm | Insulation layer thickness, mm |

| Fireplace, stove | 350 — 650 | 321 | 0.5 – 1.0 | 50-100 |

| Sauna stove | 400 — 700 | 321 | 0.8 – 1.0 | 100 |

| Gas boiler | 120 — 200 | 304, 304L, 321 | 0.5 | 30-50 |

| Diesel boiler | 150 — 250 | 316L | 0.5 | 30-50 |

| Solid fuel boiler | 500 — 700 | 309, 310, 321 | 1.0 | 100 |

| Gas piston, gas turbine units | 450 — 600 | 316Ti, 321 | 1.0 – 1.5 | 100 |

| Diesel generators | 450 — 600 | 316Ti | 1.0 – 1.5 | 100 |

How to choose a chimney for your home

- Heater type

... To choose a reliable steel chimney, you need to know the type of heater to which it will be connected. Gas and diesel boilers generate large volumes of corrosive condensate. Therefore, all elements of the smoke exhaust system must be made of acid-resistant steel grades (AISI 316L) with a wall thickness of more than 0.5 mm. Coal stoves can be equipped with heat-resistant chimneys made of AISI 310 material with a thickness of 0.8 ... 1.0 mm. AISI 321 is suitable for a wood-burning fireplace. - Chimney design

... Steel smoke extraction systems are of several types. Single wall pipes are commonly used to complement brick ducts. They require insulation due to their tendency to form condensation. Double-circuit systems with a layer of insulation can partially solve the problem of condensation. Sandwich chimneys only need to be cleaned promptly. Two-way movement of air masses is provided by coaxial chimneys. Clean air is drawn in from the street through the external channel, and combustion products are removed through the internal highway. - Installation features

... Modern smoke exhaust systems are quite simple and easy to assemble. In some cases, you can cope with the work on your own. When buying, you should pay attention to the evenness of all parts, the presence of connecting and turning elements, ease of docking. - Reliability and durability

... Determining the reliability and durability of the chimney by technical parameters is problematic. This can be indirectly judged by the steel grade and wall thickness. But complete information can be obtained only on thematic sites, where home owners and professional stove-makers share their experiences.

We have selected 11 of the best chimney manufacturers for our review. All of them are sold in stores in our country. When compiling the rating, the opinion of the expert community and feedback from Russian consumers were taken into account.

Range

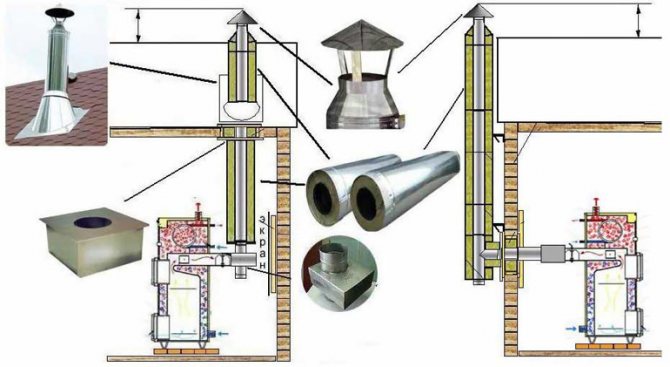

Installation of a stainless steel chimney is a rather difficult task, and therefore many people need to use a solution that is ready for installation. Many models come with various parts of the pipe, so it is quite possible to install the structure yourself.

Let's take a look at all these elements.

- Straight pipes. Their length, as a rule, is from 33 to 100 cm. Socket coupling is what firmly connects the elements of the pipes to each other.

The pipe does not need additional fasteners - Elbows at an angle of 45 °. They are best used when there is a need to deviate from the vertical.

- Elbows at an angle of 90 °. Due to them, it is possible to make transitions between the vertical and horizontal section of the place where the pipes are stretched.

Elbows 45 and 90 degrees - Condensate collector. It is placed at the lowest point of a vertically running pipe. It is used to collect water that appears when the smoke cools.

- Tee at 45 ° and 87 °. With it you can collect pipes where condensate collection is planned. In addition, such a tee is useful when connecting two heating devices that are connected to a common chimney.

- Inspection element. The revision is installed where soot is likely to accumulate. Its use is to check and clean the chimney.

Chimney inspection - Passages.This element provides insulation for the structure to protect against fire, sealing the roof and also guarantees improved pipe design.

