A pellet heating boiler is an excellent example of a solid fuel heating system for a house with high efficiency. According to this indicator, it is in no way inferior to analogs operating on main gas. But gas is not available in all settlements, and it is necessary to heat the dwelling. In this case, it is worth paying attention to pellet boilers. Because pellets are granular shavings and sawdust, that is, in fact, woodworking waste, which, even taking into account processing costs, is cheaper than firewood or coal.

Pellet boiler

The principle of operation of a pellet boiler

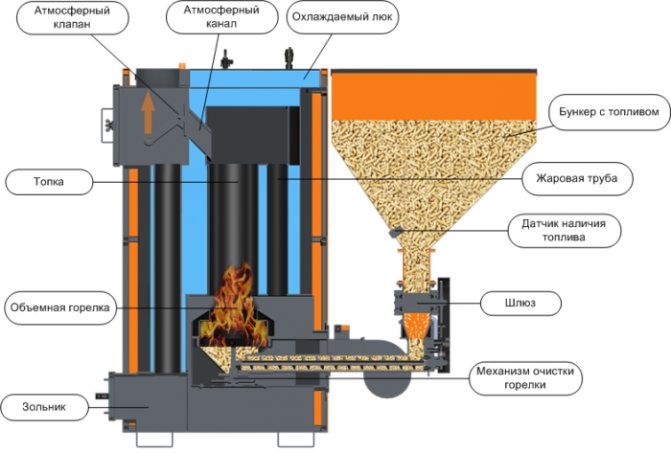

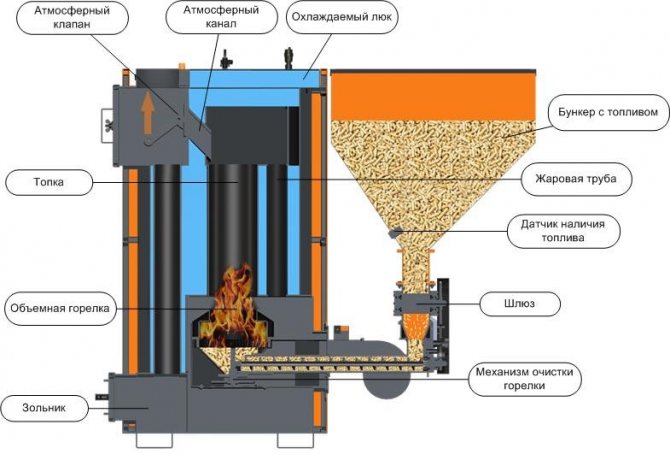

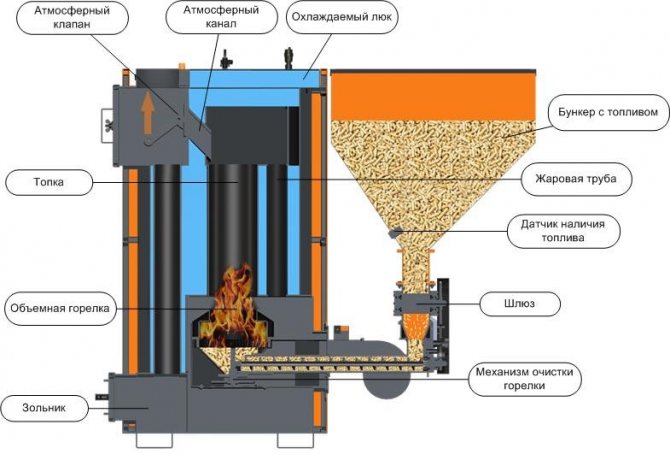

The pellet boiler can be called an improved version of the familiar wood-burning stove. It works like this: fuel is loaded into the combustion chamber (firebox), air is pumped through a special channel - blower - air is pumped in, gaseous combustion wastes are discharged through a special hood - chimney. A classic example of a furnace.

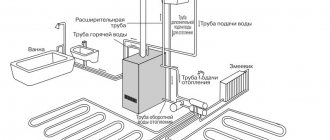

But instead of the usual firewood, pellets are loaded into the boiler furnace - pressed granules from wood shavings and sawdust. Their supply can be dosed using a special screw mechanism. It is also possible to equip another combustion chamber in the firebox for burning the gas emitted from the pellets. It is such a device that solid fuel pellet boilers of the pyrolysis type have - the most advanced version of a solid fuel heater to date. Its efficiency reaches 96%. The energy of fuel combustion in such boilers is enough for both heating and hot water supply.

