If the heating system power corresponds to the operating power range of the boiler

The maximum power of the heating system in the house may fall within the operating range of the boiler power specified in the instructions. For example, the total maximum power of radiators in a house is 11 kW. The operating power range of the Protherm Gepard 23 MTV boiler is in the range of 8.5 - 23.3 kW.

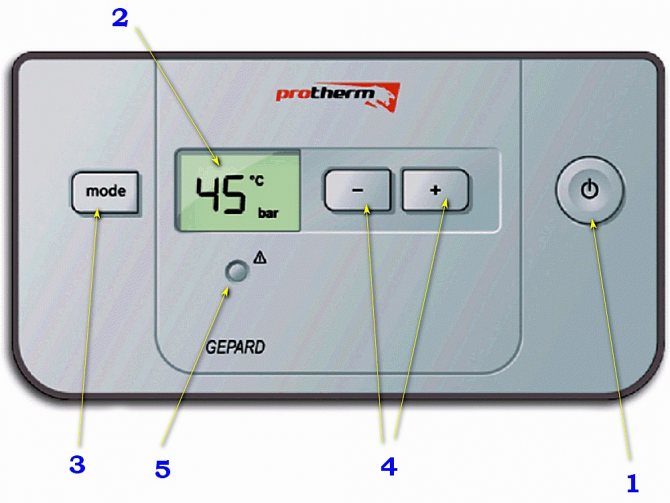

In the service menu, as described above, we find the line d.0, press the "mode" button and look on the display the value of the boiler power parameter, kW. For example, the factory setting = 15 will be visible. Using the "-" button, set a new value for the boiler power = 11.

I recommend trying to set the boiler power to 20 - 30% less than the heating circuit power, for example, d.00 = 9 kW. This power should be enough to compensate for heat losses at home, since the power of radiators, as a rule, is chosen with a certain margin.

Boiler cycle

Clocking is the frequency of switching on of equipment for heating the coolant. If no external control devices are connected to the baxi boiler, the interval between switching on the boiler can be set to a maximum of 10 minutes (by default, 3 minutes).

For example, for the BAXI ECO FOUR boiler this is the responsibility of the configuration parameter F11 Burner waiting time between two starts.

Frequent switching is not economical - the more time the boiler will work continuously, the better. On one of the forums, the user expressed concern about the long-term continuous operation of the boiler, but this, on the contrary, means that a mode has been established in which the heat losses of the room are continuously compensated while maintaining the optimal temperature of the coolant.

This problem is most urgent for owners of small-sized apartments, because the boiler is initially envisaged, including for the preparation of hot water and obviously higher power.

Since the numbers of the configuration parameters of gas boilers may differ, then to configure a specific model, you need to study the instructions.

Setting the gepard or panther gas boiler to a power below the minimum

At the third stage, the minimum boiler power is set, by an amount lower than that indicated in the instructions.

Such adjustment is not necessary in all cases, but only when the first and second stages do not bring the desired result. As in our case, when at the first stage with the "-" button we set a new value for the boiler power = 9 (the minimum possible setting corresponds to 8.5 kW.).

It should be noted that setting the boiler power according to the method described below is also useful in other cases, since it allows, through an experiment, to adjust the heating power of the boiler in accordance with the actual power of the heating circuit. The real power is usually less than the calculated one.

Before carrying out work on setting the minimum burner power, you must:

- Fully open the thermostatic and other valves on the radiators and set the room thermostat to the maximum temperature. The thermostat that controls the underfloor heating is set to the maximum permissible temperature so as not to overheat the floors.

- In the user menu of the boiler, set the maximum operating temperature, which the owners set in the coldest frosts, adding another 5 ° C. Usually it is at least 65 ° C. If the owners do not remember it, or on a new boiler in the menu, they set the factory setting for the maximum temperature of 75 ° C. The boiler burner should automatically turn off when the temperature is 5 ° C higher, i.e. at 80 ° C.

