Advantages and disadvantages

The use of chemistry for cleaning heat exchangers has both undoubtedly positive and conditionally negative sides. One side,

- the already mentioned disassembly of the units is not required, which significantly reduces labor costs - if necessary, for shell-and-tube heat exchangers, you can limit yourself to dismantling the distribution chamber (chambers) to facilitate access to each tube of the tube bundle separately; extraction of the bundle from the casing is not required;

- labor costs for carrying out the chemical cleaning of the heat exchanger itself are incomparable with the labor costs for mechanical cleaning: for chemical cleaning, it is enough to introduce the active substance into the heat exchanger system and wait for the recommended time; during mechanical cleaning, careful processing of each section of the structure is required;

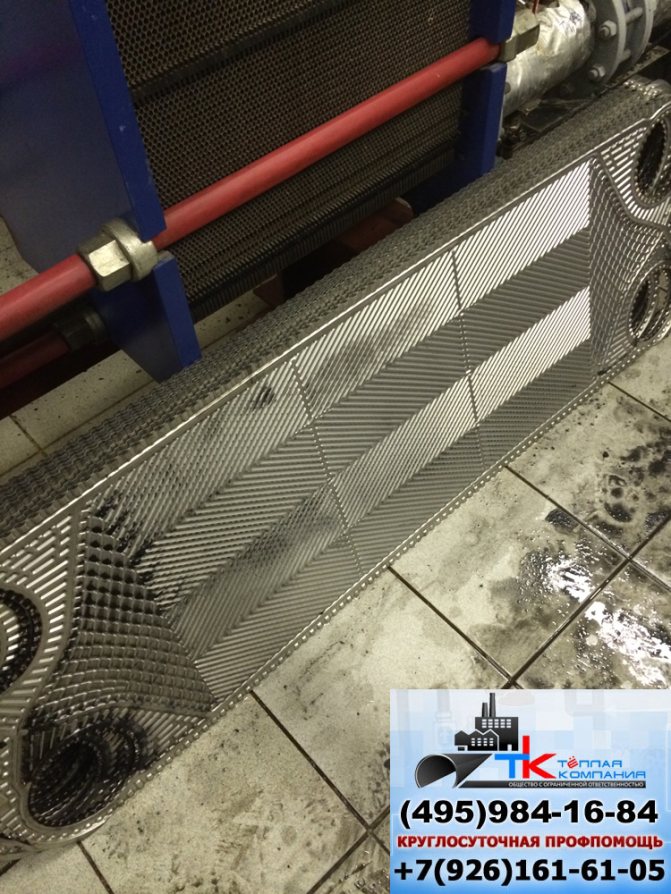

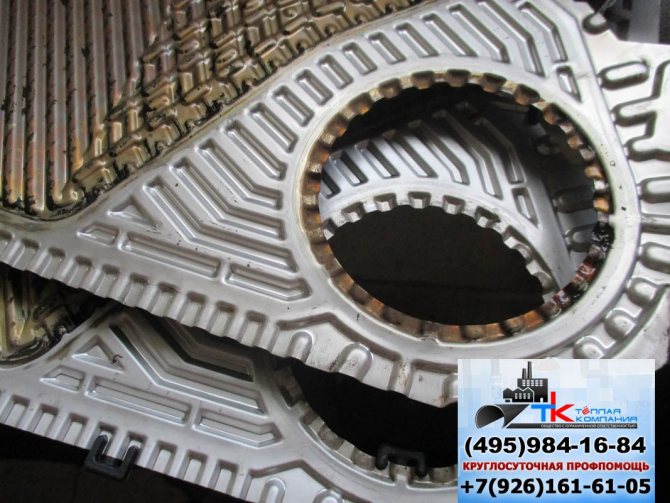

- it is simply impossible to mechanically clean some surfaces - for example, the surface of the "inner" tubes of a tube bundle of a shell-and-tube heat exchanger or thin and fragile parts of a plate; at the same time, the chemical solution will reach these "problem" areas without difficulty.

