Technical requirements

The heater is required for several functions:

- reducing fuel consumption;

- strong heating of stones, which are needed to generate steam;

- ensuring a high level of efficiency;

- maintaining the temperature regime.

Technical requirements for furnace equipment:

- The body must be solid, sealed so as not to let smoke into the premises.

- The minimum height of the ash pan from the floor is 15 cm.

- The materials used for the manufacture of the stove should not emit harmful substances when heated strongly.

Requirements for the installation of furnace equipment:

- The floor in front of the oven must be covered with a metal sheet.

- The base for the installation of furnace equipment must be reliable and stable. For a brick oven, it is better to make a separate foundation.

- There must be at least 50 cm of free space between the ceiling and the stove equipment.

- The surfaces around the oven must be covered with non-combustible plates.

- The place where the chimney passes through the ceiling must be closed with a special sleeve or a casing made of non-combustible material.

It is forbidden to install gas ovens on your own. To do this, you need to obtain the appropriate permission. Installation must be carried out in compliance with many rules, taking into account certain features.

Preparing mortar for masonry

You should know that clay mortar is used for laying the stove. One part of clay for one part of sand. The amount of sand in the solution depends, first of all, on its fat content and quality. The surface of the mortar should be rough, there should be no lumps in it. Also, the solution should not be sticky so as not to stick to the instrument. During the laying of the foundation and walls, the mortar, with light pressure on the brick, should easily come out of the masonry joint.

Clay for mortar is soaked in water 24 hours before starting work. And already pre-soaked clay is additionally diluted with water, bringing it to the consistency of sour cream. The resulting mixture is passed through a sieve, and then the required amount of sand is added to it. If the solution is thicker than required, then it is enough to add water to it and mix everything well. There should be no water on the surface of the solution. In case she spoke, then sand should be added to it.

Types

Sauna stoves can be in different groups depending on different criteria. The main ones are the material used for the fuel.

By material

Depending on the material from which the furnace is made, there are two types of equipment:

- Brick. Classic stoves for a Russian bath. They look attractive, keep warm for a long time. Since the bricks are heavy, a separate foundation must be erected for the oven.

- Metallic. Modern designs that take up a small amount of space are suitable for heating living quarters, heating bath buildings. They heat up quickly, but after the fuel burns out they cool down quickly.

A separate type of furnace equipment is combined models. The combustion chamber is assembled from metal, metal surfaces are lined with brick or natural stone.

By type of fuel

For the bath, you can choose a wood-burning stove or an electric heater. Design features

- Woodburning stove. Solid fuel is used for kindling. Thanks to the burning of wood inside the bath, a special atmosphere is created that allows you to better relax and unwind. Firewood must be prepared in advance, choosing a suitable storage location.The stove with a chimney must be regularly cleaned of ash, soot, and the combustion process must be monitored.

- Electric heater. They work from the mains. They are less whimsical to care for, evenly heat up. There is no need to create a separate storage space for fuel. Temperature control can be precisely controlled.

The choice of the stove depends on financial capabilities, personal wishes.

