Any autonomous heating system of a country house must have a chimney, therefore, before erecting a building, many owners are faced with the choice of materials for it. Often the competition is won by asbestos pipes, which are successfully used for the construction of other building elements. For example, ventilation ducts are made of them, or used in the construction of foundations. The solution is quite logical: such an asbestos structure is inexpensive, the material is non-combustible, so it will fit perfectly. However, in any case, the owners have a new concern - the need for thermal insulation work. You need to arm yourself in advance with the knowledge of how and how to insulate an asbestos chimney pipe, or structures made of other materials.

Chimneys and materials for their insulation

Such structures are necessary for any heating device: both solid fuel and gas. Despite the need for a design, not everyone pays due attention to the chimney. And in vain: it requires protection from many influences, just like it needs to be regularly looked after.

All chimneys need protection. The most common structures are made of bricks, metal and asbestos-cement pipes. Any of them is threatened with gradual destruction, as they provoke combustion waste and corrosive moisture that regularly accumulates on the walls of the channel. The question of how to insulate an asbestos chimney pipe, as well as metal or brick structures, requires a correct answer.

The choice of heat-insulating material is limited, since it must meet the requirements for heat resistance and guarantee fire safety. Neither polystyrene, nor its "relative" - expanded polystyrene, nor other analogs are suitable for this purpose. Insulation should:

- have a minimum thermal conductivity;

- be light so as not to create unnecessary load on the roof;

- be plastic, flexible, so as not to complicate the installation of the master;

- not be afraid of atmospheric precipitation, moisture, any aggressive environment;

- have a sufficiently long service life without loss of qualities.

Various materials are chosen for the role of insulation: for example, mineral wool, glass wool. They are fire-resistant and can easily withstand temperatures above 400 °. Other candidates are fiber insulation or slag concrete slabs. The most convenient are roll materials, the installation of which can be easily handled even alone.

The method of installing insulation for structures is different. For a brick, metal and asbestos chimney you need "your" material and specific technology. Naturally, speaking of thermal insulation, they mean the protection of the outer walls.

Asbestos pipes are the most controversial candidate on the list for the title of a smoke exhaust system, so you first need to consider them in detail, assess the advantages, disadvantages and potential threats.

https://youtu.be/Of9aFWob-b8

Insulation types

The following requirements are imposed on the insulation for the chimney pipe:

- the material must be available for DIY installation;

- it must be non-flammable;

- it should be suitable for insulating your type of chimney.

We recommend that you familiarize yourself with: Types of air conditioners for an apartment - which one is better to choose and installation rules

Three types of chimneys are common:

- brick;

- steel;

- asbestos.

Each pipe has its own best type of insulation:

- Refractory mineral wool (basalt insulation). This insulation can be used for any kind.For the installation of the shell of an iron pipe with high-temperature operation, basalt friable incombustible wool is used, since the metal has the highest thermal conductivity. The shell structure is produced ready-made (sandwich) or can be assembled by hand.

- Plaster. The classic type of insulation for brick chimneys. Suitable for stoves using any fuel.

- Broken brick or slag. The material at hand is poured into the gap between the outer wall of the chimney pipe and the mounted insulating casing. The disadvantage of this design is its heavy weight.

- Extruded polystyrene foam (EPS). A special heat-insulating material that is used to insulate brick chimneys or other structures that have a square, rectangular shape. Not suitable for classic wood-burning or coal stoves, since the heating temperature of the chimney exceeds the operational characteristics of the material, in other words, the expanded polystyrene will melt.

Why and where is insulation needed?

