Principles of functioning of a mini-boiler room

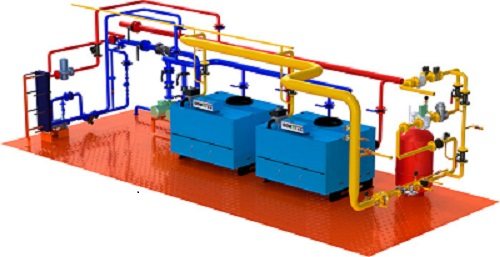

Mini-boilers are special installations that represent a container with heating equipment. The basic unit is equipped with one or more boilers for water heating. They differ in their power and are combined into a common network. There is a pump in the container, the power of which allows to provide the required pressure for the heating system. Gas mini—boiler rooms can work in automatic mode. The equipment installed in the container controls the circulation and operation of the coolant.

The operation of a separate mini-boiler room is based on several principles. First of all, the temperature in the boilers reaches a certain value. Powerful circulation equipment sets the direction of the coolant. Automation allows you to achieve smooth operation. Gas boilers in rare cases require additional maintenance, this is their advantage over solid fuel plants. Mini boiler room price over time it pays off many times over, avoids the construction of a special extension. It will take only a few days to install such an installation and connect it to the building's heating system.

Installation prices:

| Name | power, kWt | Average price, rub. with VAT premium / standard | |

| MKU-100 | 100 | RUB 2,412,500 | To order |

| MKU-200 | 200 | RUB 2,645,000 | To order |

| MKU-300 | 300 | RUB 2920000/2752500 | To order |

| MKU-400 | 400 | RUB 3,290,000 / 3,107,500 | To order |

| MKU-500 | 500 | RUB 3,485,000 / 3,327,500 | To order |

You can find a complete list of modular boiler plants on the "Prices" page. These prices are given for roof-top boiler houses in block-modular design.

Application for preliminary calculation of the boiler room

Benefits of using mini boiler rooms

The advantages of stand-alone units include their compact size. Small mini-boiler houses are in steady demand in the heating equipment market. The advantages of using gas mini-boiler rooms include:

- efficiency and economy;

- affordable cost;

- ease of installation;

- operational reliability;

- high efficiency;

- the ability to work automatically without third-party intervention;

- automatic shutdown when an emergency occurs.

All mini-boiler houses are divided according to the type of fuel used. They can be gas, solid and liquid elements, electricity. Gas mini-boiler rooms are considered the most economical and environmentally friendly option. They are also suitable for urban applications. Many residential buildings contain installations of this type.

Installation of wall-mounted gas boilers according to all the rules

Special offer! Heating equipment with discounts up to 50%. The whole range of Vaillant, Viessmann, Baxi, Bosch, ACV, Protherm, RUSNIT, Buderus, Kermi and others is available. Competent design and installation of turnkey systems.

Call (Moscow and region). Email:

A gas boiler is a universal device for heating a liquid, which is used as a heat carrier in the autonomous heating system of private houses and apartments.

For the operation of wall-mounted gas boilers, explosive gas is used and therefore the connection of such equipment must be safe for the residents of the house. The installation of such gas equipment and all work on connecting to the gas and heating mains is carried out in accordance with building rules and regulations.

Is self-installation possible?

Activities that relate to the installation of a wall-mounted gas boiler, as a rule, begin with the development of a project.The project must be coordinated with the local supervisory services. The project specifies all parameters of the boiler, describes the heating system diagram and determines the place of its installation. Only after the project has been approved can the installation work be started.

It should be borne in mind that not all manufacturers allow self-installation of their equipment.

Firms such as Viessmann, Bosch, Ariston, and others require buyers to have their equipment installed by certified installers. However, there are more loyal companies - Ferroli, BAXI, Electrolux, allow unauthorized installation of the boiler, however, commissioning of the system as a whole requires the involvement of a specialist who has permission to connect gas and electrical equipment. Thus, if you plan to independently install a wall-mounted gas boiler, when buying, you should make sure that the manufacturer allows this action to be performed independently.

Requirements for the installation site of the boiler

It is advisable to mount a hinged boiler in a separate room, which can be called a boiler room or a furnace. The requirements for this room depend directly on the type of boiler that will be installed, and to be more precise on the type of the boiler combustion chamber.

Related material: Requirements for the room for installing a gas boiler

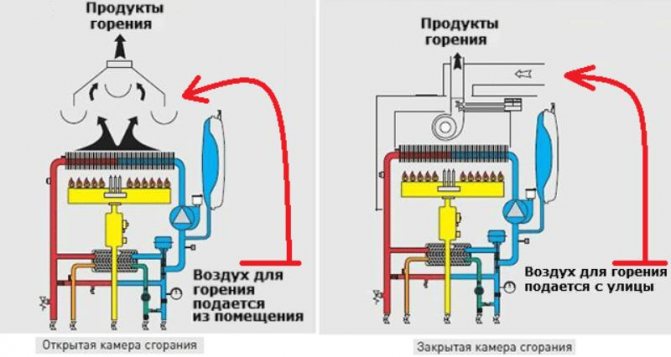

Open combustion chamber

Diagram of a wall-mounted gas boiler with an open combustion chamber

Such a device works just like an ordinary stove - it takes air from the room and throws out exhaust gases through the chimney, using natural draft.

