Types and technical characteristics

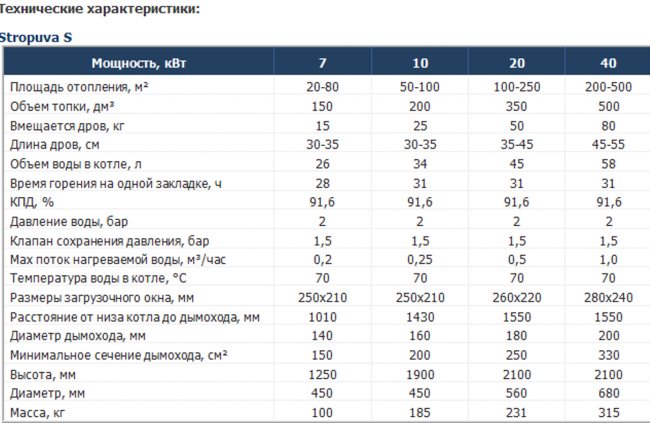

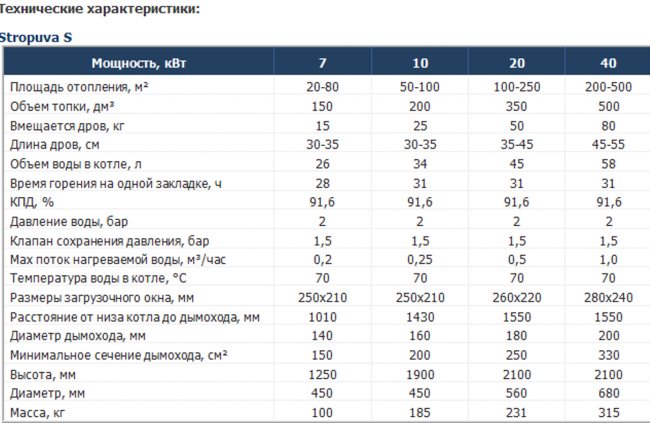

At the moment, Stropuva is available in three varieties: wood, pellet and universal. Each of these three varieties is designed for a specific type of fuel, but can work on any other, albeit with less efficiency. In total, the line includes 4 standard sizes: 10, 15, 20, 40 kW and the Mini version with a capacity of 8 kW.

The Stropuva wood-fired boiler is equipped with a special air distributor that allows you to efficiently burn wood, has the following characteristics:

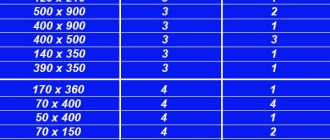

| Model | Mini S | S10 | S15 | S20 | S40 |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m2 | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency,% | 86,3 | ||||

| Firewood capacity, dm³ | 120 | 150 | 200 | 230 | 360 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Burning duration, h | 31,5 | ||||

| Price, rub | 65 000 | 87 150 | 92 348 | 97 545 | 107 730 |

The pellet version is equipped with a pellet distributor and an air supply manifold. Pellet boilers have the following data:

| Model | Mini SP | S10P | S15P | S20P | S40P |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m2 | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency,% | 86,3 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | |||

| Burning duration, h | 72 | ||||

| Price, rub | 65 000 | 91 350 | 97 072 | 102 795 | 112 980 |

The last representative of solid fuel boilers is universal. These devices are capable of operating on coal, wood, fuel briquettes and pellets. The delivery set includes distributors for all types of fuel and an air supply manifold. They have the following technical characteristics:

| Model | Mini SP | S10P | S15P | S20P | S40P |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m2 | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency,% | 86,8 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Duration of coal burning, h | 130 | ||||

| Price, rub | 65 000 | 102 700 | 114 608 | 121 380 | 127 995 |

As you can see, from the presented model range, you can choose a solid fuel boiler for any room, type of fuel and available budget.

a brief description of

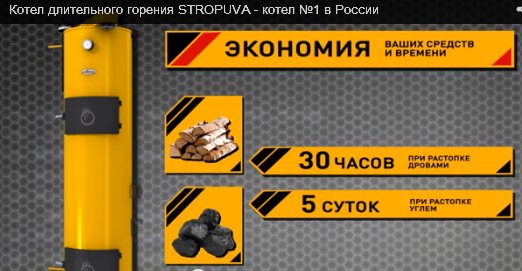

Solid fuel boilers STROPUVA belong to long burning boilers and are suitable for various operating conditions. The main value of the equipment of this Lithuanian brand is that the boilers can work for a long time without additional fuel loading. The duration of combustion of one load of fuel is: firewood - 30 hours, coal - up to 5 days. The simple design, made in compliance with the technology, guarantees trouble-free operation.

Stropuva oven

The company represents two groups of equipment:

- The S index marks boilers designed only for wood-fired operation. Equipment capacities: 7, 10, 20 and 40 kW.

Stropuva S oven

- the S-U index denotes universal models designed for heating with both wood and coal (power: 10, 20, 40 kW).

Oven Stropuva S-U

What you need to know for normal and efficient boiler operation:

- it is necessary to choose the right equipment power (calculate it yourself or trust a specialist);

- the degree of protection of the premises from heat loss;

- fuel quality (when using "a little" wet firewood, the thermal power drops by 10% or more);

- installation and connection of the boiler must be carried out in compliance with the technical requirements.

All Stropuva boilers are easy to use:

- The boiler is loaded at a predictable frequency.

- Cleaning - several times a month.

About the boiler Stropuva

New connections for solid fuel boilers Stropuva are already on sale

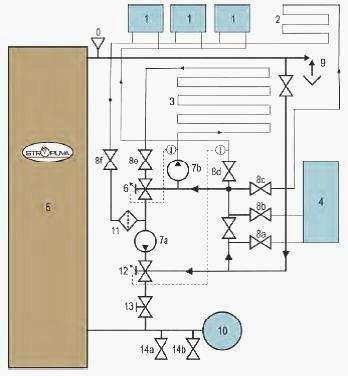

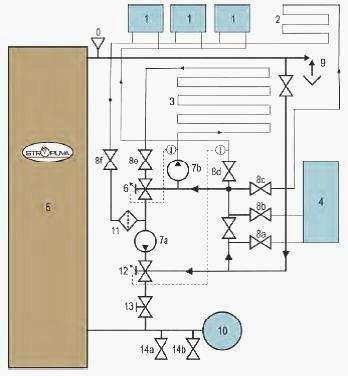

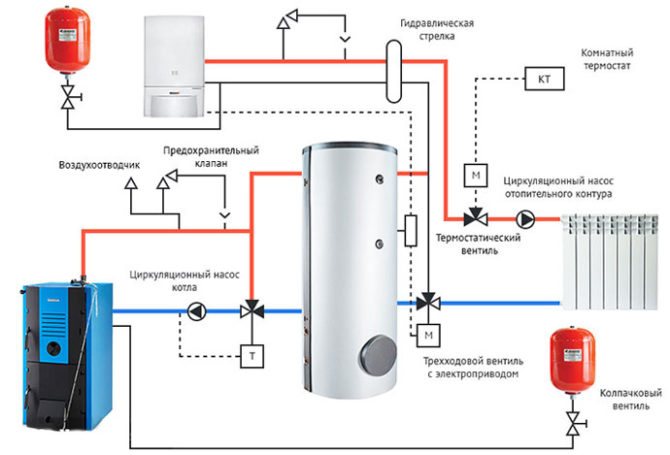

Recommended piping scheme for long-burning boiler Stropuva S40 / S40U (option 2)