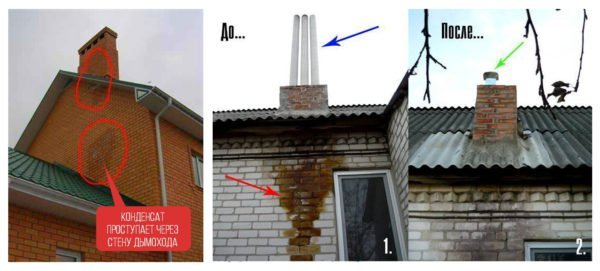

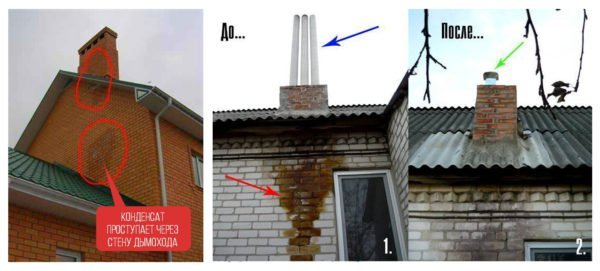

No one doubts the fact that any structure will begin to deteriorate over time. This applies to all structures: brick, metal or asbestos chimneys. In the process of exhausting gases, combustion products accumulate on the walls of the pipes. Condensation forms in them, which forms at the dew point: where cold masses meet warm streams. High-quality insulation solves several problems at once. It allows you to:

- to strengthen the structure, since the heat-insulating frame is an additional protection against temperature extremes and gusts of wind;

- reduce the risk of destruction of the walls of the structure due to constant contact with condensing aggressive moisture;

- to make the work of the heat generator more efficient, since thermal insulation implies lower fuel consumption;

- prevent problems with a deterioration in traction: high-quality insulation reduces the thermal conductivity of pipes, prevents intensive accumulation of deposits.

The insulated chimney will look better and will last longer, as the wear resistance of the protected materials increases. In addition, the roof adjacent to the structure will also receive additional protection.

Insulation is necessary in the place of the pipe where the warm surface of the chimney "meets" cold air. As a rule, this site is located either in a cold attic, or where the structure is displayed on the roof.

The subtleties of self-insulation of the chimney

Before insulating a chimney iron pipe, you need to make sure that it is assembled and installed in strict accordance with technical requirements and safety rules.

A properly functioning heating system must meet the following standards:

- The height of the chimney must be at least 5 meters in order to ensure optimal draft in the furnace.

- The gap between the chimney and flammable roofing materials (rafters, floor beams) must be at least 25 cm.

- The presence of a spark arrester on an insulated chimney installed on a roof covered with combustible roofing materials such as slate, ondulin, soft tiles and the like. A spark arrester is a special stainless steel grate, which is placed on the outlet of the chimney. To protect against debris, a metal umbrella is put over the pipe.

For fire safety purposes, when organizing a smoke exhaust system, make sure that a certain distance remains between the upper ceiling of the stove and the ceiling. For example, for metal ovens, a gap of 1.5 meters is provided.

The approach to its insulation will depend on where exactly the chimney is located and how it is used.

Tags: chimney, metal, hand, own, insulate

«Previous post

Areas of application of asbestos products

Asbestos pipes, initially considered suitable only for the construction of reclamation systems, are now used much more widely. They began to be used:

- during the construction of a gravity sewage system;

- as casing for wells construction;

- in sanitary and technical water supply systems;

- when creating drainage systems, storm drains;

- as a formwork for bored columnar foundations;

- and in the construction of ventilation systems, smoke ducts.

The great popularity of the material is explained by its advantages when comparing asbestos products with metal pipes. Asbestos cement is not threatened by corrosive processes. It has a small coefficient of linear expansion, which is acceptable when heated. The cost of asbestos pipes is quite affordable.

These products have no significant drawbacks, but there is a drawback. They can be considered as their inability to withstand strong impacts. If serious damage is not allowed during installation and operation, then the pipeline can serve for 30-40 years.

Asbestos pipes: pros and cons

Chimneys made of asbestos pipes are an option that has become widespread since the days of the Soviet Union. There was a "breakthrough" for a banal reason. This is cheapness due to the huge deposits of "inextinguishable" material and rather simple production. Later, after the collapse of the USSR, asbestos-cement pipes also turned into smoke channels, although these materials are considered far from the best of contenders.

Typically, a list of the candidates' advantages is given first. The pluses of asbestos products include:

- relatively low price;

- light weight for easy installation;

- lack of seams and resistance to moisture.

But the list of disadvantages is much more.

- Asbestos pipes can withstand a maximum of 300 °, therefore they are completely unsuitable for stoves that run on solid fuels, since in this case the temperature inside is much higher. It is 600-800 °.

- The porous structure of the material facilitates the absorption of condensate trapped on the walls. This inevitably leads to the destruction of pipes. Chimney cracks can cause a fire.

- In addition to condensation, soot accumulates in the asbestos smoke channel, which after a certain period of time begins to burn. A possible consequence is the explosion of an asbestos chimney.

