General requirements for the installation of a wall-mounted gas boiler

Heat generating devices with a capacity of up to 60 kW can be installed in any non-residential area of a house or apartment, with the exception of a bathroom and toilet. For a more efficient installation, you will have to build a special room - a boiler room.

However, both the local area of the boiler and a specially prepared site (boiler room) must meet the following requirements:

- In a gas boiler room or a room allocated for the placement of a boiler, there must be a window with an area of at least a quarter of a square meter. The exact footage of the window opening is calculated by the formula - width x length x height of the room x 0.03. That is, for every cubic meter of boiler room volume, there is at least 0.03 m2 of window area.

- The ceiling height in this area cannot be less than 2.2-2.5 meters.

- The recommended area of the boiler room or dedicated room is calculated according to the proportion of 0.2 m2 = 1 kW of boiler power.

- The fire resistance of the walls at the location of the gas boiler is at least 75 minutes. Fire resistance of the door leaf - at least 30 minutes. If the natural fire resistance of building materials is not enough, then it should be increased by finishing the walls with plaster (layer thickness of at least 10 millimeters) or tiles.

- In addition to the opening window of a certain area in the room / boiler room, there must be a natural exhaust - a through channel in the wall with a diameter of 150 millimeters, complemented by a facade air duct.

- The flow of air into the room will have to be provided using a valve in the wall or a gap under the door leaf. The dimensions of the supply duct are calculated according to the proportion - 8 cm2 = 1 kW of the boiler thermal power.

- The installation height of the wall-mounted gas boiler is chosen arbitrarily, but taking into account the mandatory 100-cm distance of the heater from the ceiling.

- The distance from the heat generating installation to the walls "adjacent" to the supporting surface should not be less than 1 meter.

- The distance from the boiler to the gas mains valve should not exceed 2-2.5 meters.

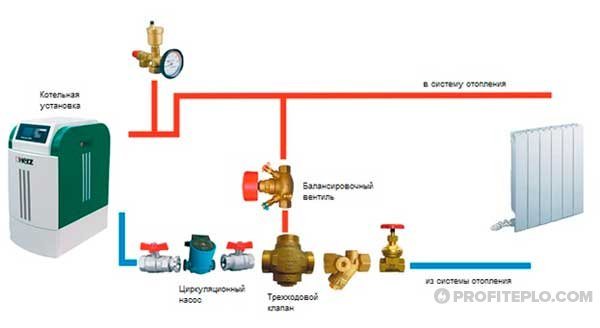

Typical gas boiler connection diagram

Try to follow these recommendations when choosing a place to install the boiler.

... Well, if you do not find a suitable room, then you will have to re-equip one of the rooms in your house, "adjusting" the parameters of the windows, supply and exhaust ducts to meet the above requirements. And only after that you can start installing the heating device and connecting the boiler to the chimney, water supply and heating system.

How to install a wall-mounted gas boiler - process overview

At the very beginning, you will have to deal with the arrangement of the channel for the removal of combustion products.

Moreover, most gas boilers are equipped with a turbocharged coaxial chimney, which assumes the following installation procedure:

- In the supporting surface

(wall), at a distance of 100-120 centimeters from the ceiling, a through hole is made. - From the outside

an external flange is mounted on top of the hole, into which the chimney pipe is passed. - From the outside

the pipe is fixed with a heat-resistant sealant and closed with an outer flange.

To do this, you will have to do the following:

- The boiler is "tried on" to the chimney, joining the exhaust pipe with the flare of the coaxial exhaust.

- At the same time, the position of the left or steam upper corner of the boiler body is marked on the wall. And only one.

- Using the marked mark, the bracket of the heater is attached to the wall, determining the position of the opposite upper point using a level.

- Then you can fix the lower part of the fastening structure.

- Upon completion of mounting the bracket, the boiler is “hung” on the fasteners, fixing its location with screws.

Installation by specialists of the heating boiler

The next step is, assuming the following actions:

- American women are screwed onto the fittings of the hot water and the main circuit - special adapters that facilitate the installation of the boiler.