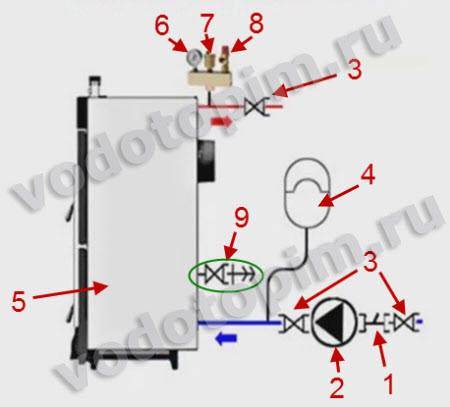

Operation of the circuit with connecting a boiler, without a backup boiler and underfloor heating

The circulation pump (P) supplies the heating medium from the heating system, passing it through the boiler.

The heated coolant from the Stropuva S 40 boiler (1k) is fed through an indirect heating boiler (B). With a sufficient diameter of the boiler inlet pipes, the valve (3) closes and the entire flow of the coolant goes through the boiler, which is connected in series, so the water in it heats up faster.

After heating the domestic water (DHW), the coolant enters the radiator system.

(bk3 - 17) - balancing valve designed to regulate the flow.With its help, the flow from the circulation pump is distributed so that it is enough to heat the radiators, and at the same time, so that it is sufficient for the boiler itself. The total flow volume depends on the power of the circulation pump and can be changed by switching the pump speed positions. A 50-100 W circulating pump is enough.

(bk1 - 3) - balance valve of the protective gravity radiator, with the help of which the flow is adjusted so that the return pipe of the radiator is about 40 ° C colder than the supply pipe.

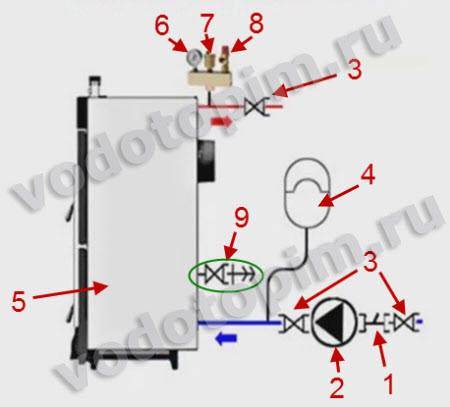

Recommended piping scheme for a long-burning solid fuel boiler Stropuva S40 / S40U with connecting a boiler and underfloor heating, without a backup boiler

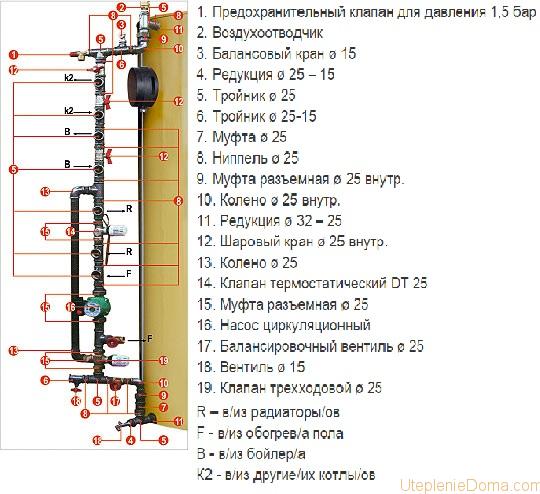

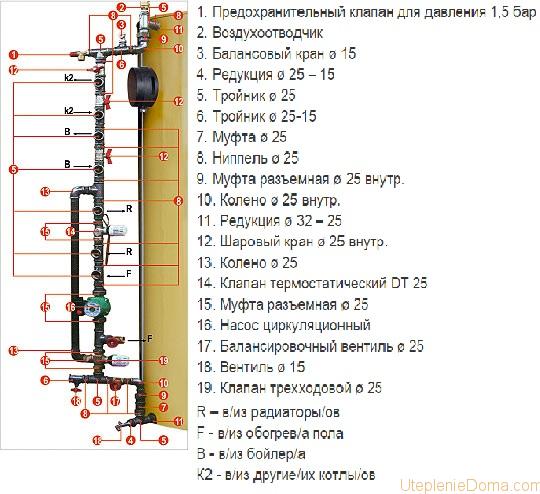

Fig. 8. Elements of the prefabricated boiler room

1. Air vent, 2. Reduction ø 25 - 1, 3. Reduction ø 32 - 25, 4. Nipple ø 25, 5. Tee ø 25, 6. Connection ø 25, 7. Elbow ø 25 internal, 8. Nipple ø 15, 9. Safety valve pressure 1.5 bar, 10. Ball valve with nut ø 25 int., 11. Ball valve with nut ø 25 int., 12. Nut connection of the circulating pump ø 25, 13. Circulation pump, 14. Ball valve ø 15 female, 15. Three-way directional valve ø 25, 16. Valve nut connection ø 25, 17. Elbow ø 15 female / male, 18. Elbow ø 25 female / male, 19. Filter ø 25 , 20. Balancing valve ø 25, 21. Reduction ø 25 –20, 22. Expansion tank, 23. Plug ø 25 out., 24. Cross ø 25, 25. Tee ø 25 - 15, 26. Three-way mixing valve ø 25 , 27. Balance valve ø 15, R - to / from radiators / s, B - to / from boiler / s, F - to / from floor heating / s, H - to / from dryer / s with thermostatic valves

3-way directional valve ø 25 (15) can be installed manually.

Fig. 9. Recommended piping scheme for long-burning boiler Stropuva S 40 (option 3)

Operation of the circuit with connecting a boiler and a warm floor, without a backup boiler

The heating medium heated in the Stropuva S40 / S40U boiler passes through steel pipes ø 25. The air is removed from the device through an automatic air vent (0). A safety valve (9) is installed on the external circuit.

The heat carrier is directed along the external circuit to the three-way mixing unit (12). The mixing unit (12) in the lower part of the circuit is necessary for mixing the return heat carrier after the circulation pump.