On the other hand,

- chemicals for flushing have some cost, and their reuse is usually ineffective (however, mechanical cleaning also consumes its "consumables");

- the quality of the cleaning of "problem" areas can be difficult to assess visually (however, the use of a technical endoscope can partially help; the results of thermal and hydraulic tests after washing also give an idea of its effectiveness);

- in the case of the wrong choice of chemistry for flushing heat exchangers, temperature conditions or exceeding the recommended time, negative corrosion processes are possible (however, if all standards are observed, their probability is quite small).

In some cases, chemical and mechanical cleaning can be used together to achieve optimal results; the main issue here is the question of cost justification.

Liquids and reagents

When selecting reagents, the consumer must take into account several features. First of all, it will be - the degree of pollution, the composition of the plaque on the surfaces, and the material from which the equipment surfaces are made. Understand the difference between fluids and reagents when flushing. Liquids are ready-to-use flushing materials diluted according to instructions. Reagents are often sold undiluted. Therefore, in no case should flushing work be carried out without reading the recommendations.

Reagents are acidic or alkaline substances, not diluted. For high-quality washing, first, you need to determine the composition of the plaque and its thickness. Most often, especially in everyday life, you have to flush by trial and error.

Also, when selecting equipment for flushing plate heat exchangers, you need to remember what material the heat exchanger itself is made of and how the equipment fits under the heat exchanger, what is the distance between the plates, is it possible to disassemble the device and clean the plates more thoroughly. How suitable the purchased equipment is for corrosive acidic cleaning fluids. The market offers the consumer a variety of options. But when purchasing concentrates, you should always consult with professionals at least.

Liquid of the SP-OM series

Means of the SP-OM series have a wide range of industrial applications and have successfully proven themselves at metallurgical plants and machine-tool enterprises. A feature of these fluids is sufficient efficiency (low concentration when diluted), which allows them to be used when washing large heat exchangers, as well as safety in accordance with the requirements of SanPiN (can also be used in drinking water supply systems).

The SP-OM-84 brand is intended for plate heat exchangers. There are modifications for both elements of the heat exchanger made of brass, copper, ferrous and stainless steel, as well as ferrous and stainless steel.

You can find out where to buy this tool and get advice at the link.

Antirzhavin

The big problem with water is that it is calcareous, the problem is that any metal, when working with water, begins to carrode. Rust begins to accumulate on surfaces, and especially at the joints. At least somehow, a corrosion inhibitor will help slow down this process. That is, a substance that is able to slow down this very corrosion. And this is exactly what Antirzhavin belongs to.

The uniqueness of this composition is that it works great with deposits, it brings them into a soluble state. In addition to dissolving minerals, the liquid helps to cope with corrosive processes. In the process of washing, it helps to form a passivating layer on the surfaces, which for a certain time inhibits the development of corrosion on the surfaces.

This composition helps to clean complex structures without disassembling them. Moreover, cleaning can take place in 8 hours and at low temperatures. This is a big plus of this substance, because sometimes it is necessary to urgently clean the equipment without disassembling it.

N-Faza

This product is specially formulated for plate heat exchangers and stainless steel appliances. Due to its minimal corrosiveness, this agent is excellent for plate heat exchangers and thin sheets of heating surfaces. The composition does not contain hydrochloric acid and chlorine. In order to flush the gas water heater from scale, you can not disassemble it, the flushing time is the maximum is 10-12 hours. One of the most convenient tools for flushing brazed plate heat exchangers, because does not require disassembly of the equipment and has a gentle gentle action.

Flushing should be carried out in protective clothing, gloves, respirator. Dissolves complex inorganics well. It dissolves in large quantities with plain water.

Cleaning frequency

There are no strict requirements for the rules on the frequency of flushing of heat exchangers - there are only recommendations indicated in the Operation Manual attached to each device. Recommendations should be adjusted in accordance with the specifics of use - the chemical properties of heat-carrying media, their physical contamination, etc. In particular, it is shown to carry out cleaning if, during a routine inspection, contaminating deposits of any nature with a thickness of more than 0.3 mm are detected on heat exchange surfaces.

In practice, the presence of such deposits may be indicated by an excessive decrease in the thermal characteristics of the apparatus recorded by external measuring instruments. Some manufacturers produce modern heat exchangers with a certain "margin", that is, with the expectation of thermal resistance of pollution. For them, the presence of deposits exceeding 0.3 mm is allowed - if the heat transfer parameters are within the normal range.

