Specifications

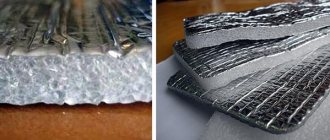

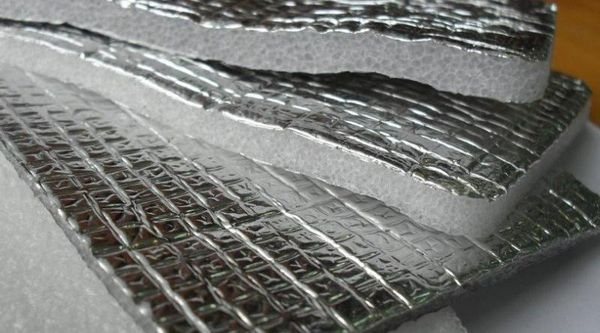

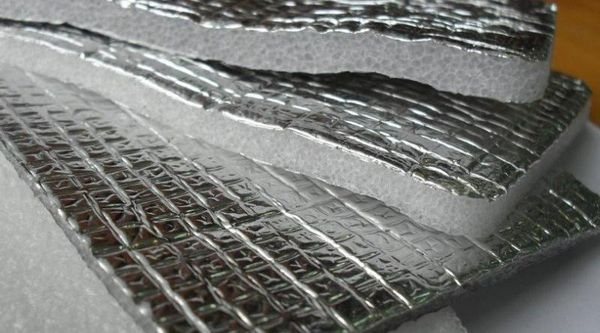

This material surprises with its field of application. They can insulate absolutely the whole house. This coating is made of polyethylene. The production technology consists in the fact that polyethylene is coated with special reagents that are foamed. The mixture is applied to a foil base. The coating hardens, providing a secure grip.

The foil backing only enhances the thermal insulation. This process occurs due to the fact that heat waves are reflected inside the building.

The most important characteristics:

- Penofol is small in thickness. It has high thermal insulation values. The material is great for insulating small rooms in which it is impossible to put a bulky layer of heat-insulating material.

- A distinctive feature of penofol is its versatility. It is widely used as a waterproofing material. Also suitable for vapor control.

- It combines well with other materials, even enhances their properties.

- This product is manufactured using the most modern technologies. The material has a long service life. Various harmful additives are not used in the manufacture. The product is environmentally friendly and does not harm human health.

- Possesses good resistance to various weather factors. Can be used at low temperatures. The lowest operating temperature is minus 55 degrees. Penofol will be difficult to melt, even at a temperature of +110 degrees.

- Insulation of the floor with penofol passes without difficulty. The material is easy to assemble. The prices are pleasantly surprising.

Insulation of the floor with penofol in a wooden house

Floor insulation - methods and materials

The floor in a wooden house, as a rule, requires additional insulation, as well as the foundation, ceiling and walls. Otherwise, very noticeable heat losses cannot be avoided - they can account for up to 20 percent of the total heat loss. For this reason, special attention is paid to the thermal insulation of the floor.

In modern construction, there are various methods of thermal protection of the floor. Various materials of the new generation are used, which very effectively help to keep the warmth in the room. Among them, a special place is occupied by foil insulation - it consists of a thermal layer with foil glued onto it. Such insulation is effective not only due to low thermal conductivity, but also due to the reflective properties of the foil - it reflects thermal radiation into the room.

There are foil thermal insulators of various types, but the most popular among them is penofol is a material made of foil and foamed polyethylene. This insulation has gained an excellent reputation due to its characteristics and ease of work with it - all work on thermal insulation of premises can be done with your own hands, even without having the qualifications of a builder.

Disadvantages and advantages of penofol

As mentioned above, penofol consists of a foil layer and a heat insulator, which is foamed polyethylene. It has the following properties:

- High heat-shielding and noise-suppressing properties;

- Absolute waterproofness - the foil repels water;

- High environmental friendliness - the materials from which it is made are used even in the food industry;

- Small layer thickness, which gives serious advantages in terms of preserving the usable area of the room;

- Non-flammable - this insulation belongs to hardly flammable materials;

- Simple and easy to use;

- Inedible for rodents - a very relevant property when it comes to floor insulation;

There are penofol of the following types:

- Type A - foil on one side, foamed polyethylene on the other;

- Type B - the foil layer is located on both sides of the polyethylene;

- Type C - self-adhesive. On one side there is a foil layer, on the other - an adhesive layer, with which the insulation is attached to the insulated surface;

- Type ALP - foil laminated with polyethylene coating.