- Large amounts of soot lead to a dangerous narrowing of the inner diameter. Due to the reduced clearance in such pipes, the thrust, which is not the best as it is, will only worsen.

- High-quality cleaning of the channel is somewhat difficult, since there is no way to make an inspection hole in it to monitor the technical condition of the chimney sections.

A serious disadvantage of asbestos products is their health risks. This has been recognized by the World Health Organization - WHO. However, the biggest hazard is asbestos dust, not the products themselves. When heated, pipes do not emit harmful substances, so there is no real threat to the owners of such chimneys.

Asbestos chimney: to be or not to be?

Arrangement of flue ducts for stoves requires a serious approach to the choice of materials. Some characteristics of asbestos pipes cannot be considered suitable for such structures.

- Heat. As already noted, the maximum for asbestos is 300 °. However, the temperature in the chimney is much higher. Another disadvantage is the use of rubber seals during installation. These elements stretch quickly, which means they lose their qualities. The pipe itself will crack sooner or later.

- Accumulation of soot on the walls. Since a large amount of heavy substances is regularly concentrated in the chimney, they invariably remain inside the duct.Due to the high porosity of the material, condensate accumulates on the walls, it mixes with soot. It is simply impossible to deduce them due to the nature of the material.

These criteria are often decisive. Especially if the installation of the chimney is done for a wood or coal stove. A porous surface leads to a rapid accumulation of soot, and in such conditions, its ignition can occur at any time. After a fire, the temperature inside will rise greatly, which means that the risk of a possible explosion will increase. A suitable option for asbestos is one. Rather, two: this is the installation of an intermediate or last section of the chimney.

A chimney from asbestos pipes can be justified only on one condition: if the equipment is gas. But even in this case, the question of how to insulate the asbestos chimney pipe is considered without fail.

How to use an asbestos chimney pipe?

Is it possible to arrange a smoke channel from asbestos-cement pipes? Yes. But in order to avoid harmful effects, two conditions must be met:

- The installation of such a channel is recommended only in those areas that are significantly removed from the heater. For example, only in the role of the final section.

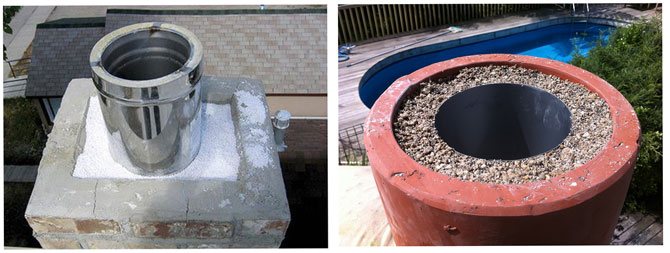

- When designing, it is necessary to provide for insulation and insulation. Often, brick protection is arranged for such a chimney. The second option is a sandwich with an outer jacket.

These measures will help to avoid possible fires, protect from the consequences associated with unsafe material. Now pipes made of asbestos cement are used much less often if we compare our time and what happened 30-40 years ago. Experts do not recommend making such a chimney: its effective operation is possible only if heating devices are not used constantly, but periodically.

How to insulate an asbestos chimney pipe?

An asbestos-cement pipe is able to withstand temperatures up to 300 °, but the material has a high thermal conductivity, therefore it quickly gives off heat to the environment. The heating of the chimney surface is almost the same as the temperature of the smoke. Warming it with a non-combustible heat-insulating material makes it possible to waterproof the pipe, significantly reduce the formation of condensate, and avoid its freezing. Such measures are necessary to increase the service life of the structure.

Simple winding of the pipe in this case will not help to achieve the goal. To ensure good thermal insulation characteristics, the work is carried out in stages. The first one is the choice of thermal insulation material. The best option would be mineral wool, or its basalt variety.

Other types of cotton wool insulation - glass wool or slag wool are also suitable for work. The most ideal insulation is one with a lower degree of water absorption. The thickness of the material for external insulation is in the range of 70-100 mm. The process of warming itself is unlikely to cause difficulties.

- Fixation of mineral wool. The heat insulator is wound around the pipe, then attached to it using a knitting wire, or with special clamps.

- Insulation protection. Minwata needs protection. A layer of foil-clad insulation must be arranged on top. It makes it possible to protect the material from moisture.

