When laying around a metal stove in a bath, it is forbidden to use ordinary silicate or red building bricks. It must be refractory. The presence of cavities is not necessary, decorative texture is allowed. Mixtures serve as an astringent:

- cement and fireclay aggregates;

- clay sand;

- cement-glue (glue is used for fastening porcelain stoneware panels).

The use of other materials will lead to cracking of the masonry. Now we will consider how to impose a brick on an iron stove, avoiding the consequences. You can see what types of ovens exist by following the link.

Foundation base for lining

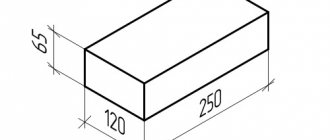

The blocks used must have a weight of 3.8-4.2 kg. The total mass of the structure, together with the metal firebox, will require a solid foundation. After completion, the weight will be about a ton.

The procedure for arranging a strip foundation is as follows:

- Cut a square hole in the floor.

- Dig a pit up to half a meter deep into the ground.

- Fill the bottom with a layer of crushed stone (fraction 10-20 mm, thickness of the filling - 10-15 cm).

- Lay waterproofing film (thick polyethylene or roofing felt).

- Install (unfasten) the formwork along the perimeter.

- Install a reinforcement frame (steel or fiberglass) inside.

- Fill the cavity with concrete, the grade of which must be at least M200, class B15.

The height of the foundation, protruding above the ground surface, is 20 cm. It is “taken out” under the floor level with the help of a thermal insulation layer. It is laid out of heat-resistant bricks "solid". The solution is the same composition that will be applied later.

Technology

There are several proven technologies for masonry around metal stove equipment:

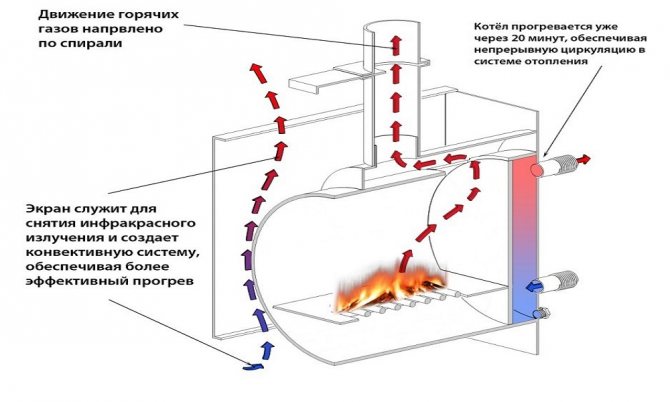

- Heat shield. A brick fence that does not exceed the height of the furnace. Promotes better heat dissipation.

- Solid cladding. It quickly gives off heat to the surrounding space, which increases the cost of heating the premises. This technology is used when it is necessary to create a beautiful decoration, sacrificing the performance of the furnace equipment.

- Convector masonry, which has air vents. Suitable for metal heating units. In this case, the size of the steam room is not important.

When to start

The concrete curing period is 27 days. The thermal insulation layer is mounted a week after pouring, when the foundation has gained 60% of the prescribed indicator. You can load it on the 28th day. During this time, the base will acquire the ability to withstand the load, it will shrink, which will exclude distortion, cracking. Installation begins with putting the firebox in place.

The choice of material for the cover

Among the recommended types of bricks, the best are red ceramic or hollow fireclay. The latter is more expensive, but its use is mandatory if the gap between the walls of the firebox and the masonry is 2-4 cm, which will warm up to 400 C.

To use ceramic, a gap of 7-10 cm is required. Then it will warm up to 200, which is uncritical. The ventilation holes will solve the problem of overheating. This will reduce the cost of the design and speed up the heating of the bath when firing up. The ideal option is still fireclay, which was originally developed for high temperatures.

Solution manufacturing technology

Ready-made dry mixes for stoves and fireplaces are on sale. The packaging contains recommendations for preparation (mixing with water). To make your own masonry mixture for lining, you need to purchase:

- refractory chamotte clay;

- construction sand (fineness module 1-1.2);

- cement without slag content (M500 D0).

Sand and clay are sieved and exclude the ingress of crushed stone, clay impurities. The proportion of aggregates is 1: 1. The introduction of cement is optional, but desirable. It will be enough 0.5 kg for a 10-liter container of dry chamotte-sand mixture. After mixing the aggregates, pour in water. The volume is determined by the consistency of the finished solution (thick, plastic, does not stick to the trowel).

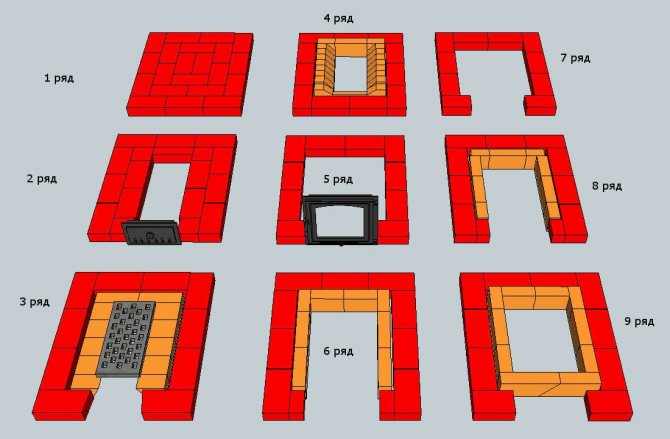

Types of masonry

In order to impose brick on the iron stove in the bath, people who do not have the skills of a bricklayer are advised to resort to laying in a "half brick" (flat).

The “quarter brick” technology, which involves laying blocks on the side edge, is suitable for those who have already encountered such work. There are two main clutches:

- Solid. Does not include air circulation holes. Suitable for the subsequent decorative cladding of the stove with facing materials.

- "In detente". Provides ventilation holes.

Walls "in brick" are unprofitable for two reasons - excessive consumption of materials and fuel.

The presence of holes leads to the earliest heating of the bath when the iron stove is kindled, but it threatens with increased heat, burns from the outgoing air. An alternative is the installation of metal, cast-iron doors (hatches) in the second or third row. The measure will allow you to control and manage the heating.

Why do cladding?

Before making the lining of furnace equipment, you need to figure out how relevant it is. It is necessary to finish finishing metal furnaces because:

The metal heats up and cools down quickly. Brickwork will help keep rooms warm for longer.

When heated strongly, metal surfaces emit powerful infrared radiation. It can burn the skin from a distance, without touching. Exterior trim will help to hide this radiation.

Metal ovens quickly heat up a room. This is not only the advantage of such models. Due to the rapid warming up, the air becomes dry. Because of this, the microclimate that is optimal for the steam room is disturbed.

To determine the effectiveness of brickwork, you can lay out a brick wall without using mortar. For this, brickwork is created at a distance of 4 cm from the metal walls. It is important to align each row so that the walls do not collapse. After making the walls without mortar, it is necessary to melt the furnace, check how much more comfortable it has become in the bath. If nothing has changed, there is no point in making a full-fledged brickwork.

Recommendations

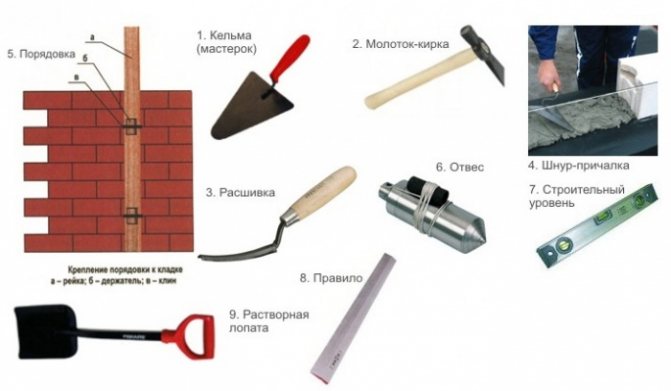

To complete you will need:

- Master OK;

- level;

- plumb line;

- container for mixing the solution.

When laying a brick around an iron stove in a bath, you should adhere to the following tips to ensure durability:

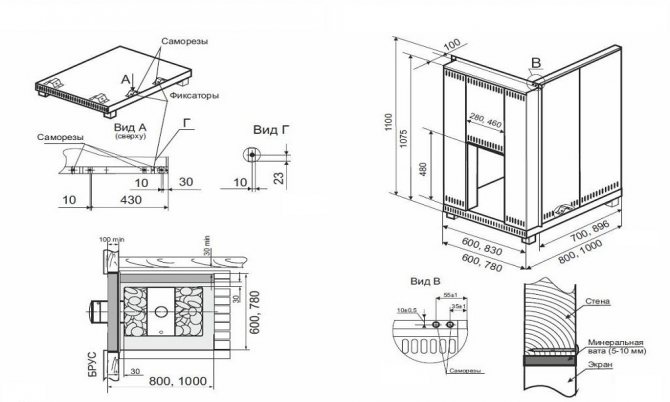

- The thickness of the seam (0.5) "in a quarter of a brick" should include a reinforcement mesh or wire 3-4 mm.

- You should adhere to the distance from the masonry to the wall of the metal stove for the bath - 3-10 cm.

- The completion of the laying of each row must be accompanied by a check of the verticality of the structure with a plumb line.

- The rows are laid horizontally in level.

- Excess mortar is removed with a trowel (outside and inside).

- If the firebox is equipped with a convection casing, remove it.

- Stoves with a thin top sheet are lined so that there is access for replacing it in case of burnout.

Some helpful tips

In order for the brick lining to be correct and to serve for more than one year, you should use the following recommendations:

- laying is done in the usual way with bandaging in half a brick;

- you cannot associate the structure with bath walls;

- maintain a seam with a thickness of 5 mm;

- leave a gap of 3-5 cm between the metal walls of the stove and the screen;

- in the lower rows, it is imperative to make openings through which cold air would freely enter. Accordingly, in the upper ones there are the same holes for hot outlet.Both from below and to overthrow there should be no more than 2 or 3 openings, otherwise the wall, like a heat shield, will not perform its direct function;

- after laying each row, it is necessary to check its level: verticality and horizontalness should be observed everywhere;

- carefully remove the remains of the solution both from the inside and from the outside.