- Ball valves are screwed to the American women, which shut off the supply of water and coolant, if necessary, dismantle the heating device.

- Two filters are placed under the valve of the inlet fitting of the water heating circuit - magnetic for fine cleaning and ordinary for coarse cleaning.

- A coarse filter is mounted under the valve of the inlet (return) connection of the heating system.

- All free ends of filters and valves are connected to the outlets of the heating system wiring and pipelines of the hot water supply system.

The connection to the gas main, despite the simplicity of this operation, we will not consider. After all, this work should be outsourced to the specialists of the local gas service.

Why not take up the connection to the gas main?

The rules for installing a wall-mounted boiler are simple and straightforward. Therefore, at some stage, there is a temptation to ignore the need to call the gas service specialists and connect the boiler to the main line with your own hands.

However, you should not do this for the following reasons:

- Firstly, some manufacturers of gas heat generating equipment will not supply your unit for warranty service without a note from a gas service specialist about connecting the boiler.

- Secondly, the relevant services may regard the independent installation as a violation of the rules for operating a domestic gas pipeline, punishing the violator of the gas supply agreement for the home in an administrative manner.

- Thirdly, errors in connecting to the wiring of the heating system or water supply threaten only with a local flood in the boiler room. Whereas an incorrect connection to a household gas pipeline, at best, will leave you homeless, and at worst, it will deprive you of your life. And forget about insurance - if you connected the boiler yourself, then the responsibility for the accident lies with you.

Everyone knows the principle that it is better to do everything right once, to comply with all the requirements than to redo it a hundred times later. Unfortunately, not all "kulibins" of our country use it. Often there are situations when an "experienced" homeowner himself knows where to install gas equipment and at the same time violates all conceivable and unimaginable norms. At the same time, there will be no connection permission, and the spent funds cannot be restored. Do not forget that compliance with safety requirements when planning gas heating is not a whim of gas workers, but a well-founded concern for the safety of human lives. In this regard, it is imperative to consult with a specialist and study in detail those requirements that are set for a room with a gas boiler. Let's consider what points to pay attention to when organizing individual heating in order to avoid problems and unnecessary fuss.

Boiler room in a private house. Norms and requirements for it

The best option is to equip a separate room in the house for the boiler room. The characteristics of such a room must correspond to those presented in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP 11-35-76, SNiP 42-01-2002, SP 41-104-2000. These documents are designed precisely to minimize the possibility of any emergency.A room with a gas boiler is considered the most fire hazardous and explosive in the house, therefore, it is necessary to take the most responsible attitude to the choice of a room suitable for the boiler room and to the correct layout. Depending on the total heat output of the gas boiler, the required volume of the room is also calculated. If the capacity of a gas boiler is less than 30 kW, then the minimum volume of the room is 7.5 m3, 30-60 kW - 13.5 m3, and for a boiler with a capacity of more than 60 kW, a room of 15 m3 is already needed.

The second significant indicator when choosing a boiler room is the height of the ceiling. It should be at least 2.5 m. It is worth paying attention to the location of the load-bearing walls in the house. It is desirable that the main walls are located between the boiler room and other rooms. It is important to pay attention to the interior decoration of the walls. The simplest option is refractory plaster.

If the white walls do not fit into the overall interior of your home, then be sure to keep in mind that all materials used must be safe. Do not use flammable and flammable substances. That is, no parquet and laminate flooring, as well as wallpaper and plastic panels, will decorate the walls of the boiler room.

It is imperative to have certain parameters of the door, window and ventilation. The doorway should not be narrower than 0.8 m, and the size of the window is calculated based on the volume of the room: 0.3 m2 per 10 m3 of the boiler room. Be sure to provide a gap of several centimeters between the door and the threshold. This will provide air exchange with other rooms. Do not forget about the flow of fresh air from the street.