- Cool the heating circuit to a heating water temperature below 30 ° C.

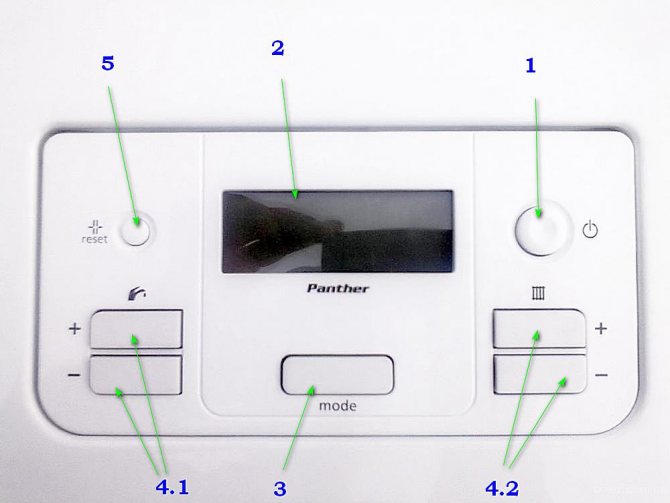

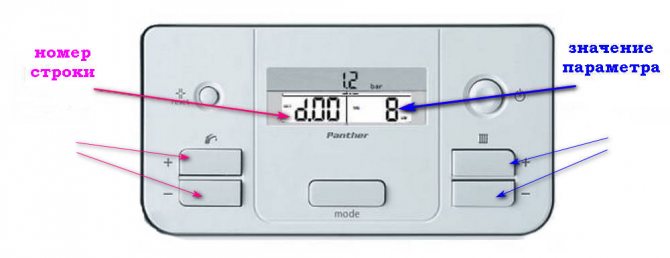

Next, start the burner in heating mode, select line d.52 in the service menu, press the "mode" button and see on the display the value of the gas valve stepper motor position parameter in the factory mode of minimum power.

Having removed the front cover of the boiler, we visually observe the magnitude of the flame in the burner. In our example, the display showed the factory setting, number = 72, and the flame height in the burner was quite high.

Press the "-" button to set the new value of the parameter in line d.52, for example = 20. 3 seconds after the change, when the new value is automatically confirmed, a significant decrease in the flame height in the burner is observed. This indicates that the useful power of the boiler with the specified setting will greatly decrease.

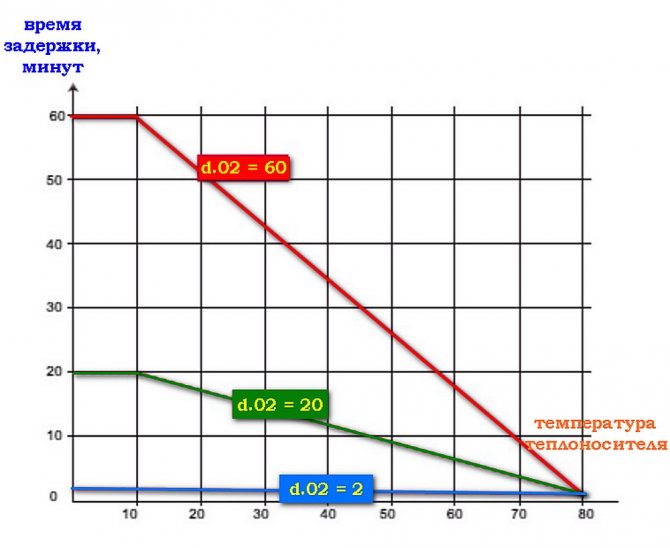

Further, the temperature rise in the direct heating pipe at the outlet of the boiler is observed on the display. Usually, the temperature rise stops when it reaches a value less than the set one, for example 52 ° C. The boiler is running and the temperature does not rise (or changes very, very slowly). This means that a power balance has been achieved between the boiler and the heating system at this steady-state water temperature.