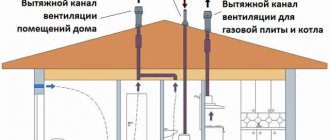

- Such boilers need a certain amount of air in the room, otherwise the gas will not burn out completely, thereby forming toxic substances that are dangerous to health.

- In addition, when installing a wall-mounted boiler, it is necessary to provide a window to the street, the area of which will be at least 0.5 m², as well as a place where maintenance will be carried out.

- The walls in the room must be treated with fire-resistant materials.

- The volume of the boiler room depends directly on the power of the heating devices that are connected - if the boiler has a power of 30 kW, then the volume of the boiler room should be 8 m³, for 30-60 kW, 13-14 m³ will be enough. And if the boiler is 200 kW, then the volume should be more than 15 m³.

Closed combustion chamber

Diagram of a wall-mounted gas boiler with a closed combustion chamber

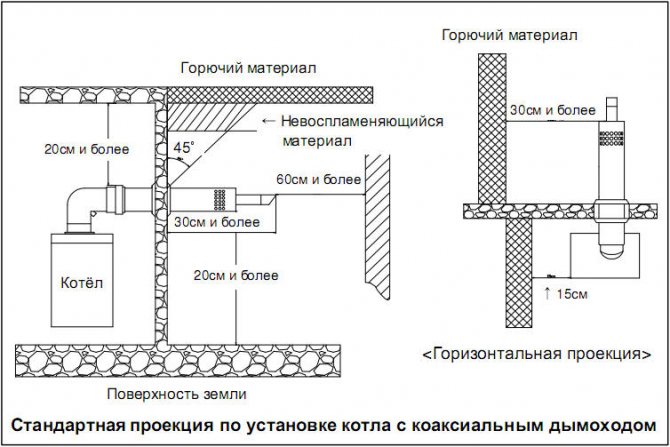

Such boilers are equipped with a special coaxial chimney. This is a double pipe, and its outer part serves to collect air, and its inner part to remove combustion products.

Installations of this type of system require an electrical connection to power the fan. The fan, in turn, circulates air in the closed chimney.

Boilers with a closed combustion chamber are safer and more environmentally friendly, for this reason, such boilers can be located even in living quarters (in a pantry, in a bathroom, in a kitchen, etc.). In this case, the requirements for the parameters of the chimney are not standardized, because the automation fully monitors the removal of gas waste.

For a city apartment, you can only get permission to install boilers with a closed combustion chamber.

The connection and installation of the boiler are important and crucial parts of the installation of the heating system as a whole. The specifics and order of work depends on the type of combustion chamber and the number of circuits that are used (heating with water supply or only heating). Recently, single-circuit boilers with a closed chamber have been most often used, and that is why the entire installation process will be described for such a modification. Where necessary, a note will be made about the features of installation or another type of gas boiler.

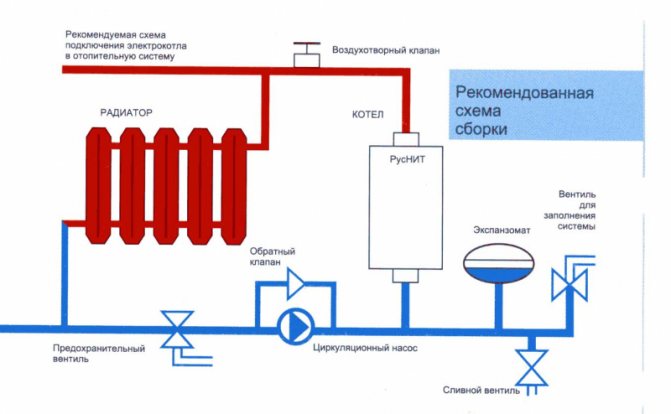

Installation diagram

- The correct installation scheme for a wall-mounted gas boiler requires flushing all the internal pipes of the device. To do this, it is necessary to remove the transport plugs and pass the water under pressure through the boiler.

- When assembling the boiler, debris could get into the pipes, which must be removed. The boiler can only be mounted on a wall that was built from non-combustible materials.

- If we are talking about wooden walls, then they should be covered with a layer of heat-resistant material, with a thickness of at least 3m. The boiler must be fixed at a distance of 45mm from the wall.

- When the diagram has already been drawn up, and the wall is prepared, we proceed with the installation and connection of the boiler.

For such work, the following tools and materials are needed:

- sealant,

- wrench,

- shut-off valves,

- filter,

- dowel and puncher.

Boiler installation

- The boiler is mounted on mounting strips, which must be installed at a height of 80 - 160 cm from the floor. The position of the boiler must be checked with a level.

- Installation of the device is allowed at a distance of at least 20 cm from other gas or electrical appliances. There should be no materials that quickly ignite near the devices.

- It is necessary to put a filter on the water supply pipe, which will prevent the heat exchanger from clogging. On both sides of the heat exchanger, it is necessary to install shut-off valves, which are needed in order to be able to clean or replace the filter without draining the water from the heating system.

