Features of internal and external thermal insulation

Energy experts say that this element is an increased risk zone: a significant part of the leaks of life-giving (and expensive) heat occurs through it. But is it really necessary to force the basement insulation with the help of penoplex or any other modern material? This can be avoided if:

- A basementless house with a low basement superstructure.

- The building is not intended for year-round use (only during the season).

- The climatic zone does not imply a blizzard and frosty winter (southern regions).

Base / plinth insulation - an important stage in construction

For such situations, it will be quite sufficient to create a warm floor with a water circuit or electric heating.

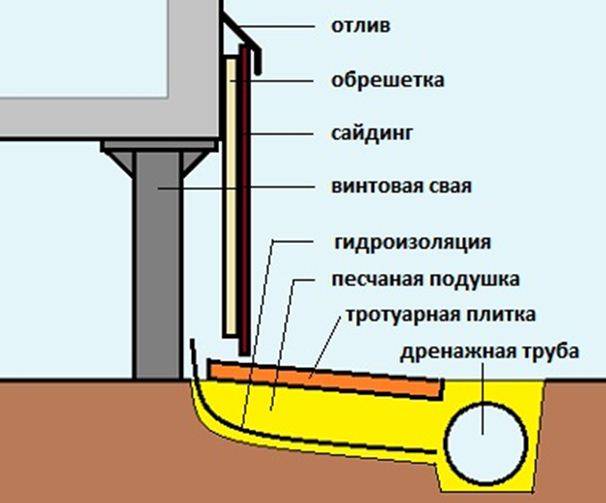

In all the rest, the basement will have to be sheathed with a layer of insulation, it does not matter - a house is built on screw piles or on an ordinary strip foundation

Warming of the basement of the house is carried out in 2 ways: outside and inside. Not knowing the basics of heat engineering, it is easy to decide that the internal structure of the insulating layer is preferable, since it can be carried out in any weather, with your own hands, and the finish of the base will not suffer. In fact, such a solution will only disrupt the normal thermal balance in the building wall, create a dew point, where condensation water will constantly accumulate. The temperature drop will lead to the gradual collapse of the wall, no matter what durable material it is made of, and expensive repairs.

That is why it is highly recommended to insulate the basement from the outside.

In this video, you will learn how to insulate the foundation:

Materials and tools used when insulating the basement with foam

In order to conveniently and efficiently insulate the basement, the following tools and materials should be prepared before starting installation work:

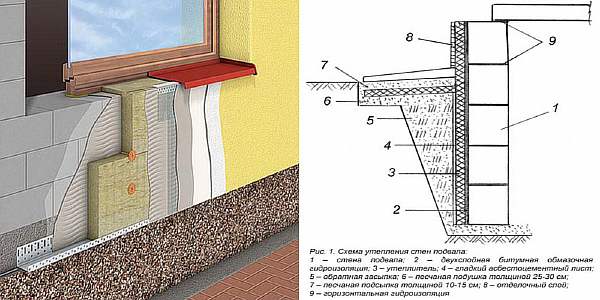

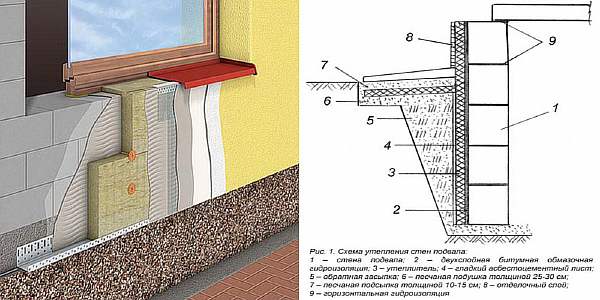

Basement floor insulation scheme.

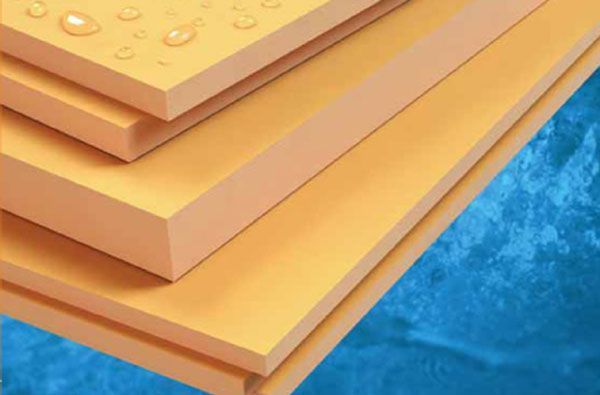

- Polyfoam (another name - penoplex), the density of which must be at least 25 kg / m³.

- Plaster (putty).

- Glue-cement (assembly glue).

- Soil (deep penetration).

- Facade paint.

- Reinforced mesh (mesh - 2.5 x 2.5 mm).

- Corner for the production of slopes.