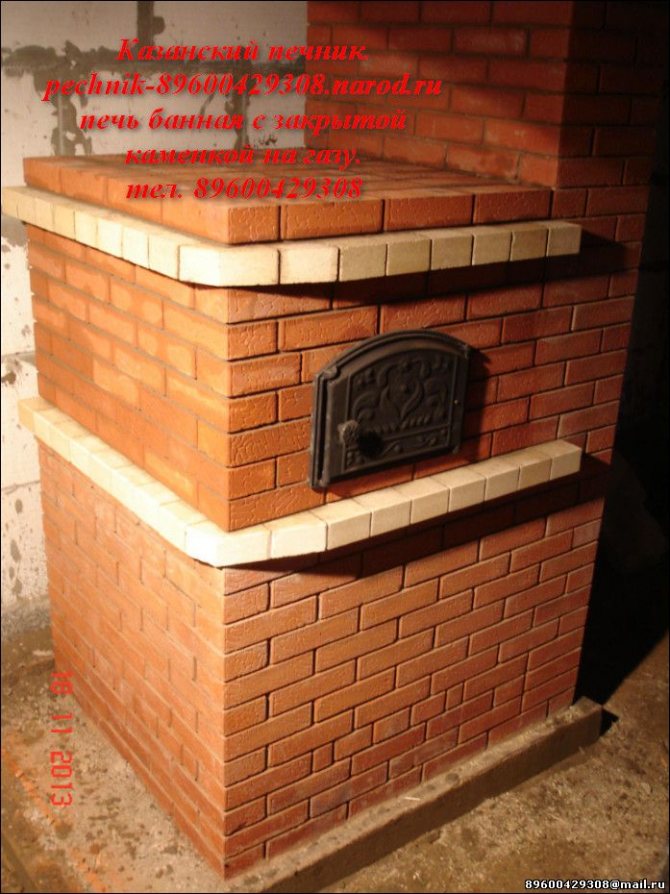

Brick heater

A thick-walled structure made of fireclay bricks, which is fired with solid fuel. A distinctive feature of such stoves is that they should be melted in advance - approximately five to six hours before taking water procedures. When the desired temperature is reached, the fuel supply stops, and the procedures begin only after it has completely burned out. For this reason, the oven can be classified as a batch device. The temperature inside the structure can reach 800-850ᵒС.

The benefits include:

- long-term preservation of heat (about nine hours);

- fire safety due to the metal base;

- the possibility of heating large areas;

- ease of installation (if you have the appropriate skills).

It is also worth noting that even the next day the temperature can fluctuate between 20-23ᵒС.

Brick heater

But still, a brick heater has disadvantages, including:

- long heating time;

- overall dimensions;

- heavy weight, requiring a deepened foundation;

- the need for relevant knowledge (for masonry).

In addition, it is required to wait for the complete combustion of the fuel, otherwise there will be a risk of carbon monoxide poisoning.

Brick oven for a bath

Refractory brick prices

Refractory brick

Selection principles

When buying a metal stove, you need to pay attention to a number of factors:

- power;

- sizes;

- length of the combustion channel;

- the material from which the door for the firebox is made (it is better to choose a glass one);

- heater type - closed or open.

If there is no hot water in the bath, it is better to choose a stove with a hinged water tank.

Popular models and prices

On sale you can find a large number of stoves, which differ in technical characteristics, fuel used, size, and the presence of decorative finishes. There are several popular stove models:

- Harvia Sound M45. The stove is from a Finnish manufacturer. This is an electric device suitable for heating steam rooms up to 6 cubic meters. Warms up quickly, takes up little space. Due to its low weight, the equipment does not need to erect a separate base. The heater can hold up to 25 kg of stones.

- Termofor Geyser 2014. Classic metal stove for a Russian bath. The body is made of alloy steel. Has a two-stage steam generation system. Suitable for heating steam rooms up to 18 m3.

- Thermophore Vitruvius. Sauna stove, which has a large fire door made of tempered glass. Outwardly, it looks like a fireplace. The heater can hold up to 45 kg of stones. Suitable for heating steam rooms up to 18 m3.

- Hephaestus PB-01. Suitable for heating several bath rooms at the same time. The total heated volume is up to 45 m3. The walls are made of cast iron up to 6 cm thick. Provides high efficiency, heats up quickly.

- Vesuvius Legend Suite. Cast iron stove, which is suitable for heating bath rooms with a volume of up to 28 m3. The stove is large and has an unusual shape. It is located around the body, on top. Capacity - up to 180 kg of stones.

- Dionysus. It is made of steel sheets with a thickness of 5 mm. The design has two heaters. Their total capacity is up to 200 kg. Designed for heating bath rooms with a volume of up to 18 m3.

- Anapa. Manufactured from stainless steel sheets up to 6 mm thick. The stove is closed, it can hold up to 50 kg of stones. The furnace channel is remote.Suitable for heating rooms up to 16 m3.

The average price for a metal sauna stove is 30,000 rubles.

Advantages and disadvantages

Advantages of a metal stove with a sauna heater:

- fast warming up of the room;

- small size;

- little weight.