The temperature difference between the supply and return coolant must be within 15-20 ° C. Accordingly, at a flow temperature of 75 ° C, the return temperature should be 55-60 ° C.

The boiler (4) is connected in a small circuit through the valve (8a, 8b). After heating the boiler, water enters the nearest radiator (2) through the balance valve (8c).

Additional radiator (2) must be connected autonomously. The radiator is necessary to prevent overheating of the boiler when the circulation pump (7a) is turned off.

The radiator system is connected at the top of the small circuit through a valve (8d). The return line from the radiators is fed to the circulation pump (7a) through a valve (8f). On a small circuit, after taking the coolant to the radiators, the underfloor heating is connected through the circulation pump (7b).

The heating medium from the underfloor heating return line is supplied to the three-way distribution valve (6) through the valve (8e).

A three-way mixing valve (6) is required for mixing the supply and return lines and bringing the temperature of the underfloor heating supply line to a temperature of 25-35 ° C.

The three-way diverting valve (12) is connected to the circulation pump (7a) to a common return line. In the lower part of the circuit, after the mixing unit (12), a balancing valve (13) with a flow meter is installed to regulate the flow of water into the boiler.

In the return line, after the balancing valve (13), drain valves (14a, 14b) are installed to make up and drain the coolant from the system, as well as an expansion tank (10). The pressure in the expansion tank should be 0.5-0.8 atmospheres.

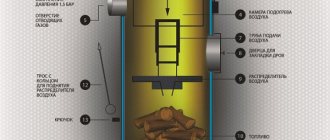

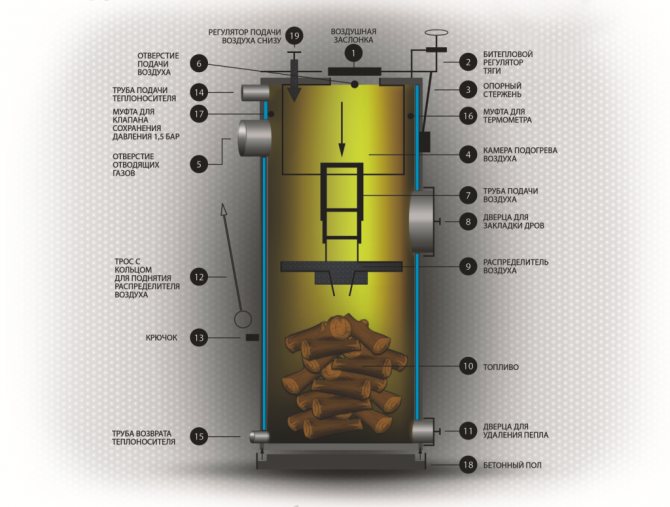

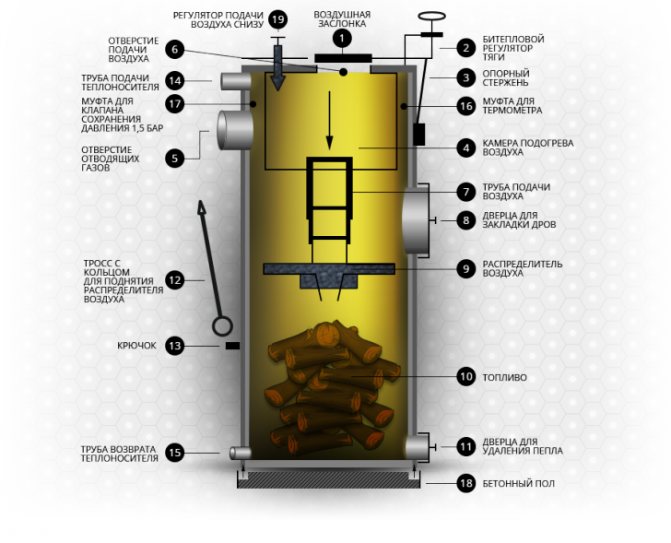

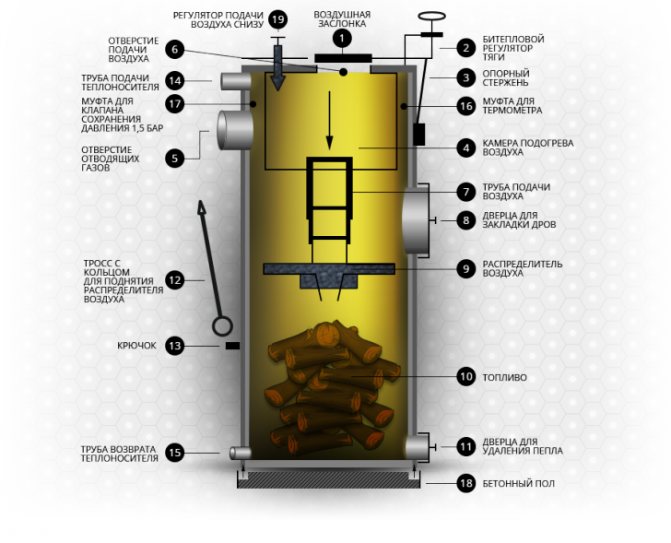

Boiler device Stropuva

To answer the question of whether it is possible to make Stropuv's boiler with your own hands, you first need to honestly determine the degree of your skill.If you are a jack of all trades with a developed savvy, then the process may be within your power. If you are a homemade "DIY", then, most likely, there will be no sense, because the task is really difficult. To verify this, consider the design of the Stropuva boiler. It consists of the following main structural elements:

- double body;

- telescopic air duct;

- air distributor;

- automatic air supply control system.

Of course, Stropuva's long-burning boilers are equipped with doors, nozzles for supplying and returning the coolant. There will be no difficulties with simple elements, it is simply impossible to make the basic ones at home. Let's start with a telescopic tube, how do you make it yourself? It's impossible without factory equipment. On this, in principle, it is possible to end, the attempt failed. Hypothetically, let's say that you managed to make a telescopic duct that can be folded by pulling on the cord.

Surely you have identified a ring on a string in Stropuv's long-burning boilers. It is designed to lift the air supply pipe.

The unit diagram is really complex. You need to do the following:

- connect two pipes of different diameters;

- in the outer pipe, cut in the pipes for the supply and return of the coolant;

- in the inner pipe from above (exactly in the middle), fix the chamber for heating the air;

- fix the already made telescopic air duct with an air distributor at the end in the chamber from below;

- you should also make a branch pipe for removing smoke from the inner pipe;

- install doors;

- put an air supply control system.

In this case, everything should be as tight as possible. Can you cope with such a difficult task? Most likely not. So Mr. Afanasy Budyakin from Kolyma thought that this was an impossible task, so he came up with an analogue of Stropuv's boiler. I didn't name him in any way, but just posted it on the network under the nickname "bybafonja". And so the name "Bubafonya" stuck to the domestic long-burning stove. We will talk about it a little later.