Requirements for the chimney and boiler room ventilation

Requirements for the chimney and boiler room ventilation

The combustion products of a gas, liquid and solid fuel boiler must be removed outside the boiler room using a chimney. When designing and arranging it, consider the following nuances:

- the chimney must be above the level of the roof. This is a prerequisite for normal traction;

- bricks, single-walled and double-walled steel pipes, ceramic, asbestos-cement and vermiculite pipes can be used as the material for the chimney. The most popular option is steel, followed by brick. Sometimes single-wall steel pipes are placed in a brick chimney;

- whatever the material, it is necessary to provide an opening for inspection and cleaning;

- if the chimney runs along the wall of the house, then it must be firmly fixed;

- it is recommended that the diameter of the flue gas outlet of the boiler is smaller than the diameter of the flue.

Requirements for the chimney and boiler room ventilation

For an electric boiler, ventilation is not particularly needed, in other cases you will have to carefully study the existing requirements:

- boiler room ventilation can be combined with the general supply ventilation of the house;

- it is necessary to provide 3 times air exchange in 1 hour, i.e. if the volume of the boiler room is 15 m3, then 45 m3 of air should be supplied to it per hour. It is necessary to maintain the combustion process, part of it is necessary for the hood;

- for the organization of natural draft ventilation in the wall opposite the boiler, a hole with a diameter of 13-15 cm is made at a boiler power of up to 40 kW and 17 cm at a higher power. A special ventilation pipe with a damper and a mesh is placed in the hole;

- if the boiler room is a separate room, then ventilation can be organized thanks to the presence of louvered grilles at the bottom of the entrance door. For 1 kW of boiler power, I provide 8 cm2 of the area of the ventilation hole;

- when using general house draft ventilation, the size of the hole is calculated based on the proportion: for 1 kW of boiler power, 30 cm2 of the hole;

- forced ventilation should work more efficiently, will not depend on various weather factors, but will consume electricity. To save a little, you can synchronize the operation of the boiler and ventilation so that the fan turns on only when the boiler is running. When using gas and diesel boilers, the fan is placed in the casing to prevent ignition.

Requirements for the kitchen when installing a gas wall boiler

If the number of residential square meters is limited and it is not possible to allocate a whole room for a source of heat and hot water, then the way out of the situation will be to place a wall-mounted gas boiler in the kitchen. This option is allowed by regulatory documents, but subject to certain requirements. We can say that this is a simplified version of the boiler room, therefore, the requirements for the room will be similar.

- Ceiling height - 2.5 m or more;

- Kitchen area - 4 m2 or more;

- The ventilation area is calculated according to the boiler output - 8 cm² per 1 kW. It will be located in the upper part of the room;

- A window with a window is required;

- Depending on the power of the boiler, the chimney cross-section is calculated: 30 kW - 130 mm, 40 kW - 170 mm;

- The chimney pipe must exceed the roof ridge by half a meter and have a protective umbrella.

The choice of a specific place for a boiler in the kitchen must be approached based on the following criteria:

- the distance to other gas units is at least 20 cm;

- distance to flammable surfaces - 20 cm;

- distance from the wall - 30-50 cm;

- avoid places in niches, gaps between walls, and in the immediate vicinity of a window.

The advantage of installing a gas boiler in the kitchen is also the presence of pre-installed communications: water, electricity, ventilation. And this is a direct cost savings.

