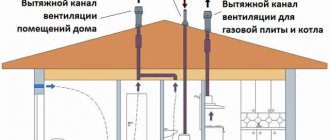

In many homes, the central element of the heating system is gas boiler. However, to maintain the device in good condition, it is necessary to take into account the peculiarities of the functioning of the equipment.

For example, during the operation of the boiler plant inside the combustion chamber air temperature rises, therefore it is important to control this parameter.

A thermocouple is specially used for this - a thermoelectric device, which is practically the only device for accurate measurement of elevated temperatures. Today, equipment is used that functions in conjunction with automatic valves.

Odnoklassniki

Features of temperature control in gas boilers with a thermocouple

The widespread use of equipment is due to the fact that this device is considered the main way to measure air temperature, as well as control the flame level.

After all, the device is not exposed to elevated temperatures and operates on a special principle that allows you to get accurate readings and quickly respond to even minor changes.

What is it for

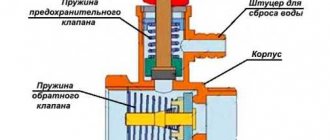

A thermocouple is a device that is installed in heating equipment and is designed to convert thermal energy into electric current for electromagnetic coils and serves as the main component of gas control protection. The device works in conjunction with special shut-off gas valve, blocking the flow of fuel.

Principle of operation

For the manufacture of the device is used metal alloy... It can withstand exposure to high temperatures. However, if a failure occurs in the equipment, the operation of the gas boiler will be stopped.

Photo 1. Thermocouple for a gas boiler with automatic equipment 345-1000 mm, Russia.

After all, this thermoelement functions in conjunction with a special electromagnetic shut-off valve that regulates the flow of gas into the fuel path, which closes immediately after the thermocouple breaks.

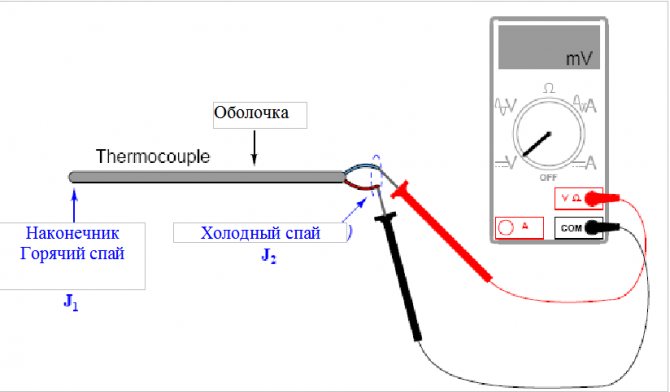

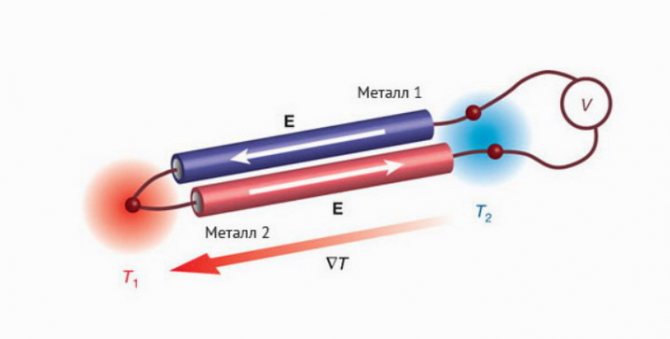

The principle of operation of the device is based on the following physical phenomenon: two metals join and when heated, at the attachment points (the working area that is placed in the flame) appears at the cold ends voltage... This is called the Seebeck effect.

Attention! Many models of solenoid valves are sensitive, so they remain open until the voltage at the input will not drop to 20 mV.

Specifications

The thermocouple has the following technical parameters:

- wide range temperatures;

- high accuracy measurements;

- increased resistance to corrosion;

- electronic control mechanism.

Features of Thermocouple Replacement

This element most often fails, so many users are interested in the question of how to check a thermocouple for a gas boiler? This can be done at home with minimal effort. The following activities will be required:

- 1. Unscrew the free end of the thermocouple from the solenoid valve.

- 2. Remove the thermocouple from the boiler and start heating the end that was located above the burner. It is best to use a candle or gas burner for this purpose.

- 3. Next, you need to take a millivoltmeter and measure the readings at the output contact. A working device will give 17-25 millivolts in less than a minute of heating. Otherwise, you can judge about the failure of the thermocouple.

The device is prone to breakage due to harmful operating conditions. Fortunately, it's not expensive at all, so checking, repairing, and replacing the thermocouple is a reasonable cost.Moreover, all these operations can be carried out independently, without calling the wizard. This will also save on maintenance costs.