- Additional accessories. To protect against precipitation inside the chimney structure, from reverse draft and from sparks, a number of accessories are installed on the roof at once, including a cap and a spark arrester.

Chimney cap

Chimneys Ferrum

This plant is specialized only in the production of stainless steel chimneys. The assortment of the plant is simply huge. Ferrum produces all the elements that make it possible to assemble a chimney. Today the plant uses two types of steel: stainless steel and galvanized steel.

Stainless steel comes in two thicknesses 0.8mm AISI 430 (goes only to the inner wall of a two-circuit chimney and to a single-circuit chimney), 0.5mm AISI 430 - goes to the outer wall of a double-circuit chimney, for gas chimneys on the inner wall and on single-wall stainless steel chimneys for gas.

Brief information on 430 and 439 steel

ASTM standard: 430 Ti AISI, 439 AISI - ferritic steels. 430 AISI is a low carbon chromium iron stainless steel.

The steel has good resistance to corrosion in mildly corrosive environments and good resistance to oxidation at high temperatures. In the annealed state, the steel is malleable, does not harden excessively during cold working and can be easily formed.

Steel has limited weldability and should not be used in welded objects subjected to stress. Having a ferritic structure, 430 AISI is brittle at sub-zero temperatures, and cannot be used in cryogenic applications.

Since the steel does not contain nickel or molybdenum, it is cheaper than any of the 300 series steels. The Russian analogue of 430 AISI according to GOST - 12X17. AISI 439 steel - comes with the addition of titanium.

The steels of the 400 series retain sufficiently high mechanical properties at elevated operating temperatures (see Fig.), Ensuring the structural strength of the structure.

Chimneys made of such steel are recommended, first of all, for use for sauna stoves, boilers, fireplaces, wood-fired in domestic conditions, boiler rooms of small capacity. In such conditions, these flues will work for a very long time.

Stages of installation of the structure

To save money, you can install the chimney yourself - we'll figure out exactly how.

- At the exit point of the smoke collector, a metal pipe of a certain height is installed, since it determines what the heat transfer to the room from the heating equipment will be. It is necessary to put the structure "in smoke". After installing the pipe, you need to put it on the branch pipe and install a gate that will block the channel. All joints are carefully coated with a special heat-resistant sealant.

- After installing the main part of the structure, you need to put on a starting sandwich chimney in the form of a double pipe, which is closed on one side. All the necessary products will then be put on this sandwich. And yes, the joints are again connected with a special sealant.

- Now you can collect all the items. Everything is installed so that the condensate drains to the desired point. All joints must be sealed with a sealant.

It is important not to forget to treat all joints with a sealant. - The installation of pipes on the roof involves the use of an unloading platform, and just below you can use special clamps. They should be used where parts of the pipes are connected, because this way you can increase the strength of the entire structure. Flammable materials are insulated with a layer of basalt wool in a box.

- All lines with twists and branches must have revisions so that pipes can be cleaned without problems.

- The last stage - the apron and the conical roof are installed together with a deflector or head.

Following the stage will allow you to install the pipes so that they function correctly in the future.

Care and maintenance of a stainless steel chimney

For more efficient operation of the stainless steel chimney, you need to follow the recommendations below.

- Before lighting a boiler or stove for the first time, you need to check in advance if there are any foreign objects or debris in the flue duct. If there is one, then you need to take some long tool and push it through until the revision. When the debris is there, you need to open the revision channel, pull it out of the pipe, and after getting rid of the debris, the chimney and the revision channels are cleaned of soot with a brush.

- Household waste should not be thrown into a working furnace or boiler for incineration, as it can worsen the condition of the chimney.

- In solid fuel heat generators, as a rule, logs from conifers are not thrown. The reason is the resin content, which will quickly build up. The only exception is aspen logs, which can create a high fire and burn soot in the chimney with it.

Several rules must be followed for the chimney to work properly.

From time to time it is necessary to inspect the roof on the roof, if it is made of metal. This is done to detect any rust that may have appeared on the outside of the pipe. Yes, it can even hit a "stainless steel", which is quite unusual.

What should I do if I find this problem?

- Clear space around the pipe.

- Dismantle the problem piece of pipe.

- Clean, sand and degrease the work surface.

- Holes and cracks should be carefully repaired.