At this moment, we increase the parameter in line d.52 of the service menu, set a new value = 30 - the temperature starts to rise again and stops again, for example, at 63 ° C. Again, add the parameter value in line d.52 = 35 and so select the parameter until the temperature stops at a value slightly higher than the maximum, for example 77 ° С.

If the radiators do not warm up well in height, the temperature difference in the straight and return pipes at the maximum temperature is more than 15-20 °, then the bypass valve actuation pressure is increased. Read below how to adjust the bypass valve. The temperature of the water in the flow and return pipe can be seen on the display if you enter the service menu, lines d.40 and d.41.

If adjusting the bypass valve, the gas valve setting in line d.52 must be repeated.

In our example, the burner heated water to a maximum temperature of 77 ° C with a minimum value of the parameter in line d.52 equal to = 28 (factory setting was = 72). With a lower value of the parameter, the burner could not heat the water to the specified temperature. And with a higher value, the burner heated the water to 80 ° C and the boiler automation turned off the combustion.

It should be noted that the above-described method for setting the gas valve, which allows, through the experiment, to balance the boiler power with the heating circuit power, is absent in the recommendations of the boiler manufacturer. This is the idea of the author of the article, which was successfully implemented when setting up autonomous heating systems with gas boilers.

Gas boiler regulation

If the automation began to work incorrectly, there were malfunctions in its functioning, then you need to find the reason and either adjust the control system, or replace the faulty elements.

IMPORTANT!

Do not ignore faults, even if they occur only occasionally. It can cost you and your loved ones life.

Let's consider the most popular problems that you can fix yourself:

- "The boiler warmed up remarkably in the fall, and in the winter the house is cold." This, in fact, is not a breakdown, but just the need to regulate the heating temperature. There is a thermostat in the body of any gas boiler. It can look like a rotating knob with a scale, buttons with a temperature screen, a scale with a slider on it. It is enough to set a higher heating value, as the house immediately becomes warmer.

- "When firing up, the solenoid valve does not work, no matter how much you press the handle." The most common failure requiring valve replacement.

- "The boiler burns normally, but after a while a pop is heard and everything turns off." As a rule, here we are dealing with the actuation of automation. But what is the reason for the "clap" will have to be clarified. It is best to invite specialists.

IMPORTANT!

Do not glue the faulty EM valve or jam it! He is responsible for the gas supply, and if you fix it, the rest of the automation will be useless. When the burner goes out or during reverse draft, you risk simply suffocating.

Stroke reduces boiler life and increases gas consumption

Anyone, even without being a mechanic and electrician, knows that the most difficult operating mode for equipment is the moment of starting, turning on mechanical and electrical equipment. During the start-up period, the greatest wear is observed, most often failures in work occur. An increase in the number of starts as a result of cyclicity, most of all, eats up the service life of very expensive parts of the boiler - gas and three-way valves, a circulation pump, a fan of exhaust gases.

For ignition at the moment of start-up, the maximum amount of gas is supplied to the burner. Part of the gas, before the appearance of the flame, literally flies into the pipe. Continuous re-ignition of the burner further increases the gas consumption and reduces the boiler efficiency.

Some cyclic operation of the gas boiler is provided for by the normal mode of its operation. For example, room temperature control without a thermostat or with a two-position thermostat occurs by periodically switching on and off the boiler burner.

The task of regulating the boiler power is to exclude excessive cyclicity - cycling caused by the lack of adaptation of the boiler settings to the heating system.

Description and functions of a gas boiler

A simple heater consists of a heat exchanger chamber, a gas burner and ventilation. The operation of all these systems is controlled by automation.

The safety device for gas boilers has a multi-stage protection system:

- When firing up, it is necessary not only to turn the gas supply knob, but also to hold it for some time until the solenoid valve (6) is triggered. This prevents accidental gas leakage in the device.