- Plank (rule).

- Marker for marking.

- Knife (for working with foam).

- Level (alcohol or laser).

- A hammer.

- Spatulas.

- Perforator (hammer drill).

- Primer brushes, roller.

External base / plinth protection

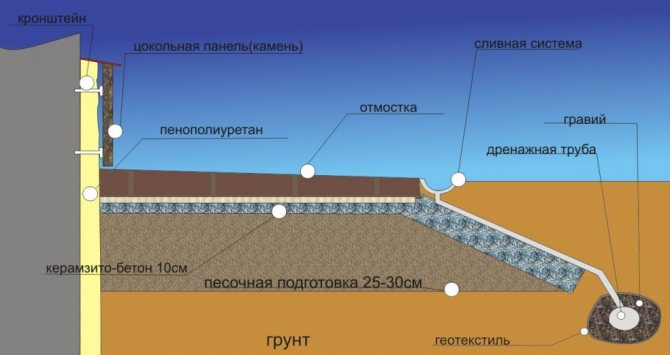

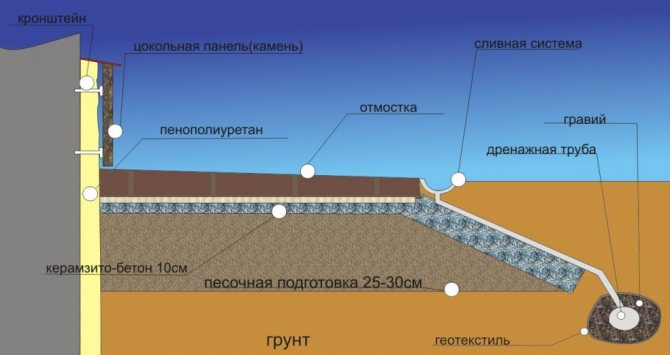

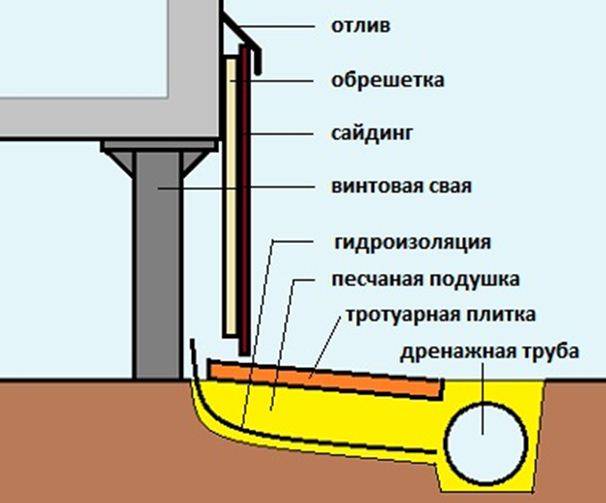

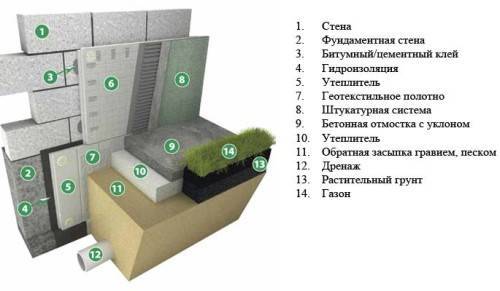

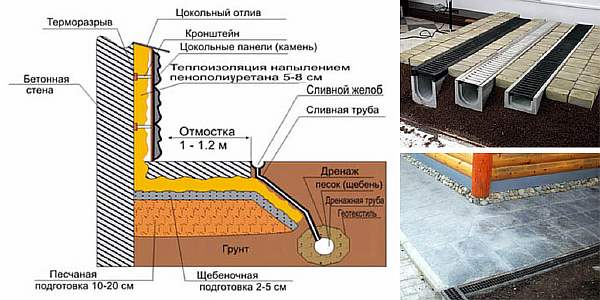

Basement drainage scheme.

Before directly insulating, a drainage system is installed around the house to remove excess moisture. To do this, a trench is torn off around the foundation base, at the bottom of which sand is poured, plastic pipes are laid on top, then everything is covered with earth. The trench should go downhill into the water collection tank. To protect against water flowing from the roof, a concrete blind area is equipped around the house. Now you can insulate the outer walls of the basement.

As a heat insulator, you can use:

- mineral or fiberglass wool, which, when insulated from the outside, is waterproofed on both sides;

- polystyrene with additives to prevent combustion;

- polyurethane foam, which does not require vapor barrier;

- foil-clad penofol, which serves as an additional insulation and vapor barrier;

- inexpensive, moisture-resistant, extruded polystyrene foam with low thermal conductivity.

