What is a hydraulic accumulator

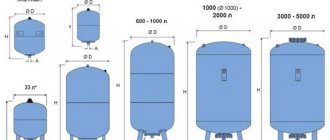

Hydraulic accumulator, it is also called a hydraulic tank, a hydraulic tank, an expansion membrane tank. In the water supply system from a well, it is used as an autonomous storage device for a summer residence or a private house, supplying water to the sink, shower and other points, and then draining it into the sewer in the same way as in city apartments. The hydraulic tanks work in conjunction with the pump.

Summing up

Hydraulic accumulators and expansion tanks have different purposes. What to choose specifically in your case? First, you need to evaluate the whole system and decide what function this device should perform. If you need a potable water pressure tank, you should use a pear-shaped hydroaccumulator.

If it is necessary to compensate for the expansion of the heating medium in the heating system, then use a membrane expansion vessel in which the diaphragm is designed to work at high temperatures.

☛ Select expansion vessel

How it works and how it works

Air is pumped between the body and the inner membrane, on one of the sides there is a nipple for pumping or bleeding air into the space between the membrane and the body. Also, it is better to choose equipment with an integrated pressure gauge and an additional nipple.

The accumulator works as follows:

- After pumping air, check the pressure;

- We turn on the pump, pump water into the membrane;

- We turn off the pump, then open the tap, the air presses on the membrane and under its influence pressure is created, the liquid enters the tap.

The hydraulic tanks work without electricity, and if the power goes out, the water will not go anywhere.

Differences between a hydraulic accumulator and an expansion tank

The accumulator and expansion tanks belong to the same type of equipment - to membrane tanks. This equipment has found active use due to a number of positive properties that it gives to its owner. However, let's try to figure out what distinguishes these devices.

First of all, what distinguishes the accumulator and the expansion tank is the price. But still, let's take a closer look at the very principles of their work.

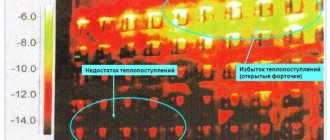

Expansion tanks are used to compensate for the excess volume of the coolant. Due to the fact that water in heating boilers is regularly heated, the expansion of the liquid occurs due to the vapors. This expansion is accompanied by heating every 10 degrees, which is accompanied by an increase in the volume of water by 0.3 percent. That is, at the boiling point, the liquid is capable of expanding by about 3 percent. To exclude the destruction of the boiler, expansion tanks are used, where all excess water will be directed, because it is practically impossible to compress it.

The accumulator can save you from the need to regularly turn on the pump when the heating system is required. The accumulator will independently control the pressure, making it as stable as possible.

In addition, expansion tanks also come in many variations. This is due not only to different principles of work, but also to the methods of fastening, and even depending on the shape. In fact, today, on the market for these products, a huge number of all kinds of membrane tanks are provided, which is practically impossible to tell about all the models. It is better to inquire about this directly from the manufacturer.

Among the criteria for the selection of equipment, special emphasis is placed on the membrane.Besides the fact that it is the most important aspect in the operation of heating systems, low-quality sellers are ready to use the similarity of these products. Yes, externally the membranes are difficult to distinguish. But you should study in advance the main external characteristics of each in order to choose for yourself one that would allow the entire system to serve for a long time and reliably.

The main criterion for heating systems is a high-strength membrane material that will withstand high temperatures and will not corrode due to operation in these conditions. For a cold water supply system, the selection criteria for a membrane are less stringent.

Prophylaxis

We recommend making diagnostics for the presence of vented air and the integrity of the hydraulic tank membrane annually. In the second case, the accumulator ceases to act as protection against water hammer. Membranes are sold separately and can be replaced in a couple of minutes.

Let's summarize. The hydraulic tank provides water to a dacha or a country house without any problems, while protecting the water supply system from water shocks leading to breakdowns, premature wear of equipment. This will make it possible to use water without thinking that it may run out, and something will happen to the equipment.