- The backdraft sensor (8) reacts to the flow of fire from the burner into the room. This can happen when there are sharp gusts of wind, a clogged chimney and malfunctioning burners. Thanks to this controller, the gas supply in the event of reverse thrust is automatically turned off and people cannot be poisoned by carbon monoxide.

- The temperature sensor (7) protects the boiler from overheating, turning on the gas as required. Thanks to it, the temperature in the heating system is maintained at the level set by the user.

Control systems in gas boilers are autonomous or volatile. The latter require an electrical connection.

Savings and regular maintenance of equipment

The basic structure of a traditional gas boiler is almost the same, regardless of the manufacturer. Heat energy from gas combustion is transferred to the heat carrier through a heat exchanger. There can be either one or two heat exchangers in the boiler. During the operation of any gas boiler, the outside of the heat removal surface is contaminated with soot deposits, from the inside with scale.

From practice, we can say that it is extremely rare that the system is filled with special prepared water or the water supply system is equipped with a water treatment system. This is especially true for apartment buildings, in which the owners receive a ready-made heating system along with the apartment.

The formation of scale and soot on the walls of the heat exchanger will gradually reduce the heat transfer characteristics and more energy will be consumed for heating.

Therefore, the annual regular maintenance will definitely affect the efficiency of the equipment for the better! This applies in particular to boilers with bithermal heat exchangers, which, due to their structural design, are difficult to flush.

Each of us wants to install heating equipment that will work not only efficiently, but also economically. Are there economical gas boilers? Depends on what you mean by this. A list of models with minimum fuel consumption could be given, but everything is relative here, and many factors affect the cost of maintenance. Let's take a look at each of them.