To insulate the base and prevent moisture from entering it from the outside, it is quite possible to rely on your own strength.First, lists of everything you need are made, then the necessary tools are prepared:

- shovels;

- construction knife;

- drill.

And materials:

- bituminous mastic;

- plates (5-10 cm thick) of extruded polystyrene foam;

- foam for fastening;

- construction mesh;

- dowels with poppet heads larger than mesh cells.

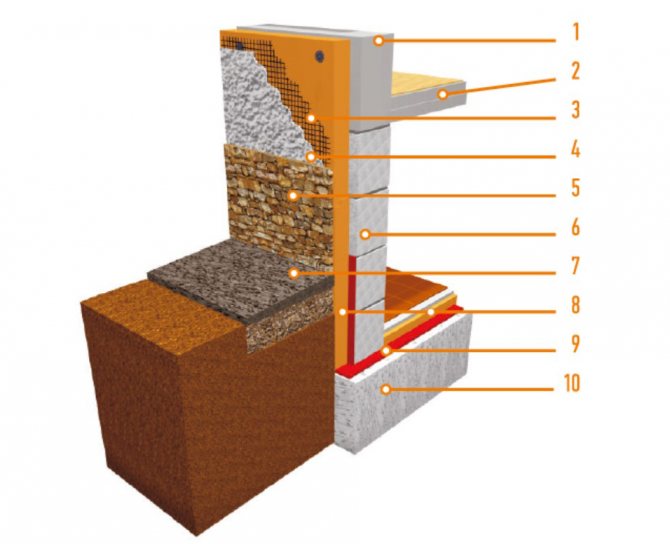

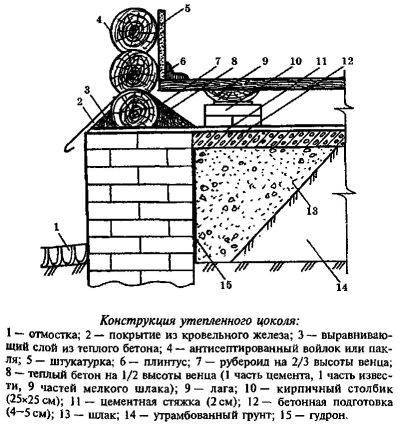

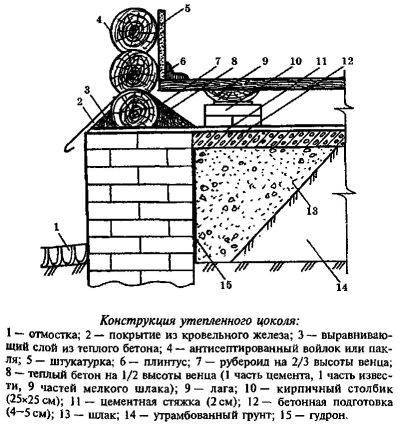

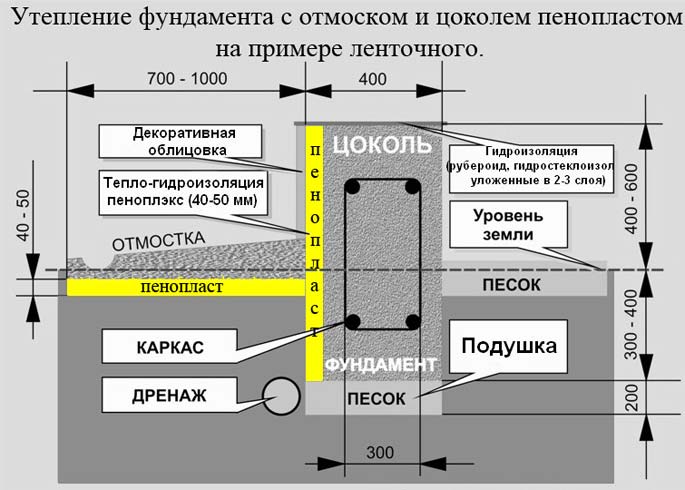

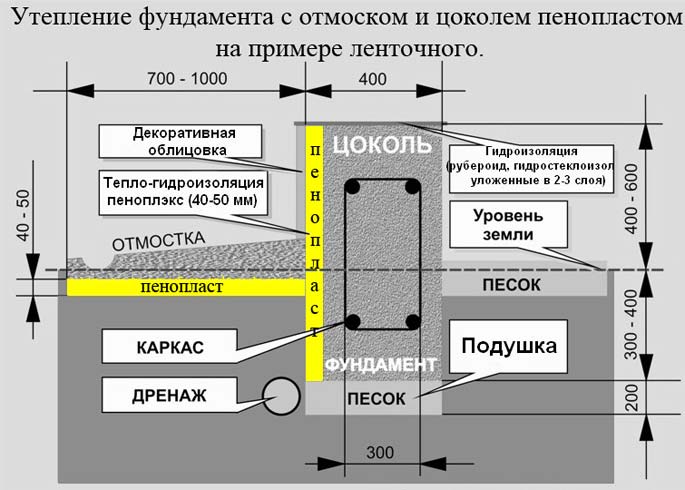

Insulated basement scheme.