Rate the article

How to determine if a membrane has deteriorated

In general, manufacturers claim that these products have a lifespan of 5 years. However, in practice, this rarely happens. After all, they don't like membranes very much:

- temperature rise above the set;

- frequent pressure drops;

- intense compression.

In practice, it is rarely possible to avoid operating the hydraulic tank in a hard mode, therefore, the service life of the bulb is reduced to 3 years.

How to determine when it is time to change the membrane in the hydraulic accumulator:

- the pump began to turn on too often;

- constant water pressure does not hold.

These are clear signs of damage to the diaphragm, however, this may also indicate damage to the accumulator housing. Therefore, before disassembling the container, it is advisable to check the condition of the tank itself.

What is an expansion tank?

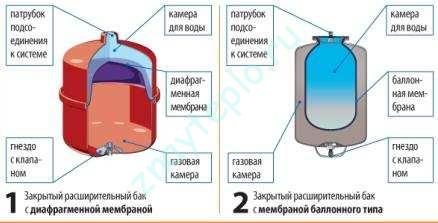

An expansion tank is a container that compensates for the thermal expansion of the liquid inside the heating system. There are two types of them:

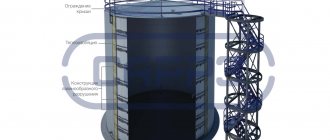

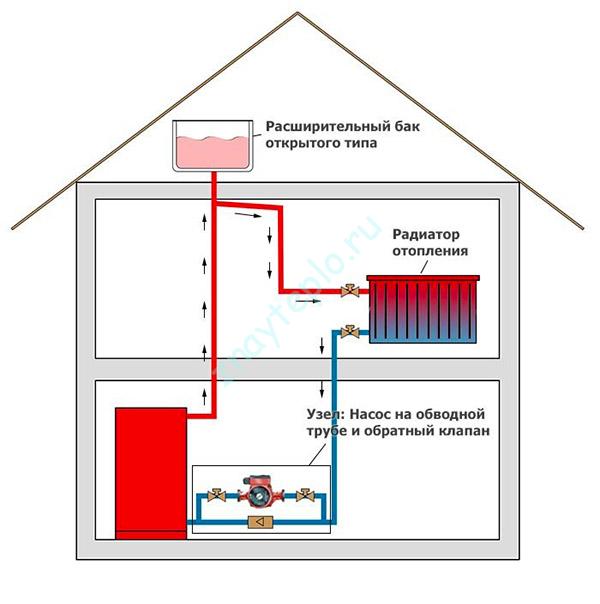

- Open type - designed to work in heating systems with a working pressure of 1 atmosphere. It is a steel container with threaded connections. Most often, this type of expansion tanks is used in gravitational heating systems. They are still popular among the villagers because of their independence from electricity.

- Expansomats or membrane tanks - this type is designed to work in closed heating systems, the pressure in which does not exceed 3 bar. The maximum temperature of the coolant in them should not be more than 100 degrees Celsius, and the pressure should be kept within 8 atmospheres. In addition, they are used for "piping" indirect heating boilers, where they compensate for the increase in the volume of sanitary hot water. It is worth remembering that in this case they do not replace the boiler safety group. Read about it separately here.

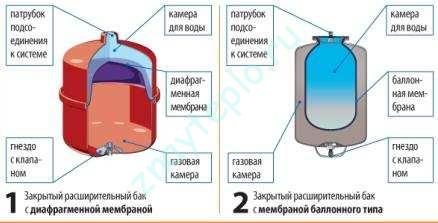

At its core, it is a steel casing divided into two parts by a rubber membrane. In one part of the tank, the coolant is under pressure, and in the other part, air is pumped in. For clarity, see the figure below:

Among buyers, models with a balloon-type membrane are more popular (in slang it is called a pear or a heating pad). This is explained by their maintainability - in case of damage, the membrane is easy to replace. The thread on the nozzle can have two standard diameters - 3/4 or 1 inch. It depends solely on the manufacturer and is not a matter of principle.The standard air pressure value, in turn, is 1.5 bar and can be changed by the consumer.