Disadvantages:

- Metal surfaces must be protected from rust formation.

- The metal stove cools down quickly.

Water tank design

If the stove in the bath is equipped with a tank, then provide it with free expansion from heating can clay asbestos mixture, which fill the space around him.

For chimney use pipe made of metal or asbestos cement... In the place of passage through the ceiling and roof, it must be isolate refractory material.

When building stoves with your own hands, you must observe fire safety... The main requirements - the structure must be not closer than 0.4 meters from elements that can quickly ignite.

If the standards could not be met, then in order to avoid fires the wall is insulated with foil or sheets from asbestos board.

There are several projects for sauna stoves:

- With stove - heating of the stone backfill in it comes from the slab and lasts a long time. The advantage of the option is that the stove, blocking the chimney, significantly reduces the formation of soot and soot.

- With a firebox "in white". Heating duration - about 12 hours... A small amount of soot is generated by a partially open chimney.

- With kindling "in gray". It heats up faster, but due to the open chimney, a significant amount of soot is formed.

- With a firebox "in black". In this version, the heating period is the shortest, but since there is no chimney in such a design, you have to wait for the fuel to burn completely.

Choosing any oven option for your own bath dictated by the preferences of the owner.

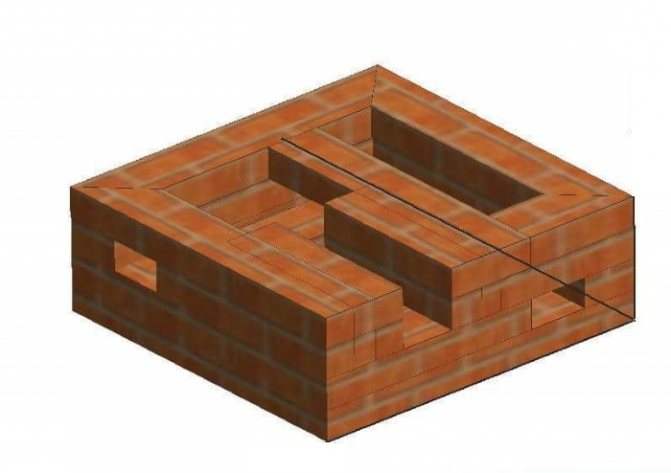

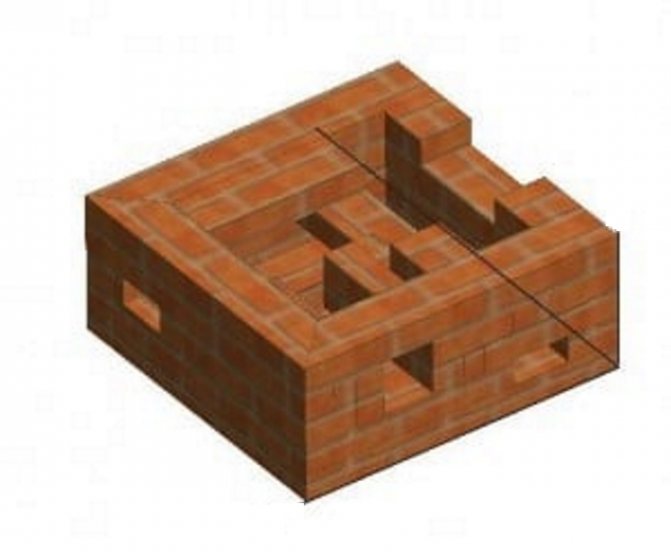

Brick sauna stove project

Any of these options is performed with or without grates. Choosing the best oven for themselves, they evaluate technological characteristics:

- When constructing a grate the fuel burns quite intensively. Such structures are difficult to operate.

- In the absence of grates it is easier to maintain the oven, it more economical in fuel consumption. When it is necessary to heat the bath with damp wood, the grates promote rapid heating and ensure stable combustion.

Having decided to build a variant of a furnace with a tank, they choose a design and calculate the required volume, which is taken from the calculation 10 liters of heated water per person.