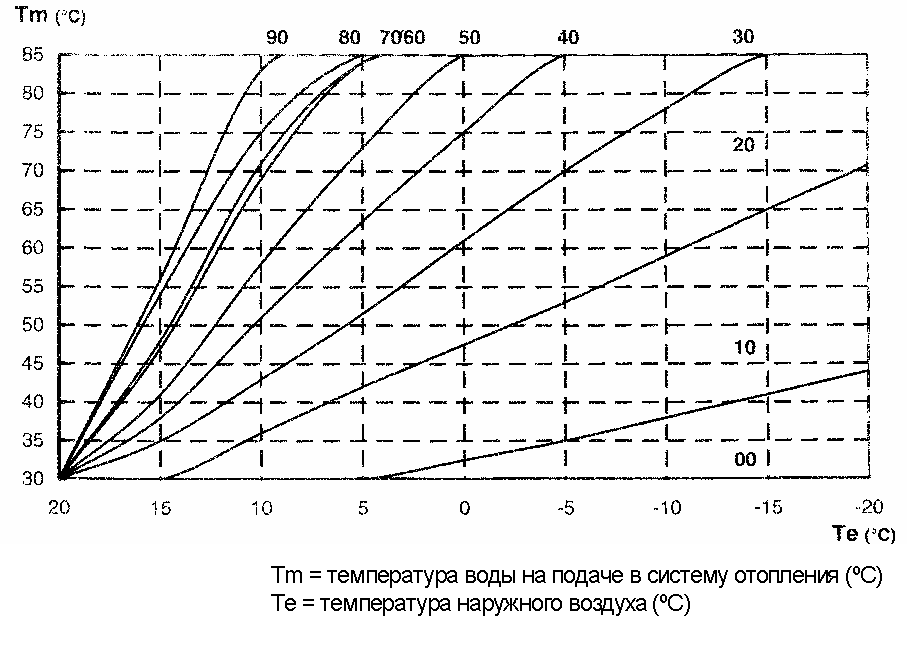

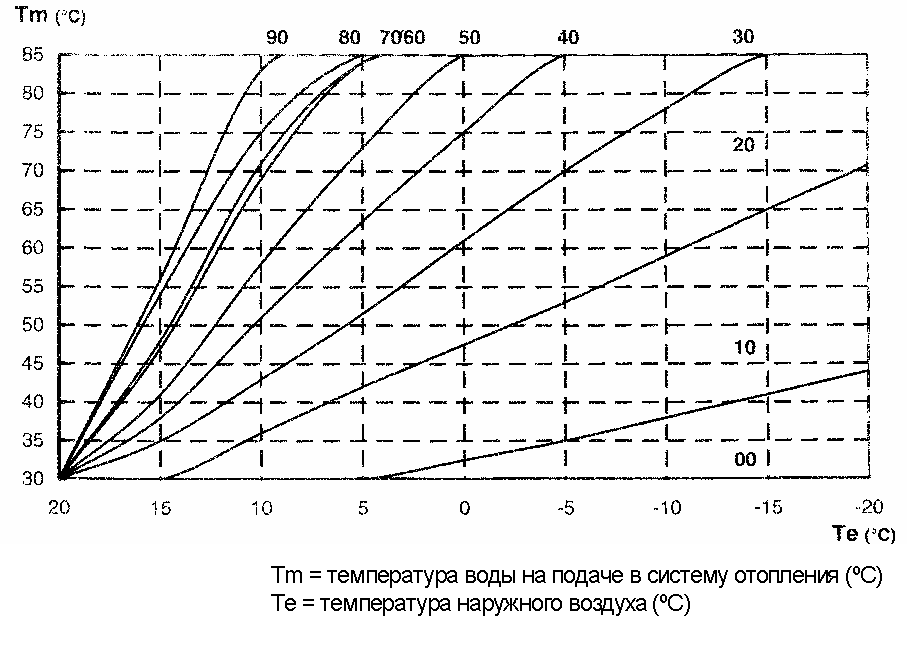

Weather-dependent automation and outdoor temperature sensor

"Do I need it, and is there any benefit from it?" - many people ask themselves a question when buying a gas boiler. So, for example, in almost all Baxi boilers, weather-dependent automation (compensation for street temperature) is included with the standard boiler kit, and in order to use it, you just need to purchase a street temperature sensor (cost up to 1,500 rubles) and set up the boiler.

When operating in this mode, the boiler will automatically lower the temperature of the coolant (radiators) when the outside temperature rises, or vice versa. That is, such an effect as in city apartments is excluded - it is already warm outside, and perhaps even spring has already come, and the radiators are still heating "in full", as at -30 degrees Celsius. Due to constant adjustment, gas savings appear, and the cost of the sensor pays off in less than a season.

Influence of temperature on the properties of the coolant

In addition to the factors described above, the temperature of the water in the heat supply pipes affects its properties. The principle of operation of gravitational heating systems is based on this. With an increase in the heating level of water, it expands and circulation occurs.

However, in the case of using antifreeze, exceeding the normal temperature in the radiators can lead to different results. Therefore, for heat supply with a heat carrier other than water, you must first find out the permissible indicators for its heating. This does not apply to the temperature of district heating radiators in an apartment, since antifreeze-based liquids are not used in such systems.

Antifreeze is used in the event that there is a likelihood of the effect of low temperature on the radiators. Unlike water, it does not begin to change from a liquid to a crystal-like state when it reaches 0 ° C. However, if the work of the heat supply is beyond the norms of the temperature table for heating in a larger direction, the following phenomena may occur:

- Foaming

... This entails an increase in the volume of the coolant and, as a consequence, an increase in pressure. The reverse process will not be observed when the antifreeze cools down; - Limescale formation

... Antifreeze contains a certain amount of mineral components. If the heating temperature in the apartment is violated in a large direction, they begin to precipitate. Over time, this will lead to clogging of pipes and radiators; - Increase in density.

Malfunctions in the operation of the circulation pump may occur if its rated power has not been designed for such situations.

Therefore, it is much easier to monitor the temperature of the water in the heating system of a private house than to control the degree of heating of the antifreeze. In addition, compositions based on ethylene glycol, when evaporated, emit a gas harmful to humans. Currently, they are practically not used as a heat carrier in autonomous heat supply systems.

