The problem with hot water for many private property owners, where there is no connection to the central heating system, remains relevant today. Installing a boiler requires serious investment, but making an indirect heating boiler with your own hands can be an alternative in solving this important issue. Its main benefit is that hot water is supplied as needed without any special monetary costs on your part.

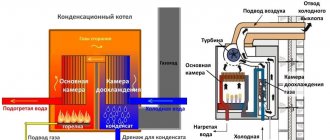

Boiler design

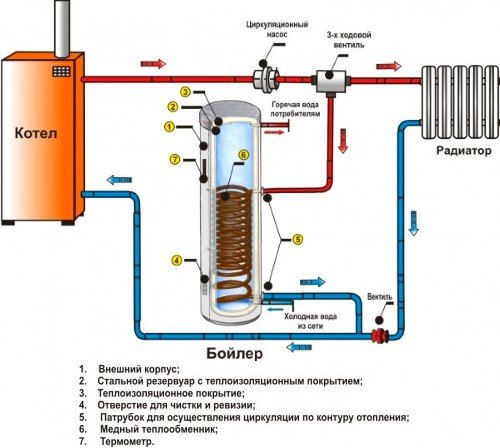

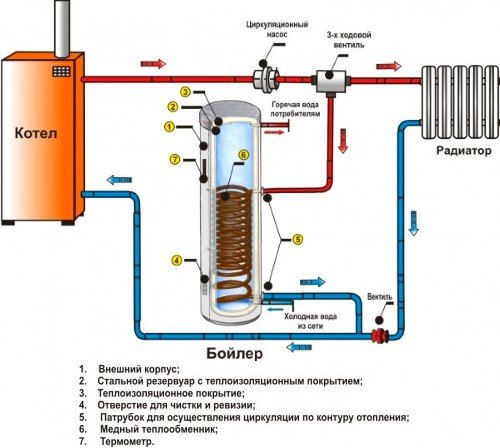

Many private homeowners are interested in the question: what kind of device it is, how the water is heated in it. A product of this type is a large storage structure that does not depend on standard energy sources (gas, electrical system), in other words, a circulation type water heater.

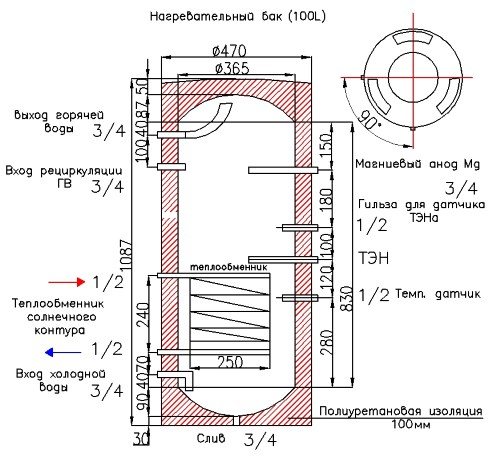

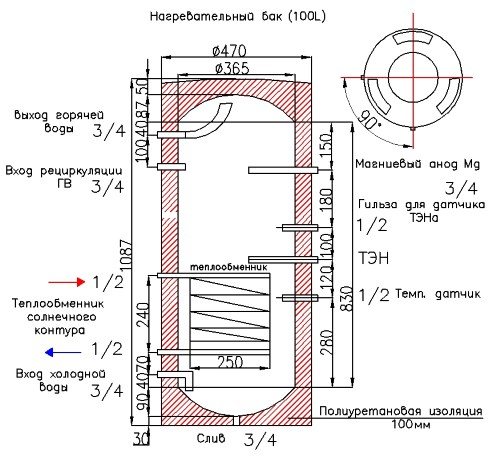

A spiral pipe is installed inside the tank - it is in it that the water heated by the autonomous heating boiler circulates. Cold water enters through a pipe located at the bottom, heats up evenly in the tank and is supplied to the user through an outlet pipe located at the top. For maximum convenience, ball valves are connected to the pipes. The outside of the tank is covered with a thick layer of thermal insulation.