- Manufacturing of a frame for thermal insulation. Metallic is more often used. For example, a steel pipe of a suitable diameter becomes the ideal outer layer of such a sandwich.

Since the thermal insulation material needs to provide reliable protection, the top of the gap is closed with cement mortar. Installing the baffle hood completes this job.

Features of insulating metal pipes with your own hands

When passing through the boiler pipe, heated gases lose their temperature, giving off part of their own heat to the walls of the structure. But at the same time, the gas must be discharged outside.

The quality of draft largely depends on the temperature of the walls of the chimney.With insufficient draft, there is a possibility of smoke in the room and even poisoning with waste combustion products.

The efficiency of the removal of combustion products, in other words, the quality of traction, depends on the speed of overcoming the moment of condensation formation. This indicator is largely determined by the material from which the chimney is made.

In the insulated chimney, the moment of condensation formation is reduced and the quality of draft improves

If a stainless or galvanized steel pipe is used as a chimney, then the period of condensation formation lasts for 2-3 minutes, but a standard brick chimney needs much more time - about half an hour.

At the moment of the appearance of condensate and until it disappears, water is actively mixed with the products of combustion, as a result of the reaction that occurs, an acid solution appears. It is this acid that has a negative effect on the pipe, causing its destruction.

If an asbestos pipe or brickwork is used as a chimney, then the residual condensate can be absorbed into their walls. In the absence of high-quality insulation, the accumulated moisture will freeze and destroy the chimney.

If you qualitatively insulate the chimney from a gas boiler, then you can identify a considerable number of advantages. The main ones are:

- Reducing the influence of atmospheric precipitation;

- Reducing heat loss during the heating season;

- Improving traction quality;

- Presentable appearance of the chimney;

- Reducing the volume of condensate that forms on the outside of the chimney.

Taking into account the above advantages, it is obvious that insulating the pipe of a gas boiler is simply necessary. For work, various heaters can be used, each of which differs not only in physical characteristics, but also in the features of the work.

Insulation is required only for the part of the chimney that is located outside or in an unheated attic. In this case, the pipes attached to the facade of the building must be completely insulated, including the horizontal section passing through the wall.

The choice of the method of insulation is determined by the material from which the gas chimney is made. Insulation of the chimney from a gas boiler depends not only on its design, but also on the material chosen.

It is possible to insulate an asbestos-cement pipe in three fundamentally different ways. Mineral wool, brickwork or plaster are suitable for their implementation.

When organizing chimneys for gas heating boilers, sandwich-type pipes have recently been used quite often. This is not only convenient, but also quite effective, because condensate does not accumulate inside the chimney, and heat loss is significantly reduced.

The process of insulating metal chimney pipes in a private house begins with the selection of the necessary heat-retaining material. The main characteristics that the insulation must meet:

- Resistance to high temperature impact and drops. The material must be both frost-resistant and non-combustible, withstanding up to -35 degrees on the outside (for example, on a frosty night outside) and up to 300 degrees on the inside.

- Relative lightness. As in the case of carbon deposits, the applied insulation should not overload the pipe structure and worsen its stability. Also, you should not allow its weight to strongly "press" on the roof or other roof material.

Mineral wool - a common insulation for chimney pipes

It is equally important to select the material (including its composition, shape and dimensions) in such a way that it matches the design and type of the chimney itself, otherwise it will be fraught with difficulties in its installation (application).

Having specified the quality characteristics of heat-retaining materials we need, we will consider a number of them that can most often be found on sale via the Internet in construction markets or in hypermarkets:

- Construction plaster. A relatively cheap material that allows you to reduce heat loss by about 25-30%. The disadvantages include the weighting of the structure from additional retaining elements.

- Mineral wool. Such insulation is the least susceptible to thermal effects and is resistant to toxic smoke fumes generated during operation. Cotton is used to cover both indoor pipe elements and those that go outside. The filler of the coating differs in fiber, fiber length and viscosity (thickness). On sale you can find cotton wool with 4 types of filler: fiberglass, stone chips, basalt and slag. The advantages include its high temperature resistance and environmental friendliness.

- Cylindrical "sandwich" heat insulator. Its undoubted advantage is ease of installation, since it is sold already in "finished form" for various diameters of the outlet pipe. The design includes cylindrical stainless steel rolled metal, in which a light mineral wool filler is laid, for example, basalt, with a longitudinal hole in the center for the pipe diameter.

