Russian-made gas boilers cannot be compared with well-known foreign brands, no matter how much we want the opposite. They are less efficient and only a few models have an efficiency higher than 90%. They have simple automation, which in most cases does not imply protection against overheating or freezing, against stopping the circulation pump. The heat exchanger is often made of the simplest short-lived steel alloys, much less often cast iron.

Nevertheless, there are significant advantages in the form of a 20-60% lower cost, ease of installation, availability of spare parts and a developed service structure. Some of the most successful domestic models have excellent, even by European standards, characteristics and have been serving without problems for more than 7 years.

Distinctive features of Russian gas boilers

The most important feature is the low cost of domestic boilers. It is achieved through the absence of customs duties, often lower transportation costs, cheaper labor, lower component costs, and lower technology research costs. Nevertheless, every year Russian models are becoming more efficient and functional, and prices in currency terms remain practically unchanged.

Adaptation to domestic conditions is also important: to low pressure of natural gas in the pipeline, voltage drops. Many Russian models, unlike rare foreign ones, are non-volatile, i.e. do not require connection to the mains, the automation is powered by a heating thermocouple.

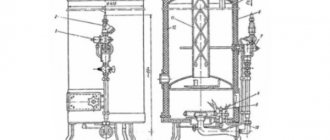

The device is based on the example of the domestic double-circuit model Conord KSts-g-30N: the minimum number of components, simple materials, uncomplicated non-volatile automation.

A simple design and principle of operation is the key to easy and quick troubleshooting. Finding a competent specialist is not a problem even in regions remote from the capital.

However, Russian gas boilers have a lower efficiency, on average by 4-6%, which means not only lower heating capacity, but also often higher gas consumption. Domestic models are less automated and less secure. Starting in most models is done manually, with the help of piezo ignition, as mentioned earlier, there are usually no additional protective functions.

Reviews of domestic gas boilers: advantages and disadvantages

Based on the technical characteristics, installation practice and owner reviews, you can visually weigh all the pros and cons of the boiler units:

| Benefits | disadvantages |

| The overwhelming majority of models are available to everyone, a lower cost in comparison with analogues. | Optimal, but still lower efficiency in comparison with foreign counterparts |

| Huge selection of non-volatile models | Lower reliability and build quality, shorter lifespan |

| Boilers operate at almost any gas pressure in the pipeline | Lack of options with modulating burners |

| There are successful parapet models that can be used for heating apartments. | Limited automation, which affects not only ease of use, but also gas consumption |

| Low cost of components, you can find and replace them without problems, in a short time | Almost all models are floor-standing single-circuit, heavy and require more boiler room space |

| Finding a competent specialist in the regions is not a problem | Usually there is no protection against overheating or freezing, stopping the circulation pump, protection against backdraft |

| In practice, noisier work is noticeable, in most models there is no heat and noise insulation |

Conord

Conord was founded in 1979.

This is a manufacturer from Rostov, engaged in the production of units with two circuits and one, of different capacities. The boilers have useful features that save up to 20% of fuel. The kit includes an additional coil.

Conord specializes in the production of steel gas boilers for heating a private house with a cast iron heat exchanger. The units do not depend on the power supply network, which means there is a piezo ignition and a stably burning igniter. Open burner.

Floor standing gas heating boilers from Russia of the Conord brand have a capacity of 8-30 kW.

A single-circuit gas boiler of Russian production is represented by the names KSts-G-8, KSts-G-10, KSts-G-12, KSts-G-16, KSts-G-20, KSts-G-25, KSts-G-30 and can to equip areas of 30-300 m² with heat. Boilers with two circuits are called KSts-GV-10, KSts-GV-12, KSts-GV-16, KSts-GV-20, KSts-GV-25, KSts-GV-30.

The best Russian manufacturers and models: characteristics and prices

Lemax

One of the best and best-selling Russian gas boilers for heating a private house. has been specializing in the production of climatic, including heating, equipment for over 20 years.

Known for boilers with fairly competitive characteristics, good reliability and affordable cost. Most models use well-known Italian automatics, more expensive models have overheating protection, an anti-freeze mode, auto-ignition, a safety valve and an air vent are installed from the factory. If you have the necessary funds, it is better to choose a model from this particular manufacturer.