The drawings for this product are quite simple and easy to read if you have at least a basic technical background.

Calculation of the main parameters of the boiler

Before proceeding with the search for material and direct manufacture, it will be necessary to calculate the minimum volume of the tank and the working length of the heat exchanger.

Tank volume and shape

The volume of the water tank directly depends on the number of residents permanently residing at the place of installation of the equipment. It is believed that a person consumes up to 80 liters of water per day. For the calculated value, it is recommended to take 45-50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure force in the water supply system. If the pressure is low, then the use of homemade square tank boilers is allowed. For high system pressures, only equipment with a round bottom and top should be used.

Square and rectangular storage tank boilers can only be used in water systems with low working pressure

The fact is that the increased pressure contributes to the emergence of bending forces on the walls of the tank, so a square or rectangular tank can be deformed. Tanks with a round bottom are more resistant to deformation due to better streamlining.

Heat exchanger power and length

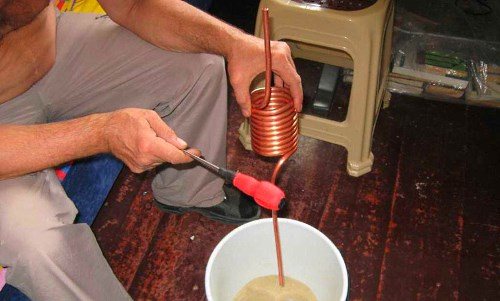

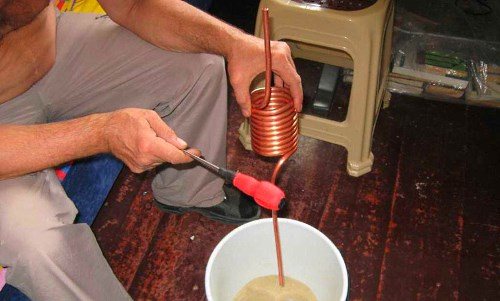

In vertical indirect models, a copper coil is usually used as a heat exchanger between the inlet and outlet.

Copper pipe boiler coil

For self-production, it is best to use a copper pipe with a diameter of 10 mm. Such a product can be easily bent by hand without the use of any tools. When using a metal-plastic pipe, it should be borne in mind that the heating temperature of the coolant should not be more than 90 ° C, otherwise the pipe will be deformed, and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙ d ∙ ∆Т), where:

- L - pipe length (m);

- d - pipe section (m);

- ∆Т - temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. With this in mind, you can calculate the length of the pipe for the manufacture of the coil.

For example, let's calculate the material for the coil that will be installed in a 200 liter boiler. The temperature of cold water supplied to the tank will be 15 ° C, and after heating it is necessary to obtain water with a temperature of 80 ° C: L = 1.5 ∙ 20 / (3.14 ∙ 0.01 ∙ 65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50-200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Loop diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the bending method and the distance between the elements. Usually the coil is positioned so that the distance between the coils and the tank walls is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler must be equipped with a tubular electric heater, then the power is calculated based on the fact that a heating element with a capacity of at least 1.5 kW is needed to quickly heat 50 liters of water. In addition, any combination boiler must be equipped with a thermostat.

Varieties of systems

Those users who use gas water heaters and various types of boilers to obtain hot water are well aware of the mass of problems that arise during their operation: you need to wait a while until the water heats up to the desired temperature, if you turn on hot water in the kitchen and in the bathroom at the same time, then its temperature will drop. An indirect boiler eliminates these problems: the water coming from it always has a constant temperature, no matter where it is supplied. Such water heaters can be of several types.

- The most common design is with a coil, which is installed inside the tank, and hot water circulates through it. Cold water entering the tank contacts the coil and heats up to the set temperature.

- Another option is when the coil is mounted along the walls of the tank, and not in its center.

- If there are two containers - a large and a small one, then the smaller one is inserted into the larger one. Water circulates between them: hot water is pumped into the small one, and around it - cold water for heating.