Before choosing a convector heater for your home, calculate the required power.

What is the best quality home heater? The answer is here.

Advantages and disadvantages

Sectional diagram of the Stropuva boiler

It is worth briefly listing the main advantages of the Stropuva boilers:

- Efficiency and convenience - they do not require expensive gas supply for their installation, and a long operating time on a one-time fuel filling saves money and time.

- Energy independence - there is no electronics in the design, therefore wood-fired boilers, when used in a gravitational heating system, do not need electricity.

- Safety and reliability - one of the advantages is control with a bimetallic valve - a simple and trouble-free draft regulator.

- Aesthetics along with simplicity - STROPUVA boilers differ from a similar type of devices in their elegant appearance and compact placement. The clear design of the unit eliminates any difficulties in operation.

Among the disadvantages, the following can be noted: their performance is strongly influenced by the moisture content of the loaded fuel. But this is rather a minus of all solid fuel boilers, and not of a specific brand in particular. The solution here is simple - keep wood or coal in a dry place.

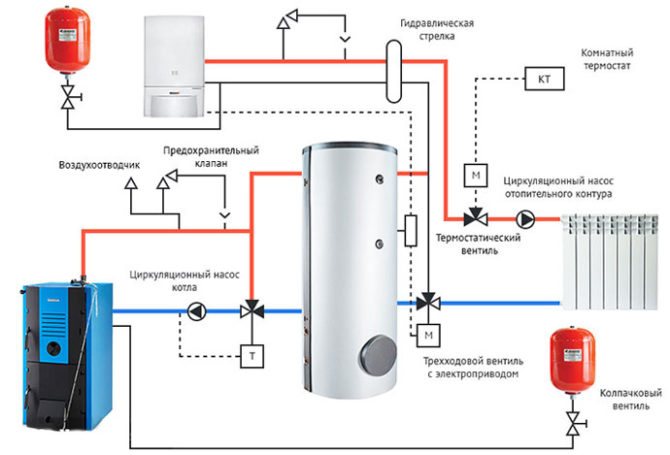

Boiler connection diagram Stropuva

Piping scheme with a backup heater, hot water boiler and underfloor heating.

After the purchase, filling out the documents, the seller will ask you: "Do you need the help of a master in installing the heater?" Take your time to answer "No." The connection diagram of the Stropuva boiler is somewhat different from other types of solid fuel boilers. On the official website, you can find three strapping options:

- with backup heater, hot water boiler and underfloor heating system;

- only with a boiler;

- with a boiler and a low-temperature underfloor heating system.

Maybe for someone it is, as they say, "one spit", but for a person without specialized knowledge, these schemes cause a stupor. This is not to mention the fact that you independently connect the Stropuva heating boiler. In general, it is still better to use the services of experts in this matter. By the way, opinions have been heard more than once on the forums about the complexity of strapping this equipment.

Checking the boiler sling

Before permanent use of the boiler, it is imperative to carry out tests of its serviceability. This is necessary in order to further operate the boiler in a safe mode.

So, you will need to fill the barrel of the apparatus with firewood up to a third. From above, it is covered with a lid, and before that you need to throw a match into the barrel so that the fire begins to flare up. For better ignition, it is imperative to add kerosene there.

Ideally, the firewood should immediately burn up. At the same time, there should be no draft, no smoke, no smell. If any of the above is observed, then you should not use such a boiler. With a high probability, he will harm the owners of the house. However, if everything was done correctly, then there shouldn't be such problems.

The specified amount of firewood is enough to heat a small room for a day.

What does the heating boiler piping consist of?

Knowing what the boiler piping should do, we can easily guess what is included in its composition and select the appropriate equipment. Such equipment is located directly near the boiler (on the walls and on the floor of the boiler room) and on it:

1 - filter; 2 - circulation pump; 3 - ball valves; 4 - expansion tank; 5 - boiler; 6 - manometer; 7 - air vent; 8 - safety valve; 9 - system make-up-drain unit

Consider the piping, starting with the return.

1. The heat carrier goes to the circulation pump and enters the filter:

- which is in front of (!) The pump.

2. The pump, as seen from the diagram, stands in front of the boiler. There are ball valves on both sides of the pump so that you can change the pump or clean the filter without draining the coolant from the entire system. Replacing the pump is quite simple as it is secured with union nuts.

In general, the main requirement when installing the boiler is to provide for a fairly easy access to the pump and other piping elements.

3. Expansion vessel between pump and boiler. The expansion tank can be installed anywhere in the system, but it is preferable as shown in the diagram.

4. Then the coolant enters the boiler, heats up and enters the supply pipe.

5. At the outlet of the boiler, a safety group is mandatory: automatic air vent + safety valve + pressure gauge. The boiler may also have a thermometer to monitor the temperature in the boiler.

6. A ball valve with a fitting, on which you can put a hose on and feed the system from the water supply. Or drain the coolant from the system.

The above are mandatory elements that must be included in the boiler piping.

The wall-mounted boiler has all the same devices, only they are already inside the body.

If you are not familiar with any of the listed equipment, then you can find full information about it in the section about heating equipment.

Basic models

You can buy a Stropuva boiler in specialized stores that are dealers of the manufacturer, as well as in online stores. The minimum price is 60 thousand rubles for the minimum power model. Let's continue the review with a description of the manufactured models.

Lanyard Mini S8

Before us is the smallest wood-burning boiler with a capacity of 8 kW, designed to heat rooms up to 80 square meters. m. It works on wood briquettes and wood, equipped with a safety valve and a thermometer. The heating temperature of the coolant is from +60 to +95 degrees. The maximum pressure in the circuit is up to 1.5 bar. The efficiency of the model is 85% - a pretty good result for solid fuel equipment.The estimated cost of this boiler is 61 thousand rubles.

Lanyard Mini SP8

This boiler differs from the previous model in its support for working on pellets. In this mode, it needs to be connected to a 220 Volt power grid - electricity is used to operate the fan used in the fuel ignition system. When working on wood and briquettes, the boiler works in an autonomous mode. The rest of the parameters are almost 100% similar.

Slings S20

One of the most popular models. It allows you to heat residential buildings with an area of up to 200 sq. m. The boiler is built according to a non-volatile scheme, briquettes and ordinary firewood are used as fuel. Burning time is up to 31 hours. If you want to forget about laying fuel for a few days, we recommend purchasing the Stropuva S20U modification - it can work on coal, providing up to 120 hours of continuous combustion. The Stropuva S20P model can work on pellets for up to three hours.