- Extruded polystyrene foam or EPS. A durable waterproof material that is used for external thermal insulation of stone and brick chimneys. It is sold in the form of plates, subdivided into classes, depending on heat resistance (or flammability). The coefficient is considered from 1 to 4, where the first two are the most heat-resistant and can withstand gas temperatures up to 500 degrees at the exit from the pipe.

- Stainless steel casing. Just like the "sandwich" cylinder, a stainless steel casing is put on the outer elements of the pipe, filling the space between it and the pipe with mineral fiber or asbestos, closing the top with cement mortar from moisture and combustible particles flying out along with the smoke.

- Tree. In order to save money, the material of the "cylinder", or rather, in this case, the outer box, can serve as a tree. It is made of panels knocked together at right angles so that 15-17 cm remain between them and the pipe. This space is then laid and sealed with a suitable heat insulator.

The cylindrical "sandwich" heat insulator is easy to use

How and with what to insulate other structures?

The most difficult work lies ahead for the owners of a brick chimney; the metal may not require additional manipulations at all. But in any case, the main requirement for insulation is its incombustibility.

Thermal insulation for brick construction

There are two options. It is possible to insulate with mineral wool (or cotton varieties) or plaster, but in the latter case, the work will take more time and will require efforts from the master.

Use of cotton wool

The easiest option is to fix mineral wool (glass wool, basalt) with tape. After wrapping, the insulation is “hidden” under cinder-concrete or asbestos-cement slabs. Or left open at all. This is not the best option, even for an attic.

Application of plaster

The whole work consists of several stages, very extended in time.

- First, a reinforcing mesh is fixed on the walls of the chimney with dowels, then a solution consisting of fine slag, cement and lime is thrown onto it. The maximum layer thickness is 30 mm. Cover all surfaces at once.

- Mineral wool is attached to the slightly dried solution, then the solution is again thrown in, which is pressed in with a fiberglass reinforcing mesh. Then they wait for the plaster layer to dry completely.

- After the mortar has set, the surfaces are leveled, this time the mortar layer is made thinner. Dried walls are treated with a primer: at least twice, with a break for drying the composition.

The last stage is painting the chimney.Often, facing brick, stone, artificial or natural, decorative plaster or porcelain stoneware tiles are used to decorate chimneys.

Thermal insulation of metal pipes

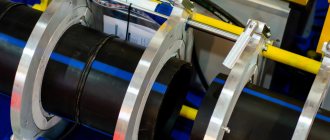

Many iron structures do not need additional manipulations, because there are products on sale that can be called semi-finished products. They consist of two pipes, heat-insulating material has already been laid between them.

If there is no such design, then such a product is not too difficult to create on your own. To implement the plan, they buy a pipe that is 60-80 mm larger than the diameter of the chimney. It is put on the channel, then fixed on the base. The space between the elements is filled with light free-flowing or fibrous insulation.

An alternative is to use the same mineral wool as a sandwich filling. If the roofing system is reliable enough to withstand the additional load, then heavy "stuffing" can be used as a heat insulator: for example, sifted slag or broken brick.

How to insulate a chimney: effective ways

Every conscientious developer understands that the foundation and walls need to be insulated. But for some reason, few people think about additional thermal insulation of the chimney. The fact is that usually the owners do not understand very well why such a procedure is needed. Finding out its relevance is first of all, because then it will become clear how important such a process is.

In this article, we will describe in detail how to properly insulate a chimney with your own hands at minimal cost.

It is unlikely that anyone will question that the chimney is capable of collapsing over time. This happens due to the fact that during the combustion of firewood, not only smoke, but also steam gets into the chimney.

Part of the moisture that rises up with the steam settles on the inner surface of the chimney. Since moisture does not completely evaporate, it freezes with the onset of cold weather.

This leads to the fact that the material from which the chimney is made begins to crack.

Condensation, which falls on the surface of the chimney due to the difference in temperature outside and in its cavity, also has a destructive effect. The chemicals that are formed during the combustion of firewood can also accelerate the destruction of the chimney. In many ways, the action of these substances is similar to that of an acid. That is, the pipe must be protected from such an effect.