I will give advice personally from myself - it is better to install a tap with a drain valve on the connection pipe. This is necessary to periodically check the air pressure. It is done in the following order:

- The tank is cut off from the heating system by closing the tap.

- Through the drain valve, the water remaining inside the container is removed.

- Air pressure is checked using a car pressure gauge.

If the check is not done, then the air pressure will drop sooner or later. This will lead to the fact that the membrane will begin to rub against the steel body with its walls, which will lead to its accelerated wear. Continuing the topic of checking the condition of the expansion tank, I suggest you watch the following video:

Expansion tanks with a membrane in the form of a diaphragm can most often be seen by opening the lid of a wall-mounted gas boiler or electric mini boiler room. It may look different, but most often you will see this:

If the "elastic" inside such a model breaks, then it will be possible to change it only as a whole. Since it is hermetically sealed at the factory. Now let's talk about these "rubber bands" in more detail.

How is the expansion tank diaphragm arranged?

As mentioned above, the membrane is needed in order to divide the tank capacity into two parts. It is a rubber product with thick walls (this is necessary to maintain tensile strength), on top of which there is a neck for a flange. If it is not clear how it looks, then see below:

Membranes are currently made from an elastomer called EPDM. It is approved for use with drinking water and does not emit any harmful impurities into it. Expansion tanks with such a "rubber band" can be used not only with boilers, but also with indirect heating boilers. And if necessary, they can also be used as hydraulic accumulators for pumping stations. We will talk about them a little later, but now we will learn how to choose an expansion tank for our heating system.

Calculation of the required volume of the expansion tank.

As we said earlier, the main function of the expansion tank is to compensate for the thermal expansion of the liquid. Therefore, the volume of the tank will depend on the total volume of fluid in the system, as well as on the coefficient of its expansion. Let's calculate the volume of the diaphragm tank you need using the following formula:

Vtank = Vheat carrier * kexpansion / P, where P = (Psystem - Pair) / (1 + Psystem).

Let's decipher the formula:

- Vtank is the required volume of the expansion tank.

- V heat carrier - the total volume of the heat carrier in the heating system.

- kexpansion - coefficient of thermal expansion of the coolant. This value depends not only on the chemical composition of the liquid in the system, but also on the operating temperature range of the boiler.

- Psystem - the maximum possible pressure in the boiler.

- Pair - air pressure in the expansion tank. It is usually 1.5 bar.

If you are too lazy to calculate everything yourself, then I suggest you use the calculator presented below. Warning - calculator does not work on turbo pages! Therefore, you need to go to the full or mobile version of the site (at the bottom of the turbo page, click "read on znayteplo.ru")

To calculate the volume of an open expansion tank, it is enough to take the pressure in the system equal to 1 atmosphere, and the air pressure will be equal to zero. Since an open tank has no diaphragm.

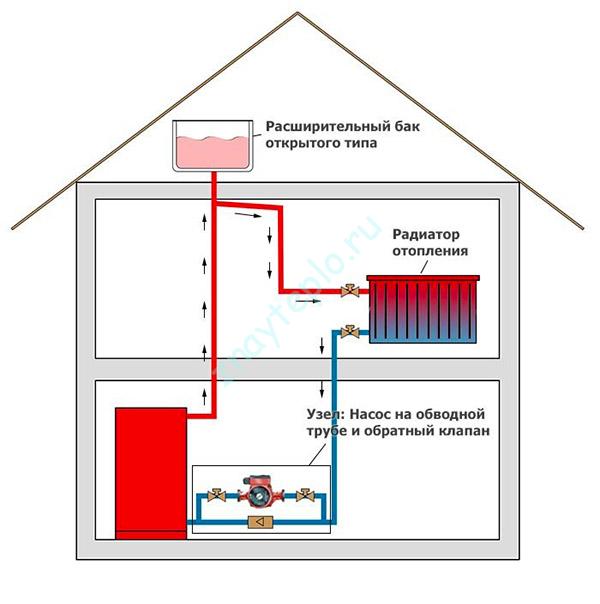

Expansion tank installation.