Before pouring antifreeze into the heating, all rubber gaskets should be replaced with paranite ones. This is due to the increased permeability of this type of coolant.

Number of contours

You can purchase a floor-standing gas boiler in two versions: with one or two circuits.

One circuit

This option is structurally simpler and, accordingly, costs less. But it is recommended to use it in cases where the issue of organizing hot water supply is irrelevant.

In principle, there is a variant of organizing DHW and when using a boiler with one circuit. For this, a boiler is included in the circuit. This is a thermally insulated container with a heat exchanger inside. The pipe leaving the boiler is divided into two branches by installing a three-way valve.

Thus, the boiler will work, then for the heating circuit, then for heating the water in the boiler. This option is quite acceptable if the hot water consumption is relatively small, otherwise the unit will only work to heat the water, and the heating of the house will be ineffective.

Two circuits

A heating unit with two circuits is more functional. It has two heat exchangers, so it can simultaneously generate heat both for the heating system and for heating the water supplied to the water supply. If the water consumption is small, then you can use a gas double-circuit boiler without additional devices. With a significant water consumption, it is better to install a boiler, which will be heated by a coolant circulating in the second circuit.

According to the reviews, the installation of the boiler is also more rational because the boiler does not need to be constantly supplied with tap water, and this increases the service life of the heat exchanger, especially if the water is hard.

What determines the temperature of the water in heating

For the heat supply to work properly, a graph of the temperature of the water in the heating system is required. According to it, the optimal degree of heating of the coolant is determined, depending on the influence of certain external factors. It can be used to determine what temperature of the water in the heating batteries should be in a certain period of time the system is operating.

It is a common misconception that the higher the degree of heating of the coolant, the better. However, this increases fuel consumption and increases operating costs.

Often, the low temperature of the heating batteries is not a violation of the norms for heating the room. A low-temperature heating system was simply designed. That is why special attention should be paid to the accurate calculation of water heating.

The optimum water temperature in the heating pipes largely depends on external factors. To determine it, you need to take into account the following parameters:

- Heat loss at home

... They are decisive for the calculation of any type of heat supply. Their calculation will be the first stage in the design of heat supply; - Boiler characteristics

... If the operation of this component does not meet the design requirements, the water temperature in the heating system of a private house will not rise to the desired level; - Material for pipes and radiators

... In the first case, it is necessary to use pipes with a minimum thermal conductivity. This will reduce heat losses in the system during transportation of the heat carrier from the boiler heat exchanger to the radiators. For batteries, the opposite is important - high thermal conductivity. Therefore, the water temperature in central heating radiators made of cast iron should be slightly higher than that of aluminum or bimetallic structures.

Is it possible to independently determine what temperature should be in the radiators? It depends on the characteristics of the system components. To do this, you should familiarize yourself with the properties of batteries, boiler and heating pipes.

In a centralized heating system, the temperature of the heating pipes in an apartment is not an important indicator. It is important that the air heating standards in living rooms are observed.

Optimal Mode Setting Methods

Many devices are programmed for the temperature of the heat carrier. When it reaches the required values, the unit turns off for a short time. The user can set the temperature himself. The parameters also change from the weather.For example, the optimal operating mode of a gas boiler in winter is obtained at values of 70-80 C. In spring and autumn - at 55-70 C.

Modern models have temperature sensors, thermostats and auto-tuning modes.

Thanks to the thermostat, you can set the desired climate in the room. And the heat carrier will warm up and cool down with a specific intensity. In this case, the device reacts to temperature fluctuations in the house and outside. This is the optimal operating mode for a floor-standing gas boiler. Although with the help of such devices, you can also optimize the mounted model. At night, the parameters can be reduced by 1-2 degrees.

Thanks to these devices, gas is consumed by 20% less.

If you want solid efficiency and savings from the boiler, get the right model. Some examples are offered below.