In order for solid fuel to ignite and continue to burn (be it firewood, wood waste, coal or peat), oxygen must be supplied to the combustion chamber. To obtain the desired temperature of the coolant in solid fuel boilers, more and more sophisticated automation is used with the use of fans and smoke exhausters. However, there is a compact mechanical device - a draft regulator, which maintains the set temperature in the heating system with quite acceptable accuracy without using electricity.

The principle of operation and functions of draft regulators for solid fuel boilers

The control of the boiler damper or the door of the furnace blower by the operator (fireman) changed the amount of oxygen in the furnace and changed the temperature of the coolant in one direction or another (due to more or less intense combustion). The operating principle of a mechanical device capable of doing this job is also quite simple.

This is what a standard mechanical top-positioned tag adjuster looks like. There are also side models.

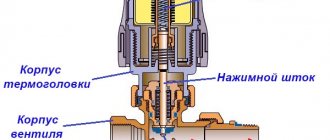

Such a thermostat consists of the following parts:

- sleeve with a heat-sensitive element;

- mechanical amplifier for temperature change;

- calibrated knob setting temperature;

- a spring, the compression of which will determine the level of the task;

- a lever with a chain that controls the ash pan (blower) door.

The setting of the coolant temperature is set by the regulator knob, which compresses the spring with the required force. The difference between it and the strength of the cold thermosensitive element is large, so the lever mechanism opens the damper by a chain to a certain large angle. A lot of air enters the firebox, intensive combustion occurs. As it heats up, the linear dimensions of the sensitive element increase, the difference between the set and operating temperatures becomes zero. The ash pan door, smoothly lowering, takes a position corresponding to the given one and then reacts to temperature deviations.

The functions of the draft regulator include the following tasks:

- stable maintenance of the set temperature of the coolant in the control range, preventing it from boiling;

- control of the power and efficiency of the boiler due to the supply of oxygen, achieving complete combustion of the fuel, which reduces its consumption.

Important. Not all solid fuel units are initially equipped with a mechanical draft regulator, so the user is tempted to use a safety valve as a draft regulator, which relieves excess pressure when the coolant boils. Such savings will result in the fact that in the event of a real emergency, it will work late or not work at all, which will entail serious repairs at least.

Modern draft regulator design

Outwardly, this device is a kind of small float, which is tied to a strong metal chain. We can say that control and adjustment of the device is easily carried out with just one movement of the hand.

Important! The draft regulator is designed in such a way that its mechanism sensitively reacts to changes in its position, so it must be used with increased care and attention.

If you move the regulator very strongly in relation to its initial fixation point, you can provoke quite unexpected and unpleasant consequences. During the heating process, every detail must be under the vigilant control of the user himself.There can be no trifles and nuances in this matter, since the safety of the whole house and the people who live in it depends on the correctness of actions.

The draft regulator for solid fuel boilers with your own hands can be quickly and efficiently made even in your garage. To implement this idea, you will need a minimum amount of consumables and a fairly simple set of basic tools that are in every home. The work itself will take you just a few hours.

The mechanism will consist of the following elements:

- The regulator body itself, which is made of durable and reliable metal.

- The head of the device is made of plastic.

- Sleeve, which is made of brass or another material that is heat resistant.

- Lever made of good metal, allowing for control action.

- The chain attached to the lever will serve to directly control the mechanism.

The draft regulator for solid fuel boilers, the instructions for collecting parts of which are quite simple, are done independently without much difficulty. Finding the elements of the device is quite simple - they can even be found in your garage. The main task is to sharpen the sleeve well. It should fit perfectly into the hole provided for it, and not be too large or too small. When the liner size is poorly matched, problems with oxygen control begin.

Feedback on the use of mechanical draft regulators: advantages and disadvantages

The owners of solid fuel boilers speak favorably about the device of various manufacturers and recognize its usefulness in creating comfortable conditions in a private country house.

Table 1. Advantages and disadvantages of mechanical thermostats for solid fuel boilers.

| Benefits | disadvantages |

| Low cost for the provided comfort | The declared characteristics are carried out in full, subject to the instructions, no shortcomings have been identified. |

| Complete independence from power supply, complex electronics and automation | |

| Accessibility for understanding the installation and use of the device for untrained consumers | |

| With proper installation and operation, it will last for a long time | |

| Due to the simplicity of the design, usually high quality workmanship |

If the boiler package does not include a draft regulator, then when purchasing separately it is necessary to choose from those recommended for this unit. However, the only negative point is that not all solid fuel boilers are equipped with a threaded socket, which is necessary for using a thermostat.

