Home & Gg; Gas boilers & Gg;

Immergas is an Italian company that has been producing heating equipment since 1954. It produces only wall-mounted units, thereby improving faster in modern technologies. There are only about 80 models of Immergas gas boilers, but not all are supplied to the CIS countries, but only those that can adapt to domestic weather conditions.

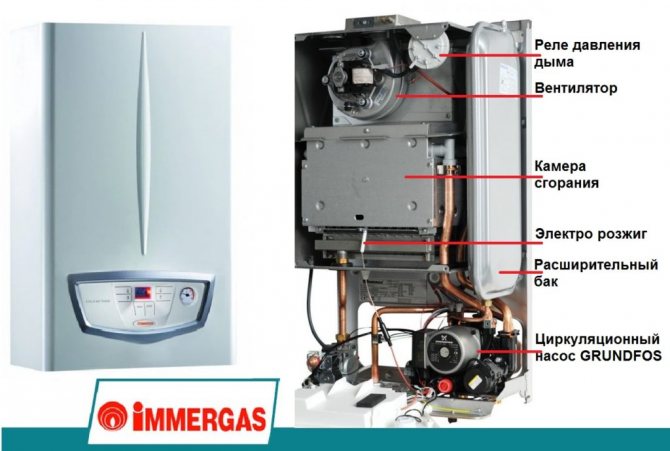

Fig. 1 Gas boiler Immergas

Many important components of the boiler are only manufactured in an Italian factory. These components include: a water boiler, which contains an original spiral heat exchanger made of high-quality stainless steel, as well as a boiler pipeline (an instruction is also attached). But do not worry that these parts will be difficult to buy, since Immergas service centers are located throughout Europe, including Russia.

Absolutely all Immergas wall-mounted boilers are high-quality products that have already become trusted by many citizens of the Russian Federation. They undergo special tests at the factory, so when buying this brand you can be absolutely calm. The buyer of the Immergaz gas unit will receive a device of very high quality that will work for a long time and without problems.

Features of these gas boilers

After you have purchased or built your home, the first question that interests you is which gas boiler to choose for your home? The Immergas gas boiler is an excellent option for this purpose, as it follows an excellent formula - price / quality, and also comes with clear instructions for use. That is, the price is acceptable for most residents of the Russian Federation and the quality of this product is very high.

So, what are the features inherent in these wall-mounted gas units:

- Due to their compact size and weight, they can be installed even in a small kitchen. The Immergas gas unit does not need to be allocated a separate installation room.

- Boilers of this brand are both single-circuit and double-circuit. If you just need to heat the room, then the first option is also suitable. If, in addition to heating the room, you also need to heat water for family use, then it is better to choose a double-circuit gas boiler.

- Many wall-mounted models of units have a liquid crystal screen on which you can see the codes of all malfunctions, if any, but one thing for sure is that you will not do the repair for a long time. The codes can be deciphered by looking at the instructions for these gas boilers.

- These units have indicators of operating modes.

- Each boiler has a natural circulation or forced circulation copper heat exchanger. If you often leave home, then it is best to install with forced circulation, since such a heating system works completely autonomously.

- Some models are equipped with a room thermostat. You can also connect a remote control to the devices - then it will become even easier to take care of the wall-mounted units.

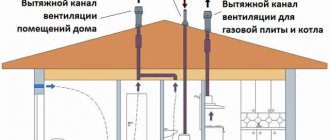

Immergas wall-mounted units do not have to be connected to a chimney, you can simply connect a coaxial pipe that removes all combustion products through an opening in the wall. This is very convenient for those who live in apartments and want to make themselves autonomous heating. The instructions for Immergas wall-mounted units tell you how to install the boiler correctly, as well as how to properly care for it if you decide to do it yourself.

The main malfunctions of gas boilers Immergas

The most common problem is with the ignition of the burner.