The principle of operation of a pellet boiler

Typical designs of pellet heaters

There are three main types of pellet boilers:

| Boilers operating only on pellets ... They are equipped with a hopper and a screw mechanism to regulate the supply of pellets to the combustion chamber. |

| Single chamber boilers working both on pellets and on wood, coal or briquettes. In this case, the pellets are loaded into the furnace through a special screw conveyor, and other solid fuel is loaded manually through the door at the end of the device. Such a boiler has one combustion chamber, so it can work on briquettes or wood for no more than three hours. |

| Double chamber boilers working both on granular pellets (they are burned in the first chamber), and on any other solid fuel (it is burned in the second chamber). The operation of such a boiler is as efficient as possible. For example, one chamber can be used for heating, and the other for hot water supply. Such an apparatus does not depend on the supply of wood-shaving pellets. |

Of course, the price of a pellet boiler, especially a two-chamber boiler, is quite high. Many of them are more expensive than gas counterparts of the same capacity. But the purchase of such heating equipment in the absence of a connection to the main gas in the long term will still be beneficial for the owner of the heated premises.

Pellets as an alternative heat source

Pellets owe their appearance on the market to German-American Rudolf Gunnerman: he received a patent for their invention in 1976. As a sawmill manager, Gunnerman wondered for a long time how to reduce the costs of transporting wood waste. Finally, the thought struck him - to press the sawdust. So pellets appeared - compressed wood pellets, which later became the most popular type of biofuel among residents of the New and Old Worlds.

An important advantage of pellets is their high calorific value: it has been established that burning 1 ton of wood pellets releases the same amount of energy as when completely burning 1.6 tons of wood, 480 cubic meters of gas or 500 liters of diesel fuel. Due to this, pellet heating seems to be more economical than, for example, wood heating.

Today there are two main types of pellets on the market - industrial, or "gray", and household, or "white". For gray pellets, a high content of bark is characteristic, which gives a high ash content, lower calorie content, as well as the risk of clogging and stopping of the pellet equipment. White pellets are made from wood waste with a low bark content and are more expensive.

You can also be offered agropells made from waste of agricultural raw materials (for example, from rice husks or corn kernels). In terms of cost, they are significantly lower than the two mentioned, but their quality also leaves much to be desired. When burned, they give a colossal volume of ash, in addition, they crumble strongly, which creates problems during their transportation, loading and unloading.

Advantages of a pellet heating boiler

| Durability - the service life of the boiler can be up to 50 years. |

| High power - from 15 to 100 kW. |

| Complete autonomy - simple models of pellet boilers do not need electricity, they work like ordinary stoves. More advanced models with an automatic control system, of course, require electric current to power the drives and control circuits. But even without electrification, the boiler will work. |

| Ease of service - a standard boiler consists of a firebox, a blower and a chimney. In fact, this is a classic stove that needs replacing the grates from time to time. Of course, a pellet boiler equipped with automation requires a little more attention, but exclusively for servicing the control unit. The boiler itself does not even need to be cleaned - the pellets burn out almost completely. |

| Low fuel cost - pellets. As already mentioned, pellets are actually pressed shavings, so they are much cheaper than firewood, coal and peat. At the same time, pellets are consumed much more economically than other types of solid fuel, and during combustion they release much more energy. |

The best known manufacturers and models: characteristics and prices

When choosing a pellet boiler with automatic feeding, you need to focus not only on the technical characteristics, but also on the manufacturer, since not everyone will be able to ensure the timely delivery of replacement parts, as well as provide a specialist for installation, adjustment and warranty service.

Therefore, in order not to be left without heating at the wrong time, it is better to choose a proven model from a company with extensive experience in this field.

ZOTA Pellet-15S

Wear-resistant pellet boiler of Russian production, supporting different types of fuel (pellets, firewood, briquettes). It is designed for use in harsh winter conditions that imported solid fuel boilers cannot withstand.

Those. options: power - 15 kW, bunker volume - 296 l, efficiency - 90%.

average cost: 150,000-170,000 rubles as standard.

Manufacturing firm: TPK KrasnoyarskEnergoKomplekt, Russia.

FACI 15

A compact boiler with a twin-screw feed system provides high combustion efficiency for almost any crushed biofuel. It is equipped with an "anti-slag" type cast iron retort burner, which allows to reduce the ash content of even low-quality pellets.

Those. options: power - 15 kW, bunker volume - 352 l, efficiency - 92%.

average cost: 130,000-150,000 rubles as standard.

Manufacturing firm: LLC FACI-RUS (FACI Caldaie), Russia-Italy.

Teplodar Kupper OK-9 with APG 25 burner

Universal boiler equipped with an APG 25 pellet burner, also suitable for conventional solid fuels, including wood and coal. The simple combined design is easy to modify, if desired, you can switch to a gas burner.