Lemax Premium-16 model.

One of the best and most demanded models is Lemax Premium-16 - a floor-standing gas boiler of Russian production with a capacity of 16 kW with an open combustion chamber. The boiler has an excellent efficiency of 90% for a floor-standing version at a flow rate of 0.95 cubic meters m / h, the model is considered one of the most economical and is ahead of many successful foreign models of the same power in terms of this indicator. The range includes similar models with a capacity of 10; 12.5; 20; 30 kW. The owners also note the almost silent operation.

Among the disadvantages is a steel heat exchanger, which, although covered with an inhibiting anti-corrosion compound, cannot be compared with copper or cast iron. Build quality and design leave a lot to be desired. The burner is not modulating (not power controlled), which could further reduce the gas consumption. In practice, there are many examples of trouble-free work for 5 and even 7 years. Cost: 19-22 thousand rubles.

Wall-mounted Lemax PRIME-V24.

Practically unique and very successful is the Lemax PRIME-V24 wall-mounted model - a double-circuit boiler with a closed combustion chamber with a capacity of 25.5 kW. In addition to Lemax models, there are practically no mounted options on the market, not to mention successful and worthy of attention. The boiler efficiency is 92.5% with a gas consumption of 1.4 cubic meters per hour, which also makes it one of the most economical. It features a modulating burner (with power control), which often allows it to be kept lit at low power - the most efficient and economical mode of operation of gas boilers.

The automation is equipped with the functions of auto-diagnostics, auto-ignition, protection against overheating and freezing, it is possible to connect an external control, for example, a room thermostat. There were no drawbacks, in addition to the simple design and the relatively high price, for the practice of use. Cost: 31-35 thousand rubles.

Parapet Lemax Patriot-12.5.

Another unique option among Russian-made gas boilers is the parapet non-volatile Lemax Patriot-12.5 with a capacity of 12.5 kW. An excellent solution for heating an apartment. Efficiency 87% at a gas flow rate of 0.75 m3 / h, a closed combustion chamber with the removal of combustion products through a coaxial (side) chimney. Known for its reliability, compactness and virtually silent operation. Cost: 16-19 thousand rubles.

How to calculate the required boiler power Individual calculation, formula and correction factors

Zhukovsky Machine-Building Plant (ZhMZ)

On the territory of Russia, the Zhukovsky Machine-Building Plant has been operating for more than a dozen years and is known for floor-standing single-circuit gas boilers. All models are reliable and non-volatile, produced in three series: Economy, Universal and Comfort. In practice, most models work for 8-11 years, after which the resource of the steel heat exchanger ends and it leaks - this is a feature of almost all steel heat exchangers.

Floor-standing ZhMZ AOGV-17,4-3 Universal N.

The best and best-selling model is the single-circuit ZhMZ AOGV-17.4-3 Universal N with a power of 17.4 kW (and its analogues of other power). 80% efficiency at a maximum gas flow rate of 1.87 cubic meters. m / h, it can also run on liquefied gas. Differs in a vertical layout, which is why it takes up a much smaller area in the boiler room. Before the expiration of the resource, the steel heat exchanger rarely needs repair, the owners note a little noisy work. Cost: 20,000-21,000 rubles.

Borinskoe

Gas boilers of this company are known as one of the cheapest domestic models, but at the same time they are quite reliable, have high characteristics and the well-known non-volatile Italian automation EuroSIT, also used by the leading manufacturer Lemax.

Floor-standing Borinskoe AOGV-11.6-1 (M) Eurosit.

The most successful is the single-circuit non-volatile Borinskoe AOGV-11.6-1 (M) Eurosit with a capacity of 11.6 kW with an open combustion chamber - the simplest and most reliable option. The model has a relatively high efficiency - 90% at a gas flow rate of 1.17 m3 / h. In practice, there are examples of trouble-free operation for more than 8 years, the boiler is relatively quiet. There is a protection against overheating of the heat exchanger. Average cost: 14-16 thousand rubles.