Slings S40

Before us is the most powerful boiler in the entire line. Its thermal power is 40 kW, burning time - up to 31 hours, heated area - up to 400 sq. m. The device is equipped with a rather impressive jacket-heat exchanger, containing 58 liters of water. The maximum pressure in the system is up to 2 atmospheres at an average temperature of up to +75 degrees. More than 90 kg of firewood is placed in the combustion chamber of the device. Modifications for work on pellets and coal are also available.

Other models and manufactured modifications

Also on sale are solid fuel boilers from the Stropuva company with a capacity of 15 and 30 kW. They are designed for areas up to 150 and 300 sq. m.All models considered in the review are available in three modifications:

- The main one is that the equipment operates only on wood and fuel briquettes (euro wood).

- With index P - it is possible to work on pellets, burning up to 72 hours.

- With the U index - units with the ability to work on coal, burning time up to 120 hours.

Naturally, the actual burning time can be shorter - it depends on the characteristics of the fuel (type of wood, degree of dryness).

Some people have design requirements for heating equipment.

If it is really so important to you how the boiler looks, then we have good news - Stropuva produces his equipment in several colors. The main color (and most common) is yellow

It is possible to purchase boilers in brown, blue, red, green and black colors. Spotted color is also provided (yellow and dirty green).

Tying a solid fuel boiler with an electric boiler

Often, wood and coal heaters become the second heating device in the furnace room, where a gas or electric installation is already present. Here it is very important to correctly connect them to each other, so that one device is a safety net for the other. This is very convenient, for example, when all the coal burns out in one of them. Then, in automatic mode, an electric or gas water heater will turn on.

Boiler TT piping with electric

A typical piping scheme for a solid fuel and electric boiler is shown in the figure. It is understood that the electrical unit has its own circulation pump.

Installation and assembly of the Stropuva S20 boiler

The Stropuva S20 / S20U / S10 boiler is installed in rooms that meet the national requirements for boiler rooms. The height of the room in which the device will be installed must be at least 215cm.

The floor must be concrete (at least in the place where the boiler will stand). The room must be insulated from the heated living quarters and must have a vertical ventilation duct and a window or hole in the outer wall so that air from outside can easily penetrate into the boiler and the ventilation duct.

Using a mirror, the inside of the chimney is inspected through the chimney cleaning hole.

The chimney must be clean. It should be free of fittings or bird nests and openings in hollow ceilings and adjacent shafts.

It is checked whether there are openings in the chimney from the outside, through which parasitic air can enter, cooling the chimney and reducing draft in it. All openings and joints in the chimney must be sealed.

If there are internal holes in the chimney in ceilings or adjacent shafts and it is impossible to seal them, an oval or cylindrical stainless steel liner must be inserted (rectangular liners are unreliable due to holes formed at the joints due to temperature changes).

The installation of the Stropuva S 20 boiler is carried out directly on the concrete floor, and the gaps between the floor and the boiler are closed with a heat-resistant material (silicone (180˚C) or a solution of lime and cement with sand or other materials).

The boiler can be placed on a concrete bottom for installation with a sealing rope.

When carrying the unit, sometimes its parts are deformed, therefore, after installing it in the chimney and closing all the doors, as well as the holes for cleaning the chimney, check the operation of the upper damper, whether it adjoins the surface of the air supply hole, and the tightness of the doors using a candle flame or matches.

Standards and requirements for the installation of the boiler Stropuva S20 / S20U

Chimney requirements

The diagonal of the chimney opening can be 10% less than indicated in the basic technical data, but not more than twice.

Stropuva's boiler or Bubafonya stove

List of structural elements of the Stropuva boiler.

In the previous article, we talked about long-burning stoves for a house, a summer residence, a bath, how to heat them. Today we will talk about two similar units in their principle of operation - the Lithuanian boiler Stropuva and Bubafonya from Kolyma, and even try to compare them. Those who think whether it is possible to make Stropuv's boiler with their own hands will have to be upset, most likely, this will not work.

Some structural elements are very complex and can only be produced in a production environment using machine tools. But the domestic, simplified analogue can be assembled in a day. Of course, it does not have such high characteristics as factory units, nevertheless, it will heat a summer cottage or garage in no time. The variant is super economical and practical, like the AK-47.

Boiler device Stropuva

To answer the question of whether it is possible to make Stropuv's boiler with your own hands, you first need to honestly determine the degree of your skill. If you are a jack of all trades with a developed savvy, then the process may be within your power.

If you are a homemade "DIY", then, most likely, there will be no sense, because the task is really difficult. To verify this, consider the design of the Stropuva boiler.

It consists of the following main structural elements:

- double body;

- telescopic air duct;

- air distributor;

- automatic air supply control system.

Of course, Stropuva's long-burning boilers are equipped with doors, nozzles for supplying and returning the coolant. There will be no difficulties with simple elements, it is simply impossible to make the basic ones at home.

Let's start with a telescopic tube, how do you make it yourself? It's impossible without factory equipment. On this, in principle, it is possible to end, the attempt failed.

Hypothetically, let's say that you managed to make a telescopic duct that can be folded by pulling on the cord.

Surely you have identified a ring on a string in Stropuv's long-burning boilers. It is designed to lift the air supply pipe.

The unit diagram is really complex. You need to do the following:

- connect two pipes of different diameters;

- in the outer pipe, cut in the pipes for the supply and return of the coolant;

- in the inner pipe from above (exactly in the middle), fix the chamber for heating the air;

- fix the already made telescopic air duct with an air distributor at the end in the chamber from below;

- you should also make a branch pipe for removing smoke from the inner pipe;

- install doors;

- put an air supply control system.

In this case, everything should be as tight as possible. Can you cope with such a difficult task? Most likely not.

So Mr. Afanasy Budyakin from Kolyma thought that this was an impossible task, so he came up with an analogue of Stropuv's boiler. I didn't name him in any way, but just posted it on the network under the nickname "bybafonja".

And so the name "Bubafonya" stuck to the domestic long-burning stove. We will talk about it a little later.

Before choosing a convector heater for your home, calculate the required power.

What is the best quality home heater? The answer is here.

The principle of operation of the boiler Stropuva

After the flame has sufficiently flared up, it will begin to burn from top to bottom.

Both the original and the analogue of the Stropuva boiler work on the same principle. First you need to load the firebox with bitter. Let's make a reservation right away that this can be done only after the boiler has completely burned out the previous supply of fuel, since the source of smoldering should be at the top. To start up the boiler you need:

- pull the ring and lift the telescopic air duct;

- remove ash through the lower door (1-2 times a week);

- fill the firebox with wood or coal, depending on the model of the unit (there are wood and universal ones);

- set fire to paper or cloth soaked in gasoline from above;

- lower the air duct and close the doors.

From one load of firewood, the boiler works a little more than a day, from a briquette - up to two days, and on coal - as much as five days.

