A diaphragm tank for DHW is an extremely important element of the indirect heating boiler piping. It is important that it be in general, it is important to choose the right volume and initial pressure.

So that you are convinced of this, I want to tell you a story, then we will move on to the choice of tank parameters, and after that we will consider the main elements of the boiler piping.

The material will be very useful, so download my manual "Diaphragm expansion tank and the main elements of the boiler piping" for your reference.

History of finding water leaks.

Once I came to the site to the customer. It was necessary to make heating and water supply to the bathhouse - a guest house with a swimming pool. There are radiators and underfloor heating, ventilation and equipment for the pool. In short, if you add subcontractors as well, then the order is monetary. The customer is not stuffy and not stingy, great.

But at the beginning of the conversation, he asks: Sergey Nikolaevich, I have such a problem in my main house: the water consumption has always been 25-40 cubic meters, and for some reason more than a hundred for the last two months. Everywhere in the house is dry. Can you see what is the reason? And I understand: if I find a leak now, I will take the order; if I don’t find it, I will lose it in disgrace.

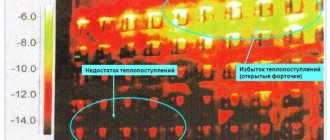

We checked all the taps for consumers - they were closed, the dishwasher and the washing machine were turned off, there was no murmur in the toilet bowls, all the taps in the garden were closed. And the counter is spinning. I went from the meter along the cold water pipe. Cold pipe, already with droplets. On the floors - collectors for water sockets - at room temperature.

Only the pipe to the boiler is cold, up to the safety valve. The valve itself is cold and you can hear the rustling of water in it. From the valve, a discharge tube is carefully directed into the drain. Also cold and wet. That is, the safety valve does not hold, and cold water flows through it directly into the sewer.

You ask, but where does the membrane tank of the boiler have to do with it? Yes, here's what: I unscrewed the nipple cap, pressed the stem, and silence. There is no air, it has leaked out. The tank must compensate for the thermal expansion of the hot water in the boiler during heating. When expanding, water goes into the tank, compressing its air part. If the pressure rises, then slowly, and will not exceed the pressure of the safety valve. And here the air has flowed out, there is nothing to compress. The entire tank is filled with water. When the doiler warms up, the pressure rises rapidly beyond 6 bar, and the valve is activated by dumping some of the water. After several dozen such discharges, the safety valves often begin to leak. And then the caring installers installed a discharge outlet into the sewer. The user does not understand what is happening at all, some miracles.

In general, the diagnosis was about fifteen minutes. I said that tomorrow our fitter would come up, replace the valve and pump up the tank. There will be no leaks. We received the order.

The customer also asked for an additional boiler to be supplied. This, 150 liters, was not enough to fill the jacuzzi. So there it is! the puzzle came together. This means that often it was necessary to heat the boiler from the minimum to the maximum, which means that the water expanding as much as possible when heated. When the air escaped, this inevitably caused an exorbitant excess of pressure and the actuation of the relief valve.

Do you understand how important it is that there is enough air in the tank for the smooth operation of the system?

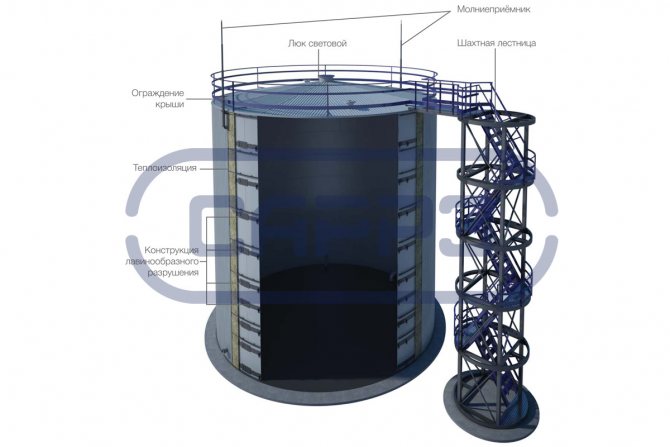

The device and design of the accumulator tank BAGV

Their design resembles storage tanks for petroleum products, but they are not interchangeable.

