Types of gas boilers

On the market, you can with equal probability find gas boilers of both domestic and foreign production. The cost of both options can vary within a fairly wide range - the final price is influenced by the country of origin, the technical characteristics of a particular model and a set of additional features. The selection of the appropriate option should always be based on these parameters.

One of the classification parameters is the installation method, depending on which there are two main types of gas boilers:

- Floor standing... This category of boilers was originally designed for floor installation. As a rule, floor-standing household gas boilers are rather large, so you have to select a separate place for them. Due to their characteristics, such devices can provide an entire building with heat and hot water. Installation of floor-standing boilers is quite simple, so there are no problems in the process of this work.

- Wall mounted... Such devices have rather compact dimensions, high power and performance indicators. Wall mounted boilers are very popular - they can be found in most private houses. Due to their good performance characteristics, such devices effectively supply the house with heat energy and hot water, and good visual data make it possible to harmoniously integrate a wall-mounted gas boiler into the interior of the room.

In addition to the installation method, gas boilers are also classified by the number of circuits, depending on which two categories of devices are distinguished:

- Single-circuit gas boilers... A distinctive feature of single-circuit boilers is the ability to heat the building and the absence of other possibilities. As the name implies, such devices have one heating circuit designed to heat the coolant and supply it to heating devices.

- Double-circuit gas boilers... This category of devices is a universal solution that allows you to provide a house not only with heat, but also with hot water. Versatility is achieved due to the presence of two independent circuits, one of which is designed to warm up the coolant, which is later transferred to the batteries, and the second - for heating water used in everyday life.

Single- and double-circuit household gas boilers are quite reliable and efficient, so you need to choose the most suitable type, taking into account individual needs. It is only worth noting that both types of boilers are in good demand and can have very different parameters.

Floor-standing and wall-mounted boilers. Differences

To select the method of installing the boiler, you should familiarize yourself with the general requirements for the placement of the heating system. So, the boiler room should be a separate room with an area provided for by fire safety standards, the walls of which should be made of fire-resistant materials. A system for removing exhaust gases is mandatory, and the possibility of their accumulation in the room must also be completely excluded. Based on these requirements, the buyer must provide for a proper room or build an extension outside the residential building. For heating a small building, it would be optimal to purchase a wall-mounted boiler, which is easier to install, and the requirements for it are not so significant. The height of placement is not less than 80 centimeters from the floor, and the space around should be completely free.If a wall-mounted installation is excluded for some reason or the required heating power is simply not possible taking into account the dimensions of wall-mounted boilers, then a floor-standing method of installing a heat source is assumed. In this case, the boiler must be placed on a concrete or metal plate, which creates sides of at least 50 centimeters around the boiler.

Characteristics of wall-hung boilers

Wall-mounted boilers are a ready-made heating system that is easy to install, takes up a minimum of space and is much easier to maintain on the floor. In modern models, it is supposed to be controlled using a remote control to set temperatures, control additional features (for example, protection against freezing of heat exchangers during the boiler shutdown period). It is the best choice for heating an apartment or a small house, and manufacturers take into account their location in the living space and try to give them an attractive design. But it should be borne in mind that such heating systems are very susceptible to fluctuations in the supply of electricity. This leads to their complete shutdown or transfer to the minimum heating mode, which entails damage to the heat exchangers (for example, the formation of condensation due to a sharp change in temperature). So, in case of instability of power lines in a building, it is worth taking care of an uninterruptible power supply.

The main characteristics that you should pay attention to when buying a wall-mounted gas boiler:

- Power. Here you can pick up without stock. If the heat loss of the house is 20 kW, then the boiler can be selected with the same power. If you buy a boiler of higher power, then it is also not scary.

- Functions. Wall-mounted boilers are essentially all plus or minus the same. They differ only slightly in insides. Therefore, you may be intrigued by certain features of certain brands.

- Profitability. Here, all boilers have the same economy plus or minus.

- Noisiness. If you install the boiler in a residential area, pay attention to the noise level of the boiler.

- Heat exchanger type. Basically, all have copper heat exchangers. But some people use aluminum ones. They are slightly worse in performance.

- What the internal parts are made of. Budget models are made of plastic, more expensive ones are made of brass. Plastic is made by itself from the position of reducing the cost, but at the same time scale does not form on it.