- Then the chimney is mounted and the presence of draft is checked. Most modern wall-hung boilers are “non-chimney”. This means that the combustion products are removed by means of a small fan.

- After installing the chimney, you can connect the gas. In this case, you cannot do without the help of a specialist. The fact is that the boiler is connected to the gas supply using a special drive or "American".

- The installation of the wall-mounted boiler ends with the connection to the mains. The boiler supply circuit must have a short circuit and overheating circuit breaker. And it will also be useful to install a voltage stabilizer, and we have already written how to choose it: Which voltage stabilizer for gas heating boilers is better.

In this case, a strong chimney draft is not required.

Rush "American"

findings

Having studied this material, you have an idea of how to install a wall-mounted gas boiler with your own hands, but remember that only a gas service employee has the right to open the gas valve and start the boiler into operation. This is done only after checking the correct installation of the equipment and the compliance of the location with existing regulations.

(votes: 2, average: 3.50 out of 5)

1pokotlam.ru

Features of installation and packaging

As a rule, the installation of a gas mini-boiler room is carried out outside the structure, which needs heating. The construction of an additional extension is not required. Pipelines are brought into the room through the walls. The mini-boiler room is controlled using a special control panel. It is installed inside the building and is directly connected to the boiler using a cable.

Mini-boiler houses are characterized by an open-type firebox, a circulation pump and a gas burner. The installations can be additionally equipped with a fire alarm, an emergency alert system, and a separate chimney.

Today buy mini boiler room Is to save yourself from a lot of problems. Such an installation runs on mains gas or LPG. All units are equipped with circulating pumps. Gas mini-boiler rooms are installed in a special metal box with special heaters. The walls of this box are made of steel sheets, which are interspersed with mineral wool insulation boards. The boiler condition is monitored by the operator remotely. In the event of an emergency, a signal is sent to the control panel, and the unit automatically stops working.

On request, a diagram, certificate, permit, passport are provided. You can buy a gas mini-boiler room using the feedback form, or call tel. 8 (8452) 40-05-31,76-10-17

Gas connection

Before installing a gas boiler in a private house, you need to do the following steps:

- The first step is to obtain technical specifications from the gas service. To do this, you must send an application indicating the approximate monthly volume of gas consumption.

- The second step is the setup project. It is forbidden to do it with your own hands. This is done by special engineers, in addition to the boiler installation project, who are also developing a project for the passage of pipes through the site.

- The third step will be the approval of all documentation in the gas service. In addition to the project, you must also attach all the documents received when purchasing the boiler.

- In case of a positive decision of the experts, installation work is allowed. If a discrepancy is found, the supervisor will send an explanation of what mistakes were made.

The entire approval process can take from 1 week to 2 months, depending on the workload of various specialists.

Despite the list of requirements and some costs for the preparation of project documentation and connection by specialists, the gas boiler will quickly recoup the costs of its installation.

Underfloor heating and gas heating boilers

If your apartment has a “warm floor” system, then when choosing a heating device, you should pay attention to the rating of condensing-type gas heating boilers. These devices create heat not only by direct, but also by latent consumption of combustion products, that is, the heat of condensation of water vapor present in the products of gas combustion.

It is these vapors that make the coolant heat up. This design feature ensures that the boilers operate more efficiently than standard devices. Despite the fact that the cost of condensing boilers is about a quarter higher than that of standard convection boilers, they are more economical during operation.

Requirements for the boiler room in the house and apartment

There are no special differences for a cottage or apartment in terms of installing an autonomous heating system.

There are SNiP criteria, applicable to all categories of premises and if they meet the established standards, a gas boiler can be located there.

Kitchens deserve special consideration. The architect, creating the plan of the house, has already taken into account the necessary safety requirements. But that's not all. Plays an important role total heat outputcoming from all kitchen units (cooking oven, heating element, heating batteries, boiler). The maximum allowable value for this indicator is 150 kW.

In a country house it is permissible to install any boiler, and usually there are no problems with the room. But in the kitchen of a city apartment it is allowed to install only one type of boiler - wall-mounted, equipped with a closed combustion chamber. Additionally, a barred opening is made in the front door, with an area of at least 0.02 m2 - to increase air draft.

There is another complication as well. The front door of the boiler room leads to the street, this rule is strictly enforced. The supervisor will require either the installation of such a door or the removal of the redevelopment. Often there is only one way out - to break through an opening in the wall, which is fraught with numerous expenditures of energy, nerves and money.

In small kitchens, the volume of which less than 7.5 m³ not allowed to post two water heaters - residents of old buildings will have to say goodbye to the idea of a separate furnace.

Photo 1. Wall-mounted gas boiler installed in the apartment. The device must be freely accessible.

In an apartment building, in the event of a fire, there is a risk of fire spreading to other premises.So, for those who want to equip a furnace in the kitchen, it is better to immediately tune in to refusal from the fire supervision - redevelopment will not be allowed.

Important! In all cases, the installation of the gas boiler is carried out only by a qualified specialist. You should never take this task on yourself!