BAGV represent a vertical or horizontal cylindrical all-welded vessel with a volume of 50 m 3 to 20,000 m 3, mounted on supports made of concrete or metal.

Accumulator tanks with a volume of up to 50 m 3 are traditionally made in a horizontal design. BAGV with volumes from 50 m 3 to 100 m 3 are produced both horizontal and vertical. It is more efficient to manufacture containers with a volume of more than 100 m 3 in vertical design.

Vertical hot water tanks Is a cylindrical body with a flat bottom and a frame or self-supporting roof. Design horizontal hot water tank Is a cylindrical all-welded body with flat, conical or conical-truncated bottoms. The type of bottoms is selected based on the operating conditions. They must be completed with a ladder, a service platform and a fence.

To maintain the required high temperature, the housing is equipped with a heat-insulating layer or a water jacket (water circuit). The climatic conditions on site determine the required degree of insulation and, consequently, the thickness of the thermal insulation layer.

In addition, there are small storage tanks that are installed on the roof or attic of buildings or in the lower part of the structure. When installed above the point of the water supply system, the tanks operate at atmospheric pressure. In the case of the bottom arrangement, they are operated at an operating pressure of 0.6 MPa. Then they must be equipped with safety valves or hydraulic locks to prevent emergencies at dangerously high pressure.

The design of the storage tanks can also be open or closed. The first modification is safer as it works at atmospheric pressure.

The design must provide for filler necks, hatches, brackets, branch pipes, flanges and fittings for connecting technological equipment.

BAGV tanks can have sections in which liquid of different temperatures can be stored.

Characteristics of storage tanks BAGV

- the temperature of the working environment should not be higher than 95 ° С

- ambient temperature above -60 ° С

- seismicity of the area - no more than 9 points

- wind load - below 0.6 kPa

- snow load - below 2.0 kPa

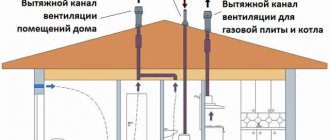

- natural or forced ventilation is required

- minimum residual level - 200 mm

Hot water storage tank technical characteristics table

dimensions

(calculated by individual order and given for reference)

| Options | BAGV-100 | BAGV-200 | BAGV-300 | BAGV-400 | BAGV-1000 | BAGV-2000 | BAGV-3000 | BAGV-5000 |

| Work product | water | |||||||

| Constructive execution | horizontal / vertical | vertical | ||||||

| Working product temperature, ºС | up to +95 | |||||||

| Main material | St3sp, 09G2S | |||||||

| Thickness of steel | 4-8 mm | 8-16 mm | ||||||

| Operating operating temperature, ºС | from -60 to +40 | |||||||

| Minimum residual level in the tank, mm | 200 | |||||||

| Seismicity of the operation area | up to 9 points | |||||||

| Bottom type | flat, conical | |||||||

| Established service life, years | 10 | |||||||

| Diameter D, mm | 4900 | 6650 | 7850 | 8600 | 10430 | 15180 | 18980 | 20920 |

| Height H, mm | 5960 | 5960 | 7450 | 7450 | 11920 | 11920 | 11920 | 14900 |

| Weight, kg | 12251 | 14000 | 17960 | 20500 | 39500 | 69500 | 118000 | 176500 |

What is the initial pressure to create in the tank.

The tanks come from the factory at 2.5 bars. Someone puts it right. I have a different approach and I will explain why.

Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come to the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Take a look:

Production of hot water storage tanks

Saratov Reservoir Plant has the necessary Certificates of Conformity for the manufacture of BAGV.

We produce storage tanks from sheet steel St3sp (for operation up to -40 ° C) and 09G2S (up to -60 ° C) with a thickness of 5 mm to 16 mm.

The manufacturing method depends on the volume. Large-volume tanks are produced by rolling on a rolling stand, when the bottom and the wall are supplied from the manufacturer in the form of a rolled-up panel.At the construction site, the wall unfolds and is welded to the bottom.

Another manufacturing option is the production of the wall shell along the belts. This method of production contributes to the preservation of the geometric shape, the absence of flaps and other deformations. At the construction site, the steel sheets are overlapped, resting on the wall and the longitudinal edge.