Characteristics of floor standing boilers

In the case of heating a large building (more than 300 square meters), it will no longer be possible to get by with a wall-mounted boiler, and the purchase of a floor-standing boiler becomes a necessity. Its installation is complex and quite costly, and improper installation can lead to problems in the form of dampness and insufficient heating due to loss of efficiency. But such boilers have significant advantages, not to mention the greater heating capacity. This is significant design flexibility - the buyer can independently design the heating system based on the building layout and various needs. Independence from the stability of power lines will also be a tangible advantage. It would not be superfluous to mention the durability of such heating systems and the possibility of free replacement of failed components, which significantly extends the overall service life (for example, heat exchangers of good quality can last for several decades).

The main characteristics of floor standing boilers that you should pay attention to when buying:

- Dimensions. The floor makers have a fairly large variation in size. Choose what suits you.

- Chimney requirements. Some boiler models may have high chimney requirements.

- Efficiency. If the wall-mounted efficiency is similar, then the spread is slightly larger. But a rare manufacturer writes an honest efficiency about his boiler. Pay attention to the recommendations of those who already use the same boiler.

- Heat exchanger type. Cast iron or steel.

- Volatility. Advanced floor standing boilers have advanced automation, powered by electricity.

- Power... A margin is usually laid here, since the power in the cold at the boilers decreases.

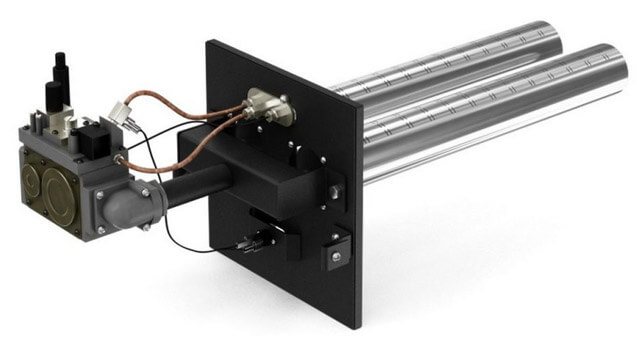

Burners for gas boilers

Gas boilers, regardless of their type, can be equipped with different burner options. The cost of the entire boiler ultimately depends on the quality of the burner and its features. When choosing a boiler, it is imperative to pay attention to the type of burner and its quality. It is better to overpay a little, but so that the burner for the boiler is reliable and durable.

There are two main types of gas burners used in domestic boilers:

- Atmospheric... This category of burners is distinguished by its extreme simplicity of design, and, as a consequence, very low cost. In addition, it is worth noting the minimum noise level of such devices - during operation, the atmospheric burner is almost inaudible. The main feature of atmospheric-type burners also deserves attention - if necessary, they can be quickly changed with your own hands to transfer the boiler to another fuel.

- Inflatable... Inflatable burners differ from the previous ones primarily in power, which is due to the fact that a certain volume of gas is supplied under pressure. Most often, such burners are used to heat houses with a large area, various industrial buildings, etc.

The main disadvantages of floor-standing gas installations

A gas floor heating boiler, both single-circuit and double-circuit, has the following disadvantages:

- the need for installation in a separate room;

- more complex installation compared to the wall-mounted version;

- lack of piping elements in the complete set;

- high cost of automation, which is equipped with the installation;

- volatility (if electricity is supplied intermittently, the boiler automation is unstable).

It is important to remember: despite the fact that floor-standing gas heating boilers are considered safe high-tech installations, their operation must be monitored, since even minor interruptions can disrupt its normal production cycle.

Floor standing gas boilers are very large

Types of heat exchangers

Another parameter that you definitely need to pay attention to is the material for the manufacture of the heat exchanger. This parameter directly affects the efficiency and durability of a domestic gas boiler.

The following heat exchanger options are available:

- Cast iron... Cast iron is a traditional material that has been used in heat exchangers for quite some time. At one time, cast iron was the only material due to the lack of competition, but today it is not used very often.

- Steel... The heat exchangers made of steel are very robust and reliable. Such devices are easily and safely transported, installed without any problems and work quite efficiently. Black steel is susceptible to corrosion, but during the manufacture of the heat exchanger, the material is coated with chromium, which provides it with reliable protection against moisture and air.

- Aluminum... The key advantage of aluminum heat exchangers is a very high heat transfer, due to which the heating of the coolant increases and the efficiency of the heating system increases. By itself, aluminum is strong enough, therefore, products made from it are easily transported, installed and do not deform under physical influences. Aluminum heat exchangers are considered the best option for gas boilers today.