Work is carried out:

- Open the foundation of the house 1 m deep and leave it to dry.

- Level the surfaces with a knife for a better fit of the styrene boards.

- From bottom to top, polystyrene foam plates are fixed (without gaps, making mismatching seams) using fixing foam.

- Having drilled holes in the plates, they fix the insulation in the corners with dowels so that they go through the insulator, at the same time reinforcing the structure with a mesh.

- The foundation surface is covered with soil, carrying out its layer-by-layer compaction.

On top of the mesh, a solution of cement and sand can be applied to the surface of the basement, on which the cladding is attached (for example, an artificial stone), or the base can be primed and plastered with facade plaster. A blind area is arranged around the base of the house.

Why do insulation

If the house has a basement (or semi-basement) room, then the question arises of how to insulate the basement floor. It should be insulated in any case, both with a heated basement and in the absence of heating. When the soil freezes in winter, the basement cools down, the cold penetrates to the upper floors.

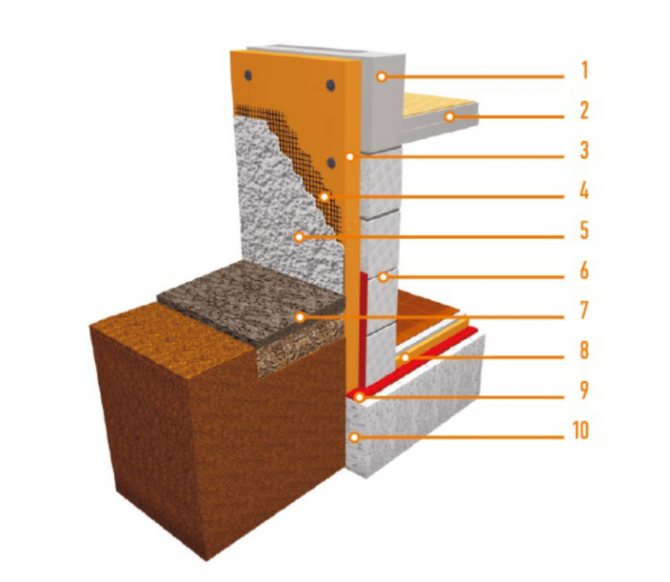

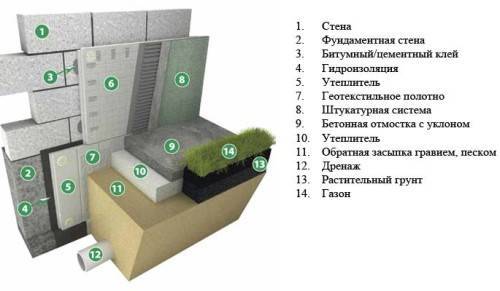

External basement insulation scheme.

There is a collision of cold air from below and warm air from the house, leading to condensation of moisture on the ceiling of the basement and the floor of the upper floor, due to which mold and mildew spread. From seasonal temperature fluctuations in the concrete structures of the basement, cracks are formed, they gradually collapse. Up to 20% of heat is lost through the underground part, which leads to financial losses. Because of these phenomena, it is required to be performed both externally and internally.

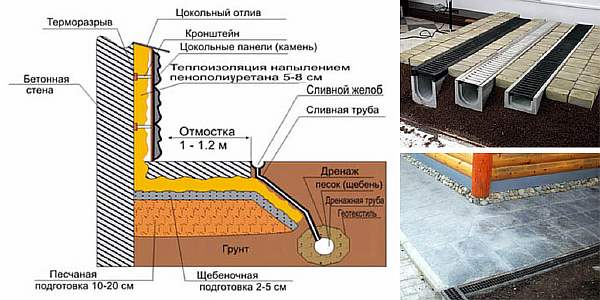

Simultaneously with insulation, steam and waterproofing of the basement is often done, because in their absence, some insulation materials get wet and cannot maintain the body. Protection of the base from dampness provides for:

- ventilation device in the basement room;

- a building around the building of the blind area, the width of which is 200 mm greater than the width of the eaves overhang (protection from precipitation);

- arrangement of vertical insulation to the height of the basement and insulation of the basement floor (protection from water in the ground);

- protection device against water penetration through concrete capillaries;

- thermal insulation of the blind area (protection against heaving of the soil during freezing).

Materials used for insulating the basement

You can make the basement of a wooden house dry and warm using various materials of natural and artificial origin. The decision on how to sheathe the basement of a wooden house, in each case, must be taken individually, taking into account the advantages and disadvantages of each of them.