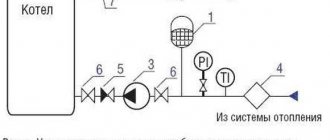

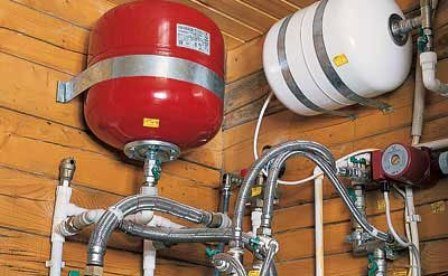

Now let's talk about how to properly install the expansion tank in the heating system. Let's start by looking at the following picture:

The illustration above shows a heating system with an open expansion vessel.With the help of this figure, the question of its installation is clearly and clearly resolved - an open-type expansion tank should be installed at the highest point of the system. Usually, it is installed in the attic or, in extreme cases, under the ceiling. If this is not done, then water or antifreeze will simply start pouring over its edge.

In the case of a closed heating system in which a diaphragm expansion vessel is installed, there are no such restrictions. Usually, they are located directly in the boiler room next to the boiler. It looks like this:

Brackets of different designs are used to fix the container to the wall. Some manufacturers combine them with security groups. For clarity, look at the figure:

This is not the only possible fastener option, but we will not consider the rest. And let's move on to the next part of the article on hydraulic accumulators.

Replacing the membrane

If the reason has already been determined, then you need to proceed with the repair. And the first thing to do is purchase a new product. It is important here not to save money and buy original spare parts, because cheap fakes can quickly fail. And the situation will turn out that in six months you will have to do everything all over again.

Training

When a new membrane is purchased, you need to prepare a set of keys and proceed to repair. First, you need to drain the water from the container itself. For this:

- the water supply to the accumulator is shut off;

- air is bled from it;

- the water is drained.

An important point - if, when the water is drained from the battery, air also comes out, then the rubber bulb is damaged. The nipple shakes the same - if water comes out when air is released, this indicates a breakdown.

The fact is that the pear divides the inside of the tank into two independent chambers. Therefore, mixing of water and air is excluded. If this happens, then the inner integrity is violated.

Repair stages

When the water is drained from the tank, you can proceed directly to the repair. Replacing the membrane in the accumulator is done as follows:

- firstly, it is necessary to remove the flange, for this, the nuts holding it are unscrewed with a key;

- after that, the old membrane gets out;

We take out the old membrane

- it must be carefully examined and the place of damage must be found. Firstly, this will allow you to make sure that it is torn, and secondly, you need to assess the size of the damage. After all, if they are small, you can try to vulcanize it;

Checking where the membrane broke

- now it is advisable to inspect the inside of the tank - most likely there will be dirt and rust in it. Therefore, it needs to be cleaned well;

- after that, you need to carefully inspect the flange - there should be no damage or burrs on it. If there is any detachment, it should be sanded off. The same applies to the seat - it must be thoroughly cleaned;

- now you need to take a new membrane, straighten it and insert it in place of the old one;

- after that, it is covered with a flange and it is tightened with nuts.

This is where the replacement process ends. Now, you need to do a test run of the accumulator. For this, it is reconnected to the water supply. But in the beginning, you need to pump air into it to the working pressure, it is 1.5-2 atmospheres.

And then, the water supply is turned on. At the same time, you should not open the feed valve at full capacity. This can lead to rupture of the membrane, therefore, water is collected gradually.

Thus, it is quite easy to change the membrane with your own hands. And this can be easily dealt with without involving specialists. Moreover, the cost of replacement in a specialized center can be quite high.