A newer and better analogue is the double-circuit model AKGV - 11.6-1 SABK GVS with an efficiency of 90% and a gas flow rate of 1.2 cubic meters. m / hour. Differs in a copper secondary heat exchanger - more heat conductive and durable. Equipped with successful domestic automatic equipment "SABK". The rest is practically no different from the previous model. Average price: 17,000 rubles.

"Signal"

The boilers of the Engelsk Heating Equipment Plant are unremarkable "average". They have good technical characteristics, average reliability, limited functionality, but also the lowest price on the market for domestic gas boilers.

Signal KOV-16 SKs.

The best model is considered to be the classic single-circuit non-volatile Signal KOV-16 SKs with a power of 16 kW. The boiler efficiency is 90% at a flow rate of 1.8 cubic meters. m / hour. It is equipped with the same well-known Italian automatic equipment "EuroSit 630". An important drawback is the non-standard 1/2 ”gas connection. Cost: 14,000-16,000 rubles.

Overview of gas boilers "Signal" Average performance at one of the lowest prices

Conord

Rostov manufacturer of one of the most inexpensive models of floor-standing gas boilers. Differs in relatively high performance and simplicity. However, the quality and reliability of the models is not always satisfactory. Cases of unstable operation of automation, depressurization of the heat exchanger or incorrect ignition after 4-6 years of operation are not uncommon.

Also, many owners who have encountered malfunctions complain about the slow and unsatisfactory operation of the service. Nevertheless, in view of the excellent characteristics for an extremely low cost, the boilers of this manufacturer are worthy of attention, especially if long-term operation is not expected.

Floor standing Conord KSts-G-16S-3.

The most successful model is the floor-standing single-circuit Conord KSts-G-16S-3 with a 16 kW steel heat exchanger. The boiler efficiency is 90%, at a flow rate of 2 cubic meters. m / hour. Cost: 17-18 thousand rubles.

Rostovgazapparat

Another manufacturer from Rostov-on-Don, whose plant was founded at the end of the 19th century, has a huge selection of gas boilers in its assortment. Known for efficient, simple and reliable, but not the cheapest floor standing gas boilers.

Siberia 11.

One of the best models is the 11.6 kW non-volatile Siberia 11. Efficiency 90% at a gas consumption of 1.18 m3 / h. Equipped with reliable Evrosit automation. Nevertheless, the high price in comparison with peers does not allow it to take pride of place in the ratings. In practice, there are many examples of work over 9-10 years, despite the steel heat exchanger. Average cost: 20-22 thousand rubles.

Overview of gas boilers Siberia One of the most reliable domestic boilers

RGA 17K.

A good analogue is a model of another line - RGA 17K with a power of 17.4 kW and an efficiency of 90%. Differs in efficiency, the maximum gas consumption is 1.76 m3 / hour. The owners note reliability and quiet operation. Cost: 15-19 thousand rubles.

Lemax

Lemax was founded in 1992 in Taganrog.

The Lemax manufacturer puts on the market heating products with an acceptable cost, while the boilers have established themselves as reliable and highly functional. In the assortment line you can see several series of units. Almost all of them are floor-standing and with an open combustion chamber.

Gas floor-standing single-circuit boiler Lemax Leader-25

All models differ in power, cost and other characteristics:

- Floor-standing gas boiler Lemax Premium Nova series have an open combustion chamber, designed only for heating (single-circuit). The series is represented by models with power from 7.5 to 30 kW. A feature of these units is the presence of a thermomanometer, which is needed to monitor the pressure in the heating system. Models imply the connection of a turbine head.

- Lemax Premium is a floor-standing single-circuit Russian gas boiler. Also has an open combustion chamber. Powered by natural gas. The line includes units with a power from 7.5 to 60 kW. All models are equipped with a removable top panel, cladding details. The efficiency is high due to the improved design - the heat exchanger has become larger and a new turbulizer has appeared.

- Lemax Premium (V) is a gas floor boiler (made in Russia). There is an open combustion chamber, one circuit. The boilers operate on natural gas. The series has five boilers with a capacity from 12.5 to 30 kW. Here the temperature controller is located on the front panel of the unit with a temperature indicator. This makes it possible to set the desired heating mode.

- Single-circuit floor-standing gas boiler Lemax Leader is made of high-quality cast iron 4 mm thick. In it, the heat exchanger is covered with a special solution that prevents rust from appearing. The units have gas valves from the Italian concern Sit. All models have different powers from 16 to 50 kW and high efficiency (up to 91%).

- Lemax Prime-V 24 is a double-circuit gas boiler. It has a closed combustion chamber and is wall-mounted. Power 24 kW. Domestic wall-mounted gas boiler of this series can heat an average area of 240 m². Has an efficiency of 92.5%.

More details about the features of gas boilers with a cast iron heat exchanger can be found here.

Prices: Summary Comparison Chart

| Brand name | Model | A type | power, kWt | Gas consumption, m3 / hour | Cost, rub | Our rating (0-5 points) |

| Lemax | Premium-16 | floor | 16 | 0,95 | 20 000 | 4,5 |

| PRIME-V24 | wall | 25,5 | 1,4 | 32 000 | 4,6 | |

| Patriot-12.5 | parapet | 12,5 | 0,75 | 17 000 | 4,5 | |

| ZhMZ | AOGV-17.4-3 Universal N | floor | 17,4 | 1,87 | 20 000 | 3,8 |

| Borinskoe | AOGV-11.6-1 (M) Eurosit | floor | 11,6 | 1,17 | 15 000 | 4 |

| AKGV - 11.6-1 SABK GVS | floor | 11,6 | 1,2 | 17 000 | 4 | |

| "Signal" | KOV-16 SKs | floor | 16 | 1,8 | 15 000 | 3,9 |

| Conord | KSC-G-16S-3 | floor | 16 | 2 | 18 000 | 3,6 |

| Rostovgazapparat | Siberia 11 | floor | 11,6 | 1,18 | 21 000 | 4,1 |

| RGA 17K | floor | 17,4 | 1,76 | 16 000 | 4,2 |

Features of the production of gas boilers in Russia and abroad.

The production of boilers for heating is the main activity of many modern enterprises. In this regard, a fairly wide range of these products is presented on the construction market. Since the production of boilers involves the use of high technologies and the use of many methods of manufacturing parts, a huge variety of models is presented to the attention of buyers, which differ quite strongly from each other in functionality, quality and price. The latter factor often has a very significant impact on the choice of our compatriots.

Modern production of gas boilers is aimed at automating the working process of heating equipment. Thanks to this, all products responsible for providing heat in the house can now function independently, that is, with minimal human intervention. In the event of an emergency, such a technique is able to notify the owner of the incident itself - sound and light signals will be transmitted to the control center.

The production of gas boilers is considered a fairly profitable business. This is not surprising at all, since a greater number of Russian consumers prefer this product. The reason for such popularity of these devices is that gas boilers have many advantages: they are easy to install, easy to operate, require minimal maintenance, and, thanks to the use of cheap fuel, they are also economical.

The production of heating boilers abroad is quite different from what we have in our country. Therefore, it is simply inexpedient to purchase foreign products with a sufficiently high cost. Compatriots are better off giving preference to products created at Russian factories, because during their development, the climatic conditions of our homeland and the design features of heating systems were taken into account. This means that the boilers are heating. made in Russia, have maximum adaptation to our environment and will serve here much better than imported counterparts.

Domestic production of heating boilers is aimed at providing heating equipment to owners of suburban real estate and private houses, the total area of which does not exceed three hundred and fifty square meters. The majority of consumers who purchase Russian-made boilers are residents of cities and urban-type settlements with an average income level.

The production of heating boilers is so popular in Russia for another reason. The fact is that gas, which acts as a fuel in these systems, is by far the most common fuel, which, among other advantages, has a low cost and fairly high efficiency. And since our compatriots are used to receiving benefits from all their acquisitions, it is not surprising that they give their preference to gas boilers. Due to the high demand for products manufactured by heating appliance factories, these enterprises are flourishing.

As the last argument explaining the popularity of the production of gas boilers, one can cite the problem with constant uninterrupted energy supply in our country.The fact is that heating systems that use gas as a fuel are completely non-volatile, which means they are able to provide a room with heat, regardless of the availability of electricity. All these characteristics make these devices ideal for domestic consumers.

620026, Ekaterinburg, Belinsky-76, tel. 269-40-80

STEK "Sverdlovsk Heat and Power Company"

1.Production of hot water and steam boilers up to 2MW

2.Reconstruction of existing boiler houses with their transfer to solid fuels

3.Installation of a fluidized bed furnace with a fiery mass and sharp blast for boilers DKVR, KE (replacement of furnaces Pomerantsev, Sherstnev, shaft furnace, etc.), in which it is achieved

- Kiev, Starokievsky lane, 5, tel / 81/86, f.243-48-86

LLC "KOMINVEST" has been successfully operating in the Ukrainian market since October 1990.

Main activities:

Design, installation and commissioning of boiler houses, individual heating points, pumping stations, heating, water supply, sewerage;

Advantages and disadvantages of using atmospheric single-circuit gas boilers

Having decided to buy an atmospheric single-circuit gas boiler in Moscow for a private house, you will get the following advantages:

- the ability to select a boiler with an optimal power value;

- full autonomy in work;

- in the case of connecting an indirect heating boiler, it becomes possible to simultaneously use more than two points of water intake without loss of pressure and temperature surges

- a cast-iron heat exchanger with a competent organization of the boiler room can serve for more than 20 years.

The disadvantages of this type of heating systems include:

- the construction of a full-fledged chimney and the purchase of an indirect heating boiler increases the cost of an atmospheric single-circuit boiler, the price of which is already high;

- the need to allocate a separate room for the boiler room;

- introduction of means to protect the boiler heat exchanger from sudden temperature changes.

The most popular brands of floor-standing gas boilers

Consider the products of the most famous Russian companies that produce floor-standing gas boilers.

Heating devices "Lemax"

Gas boilers Lemax are manufactured at an enterprise in Taganrog. They are produced with cast iron and steel heat exchangers. Lemax products are divided into 3 series:

- Premium class boilers with power up to 40 kW are made of high quality steel and covered with an anti-corrosion coating. They are equipped with protection against overheating, cessation of traction and the formation of soot.

- Premium Nova equipment has an open firebox, steel circuits and special automation.

- Single-circuit gas boilers Leader 40 are capable of heating a room with an area of up to 390 m². The primary Czech heat exchanger is made of cast iron. Despite the fact that the Leader 40 does not depend on electricity, it consumes a little gas.

Zhukovsky plant products

Zhukovsky plant produces reliable and low-cost devices that work autonomously and do not depend on power supply. The most powerful of them are capable of heating an area of up to 600 m². Floor standing gas boilers are presented in three main lines:

- Economy class units - equipped with foreign SIT automation;

- Universal class devices - equipped with the automatic Mertik Maxitrol system;

- Comfort class boilers are equipped with automatics developed in their own production.

The efficiency of the two-circuit models is 88%. This is enough to get hot water after opening the tap. Floor standing gas boilers produced by ZhMZ are produced in the form of a cylinder or a square. The entire range is equipped with steel heat exchangers only.

Equipment

The lineup of the Conord plant has a wide range of capacities. The boilers are equipped with a steel heat exchanger and have an efficiency of 91%. Single-circuit units are equipped with Italian-made automatics. Double-circuit ones are equipped with SIT automation.She monitors the safe operation of the unit. In the event of a malfunction or breakdown, the automation stops the operation of the boiler.

Conord heating devices are capable of operating even with low fuel pressure in the pipeline. They have compact dimensions, low noise level and beautiful appearance. The video shows how to replace the old AOGV model with a new one.

Floor standing boilers "Signal"

Signal gas units are produced in Engels. They produce single-circuit and double-circuit boilers with power from 6.4 to 40 kW. Units of the presented brand are equipped with steel heat exchangers, burners, safety sensors and an automatic control system. They are comfortable, easy to use and can last for almost 20 years.

Borinsky gas boilers

Floor-standing single-circuit and double-circuit gas boilers are produced in Lipetsk. The capacity of the Borinsky devices will be enough to heat a room from 90 to 300 m². There are models that are equipped with both imported and domestic automation. The presented gas boilers are distinguished by high efficiency, simplicity, reliability and economy. Their automation ensures high safety, as well as accurate and stable operation.

The disadvantages of "Borinsky" floor gas boilers include high sensitivity to gas quality and susceptibility to corrosion.