It is denoted by code 01 and may have several reasons.:

- Gas supply problems. There may be a lack of pressure in the gas pipeline, the gas valve is closed, the gas valve has failed, and other malfunctions.

- Poor burner nozzles. They may be clogged with soot, soot.

- Incorrect power connection. All European boilers are phase-dependent, they need a certain connection of all electrodes and the mandatory presence of grounding. If the connection is made incorrectly, when starting up, the boiler is immediately blocked and cannot start work.

NOTE!

Sometimes the boiler suddenly stops starting for unknown reasons. It is necessary to check the connection of the electrodes on the common shield, it is possible that they were accidentally confused during the repair.

The second common problem is boiler overheating.

It can also be caused by several reasons.:

- The fluid circulation rate has dropped due to pump problems.

- Too hard water has caused a layer of scale to form inside the heat exchanger, which is a natural heat insulator and reduces heating efficiency. This became the reason for the intensification of the combustion mode. A situation has arisen when, in order to obtain the required temperature, it is necessary to heat the heat exchanger more strongly, which causes an excessive load on the metal, increases the gas consumption, and disables all boiler units ahead of time.

Another error that often appears on the display is the presence of a parasitic flame (error 20). The system sees a flame on the burner that is currently off.

The reasons for this condition may be:

- Condensation drops on the control board.

- Due to poor-quality grounding, a static charge appears, which is perceived by the system as a signal from a burning flame.

In addition to these errors, there may be other, less frequent and not detected by electronics.:

- Gas smell, indicating a leak.

- Failure of the pressure switch at start-up, requiring cleaning of the chimney.

- A faint orange flame indicating soot or soot clogging the nozzle passages.

Most errors that occur for the first time are immediately discarded. This is done because the boiler electronics are highly sensitive and often take electrical noise as sensor signals..

However, if the error appears again and again, contact the service department immediately.

How to install the Immergas boiler

If you want the wall-mounted gas unit to work smoothly and in full force, then you will have to invite a highly qualified specialist in this field for installation. Firstly, he will have all the constituent parts for fastening the system, and you do not have to think about it, and secondly, professional work is always different from amateur work.

Fig. 2 Double-circuit wall-mounted unit Immergas

How is the installation of gas boilers Immergas:

- First you need to decide which equipment is suitable for your home, buy it, and only then think about installation.

- Next, it is worth finding an instruction in which everything will be written in detail about the installation of a gas unit.

- The boiler must be attached to the chosen place in the kitchen or in another room. If this is a wall unit, then you need to fix it to the wall.

- Then the wall-mounted apparatus should be connected to electricity, having previously made grounding in order to avoid the boiler burning during a thunderstorm.

- Next, you need to install an expansion tank and a circulation pump if you connect heating with forced circulation.

- The next step is to connect the Immergas double-circuit gas unit to the heating system.

- Then you should test the system for leaks (the instructions indicate how to do this).

- Then you need to remove excess air. How to do this correctly is also described in the instructions.

- And the last step is to start up the Immergas two-circuit gas unit.

Setting up the Immergas boiler and heating system

There is a gas double-circuit boiler Immergas Eolo Mythos 24 4R. The developer put it in, stuck it in, turned it on - it works. Nothing was set up "works the same" and "figure it out yourself."

Total available: 1) Immergas Eolo Mythos 24 4R 2) Two-pipe heating system with parallel connection for 4 heating radiators with manual control valves. 3) The mixing unit for the underfloor heating Valtec CombiMix with its own pump Grundfos UPS 25-40 is connected in parallel. 4) Two lines are connected in parallel to two heated towel rails (at the moment, they are blocked by ball valves, since there are no heated towel rails themselves).

On the street now from -5 to +10 (off-season) I do not live in the apartment at the moment, the underfloor heating is set to a minimum value of 20 degrees (the circulation pump of the mixer is stopped), the temperature of the coolant in the boiler is set to a minimum value of 38 degrees. Premises area 72 square meters, apartment.