The described processes can be made less dangerous if thermal insulation procedures are carried out. As a result, the chimney will remain in good condition for a long time, and the heating itself will be of the highest quality, since heat losses will noticeably decrease.

It is necessary to carry out thermal insulation measures in relation to the chimney for many reasons. This is one of the elements of the house that is exposed to particularly intense negative influences. In summer, the pipe heats up a lot, and freezes in winter. If you carry out insulation, you will notice the following advantages.

- Heat loss will be less.

- Roofing materials will remain in good condition.

- The chimney can last longer.

- The insulated chimney looks more aesthetically pleasing.

You can make the chimney insulated using different materials. Their cost does not really matter, since the insulation itself will require little. But the owner should pay special attention to the insulation technology itself. Usually the chimney is insulated from the outside.

To provide decent insulation, it is better to opt for fiber insulation. These include mineral and glass wool. It will be possible to increase the thermal insulation with the help of cinder concrete, broken bricks and similar materials. The most important thing is that the insulation used is distinguished by high fire safety, because the heating temperature of the pipe can be very significant.

The technology of pipe insulation is also determined by what material this element is made of. Most often, brick, steel and asbestos cement are used to create a chimney. Each of these cases has its own characteristics of thermal insulation work.

The chimney made of asbestos cement must be insulated with mineral wool. Any dust and debris must be removed from this element before the main work. The insulation will be placed in a special casing made of galvanized iron. The diameter of the casing is selected so that it is 6 cm larger than the diameter of the chimney.

The length of such a construction for insulation may be different. But it is made up of parts that are inserted into each other. Each element has a maximum length of 1.5 meters. When the casing is put on, a heater is laid between it and the pipe. After tamping it tightly, you can put on the next element, thus building up the pipe.

The remaining voids are filled with cement mortar. The last element of the cover must be inclined. Sometimes the owners manage to do without a metal casing. If this option is chosen, then the mineral wool must be wrapped with clamps. But it is better to use several slabs of mineral wool in this case.

We invite you to familiarize yourself with the ventilation device in the Russian bath

To increase the operational life of such a heat-insulating structure, it is necessary to additionally carry out steam and waterproofing. Otherwise, the mineral wool will deteriorate.

Finding a steel chimney in a hardware store, which has an additional thermal insulation layer, is not difficult today. This design is carried out using two pipes with different diameters. In the space between these elements, there is a fire-resistant thermal insulation material. But you can perform such insulation yourself.

For this, two pipes are taken, differing in diameter. The smaller pipe is placed in the larger one, and the free space is filled with a fibrous heat insulator. At the same time, you do not even need to prepare any complex tools. A tape measure, fasteners, a screwdriver, a stationery knife and a grinder are enough to cut the material. Scotch tape is also useful, with which you can fasten individual pieces of insulation.

The most difficult thing for the owner is if he is faced with the task of thermal insulation of a brick pipe. Two options are possible here, each of which should be discussed in detail.

The outer side of the brick chimney is covered with a reinforced mesh. A plaster mortar is applied to it so that its thickness is about 3 cm. You need to prepare the plaster from slag and lime, adding a little cement.

Usually 2 coats are applied, the first of which is liquid. When it dries, you can cover the work surface with a thick solution. After leveling the plaster, you need to wipe it well.

Then the chimney is covered with lime to make it look better.

The brick chimney is first covered with mineral wool, after which an asbestos cement cladding is formed. In this case, asbestos-cement slabs are used. They can be plaster later.

The most correct decision of the owner of the house would be to insulate the chimney immediately after the construction of the building is completed. If you miss such a moment, the chimney can no longer be saved, since it will begin to collapse. As a result, it will become necessary to replace or repair the chimney completely.

Articles

Many people believe that the chimney is a decorative element of the house, and the insulation of chimneys is surprising at all.

Why is it necessary to insulate chimneys? What can freeze in them?

Chimney pipes

During the combustion of a fireplace or stove, oxygen vapor (condensate) begins to accumulate in the chimney, since the temperature on the surface of the chimney is higher than the temperature of the surrounding air. Such condensate is not only damp, but also a very aggressive substance, which consists of moisture, fuel combustion products, and acids.

When the chimney cools down, the entire wall surface is impregnated with this condensate. And when it's freezing outside, it becomes especially dangerous.

Insulation of chimney pipes is just necessary to avoid this negative process.