What does one or two circuit boiler mean?

Wall-hung double-circuit boilers

When choosing a gas heating boiler, the homeowner must first decide why he needs such a device - to heat the house in winter or also have hot water supply.

For a water heating system, a device with one circuit is quite suitable. You can, of course, connect a stand-alone boiler, in which water for domestic needs will be heated. But this will take up extra space and increase the cost of installing equipment.

Domestic gas heating boilers with two circuits will better cope with the task of heating a house and simultaneously heating water. In addition, such devices will take up much less space in the room, and ultimately the cost of the equipment will be lower, given that there is no need to purchase a boiler and install it.

A device with two circuits can operate in instantaneous water heating mode or have a built-in boiler inside. Instantaneous heating is beneficial when the demand for hot water is low. Boilers with a built-in boiler are preferable for a large family when the water consumption increases according to the number of people living in the house.

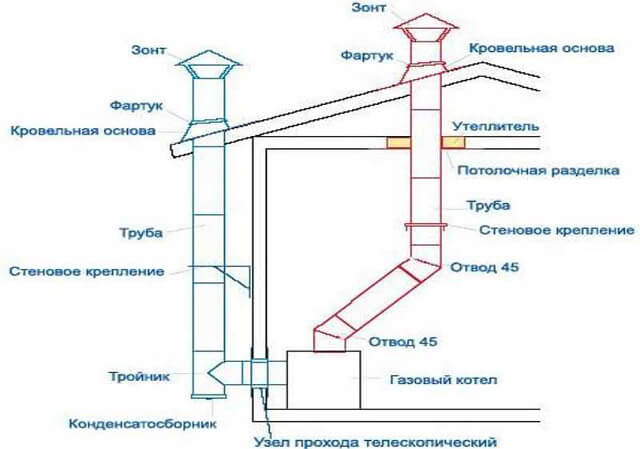

Combustion products removal

The last parameter that you need to pay attention to when choosing a heating gas household boiler is the method of removing combustion products. In floor-standing and wall-mounted boilers, similar designs are used, which differ only in some details.

There are two main solutions for the removal of combustion products:

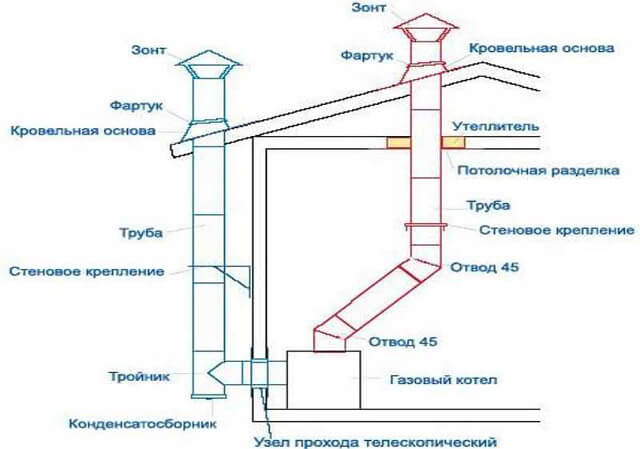

- Natural draft chimney... In this case, the exhaust gases go into the chimney in a natural way. This technology is based on physical laws - combustion products have a lower specific gravity compared to air, so they are drawn into the atmosphere. To realize natural draft, a vertical chimney must be arranged, which ensures the removal of gases.

- Forced draft chimney... The design in the implementation of such a scheme for the removal of combustion products is distinguished by the presence of ventilation units that ensure the removal of exhaust gases into the atmosphere. This system is much more efficient than the previous analogue, but, unlike it, it is volatile - the fan requires electricity to operate. However, the efficiency and safety of gas equipment operation are worth it.

Firebox

One of the main components of any heating unit is the combustion chamber. Depending on the design, it can be open or closed.

Open firebox

If the chamber is open, then the intake of air necessary for the combustion processes is carried out from the room, and the removal of combustion products is carried out through the chimney brought out to the roof.

Advice! The advantage of the open chamber model is its simple design. In addition, such gas heating boilers can be non-volatile. The disadvantage is the need to install the unit in an isolated room, in which it is necessary to equip a supply and exhaust ventilation system. Therefore, by studying consumer reviews and the popularity rating of models, we can conclude that modern homeowners are more likely to choose units with a closed firebox.