- Rinse with hot water and then dry thoroughly.

- Fill all the cracks found with a special sealant.

- Take a silicone nozzle, put it on the pipe, secure with self-tapping screws for greater strength.

Mistakes made in the arrangement of the chimney will lead to the reappearance of rust on the pipe or its transition to the roof.

The roof should not rust if done correctly

You may be interested to know which sauna stoves worth buying.

Stainless steel instead of ceramics: when is it better to choose steel?

Everyone knows that the chimney is an important part of the heater. And this means that his choice must be correct. And for this you need to know when and where it is better to use it. For a long time, the ceramic version was popular, and it could be found literally everywhere, but today it will be out of place, and therefore stainless steel, as an alternative, will look quite good.

Below, the experts of the Obzor-Expert.com website have identified three best cases when it is perfect.

- Boilers with a closed combustion chamber. It is better to use steel pipes for them. They are much more convenient than ceramic from the point of view of installation.

- Retrofitting a brick oven or fireplace. This is easier if stainless steel elements are added.

- Installation of an additional chimney. This is best done with double-layer sandwich pipes.

Important! It is quite difficult to choose the ideal option for heating equipment. Both options - both ceramic and stainless steel - have their own characteristics, pros and cons, and therefore you need to carefully study everything before choosing one.

Device and calculation

The following are used as the main elements for the chimney device:

- stainless steel pipes of various diameters and heights;

- knee at 450C and 900C. The first is necessary to change the angle of inclination, the second is a universal element of the system;

- tees - this element will simplify the care of the device;

- revision - necessary to clean the chimney;

- condensate collector - this element is designed to collect condensate formed inside the chimney.

In order to calculate stainless steel chimneys, one should determine the amount of energy released by the heater. Only then will it be possible to choose the right device for the removal of combustion products.

Stainless steel pipe options

Today, you can find as many as three options for this kind of chimney.

- Single-walled (thickness - 0.6-20 millimeters).

- Corrugated.

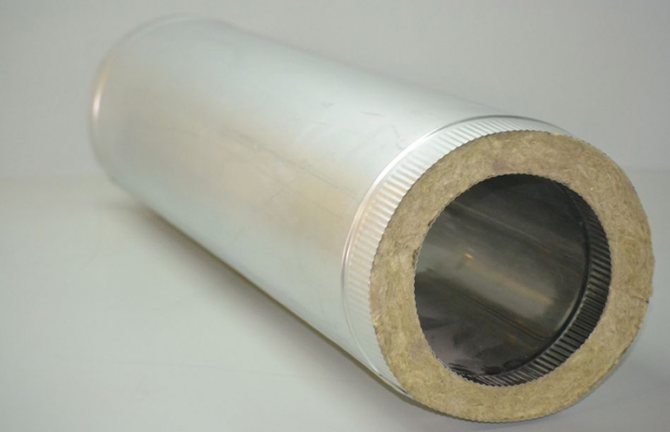

- Three-layer sandwiches (two pipes + insulation).

Let's consider each of the options, taking into account their pros and cons in the form of a table.

| Pipe type | Dignity | disadvantages |

| Single layer | Low cost, smooth inner surface. | High heat transfer rates, condensation may form, the need to install thermal insulation. |

| Corrugated | Elasticity, some flexibility. | Low resistance to high temperatures, rapid wear, corrugated inner surface, on which condensation can accumulate, is not suitable for horizontal sections of the chimney duct, it is necessary to fix and install thermal insulation. |

| Three-layer | Low heat transfer rates, versatility, easy assembly, tight joints. | The rather high cost of this type of pipe compared to others. |

Each of the types of pipes has its own characteristics that hinder or help in choosing

Extremely important! The regulatory authorities, seeing the corrugated pipes, are likely to refuse to start the gas.

Video - About choosing and buying a stainless steel chimney

Types of stainless steel chimneys

When planning the installation of a stainless steel chimney, you must first get acquainted with all the systems, since they are quite different in several characteristics.

Chimney type

There are several options here:

- Single layer, single wall models. They are made from single-sheet stainless steel, thickness - 0.5-1 mm. The pipes can have either oval or circular cross-section. Such chimneys are usually located indoors. Or outside, but then they are pre-insulated - with basalt, then fiberglass or heat-insulating foil material.