Priming

The easiest way is to fill the space between the base of the foundation and the basement with ordinary earth mixed with sand. This "finish" has been used since time immemorial, when other heaters did not exist.

Warming the basement with soil is as old as the world

The undoubted advantages of soil insulation include the relative simplicity and availability of the material. This method has many more disadvantages:

- low efficiency,

- a large number of land works,

- primitive appearance.

That is why it is practically not used at present.

Expanded clay

Warming with expanded clay is a universal option to increase the protective properties of any building structures - walls, roofs, ceilings, etc. It is also used for the basement. In this case, the following order of work should be adhered to:

- a trench 1 meter wide is dug around the entire perimeter of the house;

- a primer and waterproofing is applied to the surface of the walls outside;

- formwork is installed throughout the trench. Filling height - up to the floor surface;

- a pre-prepared mixture of expanded clay and concrete is poured into the prepared formwork.

Basement insulated with a mixture of concrete and expanded clay

Such a plinth lining retains heat much better than an earthen one. However, expanded clay is a rather fragile material, in addition, concrete significantly increases its thermal conductivity. The large width of the poured layer also plays a role.

Styrofoam

A wooden house is very often insulated with foam, since it can be inexpensively finished both the internal space of the frame structure and the foundation together with the basement. Foam cladding protects well the surface of the base of the house, and allows you to use all modern decorative materials for finishing the basement.

Since this finish is used very often, here are some important tips:

- The wall surface must be cleaned of dust and primed.

- Since the foam absorbs moisture well, it must be protected with a moisture-absorbing film.

- The height of the foam must be sufficient to cover the entire waterproofing layer of the foundation.

- The strength of the foam is not enough to withstand the pressure of the soil, so a protective structure must be made over its surface. For this, facing from the outside with brick or plaster is used.

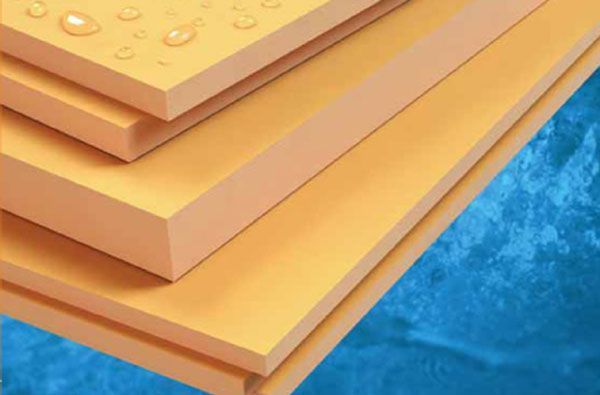

Extruded polystyrene foam and polystyrene foam

Despite their common origin with foam, these materials have a number of advantages:

- great strength;

- better thermal conductivity;

- moisture resistance.

Finishing with extruded polystyrene foam is carried out using a special glue that is applied to the pre-treated surface. Standard slabs (height 1 m, width 0.5 m) are laid tightly butt without any gaps. The contact points outside are coated with mastic or glue. If the plinth cladding is carried out in several layers, the slabs are laid with an offset to prevent the formation of "cold bridges". How this is done is shown in detail in the video below:

Polyurethane foam

The highest quality material, the finishing of which is available only with the use of special equipment. It is quite difficult to do this work on your own, therefore, such a plinth facing is the most costly.

For the application of polyurethane foam, special equipment and ammunition are required

But on the other hand, having invested quite significant funds in it, you can be calm about the safety of the foundation with the basement for many years: the service life of such insulation is 50 years or more.

Plinth trimmed with polyurethane foam

It is better to insulate the basement immediately at the construction stage. Correct and timely finishing will help in the future to save significant money on heating and maintaining a comfortable climate in the house.

Insulated foundation will keep warmth throughout the house

The base of the house is located in the zone of freezing soil. This leads to a significant dissipation of heat in the winter season. To prevent the floor of the lower floors from cooling down, you should resort to the appropriate finishing of the basement.

Insulating it will help maintain a comfortable temperature in the basement, where supply and water drainage lines are often located. They will be able to remain accessible without the risk of winter defrosting. The insulated plinth helps to keep warmth throughout the house.

To insulate the foundation of a house from the outside, it is important to choose a material that, in terms of its properties, is most suitable for the building, taking into account all its features and climatic conditions of the area.Today, the following are especially popular among many consumers:

- expanded polystyrene;

- liquid polyurethane foam;

- extruded polystyrene foam.

Expanded polystyrene

It is an improved version of polystyrene and its derivatives and is a gas-filled material. It is widely used in various sectors of construction and industry.

Penoplex installation

The main advantages are:

- Low degree of thermal conductivity. Allows you to keep warm in the room. For example, an 11 cm thick material gives the same results as a two meter brick wall.