Choosing a chemical cleaning agent for a heat exchanger

The main rule when choosing a liquid for flushing heat exchangers: the chemical components in the solution should aggressively affect scale, but be neutral with respect to plates, elastic seals and other parts of the device.This will get rid of dirt and not damage the elements of the device.

Criteria for choosing a cleaning agent for a plate heat exchange structure:

- material for making plates and gaskets;

- amount and thickness of plaque on the inner walls of the equipment;

- chemical composition of pollution.

This is how a ready-to-use installation for flushing a plate heat exchanger and a boiler looks like Source teplo-ekb.ru

To minimize the risk of damage to the internal parts of the unit, it is recommended to analyze the sediment to identify its chemical composition. This will allow you to select the most effective and safest product for cleaning the heat exchanger.

Reagents

For chemical washing of heat exchangers, two types of active reagents are used - acidic and alkaline.

- Contrary to popular belief, alkali copes much better with organic deposits: acid can only carbonize serious contamination from the outside, after which its action becomes ineffective. Alkaline eats away organic matter completely. Alkaline reagent can be purchased as a ready-to-use mixture, or you can make it yourself. For moderately soiled surfaces, the following composition is recommended. Based on 100 liters of hot (80 - 90 ° C) water, the following dissolves:

- caustic soda (NaOH) - 0.2 kg;

trisodium phosphate (Na3PO4 x 12H2O) - 0.4 kg;

- sodium nitrite (NaNO2) - 0.25 kg.

For heavy soiling for the same 100 liters:

- caustic soda - 0.4 kg;

- soda ash (Na2CO3) - 0.2 kg;

- sodium nitrite - 0.25 kg.

- 1.5% nitric acid aqueous solution - for moderate deposits;

5 - 10% nitric acid solution - for hard-to-dissolve persistent deposits.

The use of hydrochloric acid or sulfuric acid is generally not permitted. The use of the above alkaline solutions is not allowed if there are any aluminum elements in the heat exchanger.

The action of the acid is neutralized with a weak (1 - 1.5%) solution of caustic soda or caustic potash (aka potassium hydroxide, KOH). The alkali action is, accordingly, neutralized by a weak acidic solution. The insoluble salts formed during the neutralization reaction precipitate - it is advisable to wash them with a strong stream of clean water.

Containers for the preparation of reagents must be chemically resistant to their effect. Compliance with the strictest safety measures is mandatory, since these substances can be dangerous to humans both in dry form and even in the form of weak solutions.

How do you know if you need to clean the heat exchangers?

The main symptom is a decrease in performance in the heating or hot water system. The boiler does not heat well, there is not enough power. When scale builds up, fuel consumption increases and an uncharacteristic noise may appear.

The technical data sheet of the heating equipment indicates the recommended maintenance parameters, including the cleaning time. The status of work should be assessed regularly. Large manufacturers advise doing CIP cleaning annually. The procedure is most convenient to carry out during the period of planned maintenance or during emergency repairs.

The load on the secondary heat exchanger is higher than that of the primary. Running water is constantly in contact with the walls - plaque deposition is inevitable. In this case, descaling of heat exchange equipment is necessary every six months.

Procedure

There are two options for chemical cleaning:

- without using additional equipment;

- using a special pump for flushing the heat exchangers.

- First option. To carry out chemical cleaning of the heat exchanger:

- disconnect the heat exchanger from the heating medium supply and removal system and, if necessary, drain the remaining liquid in it;

seal the outlet pipes with plugs;

- fill the entire heat exchanger through the inlet pipes (in the case of a shell-and-tube heat exchanger, both the space in the tubes of the tube bundle and the annular space) with a chemical reagent heated to a temperature of 80 - 90 degrees Celsius.

- wait 30 - 40 minutes;

- remove the plugs and carefully drain the active solution;

- flush the cavity of the heat exchanger with a neutralizing solution or, in extreme cases, with a large amount of clean water;

- if possible, blow out the heat exchanger with hot air until it is completely dry.