The nuances of installing solid fuel boilers

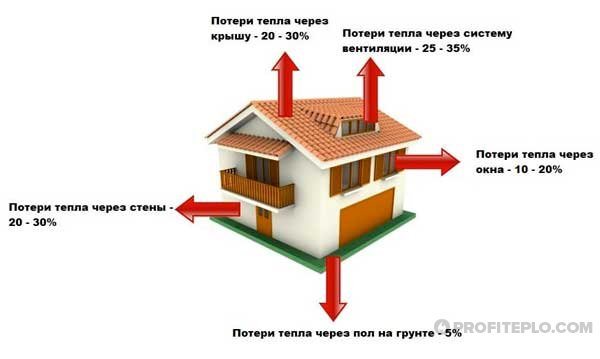

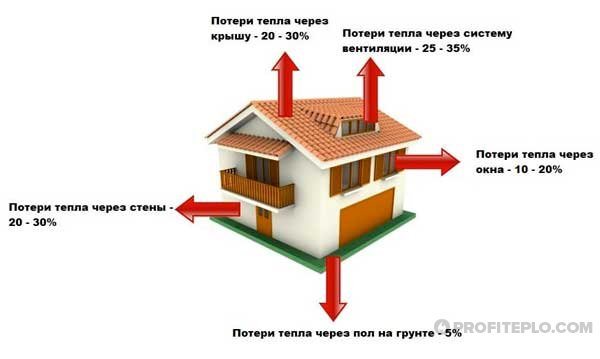

Installing a solid fuel boiler can be done by hand, but at the same time factors affecting the efficiency of the heat generator should be taken into account

:

- type and quality of fuel, completeness of its combustion;

- wind rose and wind strength;

- design features of the chimney;

- the level of protection of the building from heat loss.

Home protection from heat loss

Good traction is a prerequisite for the most complete combustion of solid fuel, at which high heat transfer is ensured. Burning wood in conditions of oxygen deficiency leads to an increased formation of carbon monoxide and soot, a decrease in the heat transfer of the fuel. So that the coolant does not overheat to a boil during the operation of solid fuel boilers in the optimal mode, a buffer tank is installed in such heating systems, the water in which absorbs excess heat. The heat accumulator gives up the accumulated thermal energy to the water circulating in the heating circuit within a few hours after the fuel fill burns out. This makes it possible to reduce the volume of harmful emissions and save wood fuel.

When organizing a heating system with your own hands, you should pay special attention to the chimney

:

- ensure thermal insulation of the pipe passing outside the boiler room;

- organize a condensate collection system;

- provide for inspection hatches for cleaning the chimney;

- provide easy access to the pipe on the roof for maintenance.

In the course of designing a heating system, it is important to correctly calculate the diameter of the pipeline - the intensity of circulation and the volume of the coolant depend on this parameter, which is especially important for gravity systems.

Related videos:

Coordination of the boiler installation with the gas service

Before proceeding to the direct installation of the equipment, it is necessary to go through several bureaucratic instances and fulfill their requirements. The first step is to write an application to the local gas service and get the technical conditions for installing the boiler. The application specifies these applicants and a brief description of the house.

Be sure to indicate which gas-using equipment you plan to install (brand, capacity) and attach a list of documents:

- Copies of title documents for the land plot on which the capital construction object owned by the applicant is located (will be located).

- Situational plan for the location of the land plot with reference to the territory of the settlement.

- Calculation of the planned maximum hourly gas consumption (not required if the planned maximum hourly gas consumption is not more than 5 m3).

The second stage is the creation of a project for the installation of gas equipment. For a private house, a plan or diagram of the wire of pipes along the site is being developed, as well as the points of their entry to the place of installation of the equipment. The project is confirmed by the state authorities of the gas service, approved and you can proceed to the direct installation.

Each of these stages takes on average 1.5 - 2 weeks. So if you decide to radically change the heating system at home, then take care of this issue at least a month before the onset of cold weather.

Thus, observing all standards for a room with gas equipment, you will ensure trouble-free operation of the gas boiler. By fulfilling all requirements, protect your family from any emergencies associated with gas equipment. Get rid of administrative penalties and reprimands from gas services for violations of requirements.

Probably, no one will argue about the statement that gas systems are most preferable for use in private houses and cottages. Gas boilers are quite reliable and efficient, have a relatively low fuel consumption and make it possible to regulate the air temperature in the room, which directly depends on the power of the boiler in closed heating systems. What you need to know before installing this equipment will be discussed in this publication.

General requirements

The rules for installing a gas boiler in a private house are strictly regulated. That is why, before creating autonomous heating based on a gas boiler, it is necessary to familiarize yourself with the regulatory documents that must be followed at all stages of the work. First of all, these are: SNiP 2.04.08-87; SNiP 2.04.01-85; SNiP 2.04.05-91; SNiP 41-01-2003; SNiP 21-01-97.