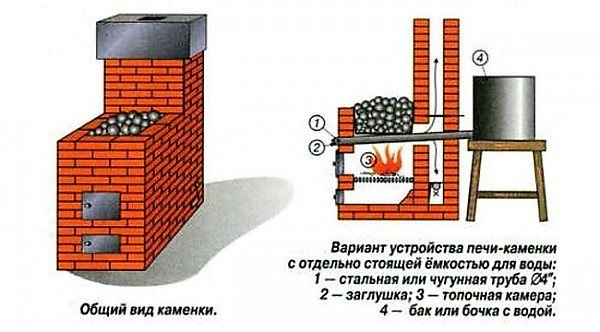

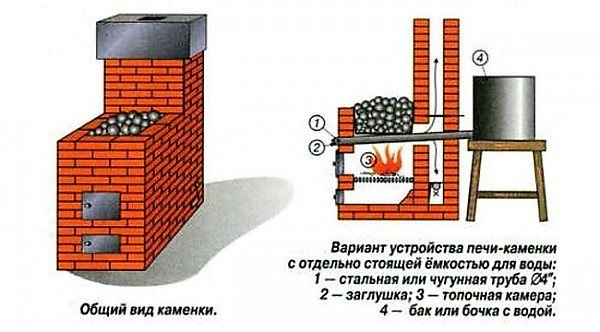

Photo 1. An example of a project of a heater-stove with a remote tank for heating water: general view and diagram of the device.

Preferable for cleaning and dehumidification when preventive work the variant of the furnace with an open tank is considered. Place the container at a certain distance and weld the pipe into it. Place it over an open flame, seal the end. Boiling, water starts to circulate: rising up, it displaces the cold liquid, sending it to warm up. This process is continuous while the stove is heated in the bath.

DIY making

The easiest way is to assemble a metal stove. It is much more difficult to make a brick structure, since you need to think over the location of the channels for supplying and removing air, making air spaces to improve heat transfer.

Preparation and design

Before you start assembling a metal oven, you need to prepare a place for it. The equipment must not touch surrounding surfaces.

If the combustion channel is remote, it must be indicated on the drawing that the heater will be inside the steam room, and the furnace door in the adjacent room will be the dressing room.

Materials and tools

To assemble the furnace, erect the base, you need to prepare:

- sheets of stainless or heat-resistant alloy steel with a thickness of 5 mm;

- welding machine;

- metal corners;

- grinder with discs;

- a set of files;

- metal brush;

- shovels, boards, bars;

- fireclay brick;

- chimney pipes;

- grate fittings;

- doors for ash pan, combustion chamber.

Separately, you will need metal sheets, plates of non-combustible material to protect the surrounding surfaces from heat.