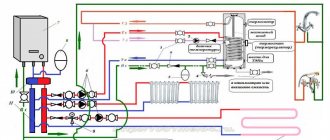

The principle of operation of such water heaters is simple, in order to clearly understand the operation of the system, there is a detailed diagram.

Step-by-step assembly instructions

After preparing all the materials, you can start assembling:

- We make two holes in the container: for the intake of hot water from the top, and for the flow of cold water from the bottom. We supply these holes with ball valves for ease of use;

if the design provides for the presence of a heating element, we make a hole for it;- to install the coil, we weld the cap nut;

- install a hot water pipe to the very top of the tank;

- we make a hole for installing a heat exchanger;

- choose the method of installing the boiler (depending on its volume), weld on the appropriate fasteners. If you have a boiler with a heating element that is attached from below, of course it is better to hang the boiler itself;

- install a heating element with a sensor;

- we connect the boiler to the general heating system, not forgetting to install a check valve on the cold water supply.

Advantages and disadvantages of an indirect heating boiler

The advantages of a self-designed indirect heating boiler over other water heaters:

- the ability to connect to a centralized heating system;

- the main tank is installed in the immediate vicinity of the autonomous heating boiler;

- installation of the entire structure does not take much time;

- reduced consumption of electricity and gas;

- the house is provided with hot water of the same temperature all the time.

There are not so many disadvantages of this design:

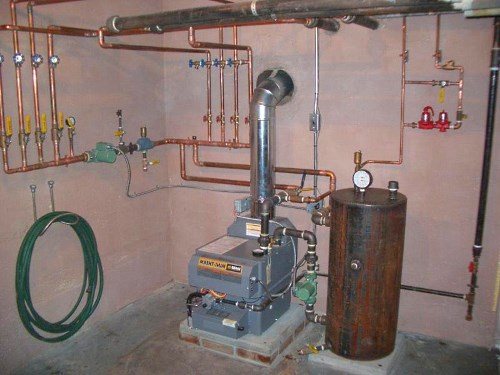

- you will need a special room for installation;

- it takes a long time to heat the water in the tank to the optimal temperature at the first start, and this guarantees losses on the general heating of all other rooms;

- the coil must be cleaned at least twice in 12 months so that it does not become clogged with deposits.

Important! This option is valid only during the autumn-winter season, after which the built-in heating element turns on. Owners of private buildings who use autonomous heating can cut off the water supply for heating the house, and continue to heat the water in the tank with the help of a boiler.

If you use electric heating elements, it is better to turn them on at night, during the benefits period.

Instructions for connecting and starting the system

First of all, a homemade indirect heating boiler must be connected to the heating main. Where a free heating system is used, the device is connected to the home boiler network.

The mechanical connection is made with the lid on the boiler tank open. After connecting, you need to slightly open the shut-off valve connecting with the return line of the heat carrier, and make sure that there are no leaks both outside the device and inside.

If no leaks are found, open the heat carrier supply line. It is necessary to wait some time for the coil to warm up to the temperature of the heating system. In full heating mode, check the coil and all connection points for possible leaks once more with the well-deserved attention.

If the check showed the integrity of the system, close the lid of the vessel and connect the lines for supplying and analyzing the heated water. The system is tested in real heat transfer mode.

Types of work and materials

To make a boiler with your own hands, you need to perform the following work:

- prepare a metal container with good anti-corrosion characteristics;

- gently bend the pipe for the coil;

- make high-quality thermal insulation of the structure;

- complete assembly of the entire system;

- bring water;

- the coil is securely connected to the home heating system;

- connect the heated water supply to the domestic water supply.

To perform some operations, you will need the following materials and equipment:

- pipes made of metal-plastic or stainless steel;

- nitro-enamel-based primer;

- nut with a diameter of about 32 mm;

- a large container - a simple gas cylinder will do for a small family;

- need welding.

We have decided on all the materials and the upcoming types of work, now we are proceeding with the direct installation.

Tank making

For the independent manufacture of a hot water tank, it is recommended to use stainless steel sheet, and in addition, alloys based on aluminum or other materials that have sufficient resistance to corrosive changes.