- Double-walled pipes - sandwich chimneys. They consist of three layers: outer and inner - stainless steel pipes, and between them - a layer of mineral insulation - from ordinary mineral wool or basalt variety. The sections are different: there are narrow materials (100 mm), the widest ones have a diameter of 1000 mm.

- Corrugated products. These are flexible sleeves that can be up to 10 meters long. Corrugation is used to obtain curvilinear transitions, to assemble a chimney to heating systems, where the boiler efficiency is low, in old buildings, to organize chimneys with non-standard geometry.

The station wagons are sandwich pipes, they can be used both outside and inside the premises. Products made of corrugated stainless steel do not always have the required level of strength and heat resistance. Single-layer components are mono-systems that guarantee excessive consumption of heat carriers, abundant formation of condensate, if additional insulation is not provided outside.

Stainless steel grades

The biggest threat to chimneys is sulfuric acid vapor deposited on the walls of the chimney. To minimize the impact on pipes, it is necessary to consider the steel grades that are used as raw materials for their production.

- 304 is a low carbon (maximum 0.08%) non-magnetic steel, ductile, but having a high density. It can withstand high temperatures, even damage to the outer layer is not able to destroy its structure. The alloy is well resistant to acids, corrosion, alkalis.

- 310 is a heat-resistant material with a high content of nickel and chromium. These components can successfully resist oxidation. Dross appears on metal only at temperatures around 1500 °. The brand is considered elite, so its price is appropriate.

- 316, 316L - steel enriched with inclusions of nickel, molybdenum. These additives increase resistance to high temperatures and acids. The alloy is considered an improved version of grade 304, so it is used to produce kits for almost all types of chimneys.

- 316Ti, 321. Titanium is added to both alloys for increased strength and resistance to aggressive environments. Another plus is better corrosion resistance.The temperature limit for them is about 850 °. These grades of stainless steel are even used for the manufacture of vessels and apparatus for working with acids.

The L stands for low carbon content. For three-layer sandwich chimneys, different grades of stainless steel are used. Internal modules are made from high quality raw materials, external ones, which do not experience such aggressive influences, from cheaper materials.

Heating system type

If you plan to purchase pipes and install a stainless steel chimney, then you need to focus on the type of autonomous heating system. Each of them requires "own" alloys, a certain wall thickness:

- gas boiler - 304, 321 (0.5 mm);

- diesel boiler - 316 L (0.5 mm);

- fireplace, stove - 321 (0.5 -1 mm);

- solid fuel boiler - 310, 321 (1 mm).

For gas and liquid fuel equipment, special acid-heat resistant alloys are required. For solid fuel boilers, the main threat is high temperature, so heat-resistant stainless steel grades are chosen for them.

Pipe connection methods

You can use two options for joining elements:

- "Through the smoke." In this case, each next module is put on the previous one. The advantage of the method is reliable protection against smoke, since there are no obstacles to its passage. The downside is the lack of a solution to the problem of condensate drainage, which will cause the heat insulator to constantly get wet. If a condensate drain tee is installed in the system, then there is no problem.

- "By condensate". This is the “opposite way” - the upper tube is not put on the lower module, but inserted into it. The insulation is completely protected from moisture, as it flows into the condensate collector. But the smoke has a good chance to get into the room, if there is even the slightest loophole. This method is used if the systems do not include tees for condensate drainage.

There are two rules about these installation methods that must be taken into account. Horizontal or inclined sections require installation "through smoke" so that the combustion products can move further unhindered. On vertical sections, it is better to use a condensate connection so that the flowing liquid cannot spoil the insulation.

Features of operation

A stainless steel chimney is quite popular today, but like other chimneys, it needs to be checked from time to time and generally looked after. Below we will show you how to do it correctly.

- The first thing to do when using a steel chimney is to thoroughly inspect the heater before each season. From time to time it may be necessary to clean it from soot and other dirt.

- Next, you need to check the draft when the time comes for the first ignition. If it is not there, then you need to find out what the matter is. As a rule, it is enough to simply warm up with improvised means and then check the traction with a match.

Important! The thrust is checked with the regulator damper or gate open.

- It is necessary to inspect the chimney, check if it is clogged with soot. You can get rid of it with a soft stainless steel brush and a plaque softener.

- At times, you can lay aspen wood, which can be used to remove the soot in the chimney.