Those. options: power - 9 kW, bunker volume - 200 l, efficiency - 68–95%.

average cost: 80,000-110,000 rubles with a torch burner.

Manufacturing firm: OOO Teplodar, Russia.

Biopellet P-15

A boiler with an original, but well thought-out design, which is easy to assemble and maintain, even by an untrained specialist. It is unpretentious in the quality of the pellets, it can be heated with both white and gray varieties without the risk of stopping the burner due to contamination.

Those. options: power - 15 kW, bunker volume - 200 l, efficiency - 92%.

average cost: 160,000-180,000 rubles as standard.

Manufacturing firm: OOO Dozatech, Russia.

START-50-GR

A powerful domestic-assembled boiler with an impressive size bunker and imported components (automation and burner). It is known for its high reliability and durability, thanks to its cast iron parts (burner, boiler door, grate) and a durable 6 mm thick steel heat exchanger.

Those. options: power - 50 kW, bunker volume - 400 l, efficiency - 95%.

average cost: 230,000-250,000 rubles as standard.

Manufacturing firm: LLC Heating boilers "START", Russia.

Required power

It is quite simple to calculate the approximate power of a heating boiler: for every 10 square meters of area, 1 kilowatt is needed. If the organization of hot water supply is required, the obtained value increases by 25-30%. Plus add another 25% of the reserve capacity so that the boiler does not work at the limit of its capabilities.

Of course, this is a very rough formula for determining the power of the boiler. For a more accurate calculation of this parameter, it is better to contact a specialist who will do this taking into account the material of the walls of the house, possible heat loss, the average temperature in the cold season and other nuances that must be taken into account.

Which burner is preferable

One of two types of burners is installed on pellet boilers:

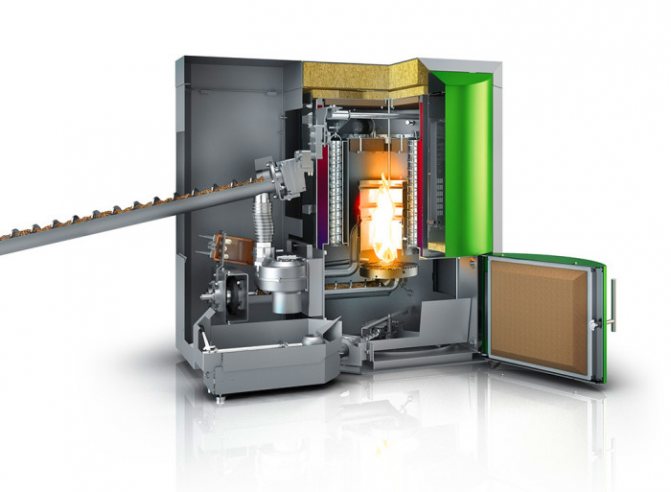

Rotary

(vertical) burner that directs the flame upward. The advantage of rotary burners is that the quality of the fuel is not important for them, and they do not require cleaning.

Stokernaya

(horizontal) burner that directs the flame to the side. Stoker burners work only with special pellets that do not form ash residue during combustion. But cleaning such a burner is still required regularly.

A rotary burner is preferable in all respects.

Control automation

Automatic boilers are attractive in that they can work independently, without human attention. Pellet feeding, power regulation and circuit operation are automatic, under the control of "artificial intelligence".

This option is attractive for its economy and efficiency: the amount of fuel is calculated by a special control unit, which turns on the conveyor only if necessary. This moment is determined by a temperature sensor installed in a heated room.

The weak point of such a boiler is its dependence on electricity. In the absence of electricity, it turns off, since the drives of the conveyors and throttle valves and other automation operate on electricity.

An ordinary, manual boiler requires attention, but it works anywhere and for as long as you like. If there are frequent power outages in the area where the house is located, it makes sense to give preference to this option, and if you choose a boiler with automation, then take care of an autonomous source of electricity.

Recommendations for manufacturing

The first step is to determine the design feature of the furnace. It is necessary to exclude the elements which will not be made by hand - they will need to be purchased - this is a set of automation and a burner device. Some craftsmen manage to make a burner with their own hands, but this will take a lot of time and a lot of effort, but the result may be unexpected, for example, high flow rate or malfunctioning.