Alternatively, you can use its regular gas cylinder, the walls of which must be cleaned and primed in advance, which will provide an opportunity to prevent the appearance of an unpleasant odor in hot water.

Homemade indirect heating boiler tank

In the prepared tank, it is necessary to make five holes, a pair of which is made on the side and used to install the coil, and two in the lower and upper parts for the inlet of cold and outlet of hot water.

To make the operation of a hot water boiler trouble-free without using the heating system, it is necessary to install a heating element, for which you need to make a hole from the bottom, providing it with shut-off valves or ball valves.

Assembly technology

We will describe in stages how to make an indirect heating boiler with our own hands - the whole complex of work will consist of the sequential assembly of different parts of the structure.

Water heater tank

The volume of the container, where water will be supplied for subsequent heating, depends on the needs of the homeowner: the standard consumption is up to 70 liters per household per day, so 200 liters will be quite enough for a family of 4 people.

The material of the tank should be chosen from an alloy of aluminum, as well as other non-ferrous metals that do not corrode, if finances allow - stainless steel. A good alternative is a gas cylinder, but the inner walls must be treated with a special primer, otherwise the hot water will have an unpleasant rotten smell.

You need to cut at least 5 holes in the tank body with your own hands: two from either side - they are designed for inserting the coil, at the bottom there are also 2 - for water supply and a drain valve, at the top there is only one - hot water extraction.

Making a coil

This element, made of a copper pipe of small diameter, but thick-walled, can necessarily have different dimensions - it depends on the volume and height of the container. Experts say that for every 10 liters. water needs 1.5 kW of heat output of the coil.

You can use pipes from a different material to save money from your home budget, but always with excellent heat dissipation. During manufacturing, you must very carefully monitor the formation of turns:

- they do not touch in any way - there must be a gap between the turns;

- you cannot make excessive efforts - this will greatly complicate the removal of the finished product from a special mandrel;

- the number of turns is strictly calculated and depends on the dimensions of the tank.

For the mandrel, use a pipe of the required diameter or a round wooden log without knots. After manufacturing, the spiral is carefully coated with a protective heat-resistant varnish.

We insulate the structure

From the outside, the tank is necessarily covered with thermal insulation to reduce losses and increase the efficiency of the product - this can be a special foam for installation or another material with excellent thermal insulation properties, for example, foam plastic.

It is fastened with wire, special ties, or put on glue. On top of the insulation, the craftsmen recommend strengthening the sheets of foil or using insulation with one foil side. For insulation, some craftsmen insert the boiler into a larger container, and fill the space between it and the inner walls with insulation of any kind.

Final assembly

When all the details of the future structure are prepared, its assembly begins.

- The coil is installed in the center or along the inner surface of the container, pipes are attached to the ends (soldering or welding).

- When placed vertically, we weld the legs to the container, when placed on a wall - special fastening loops.

- A heating element is welded to the bottom of the tank.

- A cover is installed on top and welded to the body.

- The coil is connected to the autonomous system circuit according to the selected scheme.

- We connect pipes for supplying cold water and a line for removing hot water.

- We connect the water heater to the domestic water supply system.

For a consultation, so that there are fewer questions, we advise you to watch this video:

Then you just have to enjoy the abundance of hot water without significant financial investments.

Let's start creating a boiler

First of all, you need to prepare a container that will act as a water tank. In principle, any, not even a sealed metal tank, made of stainless material - steel or enamel, will do. You can even take a plastic tank, but with one condition - it must be made of food grade plastic that does not emit harmful substances into the environment when heated.If the tank is metal, you need a welding machine to work with it.

Enamel or glass-ceramic tanks are not very durable and will need to be replaced pretty soon, so a stainless steel container will be preferable.

An economical and simple way is to take a gas cylinder as a tank: using a grinder, it must be cut into two halves, cleaned and coated with a primer, and then welded back into a single whole. In extreme cases, you can do without this whole procedure, but you should prepare for the fact that the water will have a strong smell of gas for a long time.