There are also thermocouples with electronic elements on the market that can improve the reliability and accuracy of measurements. In this case, diagnostics and maintenance will cost a little more and take more time.

When buying an element, you need to clarify the necessary parameters for a specific boiler and then check them with the selected product. The technical characteristics must match, because otherwise the thermocouple will not be able to perform 100% of its functions or will be completely unusable.

Varieties

The thermocouple is characterized by a simple structure. With the appropriate skills, this device can even be made with your own hands at home. However, it is better to purchase an industrial appliance before having studied specifications, as well as features of all types of devices.

Specialized companies produce thermocouple of three types:

- Type E - two plates are used for manufacturing: constantan and chromel. This device is characterized by increased performance. In addition, it controls the process taking place in the temperature range from -5 ° С to 74 ° С.

- Type J - instead of a chromel, an iron plate is installed in the device, which does not at all impair the technical characteristics of the device. Has increased sensitivity to changes, and the temperature range - from -4 ° С to 74 ° С.

Type K - such thermocouples are the most popular. They are equipped with plates made of aluminum and chromel.

The working range varies within from -20 ° С to 135 ° С, and the manufacturers managed to increase the sensitivity itself by several positions.

The lifespan of this device is determined by environment of use: so, in carbon dioxide, a chromel plate becomes rusty in the form of green rot, the alloy quickly deteriorates and the device loses its non-magnetic properties.

There are other types of thermocouples, however, they are not suitable for use in gas boilers for reasons:

- alloys contain expensive metalstherefore they have a high cost;

- such models are nothing no better than types K, E or J.

How the device works

The principle of operation of a thermocouple for a gas boiler is based on the relationship between temperature and voltage for different metals. During heating, a potential difference arises between the elements, which allows you to measure the temperature level. It should be borne in mind when choosing that different thermocouples are designed for different thermal ranges. It is also necessary to pay attention to the resistance to corrosion and the possibility of operation in various environments.

The total voltage is generated at the junction of different conductors, and there is a temperature gradient between them. The accuracy of measurements will directly depend on the quality of the connection, so you need to carefully monitor this point. Also, to improve accuracy and reduce error, an ultra-precise multimeter is required.

Operation of the boiler without a thermocouple is impossible due to the fact that there is nothing to control its operating temperature. It is important to ensure not the maximum load of the furnace, but the optimal level of combustion of fuel, so that it completely burns out and releases as much energy as possible to heat the room.

If you throw too much fuel into the combustion chamber, then the water will simply boil, it will be very hot in the rooms, and you will not be able to achieve a comfortable microclimate.And in the presence of control devices, it will be possible to easily monitor the state of the working environment, and make a decision on the need to add fuel or its absence. So the importance of the element, despite its rather simple structure, should not be underestimated.

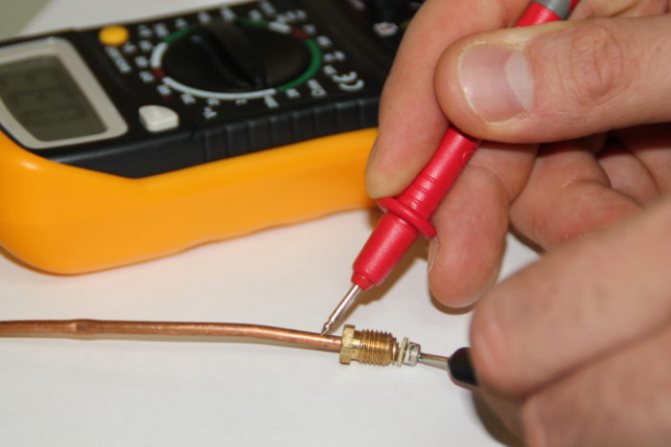

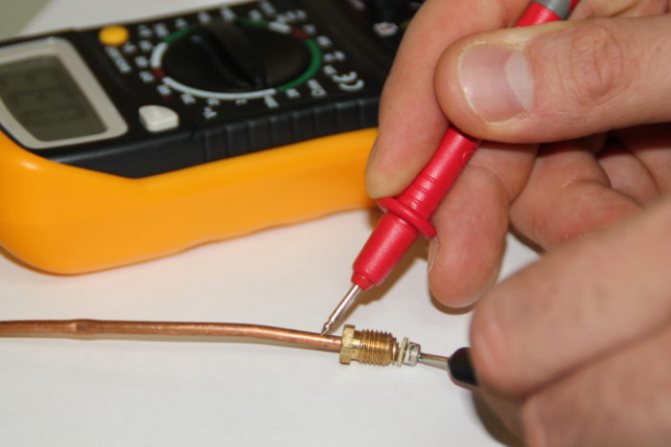

How to check if a device is working properly with a multimeter

If there is a suspicion of a breakdown, then diagnose the health of the thermostat. It is carried out in the following ways:

- One end of the appliance connects to a multimeter, and the opposite is heated by a gas burner or lighter. If the device is working properly, then the voltage below 50 mV.