Tools

Before insulating the chimney pipe, the following tools must be prepared:

- roulette;

- screwdriver;

- puncher;

- scissors for metal;

- angle grinder;

- a knife for cutting insulation;

- dowel-nails.

We offer you to familiarize yourself with a grid oven for a Russian bath made by hand

Insulate the chimney pipe with what?

Insulation from slag mortar

Correctly selected chimney insulation will allow:

- avoid destruction of the chimney structure;

- protect the roof, which is located directly next to the chimney;

- to make the appearance of the chimney more aesthetic.

How to insulate a chimney: different insulation materials are suitable for this purpose, such as:

- slag solution;

- brick;

- mineral wool;

- slag concrete slabs etc.

Advice: such insulation for chimney pipes as mineral wool requires special adherence to safety rules, particles of this insulation must not be allowed to enter the respiratory tract and eyes.

Before insulating the chimney, you need to find out what type of chimney, what material it is made of.

This will determine how and what to insulate the chimney pipe.

Asbestos-cement pipes are mainly insulated using heat-insulating materials that are applied to the outer parts.

- The surface of the chimney pipe, which is located above the attic floor, must be cleaned of dust and dirt.

- Place URSA mineral wool in a steel casing made of galvanized or roofing iron.

Advice: when choosing the diameter of the casing, it must be borne in mind that the free space between the casing and the chimney must be at least 6 centimeters.

- The casing itself should be made of several parts, the height of which should not exceed one and a half meters, this will facilitate the work of compacting this insulation.

- Each of the parts of the casing must be fastened together so that the gaps are no more than 100 mm.

- Insulate the chimney from asbestos cement to the very top.

- Install the upper part of the pipe with a slight slope.

- Seal the empty space between the pipe and the casing with cement mortar.

Advice: for cement mortar, you can take concrete of the M-150 brand.

Advice: you can use mineral wool without a steel casing, for this, wrap the chimney pipe with cotton wool and tighten it with brackets; in severe frosts, the chimney will have to be wrapped in several layers.

Insulation of an asbestos-cement chimney

Modern chimneys, which are made of stainless steel, are a construction of two pipes with different diameters.

- Insert a pipe with a smaller diameter into a pipe with a larger diameter.

- Fill the free space between the pipes with such insulation as mineral or stone wool.

- For the inside of the pipes, the thickness of the insulation is 3-5 cm, and for the outside - 7-10 cm.

The use of this method of insulation will help to solve two problems:

- provide insulation of the chimney;

- will protect the inner parts of the chimney from fire, since the insulation contributes to less heating of the outer part of the chimney.

Insulation of a steel chimney

It is much more difficult to insulate such chimneys, but there are several options than to insulate a brick chimney.

- Insulated chimney by plastering

Warming by plastering.

- Fasten the reinforced mesh to the brick pipe.

- Prepare slag-lime mortar: fine sifted and washed slag, lime, a small amount of cement.

- Apply the first layer of plaster 3-4 cm thick.

- Wait a while for the plaster to dry.

- Apply subsequent layers 5-7 centimeters thick (minimum 3 layers, maximum 5).

- Align and rub the top layer.

- When the plaster is completely dry, cover the cracks and rub them again.

- Whitewash the pipe with lime or chalk paint.

Frame - a universal option

There is another answer to the question of how and with what to insulate an asbestos chimney pipe, or a metal structure. This method is good in that it does not matter at all what is the cross section of the chimney. It is suitable for round, square or rectangular ducts. In this case, a convenient frame box is used. The works are performed in the following sequence:

- They retreat from the perimeter of the chimney by 100 mm, draw a rectangle or square. Then, a low frame is assembled from a metal profile or a bar using self-tapping screws (nails).

- It is sheathed with any available material. The space between the chimney and the frame is filled with expanded clay, sand or roll insulation. Outside, the structure is covered with asbestos panels. Their thickness is 10-12 mm.

The last stage is to ensure tightness: this is the treatment of all joints and the top of the box with heat-resistant plaster insulation. An alternative is brick cladding.

Features of insulating metal pipes with your own hands

Before proceeding with insulation, the outer surface of the chimney should be cleaned of dust and dirt. To do this, use a conventional hard-bristled brush and a broom. When cleaning a brick chimney, remove excess dust and loose cement. This can be done with a paintbrush and water.