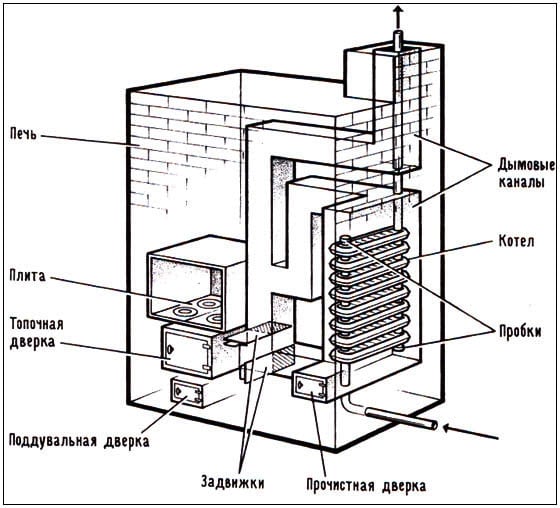

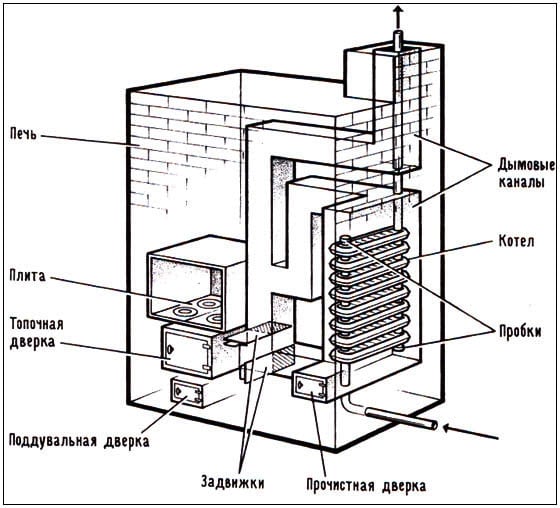

It is wiser to purchase a ready-made sample and use it in a self-made structure. In order to have the possibility of improvement in the future, it is better to make the design universal. It is more correct to make a pellet boiler with a water circuit, with the ability to burn coal and firewood... By and large, the processes of heat exchange occurring in these types of heating differ in the way of combustion and the type of fuel.

This provides the following benefits:

- in view of the fact that the production of pellets in our country is not so widespread, and interruptions are possible with fuel, it is better that the burner is removable, so that, if necessary, it is possible to heat the dwelling with coal and firewood;

- it will also be possible to use diesel or natural gas by replacing the special burner.

For the manufacture of the firebox, it is recommended to use heat-resistant steel with a thickness of at least 5 mm. For ideal performance, carbon steel CT20 is required; for the casing, you can choose the grade St3, the thickness of which is 3 mm. For the manufacture of doors and fire tubes, 6 mm are used. material, but for the grate you need metal 10 mm thick. In some cases, it's easier to buy a ready-made version.

Assembling the structure occurs by welding... The walls of the water grate must be made as rigid as possible by welding pieces of reinforcement or a metal corner on them. After completing the welding work, it is imperative to check all seams for permeability and, in case necessary, get rid of the shortcomings.

Types of conveyors

Fuel conveyors in pellet boilers are flexible and rigid. The rigid auger is affordable and very reliable, but its length cannot be more than two meters, otherwise it, like a millstone, begins to grind pellets into sawdust. The flexible auger is more expensive, but it is capable of working flawlessly even at a distance of twelve meters.

If the pellet hopper is within two meters from the boiler, then it is quite possible to do with a rigid conveyor. And if it is more than two meters away from the heater, then a flexible conveyor without options will be required.

Pellet boiler

Profitable arithmetic

Before installing a pellet fireplace, it is necessary to consider the issues of feasibility and profitability. First of all, do not forget that a fireplace is not a complete source of heat. However, this type of fireplace is not suitable as an additional source due to its high cost.

Good to know: How wood-burning brick fireplaces are built for home and summer cottages

Fireplace power ratings range from 3 to 15 kW. Theoretically, 1 kW of power is enough to heat 10-15 m2 of area. But the increased efficiency, which goes up to 95%, increases coverage. However, there are some guidelines for choosing a fireplace or boiler. Up to 100 m2 can be safely heated with a fireplace. The fireplace will also cope with an area from 100 to 300 m2, but here boilers begin to enter the "arena", and indicators over 300 m2 are not available for fireplaces.

Mobile home heating device

Which heat exchanger design is better

Heat exchangers are classified according to their location inside the boiler. There are vertical or horizontal heat exchangers, tubular or flat. Experts recommend giving preference to models with a vertical version, because such chambers can be equipped with vertical burners.In addition, ash and soot do not accumulate in them: unburned particles simply sink to the bottom under the influence of gravity. The chimney turbulization system (a complex of swirlers and turns that prevent air convection) is easier to organize on a vertical heat exchanger. They also maintain a high temperature (1000-1100 degrees) in the combustion zone and effectively cool the exhaust gases to 100-120 degrees.