Horizontal storage tanks of small volume are delivered to the installation site in full factory readiness.

Tank service.

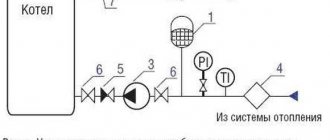

If the safety valve has worked, it means that air has escaped from the tank, or the membrane has leaked. Unscrew the tank nipple cap and push the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing went wrong, or the air hissed, then you need to pump it up: • give the union nut on the squeegee - cutoff, • open the drain cock (red handle) and drain the water, • pump up pressure, for example, with a car pump, • close the drain clan. • attach and tighten the union nut.

Tying hot water storage tanks

Structurally, being a vertical or horizontal tank, the BAGV tank is completed with technological equipment for safe operation:

automatic level controls to prevent overflow

instrumentation for measuring liquid temperature, pressure, filling level, etc.

blocking equipment, if necessary, turn off the water supply when the min level remains

devices for measuring pressure in supply and discharge pipelines

drainage system to remove residues

overflow pipe at the maximum allowable level

pipe for drainage of water from the overflow pipe

a vestibule pipe, which prevents the formation of a vacuum during drainage due to the release of the steam-air mixture

heat insulation from the outside

Specialists of the Saratov Reservoir Plant produce hot water storage tanks BAGV in any climatic design, of any design (horizontal / vertical, open or closed), completing them with the necessary technological equipment.

How to order the manufacture of storage tanks at the Saratov Reservoir Plant?

In order to buy a storage tank with a volume of up to 5000 m 3, you can:

- contact our specialists by phone 8-800-555-9480

- send the Terms of Reference by e-mail

- use the "Request for quotation" form, indicate contact information, and our specialist will contact you

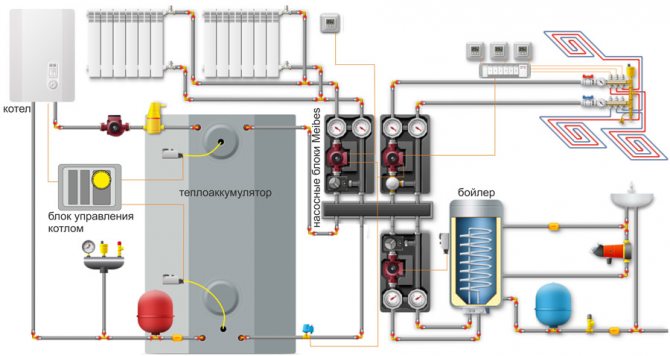

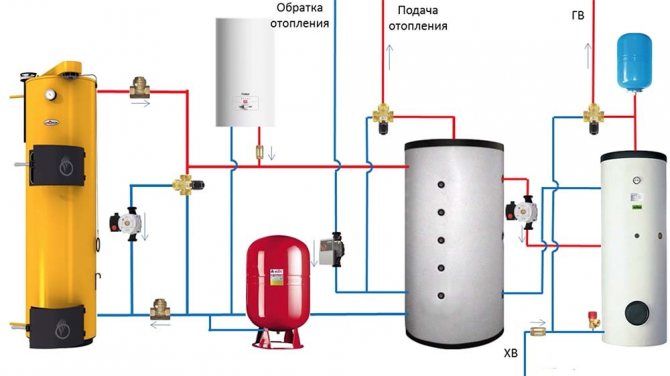

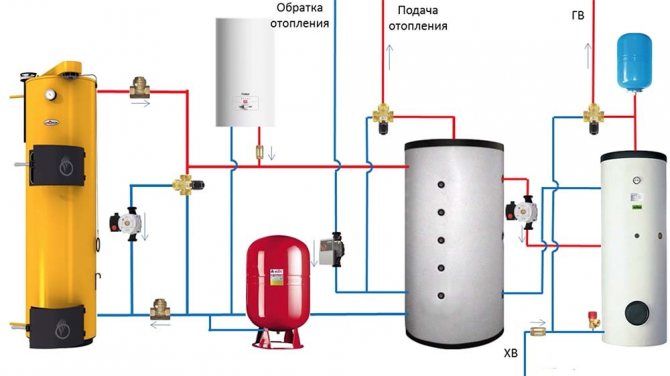

The piping scheme for boiler rooms for a private house with a heat accumulator and a standard solid fuel boiler is one of the most reliable and demanded combinations. The construction of the circuit begins with the placement of the piping of the solid fuel boiler, as well as the placement of the buffer tank. This element is installed in order to obtain an additional circuit of natural circulation. Thus, an alternate path is created, along which water will go in the event of an unplanned short-term power outage and a sudden stop of the pump.