Insulation of a brick chimney can be done using different materials. The most time consuming and ineffective method is plastering, but many still use it, since this does not require large costs. On average, heat losses after work are reduced by 20–25%.

The sequence of actions for plastering is as follows:

- In a clean container with a rounded bottom, mix a mortar based on M500 cement, dry lime and fine slag. Before kneading, the slag is sieved. The first portion of the solution should be very thick.

To prepare the plaster, it is necessary to knead a solution of cement, lime and slag - The mortar is carefully applied to the joints between the bricks. At this stage, you need to fill in all the voids. It is advisable to do this before the steel mesh is fixed to the pipe surface.

Brick chimneys are sometimes insulated with heat-resistant plaster, although this is considered the least effective method. - A reinforcing steel mesh is fixed on the surface of the chimney. Then you can start carrying the plaster mixture. The thickness of the first layer is no more than 3-4 cm. After application, the plaster layer should set and dry slightly.

- A second plaster layer is applied with a thickness of up to 5–7 cm. If the declared thickness cannot be applied, then a layer of 3–4 cm is applied. Then you will need to wait for it to set and repeat the work until the plaster coating of the required thickness is obtained.

- The finishing layer is applied. The surface is carefully leveled and rubbed with a scraper. Cracks may form when dry and must be repaired before finishing.

After finishing with a topcoat, the chimney will become not only warm, but also much more beautiful

After drying, the plaster is bleached with a solution of lime and chalk. If necessary, it is applied in 2-3 layers. Instead of a cement-slag mixture, you can use a heat-resistant plaster with a fire resistance up to 600 ° C.

Before proceeding with the installation of thermal insulation, prepare everything you need for work. Clean the pipe from dust, repair cracks and chips. It is important that the surface is dry, otherwise the quality of the thermal insulation will decrease.

Plastering

- The mixture is mixed with water using a construction mixer in the proportions indicated by the manufacturer. It is more correct to first pour water into the container, and then add the dry mixture.

- With a spatula or trowel, the solution is applied with spots over the entire surface of the pipe and leveled. The plaster is leveled over the entire pipe surface

- The pipe is covered with a reinforcing mesh over the mortar spots, which will fix it to the surface. The mesh is necessary to strengthen the plaster layer, it plays the role of a frame.

- The first layer of plaster is applied over the reinforcing mesh. It is important that it covers the entire surface without gaps. In order for the plaster layer to stay on the surface of the chimney, use a reinforcing mesh

- The plaster is leveled and left to dry.

- After that, several more layers are applied, each of which needs to be dried. For good thermal insulation, 3-5 layers are required.

- After the last layer has dried, the pipe is painted in the color of the roof for aesthetics.

Before you start insulating a chimney steel or any other metal pipe with your own hands, you need to check the correct installation of the structure. The chimney must comply with all technological standards.

The easiest way is to insulate a metal chimney with a ready-made "shell", matched to the pipe diameter

The following requirements are met:

- optimal traction in the system is achieved only with a pipe with a height of 5 meters;

- the distance between the pipe and the parts of the roof that are exposed to combustion (ceilings, rafter system) is at least 250 mm;

- if the roof structure includes combustible materials, namely slate, roofing felt or ondulin, the insulated pipe is equipped with a special spark arrester. It is a stainless steel mesh plate that surrounds the chimney along the top. To prevent debris from entering the spark arrester, the mesh is covered with a metal "cap".

We offer you to familiarize yourself with: Roofing system for slate

Work on the winding of the metal chimney can be started after checking the system for faults. It is also worth making sure that only non-combustible materials were purchased for insulation. You should additionally familiarize yourself with the manufacturer's instructions on the packaging of the insulation.

Warming errors

The most common reasons for the ineffectiveness of protection are incorrect calculation of the thickness of the insulation, its insufficient sealing. The first sign of poorly performed work is the appearance of condensation inside the chimney. In this case, it is better to "redo what has been done" right away. But already try to provide all the conditions: both the required thickness of the heat insulator and the tightness of the structure itself.

The question of how to insulate an asbestos chimney pipe can be answered as briefly as possible: with something that has a suitable weight and does not burn. For metal channels, it is better to prudently buy ready-made elements that will only have to be installed. You will have to spend quite a lot of time on brick walls.

Those who are interested in this topic will find this informative video useful: