Furnace installation

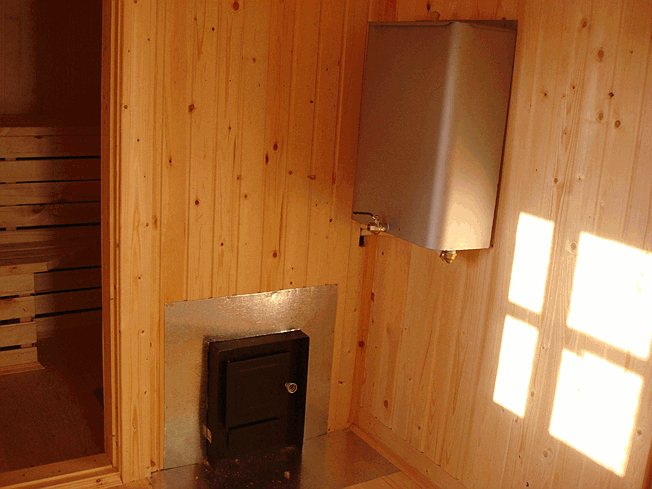

It is easier to use a hinged tank. For its assembly, installation you need:

- Make a box from metal sheets 2-3 mm thick. Weld the individual parts.

- Cut a hole in the top of the box for filling the liquid. Make a hole in the lower part, install a tap. This is necessary in order to use liquid or drain it from the tank.

- Attach metal hooks to the side of the plate.

- Weld two labels to the tank, for which it will be hung on hooks.

The optimal amount of liquid for one person is 15 liters.

Even after connecting the water supply system to the bath, questions will arise about how to heat the water. To do this, there are several ways, each of which has certain characteristics, suitable for different types of baths.

November 2, 2015

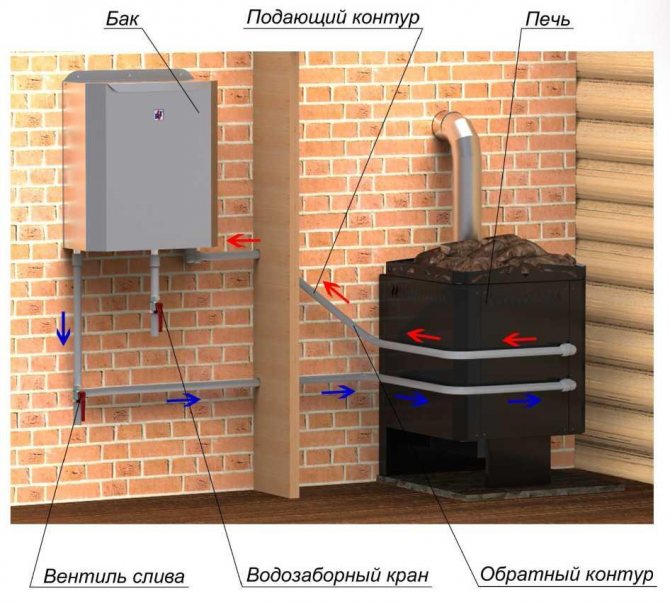

If a sauna stove with a heat exchanger is installed in the steam room, then there will be no need to spend additional funds on the installation of a boiler, which is required to heat water. Such designs are the most optimal options, due to the fact that they not only heat the room, but also provide the owners with hot water.

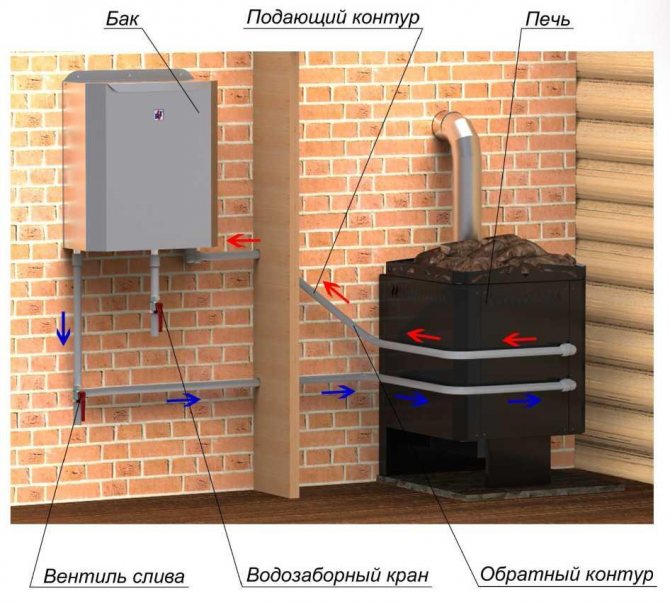

If you decide to install a stove for a bath with a heat exchanger, then you need to get acquainted with the principle of operation of this device first. Heat exchangers are also called water circuits. Regardless of where they are located, their functioning is based on the same principle. The heat energy from the furnace goes to the jacket or to the register.

The heat carrier, which is in the heat exchanger, begins to heat up. The water in the tank has a temperature below room temperature or slightly higher. Due to this difference, pressure arises in the circuit, which promotes the circulation of the coolant. Thus, the heated water enters the tank. From it, the coolant is consumed for hygiene procedures.

After that, the next portion of cold water enters the container. It is transferred to a heat exchanger, where it is subsequently heated. In the event that the system is of a closed type, which implies the operation of the tank as a heating device, then the water should be filled in even before the furnace is ignited.

In this case, the temperature difference can cause deformation and damage to the metal of the heat exchanger. The circulation will continue as long as a sufficiently high temperature is maintained in the structure. If you install a stove for a bath with a heat exchanger, then there will be no need to install a water heater, which is installed in the shower room. Among other things, the owners will not be faced with the question of arranging heat sources in the premises.

If you decide to choose a stove for a bath with a heat exchanger, then it is important to get acquainted with the technology of its installation first. Installation work is carried out after arranging the foundation, which is necessarily poured into the ground by 40 centimeters. The subfloor should rise above ground level, but the subfloor should be guided by this.

If you are making a fireplace stove with a heat exchanger, then the prepared cut blanks, which are cut from a metal sheet, must be fixed by welding. After all the calculations have been made, and you are completely convinced that there are no errors in them, you can finally assemble the entire system.

After final assembly, the system should be checked for strength. In this case, you can use the following technology. The lower pipe must be welded, and then filled with water to the very top. The outlet must be connected to the container.Then compressed air is injected, and the pressure gauge allows you to analyze the pressure.

Sauna stove with water heat exchanger

Structurally, the heat exchanger can be a coil or a tank with a maximum volume of 5 liters and two nozzles for connecting a water tank / radiator.

According to the method of fastening, heat exchangers are divided into two types:

- internal. Such products are fixed on one of the side walls of the oven or mounted on its bottom. It is also possible to install a water jacket, which literally encircles the fuel chamber from its inner side or is located in the space between the furnace casing and the walls of the firebox;

- external. Heat exchangers of this type are fixed on the chimney or attached to the wall of the furnace.

https://www.youtube.com/watch?v=fQQ7Rd1dBCI

Internal heat exchangers are distinguished by the best indicators of heat saving. The water in them will be heated until the stove has completely cooled down to its last brick or stone.

The fastest heating of water is provided by internal heat exchangers and external ones installed on the chimney. At the same time, the first products often imply the need to make constructive changes / additions to the sauna stove, and the latter cannot be called decoration of the steam room (the wide tank does not fit into the interior in the best way).

If we compare products in terms of ease of installation, then the palm is occupied by heat exchangers, which are hung on the outer walls of the furnace. Such products are distinguished by a long service life, do not spoil the appearance of the oven, however, the water in them heats up longer and cools down much faster.

Heat exchangers or water circuits, regardless of their location, work according to the same principle. Heat energy is transferred directly from the furnace to the water jacket or register. The coolant poured into the heat exchanger begins to heat up; in the tank or the water is at or below room temperature.

Due to this temperature difference, pressure is created in the circuit, which contributes to the gravity circulation of the coolant. That is, the water heated in the heat exchanger enters the remote tank. Hot water from the tank is consumed for hygiene procedures, after which a cold portion of the coolant is poured into the container. Cold water, in turn, is transported through pipes to a heat exchanger, where it is heated.

If the system is of a closed type (that is, the remote tank works as a heating device), water is filled strictly before the furnace is ignited, otherwise, due to the temperature difference, the metal of the heat exchanger may deform and burst.

The circulation continues as long as the high temperature is maintained in the oven.

Thus, if there is a heat exchanger in the furnace, there is no need to install a water heater for the shower room, as well as to equip additional heat sources in the premises.

With the help of such heat exchangers, the water will be heated much faster. Heat exchangers in the furnace can be made of tubes in the form of various geometric designs or be ordinary flat ones. The efficiency of plate heat exchangers is lower. But on the other hand, they are much more durable and easier to manufacture.

Heat exchangers must be installed at the same time as the oven masonry. Taking into account the parameters of the furnace, the dimensions of the heat exchangers are selected. Outlets of pipes can be either from one side of the furnace, or from two. The option of cold water inlet from below, and outlet from above the furnace plane is allowed. In a word, there are a lot of options both in terms of the material of manufacture of the heat exchanger and in the type, geometry, linear dimensions and design features.

For the manufacture of the heat exchanger, choose durable high-quality materials; the welds must be made in accordance with the rules and characteristics of the materials.Keep in mind that in many cases it is impossible to fix a damaged heat exchanger in a furnace without disassembling it. And what it is to disassemble and reassemble the stove is not worth explaining.

The easiest option is to purchase a factory-made metal sauna stove with a built-in heat exchanger. But such furnaces have one drawback - the low efficiency of the heat exchanger.

It is pleasant to visit a well-equipped bathhouse, in which not only a high-quality stove is built, providing light steam, but also the heating and water supply systems are well thought out. If a heat exchanger is installed in the stove, then there will always be warm water in the washing room, and if a radiator is connected to the heat exchanger, even in the winter cold, the bath will be as warm and comfortable as possible.

How can you heat the water in a bath?

- How to heat the water in a bath? How to organize the water supply to the bath?

- How to make a shower in a bath and heat water in it?

Pressurized plumbing systems, while creating unique opportunities and innumerable conveniences, nevertheless often cause a lot of trouble. For example, if you rarely use the bath, then the water in the tanks and pipes goes out, and the pipes themselves rust. Standing water in pipes freezes in winter and breaks them, and it is very difficult to fill frozen tanks and pipes in winter.

There are several ways to heat water in a bath, the most common of which are: installing a wood or gas water heater and installing an electric heater.

With small volumes of water used, it is convenient (especially in winter) methods of non-pressurized storage of water (in separate closable or open containers, as well as water conduits: overflow waterfalls and open streams). The transport of water in bottles or buckets, as well as the transport of liquids in barrels (cisterns), is not at all a consequence of a low technical level.

If the bath is used only in the warm season, the difficulties with water remaining in the pipes supplying water to it, or in the tank, are solved quite simply. The water is drained before frost, and the bath remains dry for the winter. As soon as the temperature rises, they begin to exploit it: a certain volume is driven through the water supply system in order to rinse and heat it, and then use it as usual. A much more difficult task is to establish a water supply for a bathhouse in winter, especially if it is used once a week or twice a month.

How to heat the water in a bath? A question that is appropriate in a country house, where a small bathhouse can also fit. It seems quite simple only at first glance, but in fact, the need for a large amount of hot water requires the application of certain efforts to build the necessary structure. In principle, a heater for a sauna or a bath can be purchased ready-made and easy to install, but you can solve the problem with your own hands by building a non-standard water heater for a bath, for example, on wood.

Heating features

The problem of most baths in a country or country house is the lack of hot water supply, which leads to the need to create systems for heating water. In principle, water heating in a bath can be provided in two ways: separate water heating devices are installed or bath heating stoves are used.

In the first option, various standard hot water boilers can be used, for example, gas heaters or electric heating elements (TENs), which are capable of quickly heating a large volume of water. However, such structures will have to be installed in the washing room, which creates a problem with hot water in the steam room.

The sauna heating stove is capable, in addition to the main function of heating, to provide water heating. In this case, a special tank of the required capacity (from 30 to 100 liters) with water is installed to heat the water, and heat is used, which is still generated to heat the steam room.To maintain the desired temperature, the classic Russian version is used - on the wood. Moreover, the heating principle may be different, but it is desirable to include it in the design of the furnaces already at the design stage.

Advice from the master!

Basically, 3 systems are used: a tank on the furnace (or in close contact with it); a tank with a heat exchanger and a samovar tank.

Embedded system

The simplest and most common way to install a water heating tank is to install it on one of the sides or on top of a bath stove. Ideally, a water tank is installed inside the stove and goes simultaneously into two rooms (steam room and sink). The capacity of such a tank can be any, and the heating method is on wood.

It's another matter if a sauna heating stove has already been built and a tank is not provided in it. In this case, a hinged version is used (usually on the side or in the front in the steam room). The capacity of the tank is about 40-70 liters, and such a volume (on wood) heats up in 1.2-1.6 hours. Heating can be accelerated by insulating the walls of the tank.

You can take water from such a system in different ways. The easiest method is to use a lid on top and scoop up the liquid in a convenient container. A more complex option involves the manufacture of a drain valve - in the upper or lower part, depending on the height of the tank.

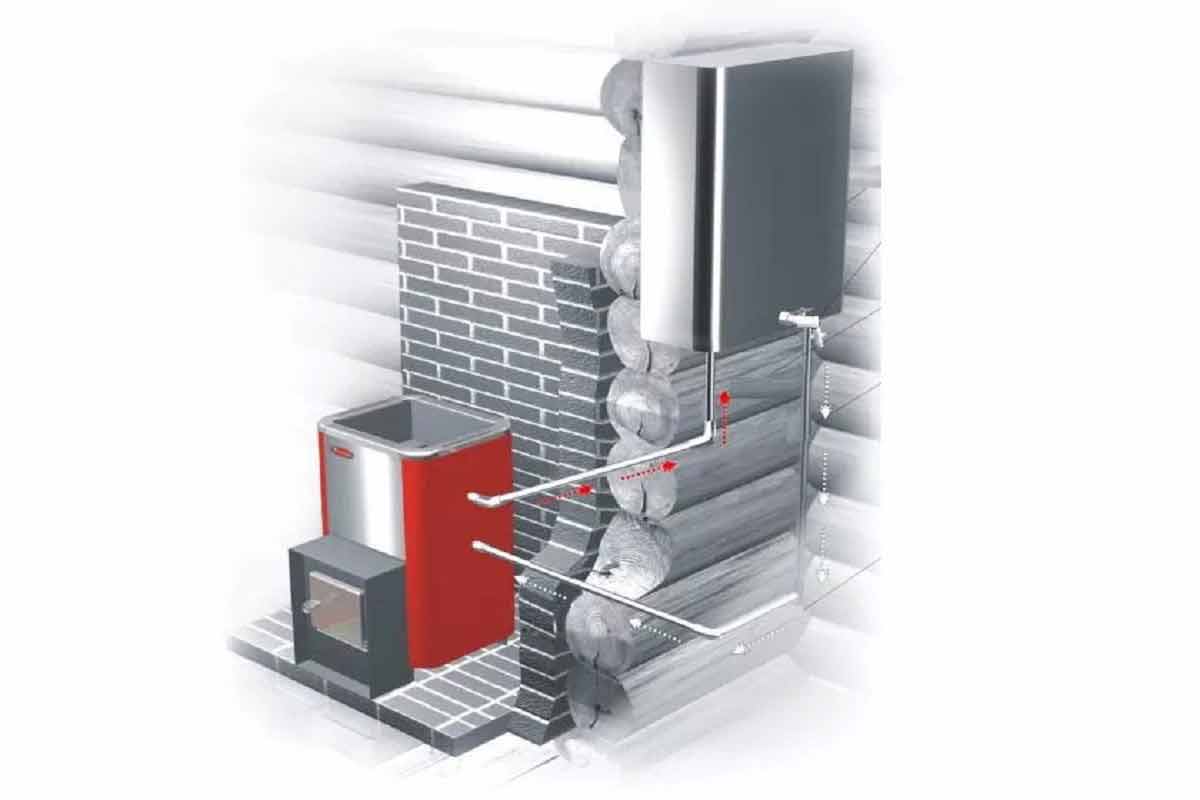

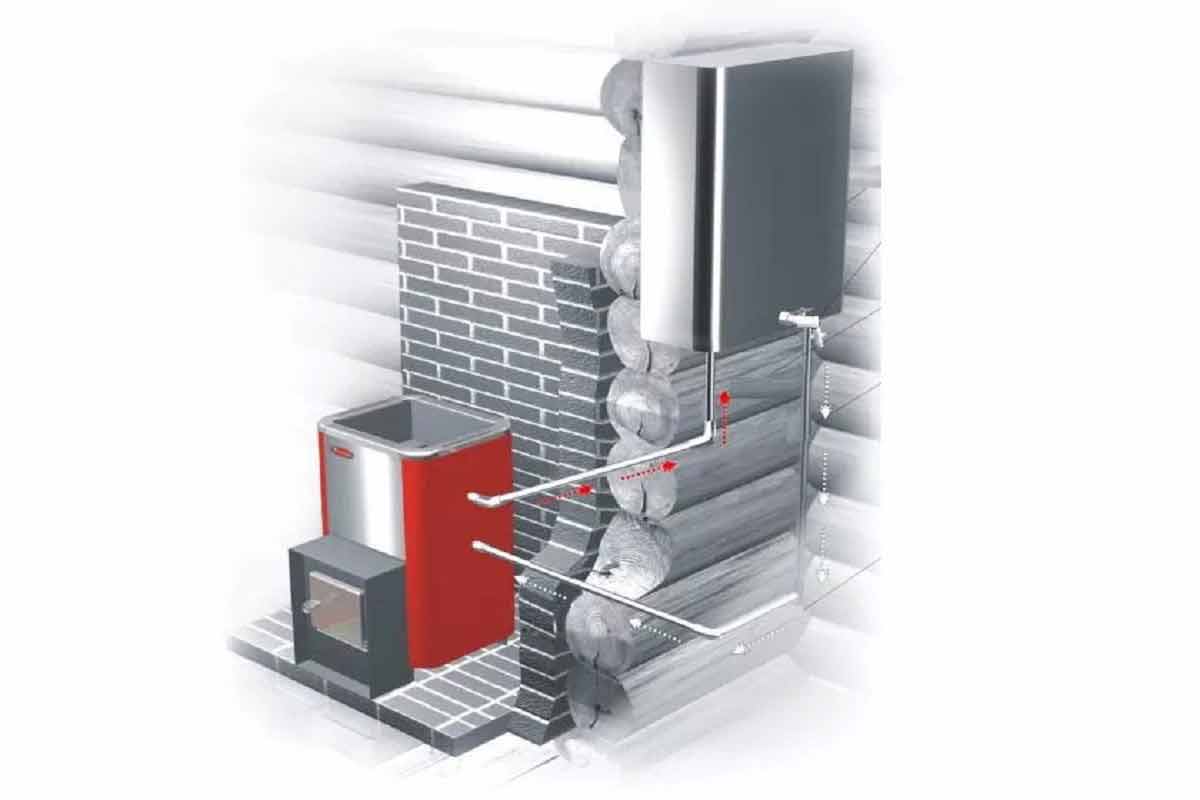

If there is a need to bind the water heating tank to a certain place away from the furnace, then a design with a heat exchanger is used. This design is based on the fact that the heating furnaces have a steel pipe coil inside, through which cold water is supplied. Passing through the oven, the liquid heats up and enters a free-standing container, where hot water is accumulated. The volume of the tank is usually 60-80 liters and heats up within 1.6-2.2 hours.

We offer you to familiarize yourself with: Wood bleach - composition, selection, do-it-yourself production

The heat exchanger uses a well-known physical law - the cold mass goes down, and the heated liquid is fed up. This determines the placement of the tank. The main advantage of the heat exchange system is that there is no need to tie the tank to the furnace. The downside of the heater is its more complex design.

The heater can be built on the chimney, and heating will be carried out from the smoke leading upwards. Such a heat source can be heated to temperatures above 500 ° C, which can be used profitably before the smoke goes into the chimney. The main design problem is to ensure the tightness of the place where the chimney enters the heating tank.

The use of cement mortar is not recommended due to its cracking under such thermal loads.

The main advantage of the "samovar" system is the use of uselessly leaving energy for the benefit of business. In addition, a sufficiently high location of the tank makes it possible to use it as a shower, if you install a suitable water spray.

The big drawback is the complexity of the design and more difficult water filling, taking into account the height of the top cover.

Choice of materials

The choice of material for the heating tank only seems simple. The most common option is steel. The main advantage is low cost and ease of manufacture using conventional welding operations. However, under the conditions of a Russian bath at a constant high temperature, high humidity and exposure to superheated steam, this material quickly rusts, and its service life is short.

Another option is cast iron. In a cast-iron container, the water heats up for a long time, but it cools down for a long time, which makes it possible to keep heat even after stopping the furnace. Disadvantages are heavy weight, high price and corrosion problems.

The best option is stainless steel. Of course, it is much more expensive than ordinary steel sheet, but it does not corrode and can last for many years.The most common steel grades for the manufacture of bath heating tanks are 8-12X18H10 (304) and 08X17 (430). Stainless containers are light enough, have excellent thermal conductivity, and the coefficient of deformation during sharp temperature fluctuations is negligible.

In principle, it is possible to use ready-made enamelled tanks. However, such containers are good as long as the enamelled protective coating is intact. When the slightest chips appear, active corrosion begins. This means that enameled tanks require extra care during operation, which is very difficult to ensure.

The question of how to heat water in a bath is decided independently, based on specific conditions. The easiest option is to install a standard tank heated by heating elements and manually deliver it in small containers to the destination point.

The more traditional way is to use the energy of an already supplied sauna stove. Which option to choose depends on the owner of the bath.

How to make a water heating system in a bath with your own hands

A good sauna in winter is a real delight. And especially when she is in her own summer cottage. But upon arrival in winter, as usual, everything in the house turns out to be cold or frozen. It takes a long time to warm up and thaw. Sometimes it comes to the point that after such events you don't even want to go to the bathhouse. There are, of course, cases when the house and the bathhouse are in a constant heated state. But, unfortunately, this is not the case for everyone. In such a situation, the question becomes logical, how to heat the water in the bathhouse in winter with your own hands and also very quickly? There is such a way.

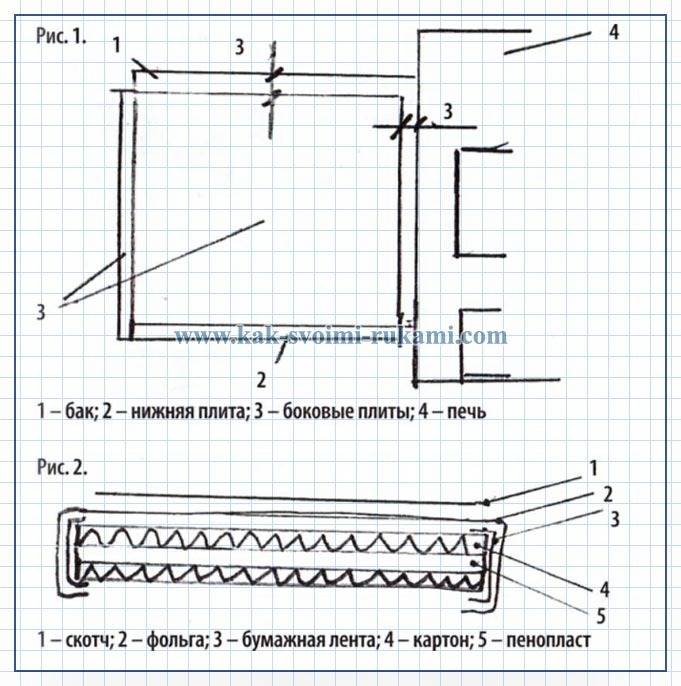

The water in the tank heats up only thanks to one wall. The other three and one more bottom simply give off heat to the surrounding atmosphere. That is, absolutely unnecessary losses. One wall of the tank heats the water, all the others are diligently striving to warm the planet. Do not heat up the water quickly. In this case, the heat loss of the three walls and the bottom must be excluded, making them also work for the benefit of heating the water. In this case, the tank should be insulated. Such actions will lead to the fact that the heat transfer coefficient is significantly reduced.

To make thermal insulation boards, you need corrugated cardboard and foam (5 mm thick enough). In addition, this homemade insulator should be supplemented with ordinary aluminum foil. This system is attached and finally insulated with adhesive tape. Plates must be prepared in such a size that they are three centimeters larger than the walls of the tank and the bottom of the tank itself.

For intensive heating of the tank, the best option would be to weld it to the firebox. But this should be done carefully. Between the firebox and the insulating surface of the tank, it is necessary to leave a smudge, three centimeters wide. Otherwise, the stove will overheat or even begin to smolder. In this case, a fire cannot be avoided. Therefore, one must be careful and attentive when installing such a system in a bath.

A cardboard surface is attached to the tank walls and bottom using PVA glue. It is better to attach it in two layers at once. Foam plates are also attached to these rectangles using PVA glue. After that, the foam is again covered with cardboard, and all excess is cut off.

To give this structure a more complete look, the edges of the foam tiles are pasted over with paper. Covering the tank with foil, it is better to do this in one monolithic layer. If such an action does not work, then it is necessary to make a spade on the neighboring foam tile with a calculation of 2-3 centimeters. Since the foil is a rather thin material, it should be protected from mechanical damage. To do this, the tank is wrapped with tape in several layers or self-adhesive film. It should be noted that the film is also usually thin, so it should also be applied in several layers.Thus, the tank acquires a neat appearance and is perfectly insulated against heat loss. All its components are protected.

After the system is mounted, it must be allowed time to dry. After complete drying (after about a day), the tank is filled with water and heats up. The system is fully tested for heat retention and water heating time. Thanks to such a simple scheme, the water in the tank in the bath will heat up 2-3 times faster than in the standard version. At the same time, the water cooling became much slower. From 100 degrees to 40, it cooled down in about half a day.

However, all of the above are rather improvised means. They are suitable for those who do not have the opportunity to organize a more thorough water supply system, in which, in addition to cold water, there will also be hot water, as in a city apartment. However, the above does not suit everyone. There is a more fundamental solution to the issue of heating water in a bathhouse in winter with your own hands.

For those who have pampered themselves with the constant presence of hot water so much that they can no longer imagine any conditions without it, there is a solution to how to make it almost constantly and in the bathhouse at the summer cottage as well. Constant hot water comes from the sauna stove.

However, you want to wash yourself with hot water, without getting dirty with soot, melting the stove "in black". Therefore, in modern brick ovens, simultaneously with the construction, a container is immediately built in, in which the water is heated. In addition, heat exchangers are also adapted, which are connected to other water tanks. There are several similar designs, so the reader should sit comfortably on a chair repaired with his own hands and carefully understand everything.

Speaking of full-fledged heating of hot water using a stove, there will be no talk of metal stoves. For a real Russian bath, this option is not suitable in any way. To install a piece of iron in a steam room is to wish from relatives to ride with unique comfort and at the same time buy a domestic car. If you really pursue such an idea, then immediately buy a good foreign car, and if there is no opportunity yet, then no one. A real Russian bath deserves an exclusively brick oven.

This method of heating water has been known since time immemorial. Our grandmothers installed a cast-iron hob above the firebox. A cast iron or steel tank with a lid was placed on it. Most often, such tanks had a tap for draining water. Plus here only in the mobility of this tank, since it can be removed, washed, cleaned.

In this case, there are a little more cons. I would like the hot water to flow directly into the washroom. But for this, the firebox door must be located in the same place. It is not comfortable. The metal hob is located in an area where gases are burned. If it is cold, it will cool them down. Because of this, firewood will be consumed faster, as the efficiency of the stove decreases. If the walls, on the contrary, are hot, it is easy for unwary visitors to press against them. More often children suffer in this situation. When the stove is heated for a long time, the water begins to boil away. The boiling water will have to be drained somewhere and the tank should be refilled with cold water. Or, in such a situation, an additional storage tank is connected. But then there can be no talk of mobility.

Another way is a tank pre-built into the oven. At the same time, the oven should be designed in such a way that the wall located next to the tank not only goes into the washing room, but also warms up better than everyone else. Otherwise, the water will be barely warm, and in order to achieve normal hot water, the stove will have to be heated for two days. But then the bricks will begin to suffer from overheating and for a long time, in this case, the beloved bathhouse will not last. When the stove collapses from the weakness of the bricks, it is quite problematic to erect new masonry. Therefore, one should not prepare in advance the fate of the barn for the bath. Let it serve for a long time and for the benefit of the owner.

There is one drawback.If the built-in tank deteriorates, it will be extremely difficult to repair it. But this is a rare case when properly operated.

To avoid these troubles, the best option for heating water in a bath is the installation of heat exchangers. The most suitable way to place heat exchangers, which will prevent the tank from overheating, drain hot water into the water supply system in time, and then create comfortable conditions for taking a shower, will be a descending chimney. It is also called the smoke channel. In the furnace, it is traditionally located near the "high" - the opening for the release of gases or, conversely, the overlap of the furnace, from where the flue gases enter the chimney.

When installing the heat exchanger, the dimensions of the furnace itself and its output power should be taken into account. You should also measure the volume of the container in which the water will be heated, the time of its heating and the constant temperature during heating. Knowing all these parameters, materials for the heat exchanger and register and its dimensions will be selected.

On average, such a stove in a bath will heat 100 liters of water to 90 degrees in about 4 hours. With such properties of the sauna stove, it is recommended to set the register with a diameter of about 40 mm. In this case, its length will be 2 meters. These are approximate calculations. In each case, they will be purely individual. If there are doubts about the correct installation of the register, heat exchanger, and even the furnace itself, then it is better to turn to professionals. The approximate power of the heat exchanger in such a design should be 2 kW.

There are often situations when it is necessary to heat water directly in the bath. In this case, the register is installed directly in the firebox. More precisely, in the place where the strongest heat is produced. Some people install the register in a special recess in the bricks of the firebox. For this kind of event, there are fireclay bricks installed in the firebox.

However, it is, of course, impossible to say for sure which will fit in this or that case. More accurate information can only be provided by a stove-maker who has agreed to take on the device of a sauna stove with the function of simultaneous heating of water during its heating.

Do not forget that a positive result and complete comfort from the reception of a real Russian bath will be only if all the systems in it are executed correctly and work smoothly. In fact, a normal plumbing is almost like in a city apartment, this is not from the category of fantasy, but quite affordable things that can be used by anyone who wants to have a bathhouse in their summer cottage. The device of a furnace with a tank and a heat exchanger does not increase the cost of the entire building so much that it has to be abandoned. As you can see from the above, the design is surprisingly simple. It does not have a complex system that requires the exact observance of any specific physical rules. The main thing is that this device is assembled correctly. When the bricks were laid out by skillful hands, then the bath will serve to the delight of its owners.

How to heat the water in a bath?

Scheme of heating water with a help of a stove with a samovar-type heat exchanger.

If in summer hot water is needed constantly, and in winter only when there is a desire to come to the country house and take a steam bath, then how to organize a hot water bath and heat the bath?

- install a wood column;

- install a large-capacity electric water heater;

- install a gas water heater. connected either to a centralized gasification or to a cylinder, if there is no gas in the house;

- use the system to heat the water in the tank through the hot water pipe from the heating stove;

- supplement the fourth system with heating elements to heat the water in the tank at a time when the bath is not heated.

All these options are applicable in the summer, and at stable negative temperatures, the water will need to be heated and supplied to the bath right in front of the firebox and drained from all containers and pipes after using the bath.

Option 3. We use a tank on the chimney pipe

If you chose a stove without a tank on the firebox and without a water circuit, then chimney manufacturers make tanks on the chimney, the water there heats up from the smoke. With this heating scheme, the water heats up longer, since the temperature of the exhaust gases is lower than in the firebox itself.

The heated water can be drained from the tank in a convenient place, so it is quite comfortable to use this scheme, the only thing, if you need to add additional water to the tank, since it may run out, you will again have to manipulate the hot elements. In this catalog you can look at such items - water tanks.

Recommendations for use

When installing the stove in a bath with a heat exchanger, heated water will flow into the tank or connected radiators. In the latter case, pipes should be used, which should be wrapped with thermal insulation. The chimney must be led out through a pre-arranged hole in the roof. It is closed with a steel sheet, in which a cut is made. The resulting joints must be well sealed.

If you have chosen a stove for a bath with a heat exchanger for heating, then it is important to consider that it will be much more difficult to install a water circuit in a firebox or a gas duct compared to the case when the heat exchanger is included with the purchased metal stove. In the first case, the register must be made in advance using a thick-walled black pipe or stainless steel.

If you make a circuit with an insignificant exchange surface, then the coolant will constantly boil, this must be excluded. Whereas excessively large sizes, on the contrary, will cause a long warm-up. Ultimately, the water will remain cool when needed. That is why it is so important to create a circuit with an optimal exchange surface.

To use a heat exchanger in a bath to be really effective, you need to remember a few simple rules.

- It is recommended to use a pump for pumping water. This will help prevent air pockets from forming.

- It is better to connect the heat exchanger to the hanging tank using copper pipes. Brass fittings are suitable for fastening, and materials that are resistant to high temperatures are used to seal the threads.

- The choice of the volume of the water tank depends on the rate of heating of the coolant. It should be remembered that the liquid must warm up at least 2 hours after connecting the entire system.

- Since the pipes will begin to expand as the temperature rises, their fastening must be movable.

- In no case should a heat exchanger be used where there is no water, because the equipment will lose its tightness due to overheating.

- When you create a device for a bath yourself, you should abandon the use of plastic pipes. This is because when heated, they can release toxic substances.

- Before operating a homemade heat exchanger, you must fill the heating tank with water. This should not be done immediately after lighting up the sauna stove, since the heated heat exchanger may leak due to the temperature difference.

A stove with a heat exchanger is considered an indispensable piece of equipment for any bath. Thanks to such a device, it will be possible to quickly heat the liquid, as well as the air in the steam room and dressing room. The main thing is that the heat exchanger itself is made of high-quality material.

Option 1 - We use a furnace with a water circuit

We buy a furnace with a water circuit on the firebox (see such furnaces in the catalog of a furnace with a water circuit). Most manufacturers make modifications to furnaces either with a welded or with a small barrel put on the firebox - a water circuit with two outlets. A remote tank can be connected to the outlets of the circuit both in the steam room itself, and in any adjacent room, even in the attic or attic.

If the tank is tightly held by the firebox, then a 50-liter volume of water during the active operation of the furnace heats up exactly in an hour. I consider this scheme to be the most convenient and efficient in terms of heating.

A few words about connection

If you have chosen a stove for a bath with a heat exchanger and a water tank, then you need to understand the point that the design is primarily intended for heating the steam room, the secondary task is to heat the water. It will be impossible to manage multiple processes at the same time. The steam room is a priority.

If the heat exchanger has the form of an economizer or a coil, then it is necessary to install a remote tank in the bath, mounting it above the level of the furnace. For the installation of this system, it is permissible to use metal or polymer pipes, however, polyethylene pipes should not be used. The diameter of pipelines and networks, where water flows by gravity, must be selected in such a way that the indicator is not less than the dimensions of the heater pipes. It is best if the diameter is one size larger. In this case, the step from the tank to the heating equipment should not be more than three meters.

Bath water drain

The easiest way to drain water in a cold bath is in the form of a ladder with a diameter of 110 mm under a regular drain pipe. If you make the drain of water in the bath with a smaller diameter, then the water can freeze at the outlet in good frosts. Over time, ice forms, which will turn into an ice plug. Agree, it's not good at -20C to try to break through an ice cylinder in a pipe 5 centimeters in diameter and half a meter long.

The ladder can be closed with a grill, or it can be closed with wooden slats and left open.

Tube heater

Modern water heaters can be divided into three groups depending on the type of fuel:

- wood-burning;

- gas;

- electrical.

Electrical

There are two types of electric water heaters:

- Flow-through are compact devices that quickly heat the liquid flowing through them. Can quickly dispense hot liquid. In winter, the water is slowly heated, it may not have time to heat up to the optimal temperature, pour cold from the tap or shower.

- Accumulative electric heaters - boilers. Not suitable for small spaces as they take up a lot of space. If the bath is rarely heated in winter, the liquid inside the system may freeze. This will damage the boiler.

To prevent water from freezing in the storage electric heater, you can:

- Install the boiler and turn on the minimum temperature regime. The disadvantage is the extra cost of electricity.

- After each use, drain all liquid from the device.

It is better to install the boiler in rooms with constant heating.

Wood burning

If there is no electricity or gas, the only way to get hot liquid is to use a wood-burning heater. It consists of four elements:

- metal case;

- chambers for solid fuel combustion;

- chimney for removing gases;

- containers with liquid located above the firebox.

We suggest that you familiarize yourself with: Bath after the flu: is it possible to go to the bathhouse or sauna after the flu, the benefits and harms

You can heat a wood-burning stove with different types of firewood. It is necessary to regularly clean the chimney, combustion chamber from soot and ash.

Gas

Gas heater is a flow-through column that operates on natural or liquefied gas. This is an economical equipment that works equally well in winter and summer.

Disadvantages of gas water heaters:

- expensive and complicated installation;

- to connect to the central gas supply system, you need to draw up a lot of papers.

To install a gas pipeline, a large amount of land work needs to be done.

Advice from the master!

Advice from the master!

Embedded system

Advice from the master!

Advice from the master!

Any bath requires hot water in it. In the old days, hot water was supplied by concurrent heating of water when the bath itself was kindled: in a boiler built into the stove, in buckets placed nearby, etc. But in our time, when planning a bath, we want to get more convenience and pleasure from bath procedures.

This assumes the presence of a shower, hot water from the tap, and not just washing from buckets. In addition, the simultaneous heating of water, stones and the room requires a carefully balanced degree of heating by the stove. It often happens that the stove needs to be heated for a strictly defined time, otherwise the water starts to boil or the stones do not heat up enough.

The ideal option is a sauna, divided into a washing and steam room with the possibility of heating the stove from the dressing room and with water heating independent of the heater. Such a water supply for a bath is possible in different ways: from a second stove specially for water to connecting to the water supply of a house with a gas boiler or centralized water supply.

When the bath is located next to a residential building, country or country house, which are already provided with hot water supply. the easiest way is to simply stretch the plumbing out of the house. Of course, in this case, there are some nuances. If the house is not connected to the gas main and the water is heated in it by electricity or other methods, then such a connection will lead to an unjustified overspending of electricity and other resources, while in the bath itself the heat from the wood will be useless to "fly into the chimney."

Heating water in a bath from a stove can be organized in several ways. This is a container built into the furnace when part of the wall or bottom of it is brought into the firebox. This is a heat exchange pipe, also brought into the firebox, when the container itself is built-in or separately from the furnace and does not come into contact with an open flame in the firebox. Often, containers are installed on the chimney of the stove inside the bath or taking them out of the ceiling.

In such cases, it is important to correctly design the oven and the location of the container in order to simultaneously achieve the required degree of heating of the stones and prevent water from boiling or insufficient heating. It should also be borne in mind that with increased water hardness in a particular area, a heat exchanger in the form of a pipe in the firebox will quickly grow from the inside with a layer of scale, which will lead to its overheating and burnout and a decrease in water heating performance. For a tank built into a stove or on a chimney, this is not so scary, since the heating and heat transfer area there is tens of times larger.

If the total area of the entire bath allows, then planning a separate stove for hot water supply can be a good option. The convenience of this method is that you can heat the stove-heater depending on the desired temperature, the number of people and the length of stay in the bath.

In turn, a separate stove for water, in addition to allowing the preparation of any required amount of hot water, is very convenient for frequent heating. You can wash and take a shower after staying in the country at any convenient moment, and if you connect an outdoor shower to this container, then there will be no excess moisture inside the washroom in the bath, which will subsequently dry out for a long time without firing the main oven.

Now the most interesting thing: how can you provide hot water under pressure in a separate bath, so that the shower stall works normally and water of the required temperature flows from the mixer. It is important that the visit to the bath was as comfortable as possible and there would be no need to fiddle with ladles and basins to prepare water of the required temperature.

If no communications are connected to the bath, it will be difficult to organize hot water supply, it is possible to install a container with hot water as high as possible above the ceiling. This will provide the possibility of using the mixer, but will not provide a full-fledged shower, only under a slight pressure, like a simple summer shower. In addition, you will have to drag buckets of water up to fill the hot and cold water tanks.

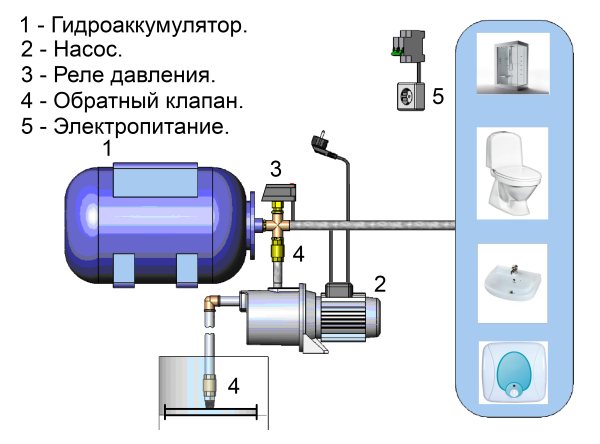

often they only provide a head of water for lifting only a little more than one meter.There are also systems for providing the required water pressure, which include a pump and a small hydraulic accumulator. They are able to maintain a given pressure at the outlet even when connected to conventional tanks located in the "traditional" way - in the bath itself.

In the case when a cold water main is connected to the bath, hot water supply for the bath can be organized using the pressure of this main itself. The author has come across an option when a used large-capacity electric water-heating boiler with a burned-out heating element was used.

With the help of a simple system of taps and a supply system, hot water, after being heated in a tank built into the furnace, fills the water heater by gravity, which is then switched with taps to the cold water main. After that, it is used as a regular domestic water heater until the hot water is completely replaced by cold water.

If you wish, if you are not afraid of the significant consumption of electricity, you can connect a working water heater in the same way, but this is a very uneconomical method, since the heated remaining water will cool down during a significant break in using the bath, and the electricity will be wasted.

Another way to heat water is a heat exchanger in a hot water boiler. The water is heated in the usual way to a high temperature in the boiler. There is a heat exchanger in the boiler. It can be in the form of a radiator like a car, or a radiator from a gas boiler. The simplest in execution is a pipe coil.

It is rather difficult to accurately calculate the performance of such a heat exchanger: the calculation for the pipe-in-pipe method gives a performance of about 20-50 ml per second for one meter when the water is heated from 15 C to 40-50 C at a boiler temperature of 55 to 95 C. This is not enough, but let us remind you that this is for one meter.

The heat exchanger shown in the photo uses only 5 meters of pipe, but this particular stove brings the water almost to a boil by the time the bath is ready, which makes it possible to fully use the shower. The disadvantage of this method is a gradual decrease in productivity, which makes it necessary to adjust the mixer towards hot water, and in the end it will be necessary to reduce the pressure.

When using various heat exchangers located in a hot water boiler, it should be remembered that, although the capacity is not quadratic, it depends on the temperature difference, the larger it is, the more efficient it is, i.e. it is better to heat a little less water in the boiler, but to a higher temperature.

You are on the portal about the repair of apartments and houses, you are reading the article "Hot water supply for a bath." You can find a lot of information on our website about design, materials for renovation, remodeling, electrical, plumbing and much more. Use the search bar or sections on the left for this.

And also on the site there are many interesting videos about apartment renovation.

Advice from the master!

Advice from the master!

Important! The use of gas boilers requires strict adherence to safety precautions. Installation and operation of equipment with a power of more than 50 kW is associated with the mandatory receipt of additional technical conditions and permits.

Electric water heaters are available in two types:

- Flow-through type with an optimal performance of 2.5 l / s. The equipment heats the water as it moves, using the largest amount of electricity.

- DHW cylinders with an optimal volume of 100 liters. They consume significantly less electricity. The water is heated for 3-4 hours, after which its temperature is kept constant.

In order to save energy and make it possible to use the shower in the sink at any time, a combined system is used.It consists of a stove and an electric water heater, which can work simultaneously to quickly heat a large volume of water, or separately, depending on the current need.

Disadvantages of other methods of heating water in a black bath

- The built-in registers cool the gases in the furnace, which leads to a longer heating of the stones and the deposition of soot on them. Not all stones are heated to the required temperature, which makes the steam more moist, with a soot smell.

- The tank boils ahead of time, soars. It is necessary to periodically drain hot water from it and add cold water. This is a rather dangerous event.

- Boiling water tanks suspended or fixed in another way have an increased danger for the bath visitors: you can get a burn from the tank or easily spill boiling water.

- Stove repair is complicated by the built-in tank.

Similar works: installation of the Gucha Lava stove (Ferguss, Ferlux) with the installation of a sandwich-type chimney and a fire wall.

Traditional water heating

Usually a brick or metal stove is installed in the bath, where the combustion of firewood is used as fuel. The advantage of the method is the possibility of periodic heating, just before taking the procedures, the disadvantage is the long heating time.

The easiest way is to install a cast-iron plate above the firebox, on which to place a metal tank with a lid. Such a removable container is easy to descale, but there is a risk of getting burned against its walls. To avoid the need to pour boiling water during a prolonged heating to reduce humidity from steam in the room, a drain valve is installed in the tank. Otherwise, the installation of external additional capacity is required, which reduces the mobility of the device.

The tank can be built into the oven. which complicates repair work when damage to its body is detected. It is more rational at the masonry stage to provide for a special recess in the structure, inside which to install a water tank. The tank can be located on the wall near the stove, provided it is sufficiently heated, otherwise the process will be too long.

Advice! When using brick ovens, to prevent the penetration of carbon monoxide into the room, it is necessary to wait for the firewood to completely burn out.

The best option is the option of installing a heat exchanger, which can have a very different design. The simplest device is a U-shaped pipe section or a section of a cast-iron battery. A heat exchanger in the firebox connects the stove to the tank. The dimensions depend on the volume of water, its initial temperature, the power of the oven and the desired heating time.

This type of water heating equipment has gained great popularity due to a number of its advantages:

- Compact dimensions;

- High speed of water heating;

- Significant fuel savings;

- The ability to adjust the temperature of air and water;

- Large volume of heated space.

The disadvantage of metal ovens is their rapid cooling.

Important! Due to the protection against depressurization of the chimney and the combustion channel, carbon monoxide cannot seep into the room, therefore it is possible to continue heating during the bath procedures.

The stove is installed between the steam room and the washing room, as if it is mounted in the wall between them. The water heating tank is made of 2 mm thick stainless steel sheet. Its installation is carried out on the wall of the washing room. Additional heating of the tank is provided by brick lining of the wall around the furnace. Communication between the elements of the system is arranged using a heat exchanger. The tank for circulating boiling water should be located above it. The container at the bottom has a tap, and in the lid there is a hole for water intake and topping up.

The system allows you to have a year-round production of 100 liters of boiling water. The temperature is controlled by changing the draft in the firebox. The position of the wood in the oven makes it possible to adjust the direction of heating. Stacking fuel near the wall heats the air in the steam room, closer to the door - water.Before the firebox, the container is filled to a certain level, the circulation of boiling water begins when the furnace heats up.

Advantages of heating the water in a smoke sauna using a hot water tank

- Not only 80 liters of water can be heated. It is very easy to accumulate water nearby in a barrel if the capacity of 80 liters is not enough for you.

- If it suddenly turns out that there is not enough hot water, then you can easily heat the stove again by adding water to the tank, because it takes a minimum of wood and time to heat it (20 minutes and the water is ready!).

- You can use a hot water boiler-stove as a steamer for brooms.

- Using such a system, you can simply heat water: for example, on weekdays for washing or other purposes.

- The oven works without electricity. You don't depend on electricity at all.

- Ease of maintenance and repair, especially for a stove without a tap.

- Durability. Checked by me personally.

- Profitability. Mainly one or two small fuel loads are burned in the furnace firebox. It can be not only high-quality birch firewood, but also waste of dry construction boards or lining. Super-requirements are no longer needed here. The main thing is dry and environmentally friendly fuel. Painted board, board impregnated with waste and oil, chipboard, OSB are not suitable.

- The design is independent of the heater itself. The stove is serviced much more often: replacing stones, grate bars, repairing brickwork, repairing doors.

- You can heat the water without heating the stove.

- The tank does not boil over, and therefore it is very easy to calculate the laying of firewood on it.

Description and types of heat exchangers

Sauna stoves with a heat exchanger are a structure with a space for cold water. Here it heats up, and then is transferred through pipes to a hinged tank or radiator. It should be noted that such a device helps not only to heat the water for the washing room, but also to provide an optimal microclimate in the dressing room.

All heat exchangers for a bath are divided into two groups.

- Internal. We are talking about a tank or a coil, which is located between the body of the sauna stove and the internal firebox. This item is sometimes referred to as a shirt. It is to it that the external tank is connected. Installation will not cause any difficulties, but if necessary, removing the device will not be easy. In this case, much depends on the design features of the sauna stove.

- External. These are heat exchangers of the samovar type. A chimney pipe is provided here, connected thanks to fittings. This option is considered optimal for the oven, because it provides more convenient maintenance. In this case, the product can be easily cleaned from the formed scale.

If we talk about saving heat, then the external option is considered preferable for the furnace. So, there is a decrease in fuel consumption. because the heat from the stove chimney is used for heating. If we talk about the built-in heat exchanger, then the heating from the firebox is important here. Accordingly, the stones, together with the room itself, may not warm up enough.

It is worth noting the fact that any types of heat exchangers intended for a bath must be filled with water. It can also be antifreeze. A hinged tank is provided for supplying liquid, which is connected using fittings. The operating principle itself is very simple. Functioning is possible thanks to the natural circulation of water. It is also possible to connect an electric pump to the oven.

Experienced builders recommend using open systems in the bath, that is, those options where there is no pressure. The most effective for a sauna stove is equipment with a pipe length of up to 3 m. This is really enough if the tank is located behind the wall of the steam room. The thickness of the pipes should not exceed 1 inch, otherwise, due to resistance, the sauna stove will not be able to move water.

With your own hands - How to do it yourself

In winter, without a bath - well, just nothing! But how to heat water in it three times faster than usual? There is such a way.

How was it with me before?

The water in the tank was heated only by one of its walls, and the three side walls and the bottom, respectively, transferred heat from the heated water to the environment. That is, to nowhere. Warmed the planet.

And if you cover these three walls and the bottom with thermal insulation? After all, then, he figured, should the heat transfer coefficient decrease, and with it the amount of consumed heat, heating time and fuel consumption?

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

I decided to test my thoughts in practice.

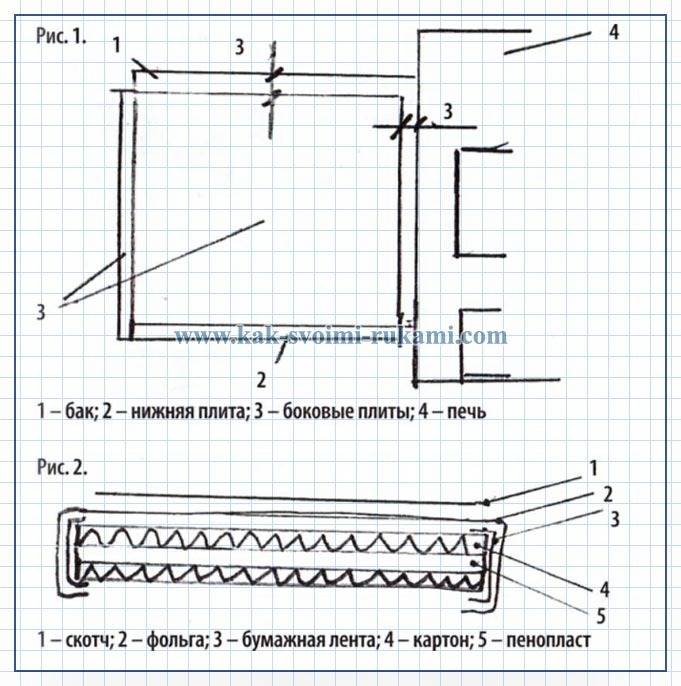

For the insulation boards, I used corrugated cardboard, 5 mm foam (the remnants of the ceiling covering), food grade aluminum foil and scotch tape. The dimensions of the slabs correspond to the dimensions of the three sides and the bottom, in height and width - 3 cm less (see Fig. 1).

I welded the tank to the firebox, focusing on the welding seam - you need to retreat 3 cm so that the stove does not overheat next to the firebox.

Fig. 1.1 - tank; 2 - bottom plate; 3 - side plates; 4 - oven

Figure 2.1 - scotch tape; 2 - foil; 3 - paper tape; 4 - cardboard; 5 - foam

For each side of the tank and the bottom, I cut 2 rectangles from cardboard. PVA glue was applied to this rectangle and foam was applied. Then I applied glue to the foam and put cardboard (cut off the excess foam).

Now we glue the edges of the resulting tile with a strip of paper.

I cut the foil so that it would go around the tile and cover the inside by 2 cm.

To protect the foil from damage, I glued it with tape (you can use a self-adhesive film).

Main advantages

For any baths, it is worth using equipment with a heat exchanger. There are many benefits to this:

- implementation of heating water, as well as air in several rooms at once;

- the possibility of placing the tank away from the furnace;

- durability;

- attractive appearance;

- ease of installation and maintenance;

- high efficiency;

- space saving due to compact size;

- the possibility of installation in a Finnish sauna or an ordinary Russian bath;

- increased power, providing fast heating;

- almost complete absence of deformation during heating.

DIY heat exchanger construction

Many people prefer to build such bath equipment on their own. The simplest option is a stainless steel pipe system. Also, if desired, you can use units created by welding from channels.

For a brick bath stove, a simple sheet metal structure would be the best option. So, from a material with a thickness of 2 mm, two tanks of rectangular and cylindrical shape are created. These parts are connected using pipes. To ensure the accuracy of the calculations, it is necessary to weld the prepared elements.

When constructing the structure yourself, it is necessary to minimize the length of the pipes. This requirement is explained by the fact that heat must be transferred to water as quickly as possible.

If the system does not provide for the presence of a pump, it is worth organizing the system so that cold water itself flows to the sauna stove, and hot water goes to the tank. Accordingly, the pipes must be installed at an angle of approximately 5 °.

It is important to remember that the main disadvantage of a heat exchanger is metal corrosion. This is due to the fact that any metal surfaces are not sufficiently resistant to water and various aggressive substances. Accordingly, it is necessary to protect the equipment. For this purpose, pipes made of steel or copper are used with spraying of certain metals, which will increase the durability of the structure.

Bath water - supply from home

So let's go. How to bring water into a bath that is not heated and how to make sure that the water in the bath does not freeze?

First of all, it is worth saying that a number of conditions must be provided:

1. Water must circulate through the water supply between the house and the bath. Otherwise, it will freeze. 2.The pipe for supplying and removing water from the bath must be well insulated, otherwise the water in the pipe will freeze. 3. The water in the pipe must be heated, for example, with a heating cable. Otherwise, the water in any part of the water supply system may freeze. 4. The outlet of the water supply system from the house when passing through the cold base should be insulated as much as possible. 5. The water inlet into the bath should be insulated as much as possible, the vertical section of the pipe with water should be heated.

Let's start with these settings. We are laying water supply from the house to the bath. We insulate it with foam of excess thickness. For example, we make a box of penoplex 300 millimeters thick. We mount the water supply pipe to the bath and the return pipe inside. We put a heating cable to them, which should wrap around both pipes. The cable is supplied with a temperature sensor, which starts it at an outdoor temperature of -2C.

If the water supply to the bath is laid in the ground, then you should not bury it below the freezing depth - this is unnecessary earthwork. It is better to lay it almost on the surface of the ground, so that the top layer of the insulated box is just below the surface of the earth. On top of it, it is worth mounting wooden walkways. If necessary, if you suddenly have frozen water in the pipes, it is easier to throw back the footbridges and warm up the track than to try to dig it out.

Usually, if the track is frozen in the ground, the owners do not dig it out, but leave it until spring. And the water in the bath is carried in buckets or a temporary hose is thrown out of the window of the house.

If you are laying the piping above the ground, it is helpful to leave a hole on the side of the house inside the duct. So the warm air from the boiler room or from the warm vestibule will heat the pipes in the area closest to the house.

We make the vertical water supply to the bath in the form of an excessively insulated caisson, in which we mount the shut-off valves and drain the water from the vertical section of the pipe.