As the fuel burns out, the air distributor moves down until it reaches the bottom. The air supply is controlled by a bimetallic plate. The developers have increased the efficiency due to the fact that an air heating chamber is built into the Stropuv boiler device.

The latter enters the furnace at a temperature of about 400 degrees. At this temperature, pyrolysis gases ignite.

But, unfortunately, the plate loses its properties and every month you need to make adjustments in the settings, and after a year, completely replace it with a new one.

Due to the fact that the air is supplied in a metered manner, it is possible to avoid temperature surges that occur during the operation of ordinary solid fuel boilers. Therefore, the piping scheme of the Stropuva boiler does without an accumulation tank, the so-called heat accumulator for the heating system.

Modern autonomous home heaters are energy-saving units with high efficiency.

Infrared lamp heaters for the home, unlike lamp TVs, are the latest heating equipment. Here you will find both types and characteristics.

Boiler connection diagram Stropuva

Piping scheme with a backup heater, hot water boiler and underfloor heating.

After the purchase, filling out the documents, the seller will ask you: "Do you need the help of a master in installing the heater?" Take your time to answer "No." The connection diagram of the Stropuva boiler is somewhat different from other types of solid fuel boilers. On the official website, you can find three strapping options:

- with backup heater, hot water boiler and underfloor heating system;

- only with a boiler;

- with a boiler and a low-temperature underfloor heating system.

Maybe for someone it is, as they say, "one spit", but for a person without specialized knowledge, these schemes cause a stupor. This is not to mention the fact that you independently connect the Stropuva heating boiler. In general, it is still better to use the services of experts in this matter. By the way, opinions have been heard more than once on the forums about the complexity of strapping this equipment.

Bubafonya stove with a water jacket

Bubafonya pyrolysis oven from a gas cylinder with a water jacket.

Finally, we got to the domestic analogue of the Stropuva boiler, which is much easier to design, since it has a non-folding pipe for supplying air to the furnace.

There are already so many instructions on how to make a Bubafon stove with your own hands that only a blind man did not see them, unless, of course, he was interested in this topic.

And all why? Because the process is so simple and if you get down to business seriously, you can get a finished product from scratch in a day. What the Bubafonya stove is not made of with your own hands:

- from a gas cylinder;

- from a barrel;

- from pipes.

It can be either round or square. We will not repeat the same thing, just read the article: "Bubafonya stove from a gas cylinder" - and everything will become clear to you.

Today we will consider a version of a product with a water circuit, as if we will try to repeat the principle of operation of the Stropuva boiler. All that is required is to make a simple Bubafon and insert it into a larger pipe.

Thus, we get a gap in which the coolant will be heated.

Naturally, this space above and below is welded so that various debris does not get there. What is important when making a do-it-yourself Bubafonya oven with a water jacket:

- use of heat-resistant steel;

- wall thickness not less than 4 mm;

- availability of a tap for draining and replenishing water.

Immediately provide a hole in the upper part through the outer and inner walls for installing a chimney into it. There should also be enough space for water. The distance from the outer to the inner wall is about 10 cm. When connecting, do not confuse the supply and return pipes (supply from above).

Comparison of the Stropuva boiler and the Bubafonya furnace

We will start our analysis with the scope. If we are talking about a residential building, clearly, the advantage belongs to the Stropuva boiler.

The characteristics of this unit allow it to work for a long time on one load, it is stable and reliable. At least there have not been any cases of complete refusal yet.

The principle of operation of the Stropuva boiler allows you to connect to it both high-temperature heating and a hot water supply system with underfloor heating. Bubafonya cannot boast of this.

Rather, it is suitable for heating greenhouses, garages, maximum summer cottages. For more serious projects, it is simply not applicable. The advantages of the Stropuva boiler design:

- continuous work on coal for 5 days;

- temperature stability;

- convenience of loading fuel, compared to Bubafony.

There are also disadvantages, such as the complexity of the piping, the need for a separate room and the impossibility of repairing until a complete stop. It is also impossible to add fuel while the stove is in operation and therefore it is necessary to re-ignite it every time after a new load of the furnace.

But at the same time, for serious projects, of the two compared units, only the factory Stropuva furnace is suitable.

But the invention of Afanasy Budyakin is great for utility rooms, since the Bubafonya stove can be made quickly and inexpensively, which in this case is of decisive importance.

Source: https://utepleniedoma.com/otoplenie/kotel-stropuva-ili-pech-bubafonya

How to start the boiler Stropuva

First you need to purchase a piping kit for connecting the equipment with the heating system. We recommend buying a kit with the ability to connect an indirect heating boiler. It includes a set of pipes, a safety group, an expansion tank and a circulation pump. Also on sale are kits for connecting warm floors.

It is not recommended to use raw firewood - this will become an obstacle to the normal operation of the boiler.

Ignition is carried out in the following way - here's a short instruction for use:

- We load a full firewood combustion chamber with the air distributor raised.

- We fill up the finished masonry with sawdust.

- We open the flap for switching to firewood.

- Open the air damper 3-5 cm.

- We kindle the top layer, cover the loading door, leaving a gap 3-5 cm wide.

- We wait for a steady combustion, close the loading door and immediately lower the air distributor.

Please note that the cleaning door must be closed. A new portion of firewood can be thrown into Stropuv's boiler at any time, but it is dangerous to do this with coal

In any case, the manufacturer recommends to always wait for the final burnout of the fuel before adding a new portion.

A new portion of firewood can be thrown into Stropuv's boiler at any time, but it is dangerous to do this with coal. In any case, the manufacturer recommends to always wait for the final burnout of the fuel before adding a new portion.

Universal boilers Stropuva

The advantages of the multi-fuel series include the ability to operate the boiler on almost any type of solid fuel:

- Angle.

- Pellets.

- Wood waste.

- Firewood.

The universal solid fuel boiler Stropuva, according to research and consumer reviews, can be attributed to the most economical types of heating equipment manufactured by Stropuva.

The use of exclusively wood waste is not allowed. A small amount of good quality solid fuel will need to be added with each firebox. Universal dual-fuel boilers Stropuva coal-firewood need regular maintenance.

In practice, it has been proven that coal is the best choice for a combi boiler. This type of fuel significantly increases the battery life from one tab, as well as the efficiency of heat transfer. In normal mode, without extreme loads, the unit is capable of operating up to 130 hours. The firebox has a capacity of 220 kg. It is not allowed to lay coal during the combustion.

Installation and operation of boilers Stropuva

When installing and connecting, you must adhere to the basic rules that apply to all solid fuel units. In the building there are two taps for supplying and returning the coolant, and connecting to the central heating of the house.

Installation of an overheating protection system is mandatory. If necessary, install circulation equipment.

A check valve and a coarse filter must be installed in the boiler piping. For the universal and pellet model, you will additionally need to purchase and install an air manifold.