- Proper use of the stove involves the use of deciduous wood that does not contain resin. It should also be noted that it is impossible to use cut plywood and chipboard for ignition.

It is necessary to take into account the presence of a number of operating features that determine the service life of the chimney

You may be interested to know which conditioners worth buying.

The elements

To create a stainless steel smoke exhaust structure, it is necessary to use not only an elbow and pipes, but also many other elements, such as:

- stainless steel chimney sealant - this material can be purchased at any hardware store. The main thing is that it is fireproof;

- stainless steel corrugation for a chimney - often corrugated elements are used for chimneys installed on walls. The corrugation must match the size of the pipe;

The picture shows an example of a stainless steel chimney clamp.

- stainless steel chimney clamp - this element has a high level of strength and is responsible for fixing the constituent parts of the structure;

- stainless steel chimney paint - you should use a moisture resistant fireproof paint.

- stainless steel chimney gate - many do not even have a clue of what the so-called gate is. In fact, an ordinary valve is called a gate valve. It is designed to regulate the draft in the chimney. An overview of the types and characteristics of ceramic chimneys is here: https://mykaminz.ru/dymoxod/obzor-vidov-i-xarakteristik-keramicheskix-dymoxodov.html.

This element is lightweight and versatile, it can be used in any type of construction;

- a stainless steel chimney flange is an element that is designed to fix the device directly on the surface of the building: on the roof or wall;

- stainless steel chimney fasteners - fasteners are often made of steel. The size of all fasteners must correspond to the overall dimensions of the chimney. Read an overview of the types of chimney for the fireplace.

Installation methods

There are two ways to locate the chimney, based on the location of the heater in the house.

- Outside the house... The simplest and therefore the most popular chimney installation technology. For the successful implementation of the venture, a double-circuit chimney with fastening in the form of clamps is used. To prevent heat loss, thermally insulated pipes are used.

- Indoors... A more complex and expensive option, which requires taking into account the design of the room, because the chimney will go through the floors and the roof to the outside, that is, to the street. The difficulty lies in the requirement to insulate the chimney, especially at the point of contact with the roof, where spark arresters are installed. However, the plus of such a system is to reduce waste on heating.

There are two different installation methods, each with its own pros

Self assembly

You can assemble the sandwich ventilation yourself, without professional help. To do this, you need to prepare all the elements of the pipeline, familiarize yourself with the stages of the work.

The main parts of the chimney:

- Knee at a 90 degree angle.

- Adapter for connecting pipes with a furnace or boiler.

- Part with a sealed cover through which the system can be cleaned.

- Tee for transition from horizontal to vertical.

- Condensate drainage mechanism.

- Tee with an angle of 45 degrees.

- If you need to get around difficult places, bends at an angle of 45 degrees.

- A plug to protect the pipe insulation from moisture ingress.

- Clamps for strengthening the connections of individual elements.

- Wall brackets.

- Trunk elements (depending on the length, complexity of the pipeline).

- Conical roof.

- A cone that covers the end of the chimney.

After purchasing all the parts, you can start preparing.

Preparatory work

Before installing the chimney sandwich pipes, preparation must be done. It includes several actions:

- Draw the finished pipeline on a sheet of paper. Think about where he will change direction to bypass other communications.

- Make a hole in the roof, walls, ceiling. In these places, the surfaces need to be strengthened.

- Mark the chimney circuit.

- Install supporting elements.

If the part passes through the insulation material, the contacting surfaces must be treated with a heat-resistant material.

Connection types

Often, when installing a chimney, pipes are connected "into a bell". To seal the joints, a special heat-resistant sealant is used. To strengthen the connections, you can use special couplings.

Tips for the location of a sandwich chimney

There are two options for the location of the sandwich pipe:

- Chimney outlet through the roof. The standard method, which involves the creation of holes in ceilings, roofs.

- Chimney outlet from sandwich pipes through the wall. This allows to reduce the load on the floors, but requires more materials for the manufacture of the pipeline.

Once the location is selected, the number of parts required to manufacture the system can be accurately calculated.

The chimney is brought out through the wall

The order of assembly of the structure

Sandwich chimney assembly procedure:

- When the holes in the ceiling, roof are made, you can start assembling. First of all, a special adapter is installed between the heating equipment, the pipe.