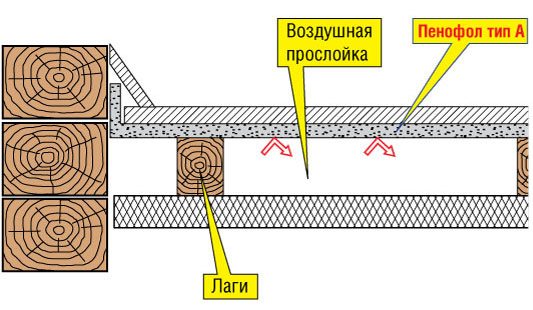

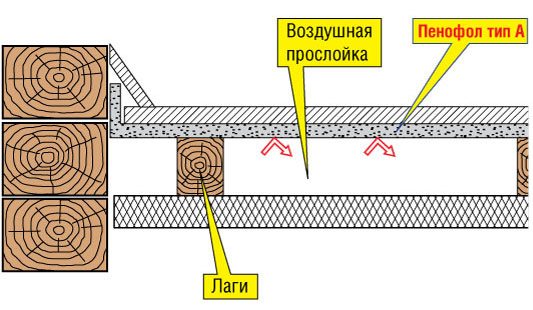

The convenience of penofol is that it does not require special hydro and vapor barrier. But when insulating the floor with foam foil in the house, it is necessary to provide an air gap - in order for the heat-reflecting properties of the foil to work and so that moisture that can settle on a moisture-repellent surface has the ability to evaporate.

Sometimes this insulation is used as an additional layer along with other types of heat insulators to protect against moisture and reflect heat into the room. It is very popular when it comes to insulating baths - in this case, the reflection of thermal radiation inside the steam room helps to maintain a stable high temperature.

Do-it-yourself floor insulation technology in a wooden house with penofol

The insulation process itself is quite simple. Penofol is very easy to use and does not require special construction qualifications. The step-by-step process is as follows:

- Preparing the basis for insulation - pouring a concrete screed with the addition of expanded clay;

- We wait until the concrete is completely dry, after which we spread the penofol. The insulation is laid with the foil side inside the room - in this way the heat will be reflected inside the house. All joints are carefully glued with special adhesive aluminum tape. The insulation should go over the walls with an overlap of 10 - 15 cm;

- We put wooden logs, checking that they lie in the same horizontal plane;

- We carry out the installation of a wooden floor on the logs, carefully making sure that the insulation and the floor have a layer of air between them. Boards must be impregnated with a special antiseptic solution to prevent rotting. To evaporate moisture that can collect on the foil surface, special vents should be made.

- An additional covering in the form of a laminate can be mounted on a wooden floor. This will further contribute to the reduction of heat loss in the house.

Penofol insulation of the "warm floor" system

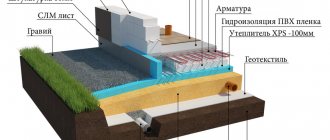

If we install a warm floor in the house, the insulation process is as follows:

- We fill in as a base a concrete screed with the addition of expanded clay;

- After the screed has dried, we spread the insulation on the base, and, as mentioned above, we glue all the joints with aluminum tape, achieving complete tightness - this is necessary to ensure the hydro and vapor barrier of the floor;

- We put heating elements on the insulation;

- We put logs between the heating elements, on which we carry out the installation of a wooden floor. If we decide to pour a concrete screed over the foam foam, then a reinforcing mesh is pulled over the heating elements and the screed is poured. In this case, it is necessary to use penofol type ALP - concrete is an aggressive medium and can destroy other types of heat insulators;

- After the concrete has dried, we trim the edges of the thermal insulator. We mount a decorative coating on top of the screed.

Until the concrete is dry, it is strictly not allowed to turn on the floor heating in order to avoid cracks. After the screed is completely dry, you can turn on the heating elements a little, gradually adding temperature and making sure that no cracks form.

Conclusion

Penofol is, perhaps, one of the most convenient types of modern insulation, which is suitable for thermal protection of almost any area in the house. The presence of a foil layer adds efficiency to its thermal insulation properties. It does not require waterproofing and vapor barrier - this role is played by foil. Self-adhesive type of foam foam removes the need for glue and other fasteners. Ease of use makes it possible to do all the work with your own hands.