The chimney is located at the rear of the body. Installation of the chimney with insulated sandwich pipes is recommended.

Cleaning from carbon deposits is necessary after each burning out of fuel. It is carried out through a special hatch located at the bottom of the boiler.

The kindling is carried out as follows:

- The air damper opens, and the draft regulator is fixed in the raised position with the help of a cable.

- Firewood is laid in layers. As a rule, large logs are located in the center of the firebox, small ones along the edges.

- The top layer is filled with sawdust and chips. Throwing up firewood until the already laid fuel has burned out will not work, due to the internal structure and the principle of operation of the unit. Therefore, it is immediately necessary to completely fill the firebox (except for the first kindling).

- The reason for the lack of draft may be the accumulation of soot in the chimney, as well as insufficient heating of the chimney. Therefore, it is recommended to leave the damper open until the firewood is on fire. This will provide good traction and reduce condensation.

About firewood

As mentioned above, the quality of the fuel is of great importance. And for the efficiency of the heating equipment, and to increase its service life. This is especially true for firewood - a very unstable type of fuel. The efficiency of the boiler depends on a uniform supply of fuel, moreover, equalized in terms of its calorific value.

This is most important for modern high-tech heating devices, burdened with automation.

Firewood, however, differ in their technical qualities - humidity, specific heat of combustion. That is why manufacturers of boiler equipment insist on choosing high-quality fuel.

Pellets and fuel briquettes - more efficient fuel for a wood-fired boiler

The simplest way to achieve this requirement is to choose artificial "logs" - pellets, fuel briquettes.

You can read more about the differences between firewood and their types in the article Pros and cons of various types of solid fuel for boilers: wood and its derivatives.

In the manufacturer's recommendations, as a rule, there is an indication of how long the logs are suitable for the particular model of the firebox. There are variants of boilers that fit meter-long logs into the combustion chamber.

A log of a log of strife

Wood of different tree species has a different density, which means - the ability to produce heat. But, in addition to it, other features of firewood are important that affect the operation of the boiler: the amount of non-combustible (ballast) substances and the presence of resins that contaminate the chimney and the internal structure of the device during combustion.

Birch firewood

Birch has dense wood, so it burns hot and emits a lot of heat - 3750 kcal, even if the wood is damp. It is highly flammable. But when burning such firewood, especially damp, tar is released - a substance useful in medicine, cosmetology or for protecting surfaces from decay, but extremely harmful to the insides of the boiler.

Soot on the boiler heat exchanger

Alder firewood

Burning alder wood practically does not emit soot. Moreover, burning alder wood helps to clean the chimney. Alder is highly flammable, burns well and emits a sufficient amount of heat - 2100 kcal.

Aspen firewood

Burning aspen, like alder, cleans the chimney. But by themselves, such firewood, when burning, emit a little heat - up to 1650 kcal.

Pine firewood

They burn well and quite hot (3800 kcal), but pine wood is resinous, and a lot of soot is formed during combustion.

Firewood in the warehouse meter

Spruce firewood

Spruce firewood is comparable in quality to pine firewood, but it has a slightly higher specific heat of combustion - 3900 kcal, moreover, it is less resinous.

Poplar firewood

Poplar burns hot, but burns out quickly.

Apple and pear firewood

Firewood from fruit trees - apple or pear - has dense wood, which means it emits a lot of heat, burns and smolders for a long time. But these breeds are usually grown for the sake of fruit, so such firewood is not common. Another feature: the trunks of pears and apple trees are gnarled, the chocks do not prick well, and the logs turn out to be knotty, it is difficult to stack them tightly in the firebox.

Oak, beech, ash firewood

Oak, beech, ash have dense wood; when these species burn, a lot of heat is released - up to 3600 kcal. Of the minuses of oak or beech firewood, one can name their rarity on sale and the difficulty in splitting and melting the boiler with them.

Taking into account the described qualities of wood as fuel, a good owner stores different types of firewood: some - so that they easily flare up, the second - so that they burn for a long time and hot, and still others - to periodically clean the chimney from soot.

Strapping in a natural circulation system

This configuration is considered simplified as it does not have a circulation pump. The user will need to organize the system in such a way that the movement of the coolant occurs arbitrarily without force support. The same applies to the outflow of cold water. A typical set of additional equipment in this system is a combination of an expansion tank and a radiator. Electrical connections are excluded, as is the connection to the network in principle. Before piping the boiler, accurate calculations are made of the diameter of the pipes, the slope of the laying contours and the scheme of interaction of the collectors with the water supply system.It is assumed that the heating unit will supply the coolant to the radiators at the upper point, and receive cold streams from the central pipeline at the lower point.

Work reservation

The Stropuva boiler will delight you with a long burning fuel. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to drop. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. Upon detecting a drop in temperature below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small, if you do not forget about laying firewood for 2-3 days. Most of the time, the boiler will burn, providing consumers with heat. Therefore, one should not expect huge expenses. In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a capacity of 2-3 times lower is quite enough, so as not to rattle teeth by the morning. We also recommend that you work on insulating your home so that it retains the accumulated heat for a longer time.

Features of piping a gas boiler

Since gas equipment runs on explosive fuels, special protective devices are provided in its communication system. Initially, the installation should be organized in such a way as to provide a direct discharge of combustion into the chimney or ventilation channel. This is also necessary to remove the remnants of the gas itself. As for protective systems, the piping of gas heating boilers in the circuits for connecting to the power grid is performed with a fuse and a voltage stabilizer. If you plan to use the unit on liquefied gas, then in the basic configuration you should dismantle the nozzles and install a gas valve. The boiler body itself is insulated with heaters and protected by a metal frame.

How to light a boiler

In cycling, the most difficult thing is not to ride, but to start and finish the movement. So it is with the boiler - the most difficult thing is to melt it. Do not expect that lighting the boiler will take you little time: you will have to allocate about an hour for this procedure.

Heating a wood boiler is a responsible occupation

Commencement of the furnace - ash removal and preparation of the boiler for operation. After the ash pan and combustion chamber are cleaned, you can proceed to kindling.

Heating up the boiler furnace and chimney

For your own comfort and proper start-up of the boiler, you need to warm up its firebox and chimney. If the heater is not equipped with a forced smoke exhaust system, in order for the fuel to start burning, it is necessary to create a draft. The formation of thrust is based on Archimedes' law: heated gases become lighter and tend to "float". For their movement and removal, heating devices operating on fuel combustion are equipped with a chimney.

Boiler diagram. Photo of the site www.viessmann.ru/

The design of the boiler is such that the path for smoke is difficult: on its way there is a heat exchanger and a convective surface of a complex shape, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult for the smoke to move. Therefore, if the boiler is not warmed up, the combustion products are looking for the easiest way. And more often than not, smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a flood (a small furnace that serves to warm up the chimney) with a door, opening which you can burn a small amount of flammable fuel (for example, paper) directly in the chimney itself. When using flooding, the inside of the chimney is warmed up.