Important! If there is a convection casing in the stove, it must be removed before covering.

Cover for finishing

Non-cladding design requires perfect geometry.

Before you impose a brick on the iron stove of the bath, you should take care of the spacers. They are objects (thickness 0.5 cm). They are laid between the rows as supports.

Excess mortar is unacceptable from the outside. It is important that there are indentations.

After hardening, the spacers are removed, and the outer cavities in the seams are rubbed with the same solution. It is allowed to introduce gypsum or dye into its composition, which will shade the joining. The next day, stains from the solution are removed with a stiff brush using a soap solution or rubbed with a drill with a brush attachment.

Features of the lining of the stove installed on a wooden floor

This method is not recommended as the presence of a foundation ensures the strength of the structure.

If this is not possible, then it is required to assess the bearing capacity of the floor. Logs (beams) should be located at a distance of 0.6 m. Length - no more than 3.5 meters. This is if beams (logs) with a section of 200 mm are laid. Boards less than 50 mm thick do not have sufficient flexural strength, so they must be thicker and less than 2 m long.

When performing work without dismantling the wooden floor and foundation, you must adhere to the following recommendations:

- The gap from the wooden walls of the room (steam room) and the lined stove of at least 10-15 cm will ensure fire safety.

- The gap to the walls of the furnace of 90-120 mm will eliminate the risk of fire due to the imminent failure of the furnace.

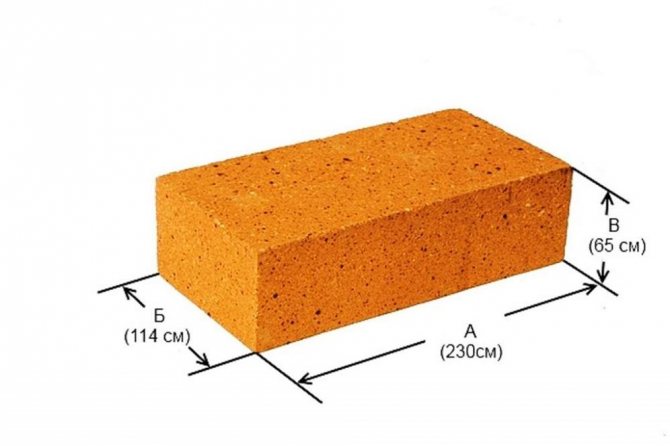

Calculation of material consumption

The base can be calculated empirically. The first row of bricks is laid on top of the continuous "dry" layer, their number is determined by height. It is formed by adding the width of the brick block and the masonry joint (5 mm). A column is built, having previously laid five-millimeter objects between the blocks.

It remains to add the number of blocks:

- grounds;

- each row;

- elevation of the front plane (if planned).

The mass is determined by multiplying the resulting quantity by the mass of one block. The calculation assumes the inclusion of the mass of the solution.

The volume is calculated as follows:

- Add two brick lengths and heights.

- The resulting length of the perimeter of contact with the solution is multiplied by the thickness of the solution layer (5 mm).

- The consumption is multiplied by their number.

Having received the volume, you need to calculate its weight. To do this, multiply it by 1.6. This is the bulk density of one cubic meter of solution. Adding all the values together will give the required value. Dividing it by the area of the base, the load is obtained in numerical value per square meter. And if it is less than 1.7 t / m2, it is impossible to impose a brick on an iron stove in a bathhouse on a wooden floor without destruction.

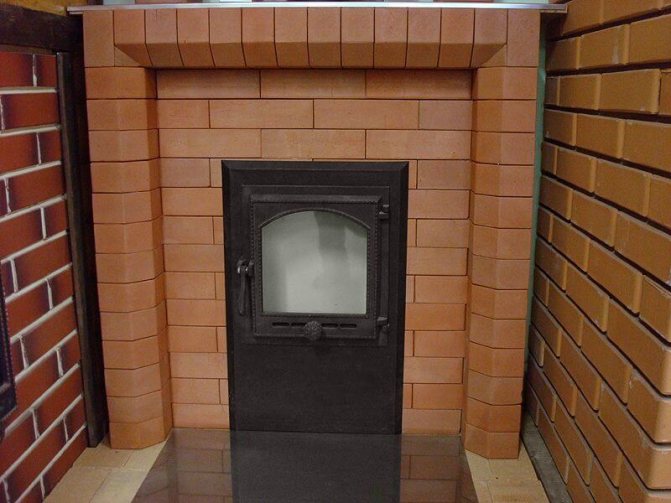

How to impose a brick on an iron stove in a bath

No one will argue that the heart of the bath is the oven. It is she who creates a kind of microclimate inside: high humidity and heat, so it is very important to choose the right unit. Of course, the ideal option is a sauna stove, built of bricks in accordance with all the laws of construction and heating technology. But this structure cannot be lifted with your own hands, if you are not a stove-maker, besides, this undertaking is costly and takes a lot of time to build.

Therefore, no one builds brick ovens in their own baths. It is easier and more convenient to buy a ready-made stove made of metal (steel or cast iron). The main thing is to choose the right power.