- You need to check the condition carefully conductors for contamination or oxidized areas. They also indicate a breakdown.

Thermocouples for gas boilers

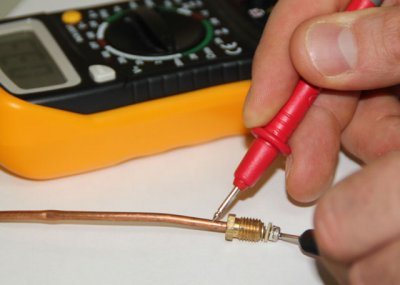

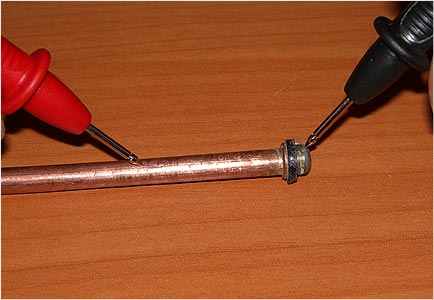

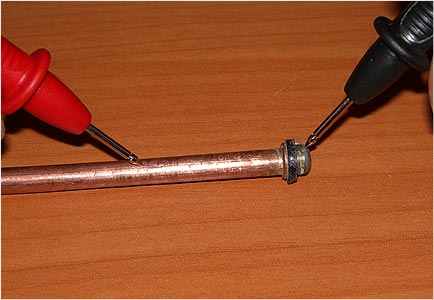

The working junction of the thermocouple in the gas boiler is heated by the pilot flame, and the other end is connected to the solenoid valve. To simulate the working state of a structure, you can take an ordinary candle... This is done like this:

- light a candle, and immerse a working junction in its flame. Remember that the protective tube of the thermocouple is very hot, there is a possibility of getting burned;

- one tester probe is connected to the thermocouple body, and the other to the output contact. In this case, the tester must be switched on for millivolts;

- if the tester reading does not rise above 18 millivolts, then such a thermocouple for a gas stove is considered conditionally working. The ideal value is 20-25 millivolts.

If the end part of the device burns out and a deep dent in black, it needs to be changed without any tests.

How to choose the right one

In order for the device to work properly and not lead to a failure of the entire system, you must carefully select the device. For this, the following features are taken into account:

- The technical parameters of the thermocouple must fully comply with to the characteristics of the gas boiler.

- The device should not have visible damage (microcracks, chips, abrasions).

- Markings should be visible.

- Preference is given to products only verified companieswho are responsible for the quality of the products.

Faulty thermocouple Economy How do I test a thermocouple?

Catalog / Instructions for the repair of gas boilers AOGV Zhukovsky

The most common malfunction of a non-volatile gas boiler is associated with the operation of a thermocouple.

This article will focus on the operation of AOGV Zhukovsky gas boilers. If you have a gas boiler with Eurosit 630 or NOVA 820 non-volatile automation installed, then reading this article will also help you understand the main reason that the solenoid valve on the automation does not "keep open". SIT thermocouple data and tests on their performance here. Data and our tests on the operation of thermogenerators can be found here. Why does the button on the magnetic box have to be tied with tape or propped up with something to keep it pressed? And all this time this button in the pressed position is fixed with electrical tape. And all the neighbors have the same. There are three reasons for the malfunction. We cover the first two, for the third reason we are preparing materials. Reason one : faulty in 80% of cases gas control thermocouple... With a working thermocouple on a working boiler, the button should always remain in the pressed position, and not jump out.

How do I test a thermocouple? Specific list of actions.

1. The thermocouple has two ends. One is heated by the igniter flame, and the other, a thermocouple with a nut, is fixed to the thread of the solenoid valve.

2. Separate the thermocouple from the boiler. We provide a stable flame. You can also use a gas burner on the stove. A calm candle flame is, we think, the most appropriate for the operating conditions of a thermocouple in a boiler.

3. Immerse the tip of the thermocouple in the flame. We place the candles over the flame at about a height of about 1 cm.

4. Attention! With prolonged heating, the heat reaches almost half of the thermocouple body. You can get burned. Don't grab the thermocouple in the middle!

five.We turn on the tester for mV millivolts. One probe for the thermocouple body, the second probe for the output contact.