- Moisture resistance. The moisture absorption is about 6%, which allows the material to be used in high humidity conditions without fear of deformation.

- Long service life. Withstands up to 60 cycles of operation in temperature conditions from -40 to 40 C.

- Insensitivity to biological effects. The material is not attacked by microorganisms, mold and fungi.

- Environmental friendliness. In production, substances that are harmless to human health and the environment are used, therefore expanded polystyrene is also used in the food industry.

- A light weight. Thanks to him, the insulation of facades becomes easy and does not take much time.

- Heat resistance. When ignited, fire-resistant polystyrene foam tends to self-extinguish.

- Soundproofing properties. This is especially important for home and apartment owners in noisy areas. The use of expanded polystyrene sheets with a thickness of 3 cm for insulation can reduce noise by 25 dB.

- Vapor tightness. The indicator depends on the density and structure of the polystyrene foam grade. Varieties with low vapor permeability are similar in this indicator to some types of wood: pine, oak.

- Chemical resistance. The substance is not attacked by ethers and alcohols, but is destroyed by solvents.

- Resistance to mechanical stress. The tensile strength is approximately 20 MPa.

- Relatively low price, which increases the availability of the material for many consumers.

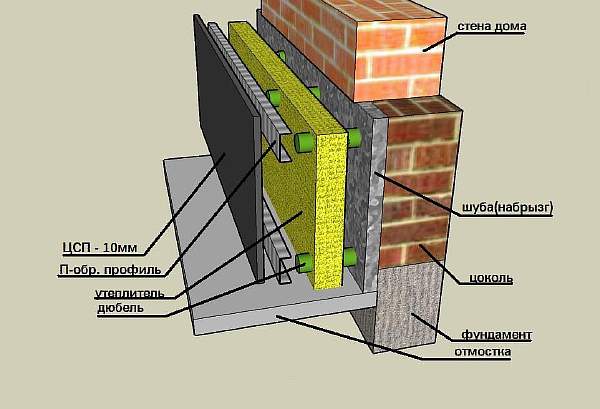

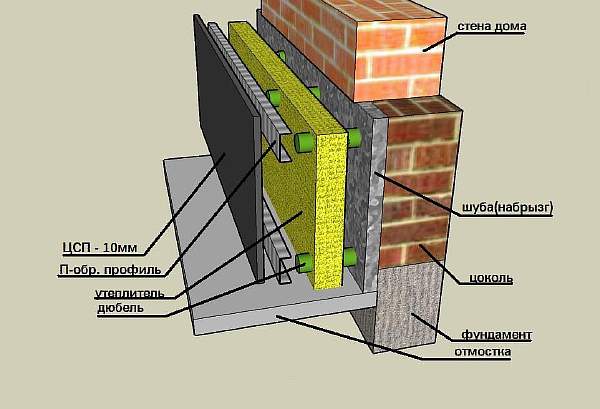

Wiring diagram

So, expanded polystyrene is ideal for various purposes, especially for thermal insulation of the foundation.

Liquid polyurethane foam is a polymer insulation that is widely used to obtain a uniform insulation coating.

We suggest you familiarize yourself with: Shower room in the bath design

It is one of the few materials that are simultaneously a thermal insulation, vapor barrier and waterproofing layer. They allow you to significantly save money and labor costs during the performance of thermal insulation work.

Cutaway

The advantages of liquid polyurethane foam are:

- Low degree of thermal conductivity. This allows you to significantly reduce heat loss.

- Long service life. The service life is over 30 years.

- The ability to create a favorable microclimate in a room due to optimal thermal conductivity and sound insulation.

- Considerable strength. Due to good indicators of density and strength, the material is able to withstand large mechanical loads without losing its operational properties.

- Absolute sealing, which is very important when performing any type of insulation work.

Thermal insulation of the foundation using a liquid polymer can be carried out both from the inside and from the outside. For external use, additional protection from direct sunlight may be required.

Protection is carried out by applying liquid rubber or facade paint, which prevents the loss of waterproofing properties and increases the service life.

It is a relatively young type of polymer heat insulator and is produced by foaming raw materials in the extrusion process.Due to a number of advantages, the material has won the trust of many consumers and today is widely used in various fields of construction.

Formwork for blind area

The advantages of the material are:

- low water permeability;

- low thermal conductivity;

- resistance to mechanical stress;

- resistance to chemical attack of inorganic solvents;

- the ability to withstand a wide range of temperature changes: from -50 to 75 C;

- long service life;

- a light weight.