At the price, penofol significantly exceeds mineral wool, penoplex, expanded clay, but the effect of its use more than justifies the financial costs, which, moreover, will pay off in the near future by saving costs for heating the house.

Where is Penofol used?

This material is good for use in the insulation of premises, as well as for the implementation of vapor barrier. Often there is floor insulation with penofol in a wooden house. After finishing work, the heat is reliably trapped in the room, providing a cozy environment. In multi-storey buildings, floor insulation on the loggia with penofol is often found. It is appropriate to use it when they combine a loggia with a living room and want to achieve the effect of a warm floor throughout the apartment.

In addition to wall insulation, penofol is also used for ceiling ceilings. They are equipped with thermal insulation in the duct. The material is suitable for work in pipelines. It is even used in the automotive industry, at the stage of thermal insulation of the car body.

Which Penofol is better?

Foamed polyethylene with a closed-cell structure is an excellent solution for insulating objects in production and in everyday life. With the help of sheets, air ducts, pipelines are insulated, they are used as a vapor barrier and a sound-absorbing layer. The main thing, when choosing systems for installation, take into account what temperature Penofol can withstand. Allowable application values are from -60 to +100 degrees, which is sufficient for most equipment.

- In the insulation of residential premises, a biostable, durable and practical thermal insulator has found wide application. To obtain a well-insulated house, the masters only need to decide which Penofol is better for insulating floors, walls, loggias, balconies or other surfaces. The only thing that needs to be observed is the gluing of all joints with reinforced tape and the formation of a closed loop of insulation.

- For log floors, type A can be purchased; it is simply shot with a stick to a wooden frame. But in order to determine which Penofol is for underfloor heating, you need to understand its design. Self-adhesive type C can be used to insulate the floors, which is glued to the base. All other components are easily mounted on top of the steam and thermal insulation: expanded polystyrene, pipes, screed.

- A polyethylene foam insulator is a good solution for a steam room. The closed-cell material does not penetrate water, it does not allow steam to pass through and reflects heat inside. It remains only to understand which Penofol is better for a bath. Here again you need to proceed from the method of attachment to the base. If we take into account that the bathhouse is most often a wooden building, then the choice of type B will be optimal, with the obligatory design of air gaps on both sides.

Which Penofol to choose for insulating a loggia and a balcony, you can read the link.

How can a wooden floor be insulated with penofol?

Older private houses usually have wooden floors. Over time, they begin to retain heat poorly, it becomes cold in the room. It is especially hard for residents in the autumn and winter periods. There is a simple method on how to correct the current situation with the floor. It is possible to insulate a wooden floor with penofol without opening. The thermal insulation material is placed on top. It turns out that the layer is on top of the wooden floor. It is placed end-to-end.It is important not to forget that the seams must be sealed with special aluminum tape.

The resulting layer is covered with plywood sheets. The thermal insulation is attached to the wood base with self-tapping screws.

Warming of a wooden floor with foam foam from below occurs by raising the upper boards. It is preferable to remove the old covering from the boards and put several layers of covering between the logs. The material must be laid with foil down. After that, the old coating is returned to its place.

Thermal insulation of the floor from below with penofol is a convenient way to work with this material. The floors will definitely get warmer.

Penofol application

Even for household needs, this versatile material is widely used. Let's consider the main directions.

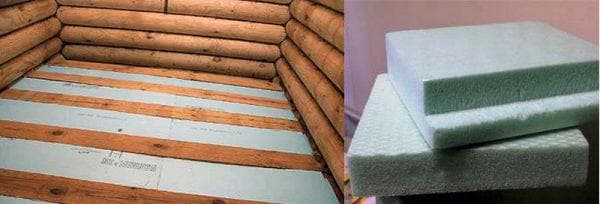

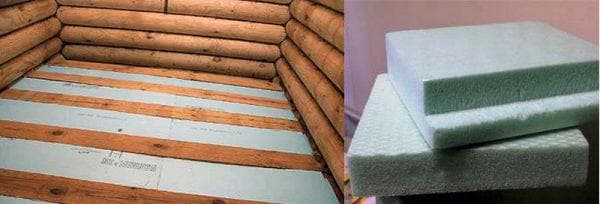

Thermal insulation of wooden floors

Most often, the floors in a wooden house are insulated with penofol. This process is absolutely simple, you can easily do it yourself, just stick to this technology:

- It is best to remove the old boards and lay several layers of foam foam between the logs. In this case, all layers of material must be laid with a foil base inside the room. Then old boards are laid in place or a sheet of plywood is stuffed.