What's in the know Installation of an indirect heating boiler:

• Device and principle of operation. • How to choose the volume of the boiler. • Simplified wiring diagram for floor and wall boilers. • Detailed diagram of the boiler piping. • Detailed equipment. • How to heat a boiler with a wall-mounted single-circuit gas boiler. • Connection of a wall-mounted single-circuit gas boiler with a boiler. • How to heat a boiler with a floor-standing boiler. • Scheme of piping of the pump manifold for multi-circuit boiler houses with a boiler. • Boiler heating control from its own thermostat. • Control of boiler heating with a separate immersion thermostat. • Scheme of boiler priority over other consumers. • Application of heating elements and night tariff. • Additional materials.

Other articles about diaphragm tanks:

one.Where in the boiler room should the expansion tank be installed for heating.

2. How to choose a membrane accumulator tank and set up a water supply system. Sergey Volkov.

Anti-corrosion protection of storage tanks

Due to the properties of the liquid, they are subject to high corrosive effects and other negative factors. Therefore, the steel grade from which the storage tanks are made must have high anti-corrosion characteristics, be wear-resistant and have good resistance to low temperatures.

Corrosion protection consists of a comprehensive treatment of the inner and outer surfaces. Sealants, aluminum metallized coating, paints, epoxy compounds, enamels, self-healing anticorrosive lubricants, cathodic protection are used as coatings.

General information

Features of the device

Heat storage tanks have the shape of a cylinder or a square. The device is equipped with branch pipes coming out of the housing. The number of branch pipes is affected by the number of supplied heating devices, circuits.

The volume of the tank must correspond to the size of the room for heating, the parameter lies in the range of 200 - 3000 cubic meters. In order to retain heat, a layer of thermal insulation is laid between the container and the external material, having a thickness of 5-10 centimeters. The internal structure of the tank depends on the type of construction.

The main details include:

1.heat exchanger (one or two),

2.electric heater of tubular type.

3.Magnesium type anode.

Double-circuit systems contain heat exchangers. These devices in the tank are represented by coils made of copper material. Electric heaters help to maintain the temperature of the medium in the circuits in case of malfunctions with the boiler.

How the tank works

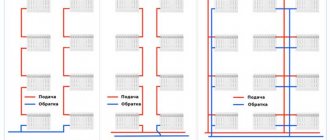

In a standard system, the heat carrier is heated in a special solid fuel boiler, which then goes through the pipes in the direction of the radiators. In heating devices, the medium is cooled, through the second line it flows back into the heater.

After the boiler burns out, the carrier cools down until the fuel is loaded again. In this case, the value of the air temperature drops. If the heating system is equipped with a storage tank, then the operation is different. As soon as the boiler starts operating at full power, the coolant begins to circulate between the heating device and the storage tank in a small circle.

The buffer tank is filled with heated water. When filling the tank with a pump, the coolant is pumped into the heating system. At this time, the boiler burns out, while the fuel is being loaded, the heating devices will receive heat from the accumulator tank.

Attention! The presence of an accumulator tank in the heating system allows keeping the air temperature at the same level in the room.

Pros of a storage tank

If there is a tank in the heating system, then such a system can heat the building for a long time if the boiler is completely turned off. The water circuit in the boiler has good protection against boiling and breakdowns. If the temperature of the carrier rises sharply, the accumulator tank will take on the excess heat, which will protect the boiler equipment. The system is equipped with a blockage against the flow of cold heat carrier through the return flow line into the hot heat exchanger during a breakdown of the circulation pump.

If the heating consists of several circuits, then the tank distributes the thermal energy of the carrier, allowing several lines to function independently. This feature allows you to reduce the cost of heat and fuel.

Attention! Installation of the tank is expensive, and the requirements for equipment placement are also increased.