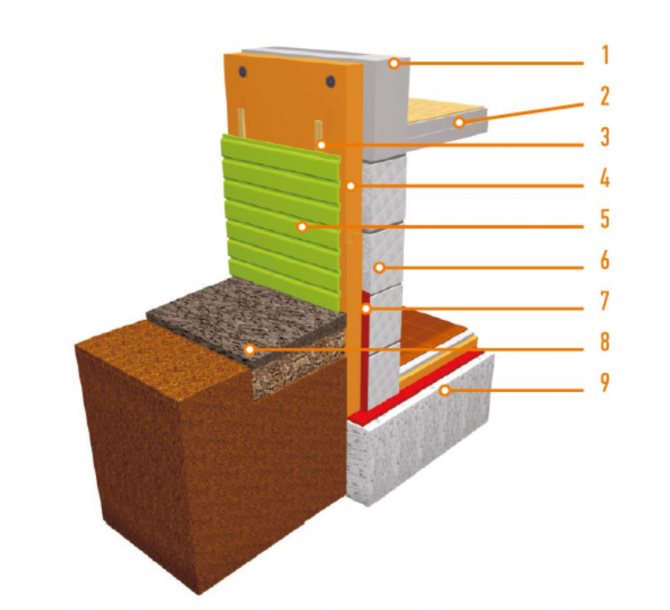

Installation drawing

Extruded polystyrene foam is widely used for internal and external insulation of buildings, roofs, is an integral part of sandwich panels, etc. One of the most common varieties is penoplex.

Insulation of the foundation from the outside with penoplex is relevant and popular due to its excellent performance. Such slabs have increased strength and withstand huge loads, providing excellent waterproofing and groundwater drainage.

Finishing

Do-it-yourself thermal insulation of the foundation with penoplex allows you to solve several problems at once related to the construction of the base and equipment of the basement.

The use of modern methods of thermal insulation is of great importance, especially in areas with harsh climatic conditions. This prevents a significant part of heat loss and freezing of soils, which increase in volume, which leads to a rise in their level.

Warming the basement of the house outside with expanded polystyrene is an excellent option to improve the thermal insulation qualities of the base of the house and prevent freezing.

Expanded polystyrene is an improved type of foam. Its use is more profitable and installation is easy.

The video tells in detail about the insulation of the base of a residential building with your own hands.

The process is carried out as follows:

- Preparation of the base. This stage can be carried out both during the construction of the building and after its completion. To do this, you need to dig out the foundation, clean it of soil, debris, rust and grease.

- Selection of sheets. In this case, you need to pay attention to two factors: density and thickness. Basically, sheets with flame retardant additives and a density of 35 kg / m3 are used.

- Waterproofing. This will prevent groundwater exposure and penetration through the insulating layer.

- Fastening of expanded polystyrene sheets with contact adhesive. You can attach two layers, but so that the panels of the second layer cover the joints of the first.

- Protection of the insulation with a reinforcing mesh to avoid strong mechanical stress and penetration of rodents. A layer of cement mortar can be applied to the protective mesh.

- Providing drainage. This step is considered mandatory when erecting a building on wet soils.

- Insulation of the basement. The base also needs to be insulated in the same way, followed by finishing. After the glue dries, the panels are additionally fastened with nails.

- Warming of the soil. The event involves isolating the surrounding land with a blind area insulated with expanded polystyrene plates.

Insulation of the foundation and blind area can significantly increase the temperature in the structure and protect the base from destruction.

It is considered a fairly effective method that reduces heat loss by 20-25%.

To do this, two liquid components are mixed with each other, forming a thick foam. When applied, it expands and hardens, forming a protective seamless layer with excellent thermal insulation and waterproofing properties. The optimal application thickness is considered to be 60 mm.

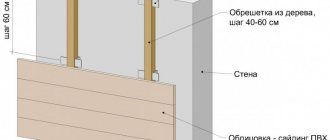

Wooden structure

The polyurethane foam layer is allowed to be applied at a temperature not lower than 5 C.Surface preparation means cleaning from dirt, and surface quality is an unimportant factor.

When solidified, the foam changes color. When performing work, various problems may arise related to equipment and neglect of weather conditions.

For example, when applied in subzero temperatures, cracks may appear, which must be repaired in the future, otherwise water may accumulate in them and freeze. After polymerization, the polyurethane foam layer has low plasticity.

Incision

As a rule, not all heaters are suitable for thermal insulation of the base. To select the right material for this purpose, you need to consider its service life: it must be as durable as the building itself.

We offer you to familiarize yourself with: Insulation Izolon: DIY video instructions for installation, how to insulate walls, floors, beehives, price, photo

Thermal insulation with extruded polystyrene foam (EPS) is considered a more reliable method than, say, foam, since this material is more durable and has excellent performance characteristics.

Blind area with trays

For this purpose, you need to purchase thermal insulator plates and suitable glue for fixing it. After this, a number of preparatory measures should be carried out:

- Dig a trench around the foundation by digging in the ground.

- Apply EPPS to the depth of freezing of the earth.

- Clean the foundation from debris and dirt.