Gas heating systems differ in many ways. During installation, an important point is the number of circuits, the location and method of exhaust gas discharge. Single-circuit boiler equipment is used to heat the premises of a private house. Many models can work with indirect heating boilers to create hot water supply. Double-circuit boilers are designed to create heating and hot water supply at the same time.

Heating equipment for a private house can be wall-mounted or floor-mounted. Floor-standing boilers, as a rule, have a large capacity and dimensions, thanks to the boiler placed in them. Such installations are demanding on the ventilation system of the room in which they are installed, the presence of a natural draft chimney, the fire safety of the enclosing structures and the quality of the base on which the equipment will be installed. Hinged boilers are less demanding, and therefore more in demand among our compatriots.

Before installing a gas boiler in a private house, you must prepare the place for its future location. The legislation prohibits placing gas minicators in living rooms. A separate room with appropriate dimensions, proper ventilation, lighting and fire safety systems is ideal for these purposes.

There is a direct relationship between the power of the boiler unit and the volume of the combustion room.

- Power ≤ 30 kW requires room volume ≥ 7.5 m 3.

- Power of 30 - 59 kW requires a room volume of ≥ 13.5 m 3.

- Power ≥ 60 kW requires room volume ≥ 15 m 3.

If a cascade connection of gas boilers is used in a closed heating system, then the required boiler room area is calculated based on the requirements: for one installation 4 m 2 of floor, with a ceiling height of at least 2 m.

With regard to the walls and ceiling of the furnace: they must be made of a material with a fire resistance of 45 minutes.

As for ventilation: the room intended for the installation of gas boiler equipment must be equipped with a supply and exhaust ventilation system with a factor of at least 3. The size of the supply air duct (when air is supplied from the street) is calculated at the rate of 8 cm 2 per 1 kW of boiler power. If the inflow is made from corridors and non-residential premises of the house, then the diameter of the duct should be calculated in the ratio of 30 cm 2 per 1 kW of equipment power.

In addition, in this room there must be a window with a glazing area of at least 0.3 m 2 for every 1 m 2 of the floor.

The doors to the boiler room must also meet strictly defined requirements: the width of the opening is at least 0.8 m.To compensate for negative pressure, in case of problems with air flow, a gap of at least 2.5 cm is required between the threshold and the door.

Basic installation rules

You can find out information about what kind of air exchange ventilation for boiler rooms should be provided in the SNiP rules. They set out all the rules that must be adhered to when working with gas boilers. Special attention to the following:

- Ventilation in a boiler room with a gas boiler is necessary, and the chimney is mounted under the ceiling.

- You can make ventilation in the boiler room of a private house, powered by natural draft or mechanical.

- The minimum size of the air duct for air intake is 15 cm.

- For correct use of the ventilation system, a check valve is installed on the inside of the supply and exhaust ducts, which should ensure the movement of the air flow in only one direction.

If you decide to install a natural-type ventilation system with your own hands, then you need to take care of the highest quality preliminary calculations.

Simple ventilation sometimes fails. For an hour of its operation, it provides a complete change of air in the room at least 3 times. If the creation of the usual natural scheme is difficult for some reason, then fans are used. These devices create the necessary traction by an artificial method.

Another important part of a heating and ventilation system is the chimney. Its design and quality affect the ventilation efficiency by more than 70%. Even for home boilers that are installed in the kitchen, you should know how to properly build it.

The chimney is an important part of the work of heating and ventilation systems

Communications

Before you connect the gas boiler to the heating system and start enjoying all the benefits of civilization, you need to take care of the availability of engineering communications in the combustion room. In addition to the pipes of the heating and gas supply system, you need to take care of the following communications.

- Electricity is necessary for the operation of pumping equipment, igniter and automation. In addition, the boiler room needs light and an additional socket for the possible connection of a stabilizer or an uninterruptible power supply. Experts recommend that the organization of power supply in the boiler room be made with a three-core cable, with a conductor cross-section of 2 mm 2. There must be a circuit breaker on the line. Light is made by using the required number of lamps with closed shades. Recall that all electrical equipment must be grounded.