There are problems: 1) frequent switching on and off of the heating system (every 3 minutes) and works no more than 20-30 seconds. the first battery to the boiler is the warmest, the last is the least warm 2) with manual balancing (pressing down the flow of the first and second radiators, the whistle of the first radiator tap is heard) 3) while after pressing the first and second radiators, the boiler immediately began to gain temperature (instead of 20-30 seconds work began to work in heating mode for 3-8 seconds).

What I tried to do and in which direction I am going to dig solutions to the problems:

1) Why do I want to turn down the first and second radiators? Because there is a feeling that the first radiator has the smallest loop, and, accordingly, it is very small itself, in my opinion it plays a bad role because it quickly heats up the return line, and because of this, the boiler turns off prematurely and only then heats up the last radiators by recirculation. 2) There was an opinion that after pressing the first and second radiators, the boiler bypass or some other bypass (for example, a heated floor mixer) began to work out because the radiators do not heat up much, but at the same time the boiler immediately began to gain the target temperature in 3-8 seconds. 3) In order for the boiler to turn on less often and work for a longer time, I want to reduce the minimum boiler power and the interval in switching on, I want to enter the boiler programming mode and move the minimum heating power limit downward, while it is possible to further increase the switching interval from 3 minutes to 10 minutes. 4) The bypass on the boiler is regulated, and if it turns out that the bypass of the boiler is bypassing, is it worth pressing it down? 5) Who should be involved in the optimal setting, regulation, programming and balancing of the boiler? Boiler specialists or gas workers? Or an ordinary plumber or a user? 6) In the next summer, I planned to shut off all the heating radiators and leave only the loops of heated towel rails (but now I doubt if this will be "too little" for this boiler in heating mode) if even now at the minimum heating temperature the boiler is switched off back and forth.

How to choose the right Immergas wall-mounted double-circuit units

Before buying a double-circuit wall-mounted unit, you need to decide what functions it should perform, what power to have, what circulation, etc. You also need to invite a specialist who will help you install the Immergas gas boiler correctly. If you need heating equipment only to heat the house, then it is better to choose a single-circuit boiler - it is both cheaper and more economical. Well, if in parallel you also need to heat water for family use, then it is better to choose a two-circuit model.

Double-circuit boilers are the most popular models around the world.

They can remove waste gases by:

- Forced draft.

- Natural cravings.

For people who live in high-rise buildings, it is best to choose forced draft to remove exhaust gases, that is, to purchase a coaxial pipe (you can find instructions and read how to install it so that you do not have to make repairs later). And residents of private houses must make a chimney for Immergas gas units.

Unit capacity setting

You can adjust the optimal power of the Imeergas gas boiler using the gas valve. The operating power of the gas boiler is adjusted as follows:

- set the DHW switch to the desired position;

- open the hot water tap;

- adjust the required power using the adjustable nut on the gas valve;

- adjust the heat output by turning clockwise to increase it, or counterclockwise to decrease it.

The minimum heat output can be adjusted using the plastic screw located on the gas valve. At the same time, the adjusting nut must remain stationary. It is recommended to disconnect the power supply to the modulating valve coil and then turn the screw clockwise to increase the pressure or counter to decrease it. After that, the coil power must be returned.

…

Note! The minimum power must not be less than that indicated in the characteristics of the unit.

Advantages and disadvantages

The advantages of gas wall-mounted boilers Immergaz include the following:

- Lots of features. Such a gas boiler can operate autonomously and does not require frequent repairs.

- Small size. This equipment contains two equipment: a system for heating water and a boiler for heating a room. The instructions for the gas boiler are very simple, so everyone can figure it out.

- Wall-hung boilers can be with a closed or open combustion chamber. A closed combustion chamber is safer for health. But gas boilers with such a chamber are more expensive. After the installation of such a boiler, repairs will not be required for a long time.