- The second option involves the use of a pump for flushing heat exchangers, which combines the pump itself, made of chemically resistant polymers, a container for a reagent and a thermoelectric heater to maintain the desired temperature of the reagent. In modern models, the pump is equipped with two hoses connected to the inlet and outlet of the heat exchanger. Through the first hose, the reagent is pumped under pressure into the heat exchanger, removed through the second hose back into the tank and supplied again. A filter can be installed between the "drain" hose and the container to filter out undissolved dirt particles.

If an incomplete removal of deposits is found prior to the rinsing and drying steps, the cleaning procedure can be repeated with fresh active solution.

Naturally, the heat exchanger is flushed and dried after the pump has been used.

How to properly flush the heat exchanger of a double-circuit boiler

Mikhail, Yekaterinburg asks the question:

Good day! 3 years ago we supplied ourselves with a double-circuit boiler. This is a very convenient device, since it is now warm in the apartment, and there is always hot water. At the time of purchase, I was told at the store that it is necessary to clean the boiler once a year if the water in the tap is very hard. To do the cleaning, you need to call specialists, but it costs a lot of money. As a matter of fact, that's why we didn't clean the installation for so long. Tell me, at what intervals should you clean? And how to flush the heat exchanger of a double-circuit boiler from lime deposits? Thank you so much in advance for your help!

Hello! You should not worry too much, since modern models of double-circuit boilers do not deteriorate at all if they are cleaned every 3 years (even if the water is very hard). The main thing in this # 8211 is not to start the process until 5 years of use. What the store told you to do once a year is only partially correct. But this does not make sense, since you will only waste money once more. The ideal option # 8211 is to perform such work every 3 years, provided that the boiler is used constantly.

It is necessary to understand how to flush the heat exchanger under a double-circuit boiler correctly. There are several cleaning methods. The most effective is considered to be standard flushing using a special liquid that is capable of peeling off limescale from the inner walls of this installation.

Before getting to work, you need to turn everything off. First, turn on the tap at the bottom of the boiler, which ensures the flow of cold water into it. Next, you need to release the pressure to zero. If there is no such valve to reset, skip this step. Now, without fail, disconnect the boiler from gas and electricity. This must be done to ensure your safety. If possible, drain the boiler immediately.

Now you need to remove the casing from the boiler. To do this, at the bottom, you need to unscrew the four nuts. Please note that water may flow from below. Therefore, it is recommended to do this over a large basin or even take the boiler out into the street, removing it from the eyelets on the wall before that. Unscrew the heat exchanger slowly so as not to damage the parts.

Next, the heat exchangers are washed.This can be done with ordinary running water. You will see for yourself when the water becomes cleaner after rinsing. Full transparency will indicate that most of the wash was successful. Now you can rinse everything with boiled cold water.

Now it's time to use the cleaner. A special fluid for flushing the circuits is purchased in advance, which removes deposits on parts. Such a liquid is poured into two basins, then contours are placed in these basins so that their entire surface is covered with the product. Leave it all on for 15-20 minutes. But before that, read the instructions carefully. Indeed, some funds may require more or, conversely, less time for souring.

After that, the contours are pulled out of the containers. Now, instead of liquid, it is necessary to pour boiling water into the pans with washing powder diluted in it. The amount of powder must be sufficient. Put heat exchangers in this solution for 3-5 minutes.

Now you just need to rinse the contours several times so that there are no traces of concentrate and powder.

The flushing of the double-circuit boiler can be considered complete. You now just have to install the heat exchanger in place. To do this, you first need to install new rubber pads, even if the old ones are still quite suitable.

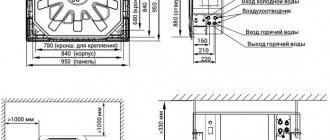

Then everything needs to be returned to its place, trying to tighten the nuts as tightly as possible. It is good to use a wrench for this. When everything is assembled, hang the boiler back on the hooks. Then you can connect the unit to gas, electricity and water. You have seen that it is not so difficult to understand everything. And if difficulties arise during the assembly or disassembly of the circuits, you need to refer to the instructions. There is a diagram where everything is shown in detail, so it is almost impossible to get confused.

additional information

Since contamination (in particular, scale) can play the role of a kind of "patches" in the heat exchanger, sealing possible cracks or damage to the integrity of the joints, after the procedure of chemical and / or mechanical cleaning, it is mandatory to carry out hydraulic tests of the heat exchanger. If damage is found, it seems reasonable to decide on the economic feasibility of repair or further operation of the apparatus - in some cases (especially when the service life is approaching), it may be more profitable to replace the damaged block element or the entire heat exchanger assembly with a more modern and efficient one.