- The rest of the elements are installed before the overlap.

- A special adapter is fixed in the hole, which has two plates, a branch pipe.

- A tapered roof or a stainless steel sheet with a hole must be installed at the point where the pipe comes out of the roofing material.

- All joints, connections, chimney exit points must be sealed. For greater protection against the occurrence of ignition, it is necessary to additionally insulate the floors, the place of contact with the roof.

- Extension of pipes above the roof is calculated according to SNiP.

If you need to connect a sandwich pipe to an old brick chimney, you need to buy a special adapter. At the end of the work, you should check the reliability of holding the one-piece structure with the brackets, tighten the clamps. Check the system for leaks. To do this, it is enough to set fire to a small amount of fuel and wait 15–20 minutes. Inspect all joints for smoke leaks. Sandwich pipes have been gaining in popularity over time. This is due to their reliability, resistance to weathering, tightness of the joints. Simple installation saves money on professional assistance. For the owner of a private house, it is enough to choose a steel grade, a type of insulation, buy all the elements of the pipeline, and perform the work according to the instructions.

Installation Recommendations

The recommendations below will help you install the chimney correctly so that it functions without any difficulties.

- If you put a pipe with a height of five meters or more, then you can achieve good traction.

- The length of horizontal sections should be up to one meter, not more.

- Installation of a chimney on the street or in an unheated room involves the installation of thermal insulation material.

- If the chimney passes through a roof built with combustible materials, a spark arrester must be installed.

If you strictly follow the suggested recommendations, you can install the chimney without any problems

Important! Docking of uninsulated pipes in the wall is prohibited if the chimney ducts are not insulated.

Tips for the location of the sandwich chimney

Before installation, you should carefully consider the layout of the chimney. There are 2 methods of placing sandwich chimneys:

- Inside the house with a pipe leading out through the roof.

Such a scheme allows to increase the energy efficiency of the house due to an additional source of heating, to protect the structure from negative atmospheric influences, to reduce the volume of condensate, and to naturally improve the traction force. However, placing a chimney in a building increases the risk of carbon monoxide being released into the room and causing a fire. In addition, increased attention will be required to work on the thermal insulation of the passages through the interior and roof ceilings, as well as to seal the place where the pipe goes to the roof.

- Output of the chimney to the street immediately after connecting to the heat generator.

Here, all the advantages of the previous scheme are reduced to naught, but the safety of using the chimney is increased and the technology of removing the pipe through the wall is simplified.

On a note! Sandwich chimneys of some heat generators, for example, operating in the smoldering mode, according to the requirements of SNiP, are prohibited from being placed inside the household.

When developing a chimney scheme, you should adhere to the following rules:

- Height is not less than 5 meters.

- No more than 3 bends.

- The total length of horizontal sections is no more than 1 meter.

- It is forbidden to withdraw the chimney into the ventilation, as well as the connection of ventilation lines to the chimney.

- Equal distance of the sandwich from the wooden elements of the rafter system.

- The minimum elevation above the roof made of combustible materials is 1.2 m, the installation of a mesh spark arrester is mandatory.

- The minimum elevation above a flat roof is 0.5 m.

- With a gable roof, the elevation level depends on the location of the pipe outlet:

- When removed from the ridge of the roof at a distance of up to 1.5 m - 0.5 m above the ridge element.

- At a distance from the ridge of the roof at a distance of 1.5–3 m - at the level of the ridge.

- At a distance of more than 3 meters from the ridge of the roof - at the level of a line drawn from the ridge element at an angle of 10 ° to the horizon.

- In the presence of a taller building adjoining closely, the pipe is brought out higher than the last one.

- Mandatory presence of at least 1 revision compartment.

Important! The passage of the smoke sandwich pipe through the living quarters is prohibited.

Voting: the best chimney manufacturers

Which chimney manufacturer would you choose or would you advise to choose?

CRAFT

30.77 % ( 4 )

Volcano

23.08 % ( 3 )

ROSST IN

0.00 % ( 0 )

Jeremias

0.00 % ( 0 )

Thermophore

0.00 % ( 0 )

Ferrum

7.69 % ( 1 )

Elits

7.69 % ( 1 )

Inzhkomtsentr VVD

23.08 % ( 3 )

Phoenix

7.69 % ( 1 )

Baltvent

0.00 % ( 0 )