Learn about single-circuit and double-circuit industrial boilers here

How to choose a floor-standing gas boiler and not be mistaken

Features and principle of operation of a floor-standing atmospheric single-circuit gas boiler

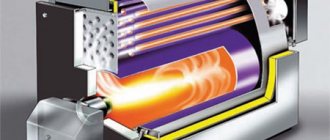

Due to the fact that atmospheric single-circuit gas boilers are distinguished by the presence of an open combustion chamber, for their installation it is necessary to equip a separate boiler room. This is due to the fact that in order to maintain the combustion process, air is taken from the room where the boiler is installed by its natural draft. If the room is poorly ventilated, there is a high risk of poisoning by gas combustion products or oxygen deficiency.

By installing an atmospheric single-circuit gas boiler in a private house, its price will vary greatly. The cost is influenced by the burner operation scheme. There are three types of burners:

- single-stage - they work exclusively at their full capacity;

- two-stage - can operate at 100% capacity and half capacity;

- modulating - the burner operation power depends on the programmed coolant temperature and can be in the range of 20-100%.

Cast iron is used as a heat exchanger material in floor-standing atmospheric single-circuit gas boilers. This is due to its long service life and acid resistance. However, such heat exchangers have disadvantages: low strength and fear of sudden temperature changes. These disadvantages of cast-iron heat exchangers must be taken into account even at the stage of equipping the boiler room.

Requirements for the installation of a floor-standing atmospheric single-circuit gas boiler

For ease of operation and to ensure the safest possible operation of an atmospheric single-circuit gas boiler, installation is carried out based on the following rules.

- The area of the room and the ceiling height of the boiler room must be at least 7.5 m3 and 2 m, respectively.

- The obligatory presence of supply ventilation, the calculation of the performance of which is carried out as follows: for every 10 kW of boiler power, 12 m3 of fresh air must enter the boiler room. In this case, it is necessary to add its excess amount from 20 to 40%. For example, for a 40 kW boiler, ventilation installation with a capacity of 58 m3 of air / hour will be required.

- The distance from the installed atmospheric single-circuit boiler to the nearest wall is at least 30 cm.

- When organizing a boiler room in the basement, an emergency exit must be provided.

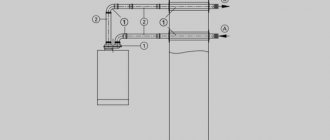

Features of the organization of the chimney of an atmospheric single-circuit gas boiler

In order to realize natural draft for normal operation of the burner with an open combustion chamber, only traditional chimneys are allowed. Their construction requires additional investment, so the final price of a floor-standing atmospheric single-circuit gas boiler increases significantly.

To ensure the normal operation of the chimney, implement its construction taking into account the following requirements:

- at least 1 m there must be a straight section from the boiler, after which the chimney pipe is bent;

- when the chimney passes through the wall, a fire seal of at least 50 cm is applied above and below the hole where the chimney is located;

- from the axis of the boiler to the axis of the chimney, located already from the street, the distance should be no more than 2 m, otherwise the natural draft of the smoker is reduced;

- to prevent the appearance of condensation, the entire section of the pipe outside the room must have thermal insulation;

- mandatory presence of a pocket for cleaning the chimney and condensate drainage;

- acid-resistant stainless steel or ceramics should be used as a chimney, due to the acidic origin of the flue gas condensate.

Domestic manufacturers of solid fuel boilers

The principle of operation and design of domestic and foreign boilers are almost identical. Regardless of the manufacturer, the scheme of operation of solid fuel units is the same. The difference lies in the thoughtfulness and debugging of the combustion process.

The highest quality solid fuel boilers of Russian production are made of cast iron. But, in most cases, high quality stainless steel is used for the production of the heat exchanger.

The entire range of products of domestic manufacturers can be divided according to the following criteria:

- Combustion principle - Russian-made solid fuel boilers are made in classic and pyrolysis versions.

- Automation - heat generators are equipped with mechanical draft regulators. The latest models of the Teplodar, Termofor, Medved companies are offered with automation that makes the operation of the boilers as autonomous as possible.