- Apply a special primer in two layers, wait for it to dry and soak into the concrete.

- Provide waterproofing with bitumen mastic.

- Apply glue to the boards.

Fastening the slabs to the outer section of the foundation is allowed 1 minute after applying the glue. If the panels have a large area, the adhesive should be applied in several strips using a comb trowel. If the slabs have locks, then a few days later the seams are sealed with polyurethane foam, and the slabs themselves are additionally fastened with dowel nails.

Two-story mansion

Many owners of wooden houses believe that it is enough to insulate the walls and floor to ensure favorable living conditions. However, this is not the case, because serious heat loss can occur through the wooden floor - up to 20%. Therefore, thermal insulation of the foundation is a must, especially if the house is located in an area with harsh weather conditions.

Insulation of the foundation of a wooden house from the outside will not only create favorable conditions in the room, but also prevent adverse effects on it. For this purpose, polystyrene foam and its varieties are usually used, as well as expanded clay.

Stone decoration

Thermal insulation of the base with foam

Now this material is used almost everywhere, in addition, with the help of the foam plates themselves, you can make any basement section protruding.

For example, take a plinth in a single plane with the outer walls. We use a special paint for finishing. Let's start with our own hands.

Defining boundaries

The foam plates should slightly overlap the waterproofing, so the basement area should be made a few centimeters higher. Take a pencil and draw a horizontal line across the entire wall. You can also pull a regular lace above the waterproofing layer. The border is ready.

At the same stage, we will equip a groove with a depth of approximately 5 cm, in order to then slightly drown the foam plates.

Cleaning the base

The wall surface where you are going to stick the foam must be well cleaned of dirt and dust.

When the primer is dry, you can move on to the next step.

Bonding boards

Strengthening the foam with a special adhesive starts from the corner sections. Using a wallpaper or any other sharp knife, mark and cut a couple of pieces of material that will be needed a little later.

Glue application

Apply glue to the basement area with a notched trowel.Having smeared with the composition, we attach the trimmed products to the desired areas. The joints between the plates and the ends are well covered with an adhesive solution.

When a couple of products are glued, we proceed to dowelling using the previously prepared pieces (they will give additional fixation). A hammer drill is needed to drill holes. Dowels are inserted into the holes formed, after which nails are hammered.

So the entire basement surface is completely covered with foam plates. At the very end, a primer layer is applied again. It is used to create a base for subsequent layers.

Installation of a slope corner and reinforcing mesh

For the installation of a sloping corner made of metal, the previously used glue for the plates is suitable. Fortification sites are the upper perimeter and corner sections of the building.

Reinforcing mesh, like a corner, is glued to the foam. This time directly from above. Before starting work, the product is cut, depending on the size of the plates. When the required number of elements is ready, the surface of the future insulation system is covered with glue using a wide spatula. Ultimately, the reinforcement mesh is placed on top of the products and is equal to the spatula.

Putty, painting, installation of ebbs

It is allowed to putty the basement areas only with materials intended for outdoor use with a wide trowel. When the composition is dry, the surface is primed again and then painted.

But for additional protection, ebb tides can be installed to prevent moisture from entering the insulation and other places where it should not be.

Using this technology, you can insulate the basement with your own hands with both foam and polystyrene foam, since they are almost identical. If any defects appear on the surface of the insulation system, they can be easily eliminated by a new primer followed by painting.

Finishing the basement of the house

Insulating the basement of a house with foam and arranging the final layer are completely different works. However, in most cases, these works are carried out in an integrated manner, which is why they are considered in a single context. You can often find recommendations for insulating the basement, which describe the technology of thermal insulation using expanded polystyrene. The fact is that expanded polystyrene and polystyrene are practically the same thing. The differences are not very significant to be considered and taken into account. Therefore, the technology of insulating the basement of the house is similar when working with these two heaters.

It is not recommended to finish the basement areas with silicate bricks or ceramic tiles. As a result of exposure to low temperatures, the glaze, which covers the slab elements, can simply break off in winter. As for the sand-lime brick, chips appear most often in the area of the first rows due to the same low temperatures.

Styrofoam is not resistant to constant exposure to ultraviolet radiation (sunlight), so if you decide to insulate the basement of your house with foam, be sure to put a layer of plaster on top of it.

The scheme of insulation of the basement with polystyrene foam.

The most reliable and high-quality, but at the same time quite expensive, is the option of facing the basement with the help of wild stone. This material is worth a lot, not only because of the cost of the products themselves. If the base is finished with stone, then the rest of the structure will also have to be covered with appropriate materials. Otherwise, it will simply look ridiculous.

They often use ordinary or decorative plaster. If necessary, it is restored in a fairly short time, regardless of the variety. The cost of the plaster is quite acceptable, which reduces the financial costs of facing the entire structure. In addition, it is easier to select materials for the plaster.