Closed firebox

The good thing about models with a closed combustion chamber is that they do not use indoor air. Therefore, such a gas boiler is allowed to be installed in the kitchen or in another suitable non-residential area.

The air is supplied to the burner of the unit with a closed chamber directly from the street. To ensure the supply of oxygen, gas boilers of this type are installed complete with a coaxial chimney.

This is a device that performs two important functions at once - it provides air supply to the burner, which is equipped with a combustion chamber, and also provides smoke removal.

It should be noted that a unit with a closed combustion chamber is always volatile models. Such a gas boiler is equipped with a fan, thanks to its operation, air is pumped into the furnace, as well as the removal of combustion products.

A significant advantage of a coaxial chimney is that the pipe does not need to be raised to a great height, the chimney must be cut into the outer wall, which has a gas heating boiler. Thanks to this, models with a closed combustion chamber can be installed not only in private houses, but also in apartments.

In addition to the listed advantages, heating units with a closed firebox are more efficient. The fact is that in models with an open chamber, not only combustion products go into the chimney pipe, but also part of the thermal energy.

In models with a closed firebox, heat loss is minimized. Since in units with a closed firebox, a specially designed system for retaining water vapor and its condensation is used. In the process of condensation, additional energy is released, which is used to heat the coolant.

Advice! The efficiency of the models with a closed combustion chamber is about 10% higher than that of conventional units. But the cost of such units is also higher.

The advantages of household gas boilers

Installing a gas boiler is one of the simplest, most convenient and inexpensive solutions to heat a house. In order for the system to be extremely versatile and efficient, it is worth choosing a double-circuit natural gas heating boiler, which can not only heat the house, but also provide its residents with hot water supply.

Regardless of the individual characteristics and equipment, all household gas boilers have the following number of advantages:

- Ease of operation... When using main gas, the system can operate independently - constantly monitoring the fuel supply, the combustion process and other operational processes are not required. Some nuances arise only when using liquefied bottled gas.

- Profitability... Gas is still the cheapest fuel - it outperforms any liquid or solid fuel in terms of price. In addition, gas boilers consume a minimum of fuel, which indicates the high efficiency of such devices. Even with the constant increase in energy costs, gas heating is still the most profitable option.

- High efficiency... Gas, despite its low cost, is one of the most heat-consuming energy resources, which, in addition, is suitable for heating any premises. Provided that the boiler is correctly selected, the whole house will be well warmed up and provided with hot water, and the resource costs will be minimal.

- Equipment availability... In the modern market of heating equipment, gas boilers are presented in a large assortment, so it will not be difficult to choose the best option for specific operating conditions. Also, one cannot fail to note the widest range of prices, which allows you to find a boiler that can fit into any budget.

Parapet boilers

Gas parapet boiler Colvi

These devices are called smokeless boilers and they are the middle link between wall-mounted and floor-standing units. They do not require a chimney device, since the combustion products are removed using a coaxial chimney arranged directly in the outer wall.

Parapet boilers can be placed anywhere in the room - even under the window. They are used mainly for heating small houses and apartments in multi-storey buildings, where it is not possible to arrange a vertical chimney.Their power varies within 7-15 kW, but, despite such a small figure, along with heating the premises, they successfully produce hot water for domestic needs.

Note! The advantages of such devices include the fact that when the gas burner is operating, oxygen is not taken from the dwelling, which is only beneficial to the residents.

The heat exchanger of the parapet boiler is made of 3mm steel.

The uniqueness of these structures lies in the fact that heating and hot water supply can be connected to the gas main and pipelines from either side. Such a design of the parapet boiler heat exchanger allows it to be installed in small kitchens, where it organically fits into the space.

Installation of units

There are no special difficulties in the technology of installing gas boilers, and most of the stages of this work can be carried out independently. To better understand how to install a gas boiler, it is worth reading the corresponding article, which will describe all the smallest nuances and details.

In short, the installation of boiler equipment is always preceded by a number of preparatory work. First of all, you need to do the design - and this is the calculation of the heating system as a whole, and the determination of the required boiler power, and the selection of a place for its installation, and a number of other issues. The installation of equipment is in a sense simpler than all these operations - usually the installation instructions are attached to the boiler, and you can always follow its instructions.