- The design of the combustion chamber - the consumer is offered boilers with top and bottom loading. One of the most popular solutions is a shaft-type heat generator. These models are unpretentious in terms of fuel quality, it is allowed to use firewood with a moisture content of up to 42%.

- Fuel - Most manufacturers produce single fuel and multipurpose models. So, two-fired boilers Phantom, from the F.B.R.Zh. company, are absolutely omnivorous. By means of built-in automation, the combustion mode is selected, which is optimal for each type of fuel. It is allowed to use coal, wood waste, fuel briquettes, etc. These are the same characteristics that distinguish the Trajan models.

- The material of the heat exchanger - Russian-made cast-iron solid fuel heating boilers, is practically not produced. The domestic manufacturer focuses on the production of cheaper models from structural or stainless steel. There is a partial complete set with cast iron inserts: grate bars and a hob.

- Power - high power boilers are represented by the Gazgen and Geyser models. Low-power boilers, you can choose from the Bourgeois-K, Teplov and others series.

- Complete set - heat generators offered by Lavoro are assembled according to Italian technology. Automation and some of the most important components are supplied from the factories of Lavoro's partner located in Italy.

- Equipping with a tubular heater - in the configuration of the best boilers of the latest development, a built-in heating element is provided. The automation that controls the combustion process, after the combustion of the main fuel, gives a signal to turn on the electric heater. Heating of the house with electricity continues. This function is provided in products Bastion, Termofor, etc.

Domestic companies have almost completely abandoned the use of cast-iron heat exchangers, therefore, the buyer is mainly offered steel pyrolysis solid fuel boilers of Russian production.

Rating of aggregates produced in the Russian Federation

Organizations produce a large selection of floor-type products of Russian origin, intended for heating residential and non-residential buildings.

The following models are widely used:

Lemax AOGV (15.5)

High-quality outdoor gas unit manufactured in the Russian Federation. The burner device and control unit are made in Italy. The product is equipped with a tubular heat exchanger with a wall thickness of 2mm.

The maximum power of the boiler unit is 15.5 kW. The model does not require an electrical connection. Differs in reliability and ease of use.

Lemax premium (25)

Russian-made model with high efficiency. Has a steel heat exchanger with an increased area. The unit is equipped with protection systems against exceeding the permissible temperature, accumulation of soot, deterioration of the degree of traction and extinction of the flame. The manufacturer has equipped the model with two working circuits. One is designed to supply the coolant to the heating system. The second is necessary for the preparation of hot water supply. The product is highly reliable and easy to use.

Borinskoe (11.6)

Model of a gas floor boiler of Russian production. A distinctive feature is the heat exchanger made of corrosion-resistant steel. It is characterized by thermal conductivity, which increases the efficiency of the boiler.

The advantages of the boiler unit are low gas consumption, the presence of a device for stabilizing the outlet pressure, no need to connect to electricity, ease of control and safe operation.

ZHMZ (17.4)

The model is equipped with a heat exchanger made of steel. There is a possibility of converting the boiler to use gas from cylinders as an energy carrier. The power of the unit is 17.4 kW. The boiler is used to connect to open or closed heating systems.

Organizations producing boiler units in the Russian Federation

Companies provide a large selection of gas boilers manufactured in the Russian Federation. Various organizations are engaged in the production of boilers. Below are the manufacturers of heating equipment, whose products are in high demand among consumers.

ZhMZ

The company is engaged in the production of heating equipment. Products are completed with Russian and foreign control units. A distinctive feature of ZhMZ models is energy independence. The list of products includes single-circuit and double-circuit floor gas boilers that do not require an electrical connection. This allows the use of boilers in places where the power supply is intermittent.

Zhukovsky plant

The models produced at the factory are distinguished by a low price. Despite this, the boilers have an efficiency of 80 to 92%. This allows you to warm up rooms of various sizes with minimal fuel consumption. High quality materials are used in the manufacture of boilers. This has a positive effect on the service life of the products.

Borinskoe

One of the manufacturers of boiler equipment is JSC "Borinskoye". The company has been manufacturing products for over 20 years. Boiler units are equipped with automatic equipment from foreign manufacturers.

Together with high-quality materials used in the manufacture of components, this makes the models reliable. A distinctive feature of the products of this enterprise is their low cost.