This is how the seat for the lateral draft thermostat looks like.

Installing a prepared draft regulator

The location of the regulator on the boiler itself can be strictly vertical or horizontal. This factor directly depends on where a small hole is provided for subsequent installation.

The installation of the regulator is quick and easy:

- Horizontal option. The fixing screw is in the upper position.

- Vertical option. The fixing screw is located on the other side.

- When you take the regulator out of its packaging, you may notice that the lever has been removed. This makes the packaging look more compact. The lever is fixed with a screw in the desired position so that the mount itself is exactly in the flat part.

- The chain is attached so that the position between the choke and the lever is exclusively vertical. To begin with, the chain is fixed to the lever, and fixing directly to the damper is necessary when setting up the device.

Important! In any manual for regulators of different modifications, the maximum damper mass is indicated, which is allowed with the active use of the draft regulator. You should immediately pay attention to this factor.

How to choose the right mechanism

The possibility of installing a mechanical thermostat is indicated by the presence of a sleeve welded into the boiler drum from the side, front or top, in addition, the ash pan door must open upwards. For units in which the blower door opens to the side, there are still no serial regulators. The space around the housing should allow the device to be easily mounted and adjusted.

The selected device must meet the following requirements:

- The internal thread of the sleeve defines the external thread of the regulator.

- The design and power of the lever mechanism should allow unhindered fully raise and lower the blower door, so look at what force the mechanism is designed for and compare it with the weight of the blower door.

- Most regulators operate reliably in the 60 ° -90 ° C range.

The choice of model and brand of device depends on the user's preference and the purchase budget. Experience shows that it is enough to take any of the well-known thermostats, all of them are quite accurate, of high quality and reliable (in view of the simplicity of the design as a whole).

Types of regulators and features of choice

If the basic configuration of the solid fuel heater is not equipped with a draft regulator, the device will have to be installed independently.

A prerequisite for this is

:

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are produced that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

On the left is the boiler with the possibility of installing a regulator, on the right - with manual control

When choosing a model, pay attention to the following parameters

:

- the effort that the drive develops (the value is indicated in the passport, it should be enough to lift the ash pan door);

- temperature range of heating the coolant (60-90 ° С);

- working stroke of the actuator (it should be enough to fully open and close the damper);

- type of threaded connection on the body - it must correspond to the thread in the sleeve of the boiler unit (usually 3/4 ″).

The design of the draft regulator can provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the boiler water jacket. With these models, the immersion sleeve is removable.

Related article: Heating circuit elements

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of more and more complex systems for automatic control of heat and hot water production processes. They are more accurate and do not require user participation in most operations. However, such systems are becoming more and more dependent on electricity and more expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. It works reliably in the range of 35˚-95˚С, operating temperatures from –20 ° C to + 150 ° C. It can be used with various antifreezes, and the thermostatic element can be replaced. Requires heating when used in low temperature environments. Installed in any position, does not need service. Fits into a 3/4 in. Pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuels, due to its extreme simplicity, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device is mounted vertically and horizontally, the scale of temperature levels allows this. The temperature control range of the heating agent is 30–90 ° C, the maximum operating temperature is + 120 ° C. Coupling with internal thread G3 / 4 ”. Device weight 0.42 kg, manufacturer - Czech Republic.

Cost: from 1500 rubles.

Honeywell FR 124

High quality mechanical thermostat from Germany, compatible with many domestic and foreign boilers. The water temperature control range is from +30 to + 90 ° С, the maximum operating temperature is +115 ° С. Chain load from 100 to 600 grams, lifting stroke up to 60 mm. Standard installation in threaded sleeve G 3/4 ". The peculiarity of this regulator is the presence of a removable immersion sleeve, for replacement of which it is not required to drain the water from the boiler. Device weight 0.47 kg,

Cost: from 1900 rubles.

Traction force

The thrust force depends on various factors:

- Flue gas temperatures.

- Chimney cross-sections.

- Weather conditions (humidity, outside temperature, etc.).

The influence of these parameters on the operation of heating devices can be different, therefore, it is always necessary to consider the specific conditions for the operation of communications. One more parameter should be noted, which often escapes the attention of consumers, but has a significant impact on the traction force - the type of boiler equipment. As practice has shown, the dependence of the operation of gas and solid fuel boilers on their type is as follows:

- During the operation of gas equipment, the thrust force fluctuates slightly, the indicator can be considered stable. This is due to the fact that the flue gases generated during the operation of the boiler have practically the same temperature. Unevenness can occur only when the chimney is warming up and is short-term.

- Solid fuel boilers show different data. It is impossible to unequivocally judge the influence of absolutely all models on the traction performance. This is due to the use of different types of fuel (wood, peat, coal, pellets, sawdust). Also, the heterogeneity of indicators may depend on the type of solid fuel boiler.

- Regardless of the type of boiler and the type of solid fuel, there are a number of similarities. The most important are the following: the long time required for the fuel to ignite, a significant temperature difference between the exhaust flue gases at the beginning of the operation of the equipment and after the boiler has returned to normal operation.

- When operating solid fuel boilers, there is a possibility not only of a decrease in thrust and deterioration of the combustion process, but also of the appearance of hyper-thrust. A sign of such a phenomenon is loud noise during the operation of the equipment, and the most "pleasant" consequences are smoke and increased fuel consumption.

Installing a draft regulator allows you to get an important advantage - to compensate for the features of boiler equipment, fuel, chimney.

Prices: summary table

| Model | Regulation range | Max sensor temperature | Weight, kg | Cost, rub. |

| ESBE ATA 212, Sweden | 35–95 ° C | 150 ° C | 0,38 | 2 800 |

| Regulus RT4, Czech Republic | 30–90 ° C | 120 ° C | 0,42 | 1 500 |

| Honeywell FR 124, Germany | 30–90 ° C | 115 ° C; | 0,47 | 1 900 |

How to install and adjust the regulator

In most cases, installing a thermostat with your own hands entails emptying the boiler water jacket. This will not create a big problem if the piping of the solid fuel boiler is done correctly and the water heating system can be cut off with taps. Otherwise, you will have to drain all the coolant. After that, the plug is removed from the sleeve, and instead of it the device is screwed in and the system is refilled with water.

To adjust the draft regulator, you need to ignite the boiler and follow the instructions:

- Without attaching the chain to the door, open it to allow air to enter.

- Loosen the locking screw on the adjusting handle.

- Set the handle to the position corresponding to the required temperature, for example, 70 ° C.

- Watching the boiler thermometer, connect the chain drive to the damper when it reads 70 ° C. In this case, the flap should only be slightly open by 1–2 mm.

- Tighten the fixing screw.

Attention! It must be ensured that the chain free play does not exceed 1 mm.

Next, you should check the operation of the thermostat in all modes, up to the maximum. It should be borne in mind that between the moment the damper closes and the temperature drop of the coolant, some time passes and do not rush to reconfigure the device. Solid fuel heat generators tend to lag, because firewood or coal in the firebox cannot go out at once.

Principle of operation

Draft adjustment is carried out by changing the degree of rarefaction of gases in the pipe. For this purpose, a stabilizer is built in between the chimney from the firebox and the entrance to the chimney. It can be operated in manual or automatic mode.

The chimney draft regulator is a damper (valve) built into a separate housing. When the thrust is increased, the valve opens slightly and releases a portion of air from the room. The gas flow cools down, the lifting force from the thermal component decreases, and the ejection rate decreases. Conversely, with the closing of the valve, the flow of cold air decreases, the force of the outlet increases.

Note! That is, when the valve is closed, the maximum output of combustion products is ensured. Fully open damper - minimum gas flow.

It is advisable to install the draft stabilizer on solid fuel boilers operating:

- on coal;

- wood;

- pellets;

- peat or coal briquettes, etc.

This is due to the presence of a time at which the boiler reaches the planned output and, accordingly, a stable operating mode. That is, the oven must melt.

How does it work

It seems very difficult to control the process of burning coal or wood. At all times, the boiler setting was purely individual for each boiler, it was carried out manually and required a lot of experience and skill. As a good result, maximum efficiency was achieved in combination with fuel economy. However, with an incorrect setting, most of the heat simply flew into the pipe.