- Water pipes.Everything is simple here: despite the fact that the heating system is closed, over time, the amount of coolant in it decreases. For recharge, you need a water supply. If it is supposed to connect a double-circuit gas boiler, then a water supply is needed to create a hot water supply in the house.

- Sewerage. The need for a sewage system is usually thought about only after the blasting valve has been triggered, as a result of which the masses of the coolant end up on the floor. The best option is to have a floor drain.

Smoke exhaust system

The chimney is an integral part of any gas (and not only) heating equipment. For turbocharged boilers, they are used that are small in size and are brought out into the street through a hole in the supporting wall. Installation with atmospheric burners is another matter: the temperature of the exhaust gases at the outlet from them reaches 800 ° C. It is these devices that require a major chimney made in accordance with all fire safety rules.

Chimneys should have another most important quality - create natural draft. To do this, they must run strictly vertically, have a diameter corresponding to the capacity of the boiler and be properly discharged through the roof. The figure shows the height of the chimney head, depending on the location on the roof.

As for the dependence of the diameter of the chimney on the power of the boiler unit: here you should be guided by the data that are indicated in the passport for the installation.

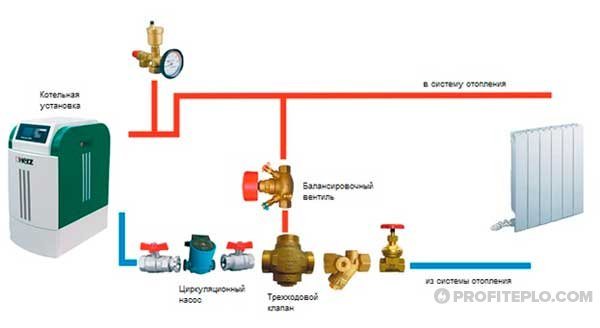

Forced circulation heating

The installation diagram of a solid fuel boiler for a forced-feed heating system provides for the installation of a bypass and a three-way valve to create a primary circulation circuit.

Installation of a solid fuel boiler in a forced circulation heating system

This principle of connecting solid fuel boilers excludes the formation of condensate in the combustion chamber of a steel boiler or the destruction of a cast-iron unit when a cooled coolant enters the water jacket of a hot heat generator. A three-way valve, adjusted to a predetermined temperature, and a bypass allow the heated coolant to be mixed into the return flow until the heating system reaches the optimal operating mode.

Related article: Boilers from Ferroli

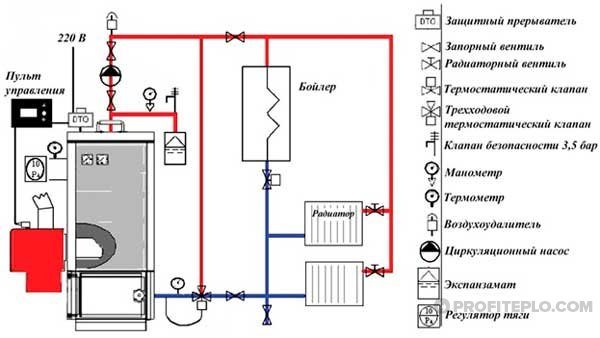

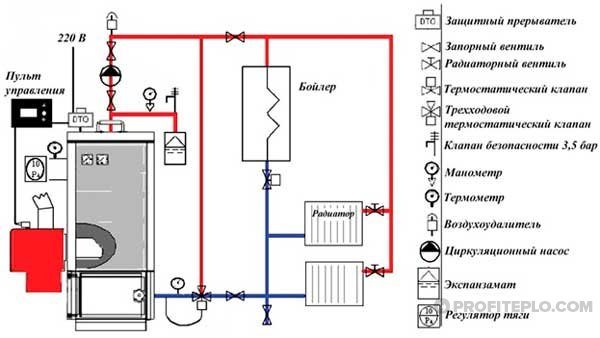

The installation diagram of a solid fuel boiler may include a tank for preparing water for hot water supply - an indirect heating boiler. Its heating element is a coil through which the coolant heated by the boiler passes.