Most models have control units that do not require a connection to a household network. This allows the boilers to be used in conditions of unstable power supply. The heating equipment is equipped with a cast iron heat exchanger.Compared to other parts, a cast iron heat exchanger has a number of advantages:

- resistance to corrosion processes;

- extended term of work;

- high heat capacity.

The company presents gas boilers with one and two circuits. So you can choose a unit for heating and preparation of hot water supply.

Signal

The Heating Equipment Plant produces single and double-circuit gas floor boilers. The products of this manufacturer are distinguished by a good price-quality ratio.

The plant's products are presented in two series:

- "Comfort". Syria consists of units with a capacity of 10, 12.5 and 16 kW. A distinctive feature of the models of this line is high efficiency. This figure reaches 90%. With the correct setting, gas boilers can save up to 25% of fuel;

- "Standard". The series includes boilers of various designs. The power of the equipment, depending on the model, can reach 100 kilowatts. The products have a steel heat exchanger and a modern design. The built-in thermostat allows you to regulate the intensity of the unit and maintain the temperature in the heated room in the desired range.

In comparison with foreign boilers with similar characteristics, the products have a low price. At the same time, the quality of the components remains at a high level.

Lemax

Russian manufacturer of boiler equipment. Most of all products are floor-standing units. The organization produces gas units with two types of heat exchangers - steel and cast iron. In the first case, the wall thickness is 2 mm. A heat exchanger of this type is susceptible to the development of corrosion processes on its surface.

The manufacturer equips the boilers with one or two circuits. The products can be used for both heating and hot water supply.

The cast iron heat exchanger has a wall thickness of 4mm. Its surface is less susceptible to the negative influence of an aggressive environment. Floor-standing units are equipped with section-type heat exchangers. The organization manufactures its products in 2 versions - connected and not connected to the household network. This allows you to choose a model for rooms in which the electricity supply is intermittent. The efficiency of products from this manufacturer reaches 90%. The products are adapted to changes in gas pressure in the system and sudden changes in temperature. In comparison with foreign counterparts, floor-standing gas boilers are distinguished by a low price.

Rostovgazapparat

Manufacturer of gas floor heating boilers for various types of premises. Rostovgazoapparat products are of high quality and reliability. The units are adapted to the pressure drops in the gas pipeline.

Rostovgazapparat produces good products

Heat exchangers of boiler equipment are made of structural steel, cast iron or copper. The most demanded products with cast iron heat exchangers. They are resistant to overheating and corrosion on the wall surface.

Cast iron models are heavy. This requires the manufacture of a solid foundation when installing heating equipment.

The company manufactures single-circuit and double-circuit models. The units are distinguished by a low level of sound emitted during operation. This allows the unit to be used in a domestic environment.

Imported manufacturers of gas heating boilers

I will name a few of the foreign manufacturers of gas boilers. The list is formed alphabetically and does not show the popularity and any ranking of manufacturers of gas boilers.

- ACV (Belgium),

- Ariston (Italy-Italy),

- Baxi (Italy-Italy),

- Beretta (Italy-Italy),

- Biasi (Italy-Italy),

- Bosch (Germany-Germany),

- Buderus (Germany-Germany),

- Chappee (France-France),

- CTC (Sweden-Sweden),

- Dakon (Czech Republic-Czech Republic),

- De Dietrich (France-France),

- Demir Dokum (Turkey-Turkey),

- Ferroli (Italy-Italy),

- Fondital (Italy-Italy),

- Frisquet (France-France),

- Hermann (Italy-Italy),

- Kiturami (South Korea),

- Lamborghini (Italy-Italy),

- Lotte (South Korea-Korea),

- Modratherm (Slovakia-Slovakia),

- Mora (Czech Republic-Czech Republic),

- Navien (South Korea-South Korea),

- Protherm (Slovakia-Slovakia),

- Rinnai (Japan-Japan),

- Roca (Spain-Spain),

- Saunier Duval (France-France),

- Sime (Italy-Italy),

- Vaillant (Germany-Germany),

- Viessmann (Germany-Germany),

- Wolf (Germany-Germany).

© ObOtoplenii.ru