However, despite the possibility of self-installation of gas boilers, it is still best to entrust this work to professionals who have the appropriate qualifications, the necessary experience and the required tools. In order to put gas equipment into operation, it will be necessary in any case to invite specialists from the gas service - only they can confirm the correctness of the installation and issue permits. The ideal solution would be to invite licensed specialists who can both install equipment and put it into operation - this is much more convenient and simpler.

Gas boiler - the main element of an autonomous heating system

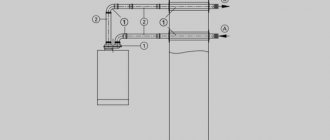

An autonomous household water heating system based on a gas boiler consists of the following main parts:

- heating boiler with pump;

- automation system;

- ventilation system;

- coolant piping;

- radiators.

The main element of the heating system is the gas boiler, which provides heating and circulation of the coolant. Let's consider this unit in more detail.

Purpose and functions of gas water heating boilers

The main task of gas boilers is to heat the interior and provide DHW (hot water supply systems). Household autonomous boilers, gas heat generators use natural gas as fuel supplied to the autonomous heating system of housing from the central highway. The use of gas heating boilers for the household heating system and SGW is due to their following characteristics:

- compactness;

- performance (power) gradation;

- relative ease of installation;

- profitability;

- efficiency;

- ease of use due to a high degree of automation.

Identical industrial equipment differs from household equipment in power, dimensions and technical equipment, therefore, the operation of industrial gas boilers requires professionalism from the service personnel and constant monitoring of the unit's operation.

The use of gas boilers in everyday life should be safe, therefore, the control and maintenance of these units should be simple and not require special skills from the consumer.Modern models of gas boilers, due to the use of special technologies in their production, fully meet the requirements.

Modern heating boilers, in contrast to outdated models, have an efficiency close to 90%. In addition to heating the internal premises, modern household gas-heating equipment of the latter is capable of automatically ensuring the operation of the hot water supply system for housing.

Modern boilers are optimally automated, the degree of automation depends on the purpose of the unit and the performance class. The consumer market for water heaters is represented by household appliances of various types and types. Buyers have a wide variety of models at their disposal, from powerful floor-type household boilers for heating large private houses to compact wall-mounted units for city apartments. For each type of housing and operating conditions, you can choose a boiler of the appropriate type - a single-circuit or double-circuit gas boiler, a unit with an open firebox or with a closed combustion chamber, boilers with cast iron or bimetallic heat exchangers.

Important! The high degree of automation of gas boilers has reduced the proportion of human participation in their operation, but did not reduce its role - the fulfillment of all the requirements for the safe use of gas heating equipment set forth in the operating instructions is strictly mandatory.

Repair and service

Despite the high indicators of reliability and durability, gas boilers still need to be regularly serviced, and sometimes even repaired. The main rule of repair is as follows - since gas equipment is dangerous, in no case should you try to repair it yourself. In addition to the danger of gas leakage, there are more trivial, but unpleasant moments - for example, you can accidentally make a mistake during repairs and provoke a number of additional problems.

If problems arise in the operation of gas heating equipment, it is best to immediately contact the professionals - the domestic market does not lack good specialists who can deal with any problems. Experienced professionals will fix the problem as soon as possible and fairly cheaply.

So that when repairing a gas boiler there are no additional problems, you need to think carefully about its location in advance. One of the conditions for the competent selection of a place for the boiler is the possibility of free access to all its elements. Only if this condition is met, repair work can be carried out quickly and safely.

For work on regular maintenance and monitoring of equipment operation, this requirement is also relevant - if it is not even possible to approach the boiler normally, then the place for it is not chosen correctly. This moment must be thought out in advance and correctly installed the boiler, bringing it to all the necessary communications.

Other aspects of choice

A single-circuit or double-circuit gas boiler should be chosen not only for the listed indicators. It is also important to take into account the possibility of regulating the power of the device. According to this parameter, boilers are divided into types:

- Single stage;

- Two-stage;

- With the possibility of smooth adjustment.

The concept of "single-stage" means equipment with one power level, but if single-circuit gas boilers have two-stage characteristics, this means that they have two power levels. Smooth regulation allows rational gas consumption depending on external changes in temperature and humidity. Important! The gas boiler operates at full capacity for about two months a year. The rest of the time, spending the full amount of power is irrational. It is advisable to take this fact into account when choosing equipment for a private house.

Smooth power control allows economical gas consumption during boiler operation