Schematic representation of the installation of a solid fuel boiler with an indirect heating boiler

In the above diagram, the boiler and heating branches are installed in parallel, immediately after the primary circulation circuit. Such a connection allows you to prepare water for hot water supply using the most heated coolant. A straight-through thermostatic valve, which is mounted at the outlet of the boiler, does not allow the coolant to pass freely through the coil. It passes water that has cooled down to the set temperature, which has given off heat for hot water supply.

The complexity of piping the boiler unit is also affected by the presence of a second heat generator (gas or electric boiler), the number and types of heating circuits (radiator heating, underfloor heating).

There are different schemes for connecting two multi-fuel boilers for servicing one heating system. The best option is to use a heat accumulator (buffer tank), to which a solid fuel unit and an electric boiler are connected, each with its own pump for circulation.The electric heat generator is turned on by a signal from the controller with an air temperature sensor when the room temperature starts to drop after the fuel in the main unit has burned out and the coolant in the system has cooled down.

Diagram and stages of connecting gas boilers

It is best if the connection will be handled by specialized specialists or services who will be involved in servicing your heating system. If your initiative for self-installation of boiler equipment finds support in the relevant authorities (which is very doubtful), then after the preparation of the project and the necessary permits and the purchase of equipment, you can proceed to the installation of the boiler unit.

- Installation. The wall-mounted boiler is mounted on the wall using special fasteners or strips, which are usually supplied in the kit. Floor standing is mounted on a flat, fireproof surface. Unlike wall-mounted equipment, floor-standing boilers are installed at a distance of 25 - 30 cm from the wall. It is important to know that the installations must be accessible from all sides.

- Connection to the flue gas system. Important! After connecting, you need to make sure that there is a draft in the chimney. It is imperative to check the tightness of the connection of the branch pipe to the chimney.

- Connection to communication systems. A typical diagram for connecting a gas boiler to a heating system with a two-pipe piping looks as shown in the figure.

The following is a classic wiring diagram for a wall-mounted double-circuit gas boiler.

From left to right: coolant outlet into the heating system; tap water inlet; connection of the gas main; hot water to the DHW system; chilled heat carrier inlet from the heating system.

First of all, you should take care of installing taps on the water supply, heating and gas systems, which will be responsible for disconnecting these systems from the boiler, during its maintenance and repair, as well as if an emergency shutdown is necessary. Further, a coarse filter should be installed at the inlet of the water supply system and the "return" of the heating system, using shut-off elements before and after it. The final stage will be the connection of the boiler unit to the heating system and a test run of the installation. It should be carried out in the presence of gas experts.

This is not an easy task. The boiler cannot be hung up somehow, since the safety of people living in the house often depends on how correctly the wall-mounted boiler is installed. This is due to the fact that the installation of this device is carried out in strict accordance with the technical requirements and standards adopted in Russia at the legislative level.

That is why installing a wall-mounted boiler with your own hands is an extremely time-consuming and difficult process for a beginner.

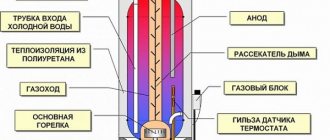

The device and types of solid fuel models

Before installing a solid fuel boiler in the house, you must select it. In addition to logs, boilers can be designed to burn pellets (compressed sawdust), peat and coal. First of all, one should focus on the availability of fuel.

You can install in a private house:

- pyrolysis - with two combustion chambers (in the first, the fuel, burning out with a small amount of oxygen, releases combustible gas for the second main furnace);

- long burning - firewood in a large firebox does not burn, but gradually smolders;

- combined - for several types of fuel.

At least inside there will be a heat exchanger with one circuit for the heating system. And it can be purchased with two or three circuits, which will provide the home with hot water supply and connect a "warm floor". The choice is quite extensive and there is always an optimal solution for a particular private cottage.

The design of any solid fuel boiler practically does not differ from a conventional stove and includes:

- firebox (one or two-chamber);

- fuel loading window;

- ash pan;

- chimney.

In general, regardless of the features of the device, the installation of a solid fuel boiler with your own hands is almost the same. It is necessary to equip a pedestal under it, equip a chimney with ventilation and connect heating pipelines.