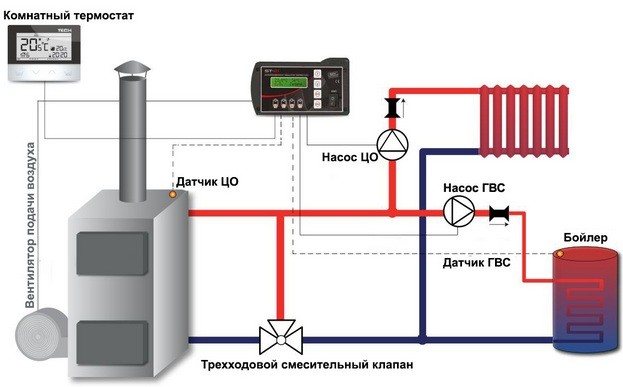

The automation process, which has long become commonplace for all other types of boilers, has reached solid fuel boilers. It turned out that it is enough to use a very limited set of tools and sensors to ensure a controlled combustion process, increase the safety of boilers and precisely maintain the temperature of the water in the heating circuit.

Automation for solid fuel boilers includes:

- blower fan;

- controller;

- circulation pump (optional);

- draft regulator (optional).

The principle of operation of the automation is extremely simple. It is enough to take over the airflow control, to control the volume of air entering the combustion chamber in order to ensure the optimal fuel combustion and the safety of the operation of all boiler equipment.

The fan is installed instead of the standard damper through which fresh air enters the combustion chamber. The controller controls the fan and, in accordance with the settings, is able to change the volume of the incoming air:

- If it is necessary to obtain the maximum heat output, the fan is turned on at full speed and delivers a large volume of oxygen-rich air. Active combustion of fuel is accompanied by an increasing output of thermal energy

- In operating mode, the fan switches to moderate speed and maintains combustion at the optimal level necessary to obtain the desired temperature of the coolant.

- In the event of overheating or a decrease in the target water temperature in the circuit, the fan stops and without oxygen access, the fuel barely smolders, releasing a minimum amount of heat.

A similar cycle repeats over and over again, providing albeit stepwise, but regular combustion control.

The reference data for the controller are the readings of the water temperature sensor in the boiler. Actually, this is enough to ensure the normal operation of the automation. In addition, some types of automation control the temperature of the outgoing gases entering the chimney, the temperature outside the house and inside the room. In this case, additional protection and safety is provided, as well as the possibility of extended boiler settings with automatic correction of the target water temperature in the boiler, the ability to control heating to maintain a comfortable temperature in the house.

In addition to a controlled fan, the automation can control a circulation pump to promote a constant and even distribution of heat throughout the heating circuit. By increasing or decreasing the rate of circulation of water in the circuit, it is possible to influence the efficiency of heat transfer from the combustion chamber to the coolant, directly increasing the efficiency of the boiler.

Additional functions of the solid fuel boiler automation unit may include:

- GSM-module for remote control of the boiler operation and the possibility of remote setting.

- Scheduling the operation of the boiler, according to the schedule, setting the desired temperature depending on the time of day and day of the week.

- The introduction of a solid fuel boiler into the general control system "Smart House".

Automation scheme

With automation for solid fuel boilers, it is no longer necessary to constantly and independently monitor its operation, adjust the settings of the dampers, and worry that the fuel will be wasted or clearly ineffective. In addition, real cost savings are obtained, because with accurate regulation and constant control of fuel combustion, less fuel is spent, it is used more efficiently and purposefully. The controller monitors the water condition and controls the combustion process 24 hours a day every day throughout the entire heating season.

The cost of automation for solid fuel boilers, if we take offers in the middle price range, is comparable to the cost of fuel per half of the heating season or even a third. If we take into account that when using the controller, fuel is saved for heating, then the equipment will pay off in literally two to three seasons. And yet, the main advantage remains that the user does not have to, as before, check the boiler operation every half hour or hour and correct it in the hope of obtaining the desired water temperature, moreover, with a large error.

Automation for solid fuel boilers is more often produced by manufacturers who are not directly involved in the production of boilers. These are firms and companies that, in principle, specialize in process automation. Therefore, it will be useful to find out a list of the most common and already proven manufacturers of command controllers on the market.

What is a chimney draft stabilizer

A draft stabilizer or a breaker is a special mechanism that performs a secondary supply of air in certain doses, which makes it possible to maintain an optimal draft in the chimney for the operation of a boiler or furnace in an automatic mode without human intervention. The breaker is equipped with a safety flap to prevent overpressure.

Chimney draft stabilizers are universal, made of stainless steel and can be used with any heat generating device, they need a minimum area and are quite easy to install. The devices are able to function at an operating temperature of up to 500˚C, as well as in heating systems with heat-generating condensing-type devices, in which the temperature of the burned gases is below the dew point.