JSC "TSEEVT" produces heat exchangers of standard and improved characteristics, of various designs and purposes, with a wide range of applications. It is possible to use devices manufactured by JSC "CEEVT" both as part of new systems and as a replacement for exhausted heat exchangers. In each case, the calculation of the heat exchanger is made individually, for specific tasks and technical characteristics specified by the customer.

To clarify any technical or practical points, it is enough to contact the company's representative office in any convenient way from those indicated in the "Contacts" section of this site or fill out an application by filling out an electronic form.

What happens if you neglect to clean the heat exchangers?

Scale interferes with the full operation of the device and leads to the following consequences.

- Waste resources. Salt deposits on pipe walls are more resistant to heat transfer than metal coatings. It takes more energy and time to warm up.

- The heat exchanger is overheating. Cooling of the system elements is provided by the heat carrier, but the scale layer impedes the process.

- Termination of work, expensive repairs. When deposits accumulate, the load on the elements of the system increases. The power of the work drops. With a thick layer of scale, the system does not cope and may fail.In this case, serious repairs will be required.

How often should the heat exchanger be cleaned

Many Internet sources on this topic indicate very contradictory information regarding the frequency of cleaning the heat exchanger. Some of them advise to adhere to the manufacturer's instructions, others rely on the opinions of experts.

They may be all right, but the most realistic option would be that the heat exchanger must be flushed when the following symptoms begin to appear:

- the burner in the gas boiler is on all the time;

- the circulation pump operates with a characteristic hum, which indicates overload;

- heating radiators heating takes much longer than usual;

- gas consumption has increased significantly with the same operation of the boiler unit;

- weak pressure of hot water in the tap (this feature is applicable for double-circuit boilers).

All these points strictly indicate that problems have appeared in the functioning of the heat exchanger, and this, in turn, means that it is necessary to start flushing.

Specialist's note: irregular cleaning of the appliance will reduce the efficiency of the gas boiler.

Booster work

A non-dismountable heat exchanger is washed on a booster. The device consists of a pump, a tank and a heating system. The cleaning solution is poured into the pressure tank. The composition is heated and fed to a heat exchanger. The pump creates pressure - the liquid circulates between the elements of the heat exchanger and washes away the deposits. The cleaning time of the heat exchange equipment is set individually - on large systems; with a thick layer of scale or complex contamination, it takes several hours. After complete cleaning, the reverse mode is activated: the dirty solution is drained. Then clean water flows through the pump for the final stage - flushing the system. The task is to remove the reagent residues from the system: aggressive chemicals, with prolonged contact, can damage the elements and disrupt the operation of the boiler.

When is a CIP required for a heat exchanger?

- If it is impossible to disassemble the heat exchange equipment. (For brazed and semi-welded assemblies.)

- With a relatively low level of contamination, it is rational to use a CIP method for cleaning heat exchangers.

Scope of work on flushing (cleaning) the internal cavities of the heat exchange equipment:

- Preliminary diagnostics of water circuits of heat exchange equipment by hydraulic method with excess pressure. (for the tightness of the circuits)

- Chemical CIP flushing of heat exchange equipment, with monitoring of the course of the reaction by measuring the pH level throughout the entire flushing.

- Neutralization of the flushing solution, repeated flushing with a neutralizer.

- Hydraulic tests (pressure testing) of heat exchangers.

Hydrodynamic cleaning

The elements of the system are disassembled and washed under a powerful pressure of water. The method allows you to clean up to 98 percent of the deposits. Hydrodynamic cleaning is also suitable for tubular structures that cannot be disassembled. In this case, water is allowed into the heat exchanger through hoses with nozzles. The fluid enters under high pressure, is distributed through the holes of the nozzles in all directions and removes even a thick layer of dirt. The advantageous difference between hydrodynamic cleaning is environmental friendliness. No hazardous chemicals are used. The cost is high because expensive equipment is used and a lot of water is consumed.