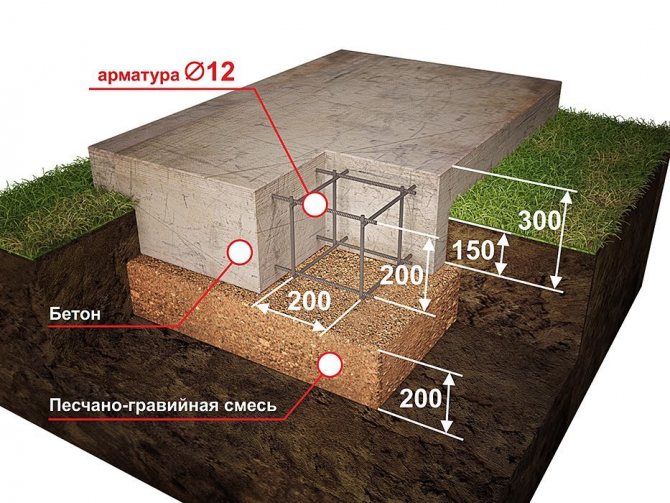

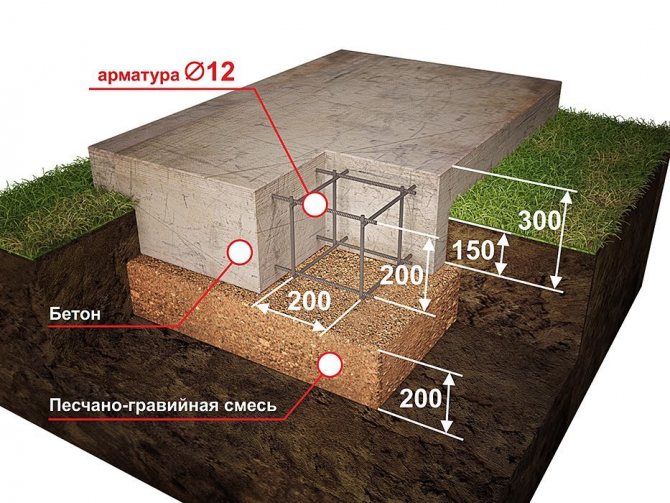

Site preparation and foundation construction

It is necessary to erect a base for furnace equipment at the first stages of building a building. Features of preparation, construction of the foundation:

- the depth of the pit for the base under the stove is from 50 to 80 cm;

- the base should be 15 cm larger than the oven on each side;

- at the bottom of the pit, you need to lay a sand pillow 15 cm thick.

Furnace foundation diagram

Base construction

Stages of construction of the base:

- Use shovels to dig a hole for the foundation.

- Fill up with a layer of sand 15 cm thick, tamp it.

- Knock off the formwork from boards, bars. Its height should reach the floor surface in the bath.

- Tie the reinforcing frame from the reinforcement, place it in the formwork.

- Mix the cement mortar. Fill the formwork with them.

After 3-4 weeks, you can start further work. It is necessary to dismantle the formwork, fill the vacated space with expanded clay or sand. The concrete should be covered with 1-2 layers of roofing material. On top it is necessary to lay out two layers of fireclay bricks on which the furnace will be installed.

Stages of self-assembly of a stove with a sauna heater:

- Mark the metal sheets, cut them with a grinder to the required dimensions.

- Weld the oven body.

- Close the seams with metal corners, weld them.

- Cut holes for the furnace door, ash pan.

- Divide the interior into 2 parts using a grate.

- Make a hole in the upper part of the body for fixing the chimney.

Weld 4 rectangular metal plates on the top of the case. They will act as walls for the heater.

If consumables remain, a hinged water tank can be welded from metal sheets. It can be fixed to the chimney or leaned against one of the walls of the stove.

Possible mistakes

Common mistakes:

- Installing the stove on a wooden floor.

- Use of a chimney cover without ventilation gaps. This disrupts the circulation of hot air.

- The use of low-quality stones for the heater.

- Wall upholstery with reflective screens made of flammable materials.

- Lack of funds to extinguish the fire in the bath.

Another common mistake that can lead to dangerous consequences is pouring concentrated essential oil on stones.

Exploitation

Features of the furnace operation:

- The first heating after assembly must be done outside. This applies to homemade stoves, purchased stove equipment. When melting, do not use large firewood. Chips, straw will do.

- The amount of firewood in the firebox should not exceed 2/3 of the total volume.

- Once a month, it is necessary to heat the stove with aspen wood so that they clear the chimney from soot.

- When choosing stones, you need to throw cracked boulders aside. The rock should not have extraneous inclusions.

- Correct placement of stones in the heater - from large to small, from bottom to top.

The stove can be fenced off with a decorative wooden fence so that visitors cannot get burned by accidental touching it.

A stove with a heater is needed to generate steam, to carry out various bath procedures. The stove is filled with rock, which is resistant to temperature extremes and strong heating. After water gets on the stones, steam is released, which is necessary for bathing procedures. You can assemble a stove with a heater yourself or buy a ready-made model in a store.

The health-improving role of the bath

Everyone who steamed in the right bath knows how easy it is to go outside after it. In the bath, illnesses go away, it treats sciatica, joint pain, many diseases of the back and lower back. There is no need to talk about a simple flu or cold. After steam with a broom, all diseases go away by themselves. For a full, proper rest, it is very important to choose not only the right broom, but also to create an optimal temperature of 70-80 degrees with wet steam. In this case, the sauna heater should warm the room evenly. In this case, the bath will really be beneficial, it will help to cope with chronic and acute diseases.