The next stage in creating a boiler is the thermal insulation of the walls of its tank. To reduce the level of ordinary heat transfer, you need good thermal insulation. By the way, it will be more convenient to do all this before installing the tank. Any material will do to insulate the tank, even polyurethane foam. Glass wool or other insulation can be attached to the tank with rope, wire, glue. For the insulation to work, the condition must be met - the insulating material must cover the entire surface of the container with water. There is another option for improving thermal insulation - install a smaller tank in a larger tank, and put a layer of insulating material between them.

You can make a coil from any small pipe, be it plastic or metal. Then the task becomes more complicated - the pipe needs to be wound on some cylindrical object, for example, a log or other pipe. Threaded fittings are installed at the ends of the wound spiral. The spiral from the pipe should not be too tight, since during operation the coil will be covered with scale, and it will be difficult to remove it. From the boiler itself, you need to remove and clean the coil at least once a year.

After all the elements of the water heater are ready, it is time to assemble the boiler. Two holes are made in the selected tank - for the inlet pipe with cold water and for the outlet, which will supply heated water. Cranes are attached near the holes. In principle, holes can be made anywhere in the tank, but in practical use it is much more convenient if the cold water pipe is connected from below, and the heated supply pipe is connected from the top. At the very bottom of the tank, a drain pipe is mounted, through which it will be possible to completely remove water from the tank if necessary, for example, for cleaning or repairs.

Then you need to cut out the holes for the coil, and weld metal fittings to the wall of the tank, which have a threaded connection, to which the coil itself will be attached.

The tightness of this tube must be checked, and this procedure should be carried out especially carefully if antifreeze or another substance potentially hazardous to human health is used as a coolant. You can check the tightness by blocking one hole and supplying compressed air to the other with a compressor. When checking, the coil should be slightly moistened with soapy water. If there is no tightness, the coil tube must be soldered again.

In order for the heat to not go away from the tank, it must be closed with a lid with latches. The cover must also be insulated with insulating material. That's all!

Do-it-yourself indirect heating boiler only needs to be installed and used!

Make-up of the heating system from the boiler

Budget manufacturing option

Experts offer an original version of the manufacture of a similar type of water heater, but for this you need the following components:

- copper or bronze pipe;

- boards of different sizes;

- sheet aluminum;

- a collector made of copper or its alloy;

- glass sheets of a certain format;

- special composition of paint.

We make a case from boards of the required size, sheathe it from the inside with sheet aluminum.Along the perimeter, we install pipes like a coil, we attach a collector to them, taking into account which side the entrance will be, and where the exit will be.

Such a system is quite simple and functional - with its help you will heat the required amount of water, and the manufacturing technology is similar to the standard version.

To make the structure better absorb heat and not give it to the outside, glass and special paint are used.

In the manufacture of such a water heater, an enviable saving of money resources is obtained - you just have to choose an option that is acceptable for your premises and start work.

Do-it-yourself installation of a safety valve on a boiler

When assembling a boiler with your own hands, you must follow the rules.

More precisely, do not forget about:

- Compliance with the sequence of works;

- Accuracy;

- Purchase of all necessary parts, including a safety valve.

The last mini-detail in the water heating system is especially important, since when the water is heated, it expands in the tank, which increases the pressure. When the critical level is reached, the safety valve begins to function, due to which water is released until the pressure drops to the desired level.

The safety valve must be installed on the boiler

The valve is connected to a flexible tube connected to the sewer.

If the reservoir is too large, a diaphragm expansion vessel is additionally installed. It is he who has the ability to compensate for large volumes of expanding fluid. When purchasing a tank, choose the one that is suitable for the water supply system, and not the heating one. It can be distinguished by the working pressure it has (7-8 bar of DHW). In addition, when preparing for arranging the tank with your own hands, you need to purchase valves, filters, and other parts.

It is important that even if you plan to assemble the tank yourself, you do not need to save on materials in order to avoid breakdowns and emergencies. A competent approach to planning and building a boiler will allow you to get a quality product that fully meets expectations.