6. Approximately 30-40 seconds after the start of heating, a working thermocouple will give an EMF from 17 to 25 mV. If yes, then it is recognized as suitable and the point here is no longer in the thermocouple, but in the poor electrical contact of the thermocouple with the solenoid valve. It could be second reason rebound valve button.

If the thermocouple initially shows no more than 18 mV, this does not mean that it is faulty. She needs to be moved in the flame and see if there is a change. The solenoid valve "holds" ideally when delivering an EMF of the order of 20-25 mV. According to practice, 18 mV also "hold" the valve. But, if the EMF is less than 16 mV, the button will no longer hold. Now so. If you visually see burnout at the end of the thermocouple (deep black dent) from time to time, then definitely - a thermocouple for replacement. There were cases when the pilot hole was specially "poked" to such an extent that the thermocouple gave out 30 mV, but served much less. By the way, thermocouples of all boilers in the world "burn out" over time and there is nothing special about that.

The list of thermocouples installed on gas boilers AOGV Zhukovsky with an Economy gas valve (Thread M12): Thermocouple 336006 for boilers AOGV-11.6 and AKGV-11.6 Economy release until May 2004. Supplied without kinks. Length 62 cm Thermocouple 390005 for boilers AOGV and AKGV-11.6 Economy release from 05.2004. Length from the nut to the lowest bend 47 cm Thermocouple 301059 for boilers AOGV and AKGV -17.23.29 Economy release from 01.06.1996 to 02.2002. Length from the nut to the lowest bend 57 cm Thermocouple 301002 for boilers AOGV and AKGV-17.23 Economy release until 01.07.1996. Length from the nut to the lowest bend 62 cm Thermocouple 364018 for boilers AKGV and AOGV-17,23,29 Economy release from 01.02.2003 to 05.2004. Length from the nut to the lowest bend 61 cm Thermocouple 364022 for boilers AOGV and AKGV-17,23,29 Economy release since 05.2004. Length from the nut to the lowest bend 61 cm Thermocouple 378003 for boilers KOV SG 43, KOV SG 50 of the Economy series since 2002. Length from nut to lowest bend 53 and 64 cm

WARNING! If the valve button is clamped purely mechanically, remember that in the event of a sudden blowing out of the igniter or boiler burner, the house will begin to fill with gas. The pressed button excludes the operation of the protection when the gas is turned off or the boiler goes out. You keep the gas entrance to the house wide open. Replace thermocouple in time. Eliminate the problem.

- Solenoid valve AOGV Products] JSC "Zhukovsky Machine-Building Plant" (Russia) [/ anchor]

Learn more about the product

Price: 2200 rubles

Add to cart

Replacement if it cannot be repaired by hand

The device crashes for a variety of reasons. You can replace a broken device with a new one. on my own... To do this, you must follow the step-by-step instructions:

- First unscrews with a key special nut, which the thermocouple is attached to the nozzle.

- Unscrews compensation screwsecuring the fixture in place (located directly under the mounting bracket).

Carefully withdrawn old device.- In the vacated hole is inserted new device.

- Everything is fixed compensation screw, and then nut.

- Performed check for tightness. If necessary, a sealant is used - polymer or ceramic.

When carrying out the procedure, it should be remembered that an under-tightened, as well as an over-tightened threaded connection will be dangerous for the serviceability of the system.

Installation

Regardless of which type of thermoelement is chosen, the installation method remains the same. If desired, you can install the device yourself. Algorithm of work:

- in order to dismantle the old element, it is necessary to unscrew the copper (less often lead) nut, with which the device is attached to the threaded branch pipe;

- then you need to unscrew the screw that holds the device; there is a screw under the mounting bracket;

- now you should carefully remove the failed thermocouple and insert a new device in its place;

- fastening is done in the reverse order, first the screw is tightened, then the nut;

- make sure that the connection is tight, if not, a polymer gasket should be used.

The thermocouple is an important element of the heating unit that protects the equipment from overheating. The device has a simple design, so it is reliable and unpretentious. If necessary, you can replace the thermocouple yourself, having previously disconnected the gas supply and the power supply to the boiler.

Connection nuances and verification

The thermoelectric converter is connected to the measuring device using a compensation cable. To minimize the measurement error as much as possible, the cores of this wire are made of the same material as the sensor itself.

Check the functionality of the thermocouple as follows:

- one end of the device is connected to a multimeter;

- the other end is manually heated with a lighter or gas burner.

To check the functionality of the thermocouple - one end of the device is connected to a multimeter

If the device is in good condition, this is indicated by the presence of a voltage in the region of 50 mV.