But there are some disadvantages in Immergaz gas boilers:

- Inexpensive spare parts.

- If the gas boiler was assembled in Italy, then its cost will be high.

- The buttons on the control panel are awkward and hard to press.

Immergas gas boilers are among the best in Europe.

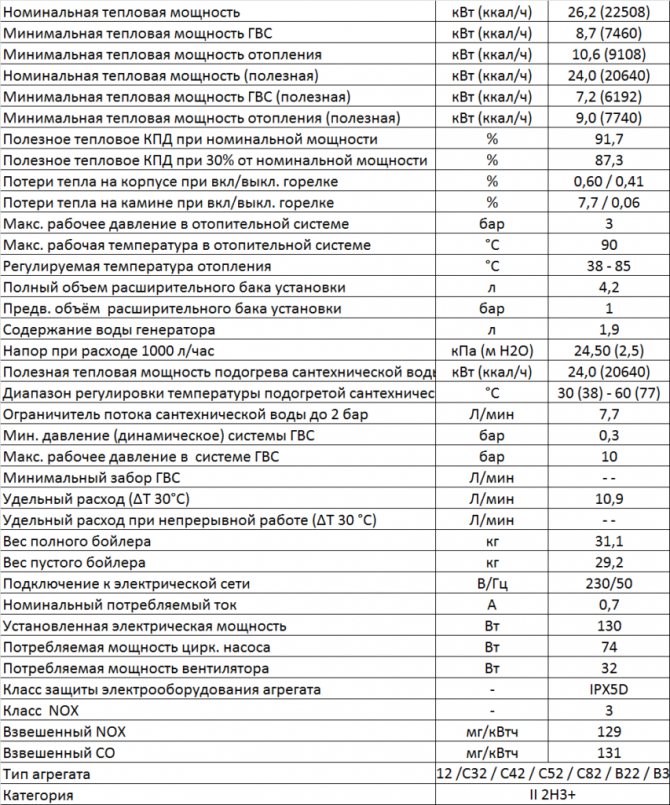

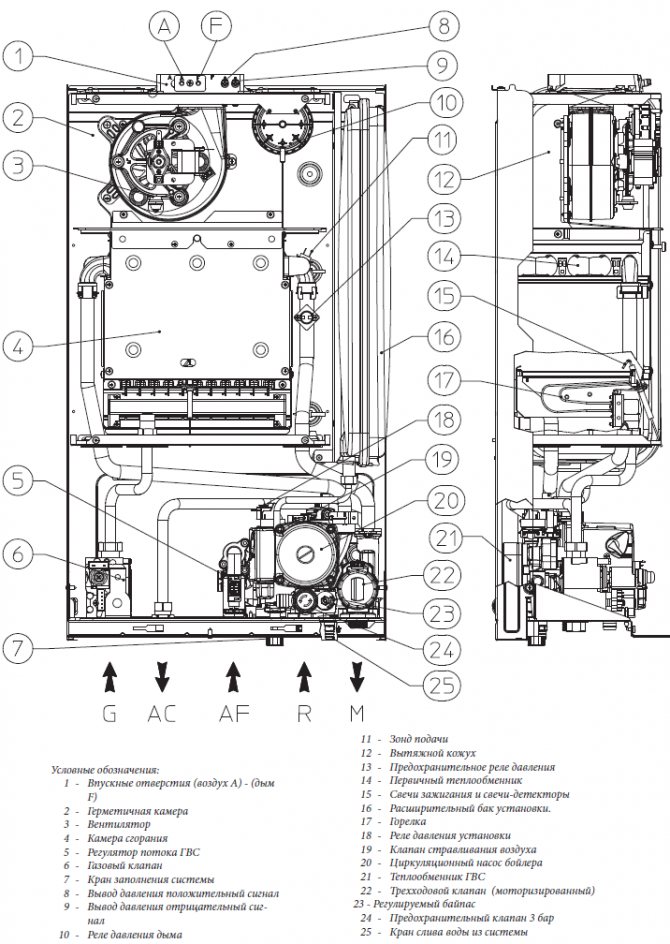

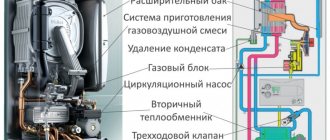

Boiler design and main elements

It is important to know your boiler in order to perform the simplest maintenance procedures. Although the model may differ from the model, the main elements can be found in the case:

- combustion chamber;

- heat exchanger;

- expansion tank;

- gas burner;

- circulation pump;

- Control block.

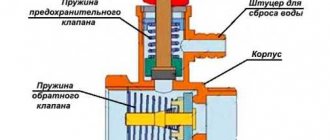

Particular attention must be paid to the device of the lower part of the case, since this is where the inputs and outputs of the circuits are connected, and other important parts are located.

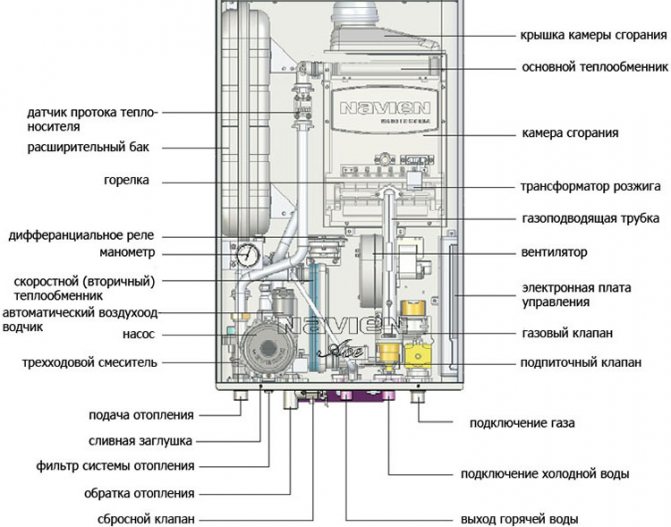

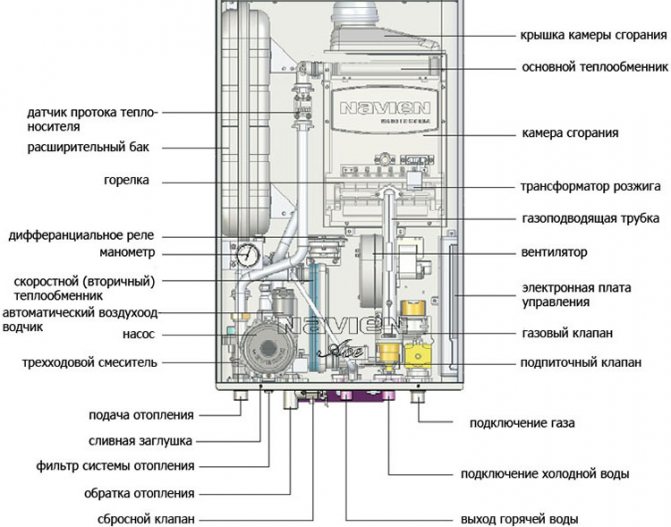

Boiler scheme Navien

Closer to the wall there are 4 connecting pipes:

- Feed inlet.

- Return flow inlet (with safety valve).

- Hot water outlet.

- Cold water.

Next is a small gas supply pipe.

There is a hot water filter in front of the return inlet, and even closer - a drain plug.

In front of the DHW outlet, there is a make-up tap, with which the system is filled with water.

The principle of the system from freezing. When the temperature in the pipes drops below the -10 ° mark, the pump automatically turns on, which drives the coolant and prevents it from freezing. If the temperature continues to drop, and it reaches -6 °, the burner is triggered, which heats the water to + 21 °.