If such a possibility is not provided, then a kindling is laid in the firebox - crumpled paper, birch bark - something highly flammable. On top of the kindling - chips and splinters, then logs of small thickness. The combustion chamber must be filled with firewood to no more than half of the estimated volume.

At the moment of kindling, you need to open the chimney gate and the blower valve, ensuring the flow of combustion air.

There are tips to open the window in the boiler room before starting the furnace, if there is one: do not forget that oxygen is needed for the physicochemical combustion process.

How to properly heat the boiler with wood

It takes about 5 cubic meters of air to burn a kilogram of firewood. If the air flow into the boiler furnace is made from the boiler room, then it is imperative to arrange supply ventilation - especially if there are no windows in the boiler room or they are sealed (with double-glazed windows).

After placing the logs, the kindling is ignited. When a stable combustion appears, the door of the firebox must be closed and the bookmark must be allowed to burn out.

Achievement of design power

As soon as the combustion chamber and chimney have warmed up sufficiently, you can proceed to the main stage of the boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main laying of firewood is already complete in order, according to the instructions for the device, to fill the combustion chamber.

After the fuel has ignited, the boiler will reach its design power after a while. Now the combustion process will take place on its own for some time. How long depends on the volume of the combustion chamber and the principle of operation of the boiler. After the firewood bookmark burns out, you need to make a new one.

A properly working boiler is a source of heat and comfort in a country house

Important! When lighting up, do not use ignition liquids or flammable gasoline, diesel fuel, etc.

The principle of operation of the boiler Stropuva

After the flame has sufficiently flared up, it will begin to burn from top to bottom.

Both the original and the analogue of the Stropuva boiler work on the same principle. First you need to load the firebox with bitter. Let's make a reservation right away that this can be done only after the boiler has completely burned out the previous supply of fuel, since the source of smoldering should be at the top. To start up the boiler you need:

- pull the ring and lift the telescopic air duct;

- remove ash through the lower door (1-2 times a week);

- fill the firebox with wood or coal, depending on the model of the unit (there are wood and universal ones);

- set fire to paper or cloth soaked in gasoline from above;

- lower the air duct and close the doors.

From one load of firewood, the boiler works a little more than a day, from a briquette - up to two days, and on coal - as much as five days.

As the fuel burns out, the air distributor moves down until it reaches the bottom. The air supply is controlled by a bimetallic plate. The developers have increased the efficiency due to the fact that an air heating chamber is built into the Stropuv boiler device. The latter enters the furnace at a temperature of about 400 degrees. At this temperature, pyrolysis gases ignite. But, unfortunately, the plate loses its properties and every month you need to make adjustments in the settings, and after a year, completely replace it with a new one.

Due to the fact that the air is supplied in a metered manner, it is possible to avoid temperature surges that occur during the operation of ordinary solid fuel boilers. Therefore, the piping scheme of the Stropuva boiler does without an accumulation tank, the so-called heat accumulator for the heating system.

Modern autonomous home heaters are energy-saving units with high efficiency.

Infrared lamp heaters for the home, unlike lamp TVs, are the latest heating equipment. Here you will find both types and characteristics.

Solid fuel boiler Stropuva design and principle of operation

Introduction

Solid fuel boilers Stropuva noticeably differ from other solid fuel heating devices and not only in their original color. Their design is also very unusual. Today we will try to figure out what are the advantages of their design and what are the disadvantages.And the real owners of Stropuva heating boilers will share their experience of using them with the readers of kotlydlyadoma.ru.

The history of the Stropuva boiler began in 2000 in Lithuania, when it was invented and patented. Since then, thanks to its original technology, burning duration, high efficiency and energy independence, these devices have taken a worthy place in the heating equipment market.

Features and benefits of sling boilers

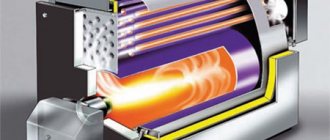

The main difference between the boiler in question is the innovative top combustion. In addition, the sling heat exchanger has a rounded shape. These factors made it possible to achieve the maximum duration of the equipment autonomous operation, significantly increasing its energy independence and efficiency.

Confirmation of the efficiency and profitability of sling boilers are all kinds of certificates, numerous awards and, of course, many positive user reviews. However, factory-assembled equipment is quite expensive. And why waste money if the boiler can be quickly assembled with your own hands.

You can verify the effectiveness of top combustion with a simple experiment. To do this, you just need to take two matches and set them on fire. Hold one with fire up, the other with flame down. The match that you turn down with fire will burn out much faster.

Solid fuel boilers long burning STROPUVA

In the boiler, the fuel is burned in layers. First, the surface part burns, and only after that the flame passes to the lower layers. This allows ensuring the most rational fuel consumption and achieving high efficiency even when operating the boiler at minimum power.

Design

Design

Boilers of this type have an extremely simple design, but their efficiency does not suffer from this. As the fuel burns out, a special telescopic distributor will drop down, providing air supply directly to the combustion site, and not to all the fuel, which will also contribute to the most economical fuel consumption.

The boiler heat exchanger has a rounded cylindrical shape. This eliminates the risk of explosion of the unit from excessive internal pressure of the coolant.

Despite the fact that the finished unit has relatively large dimensions, its design remains very ergonomic and original. The aesthetic cylindrical shape, the minimum number of protruding elements, the compactness of the placement, the almost complete absence of contamination in the boiler room - all this is also the indisputable advantages of the unit in question.

Benefits

Solid fuel boilers STROPUVA

Sling boilers have many advantages, including:

- very high efficiency. It reaches 90% or more, which is a very impressive figure, especially when compared with other solid fuel boilers;

- the maximum battery life for its class on one fuel load;

- independence from power grids and automation equipment (for wood-burning models);

- ease of use and maintenance;

- operational safety;

- reliability and long service life.

Stropuva S

Solid fuel boilers sling do not need to be connected to all sorts of automation systems. The mechanism of action of the equipment is based on the thermostatic characteristics of the metal, which gives a number of advantages. Among the main advantages, it is necessary to highlight the absolute independence from electricity. This advantage becomes especially noticeable when it is necessary to equip the heating system in places with problematic power grids or where there is no electricity at all.

That is, a home-made slingshot boiler can be successfully used where there is no access to any other sources of heat, except for solid fuel.Moreover, such a boiler is able not only to effectively heat the premises, but also to heat the water.

In the homeland of this equipment, in Lithuania, due to the rather high cost of other energy resources, many people install low-power sling boilers even in ordinary apartments.