- Another way is to lay the heat insulator on top of the wood flooring. One layer of insulation is used, while the laying is done end-to-end, and the seams must be glued with aluminum tape. Then plywood sheets are laid on the laid heat-insulating layer and screwed to the wooden base with self-tapping screws.

Advice! It is impossible to fix penofol to a wooden base mechanically, for example, with staples. If there is a need to fix the insulation, it is better to treat it with glue or use an adhesive-based material.

Thermal insulation of concrete floors

As a rule, penofol for warming concrete floors in a house or on a balcony is used in conjunction with other types of thermal insulation materials. The technology of work in this case is as follows:

- First of all, the concrete base must be thoroughly cleaned and leveled. In some cases, a self-leveling screed or self-leveling mixture is used for this.

- Then penofol is placed on the base. For this, it is better to use a material with a double-sided foil layer. All joints must be made end-to-end and sealed with aluminum tape.

- After that, a wooden frame is installed from bars with a minimum section of 5 × 5 cm.

- The next step is to fill the space of the wooden frame with any insulation: pressed mineral wool, foam or others.

- Now you need to lay another layer of penofol. For this, a one-sided foil base is suitable, which must be directed into the room.

- The insulation of the concrete base is completed by the installation of plywood or boards on top of wooden logs.

The use of penofol in the underfloor heating system

The use of penofol is very common when arranging a system of underfloor heating, both in a private house and in an apartment or on a balcony. The use of this reflective material increases the heat transfer of the entire system by 15–20%, which is a significant saving at the current cost of energy carriers. Penofol is used when installing warm floors using the following technology:

- After the main insulation has been laid, foil material is mounted on it.

- In this case, the general rule is observed: installation is carried out end-to-end, the seams are sealed with aluminum tape.

- For this option, the one-way option is usually used. If you need to fix the reflective layer, you can use foam foam with an adhesive base.

- Then an electrical cable or a water circuit pipe system is mounted on the foil.

Advice! You can cover the heating elements of the underfloor heating system not only with boards or plywood, but also fill in with a cement screed. Foil base of penofol is resistant to various aggressive operating conditions.

Having studied the properties and familiarized yourself in more detail with such a material as foil-clad penofol, it is easy to agree with the opinion of professionals that this material is an excellent addition to existing insulation technologies. In addition, this insulation can be used as an independent heat insulator.

Using penofol on concrete floors

Floor insulation in a private house with penofol is widely used even on a concrete base.

To get a high-quality coating, you need to do the work sequentially:

- The concrete pavement is leveled. It must be cleaned of all kinds of contamination. It is better to use a self-leveling screed. Some people prefer a self-leveling mixture.

- Penofol is placed on the resulting flat surface. It is recommended to choose class "B", where there is foil on each side. It is necessary to make high-quality joints, and then close them with aluminum tape.

- The next step in warming the floor with penofol will be the installation of a frame made of wood. The section of the timber used must be at least 5.5 centimeters

- Insulation is selected, which is placed in a wooden frame. It must be compressed with mineral wool. The use of foam is possible.

- Next, the second layer of penofol is laid. For this stage, you can take the class "A" of the desired product, which has a foil on only one side.

- The final stage of insulation will be the installation of boards, which are stacked on top of wooden logs.

Insulation of a concrete floor

Usually, a cold base has to be insulated using an additional heat insulator.

This is done using the following technology:

- Preparatory stage. It is necessary to clean the surface of dust, then cover it with expanded clay. At the same time, you should dilute the cement milk and pour it over the resulting layer. After that, you should wait 24 hours, during which time the solution will set and completely solidify;

- Align the floor with a screed along the horizon. Once again we clean the concrete, vacuum it, cover it with a primer;

- We lay out a roll of insulation on the surface, cut off the excess. If there is no sticky layer on the material, fix it with glue. Paying particular attention to the edges, the glue is applied to the matte side. Allow the product to harden for a couple of minutes before gluing. Then place the cut on the concrete, iron it and press down to secure it completely;

- If the area of the room is large, lay the second piece here, connect the joints with aluminum tape;

- Place the slats around the room, fix with dowels to the surface. Install the beams in a horizontal plane;

- Place another piece of material on top of the first, shiny side up;

- To finish covering the floor, nail boards or plywood sheets to the joists. On top you can lay linoleum, laminate.

Instead of expanded clay, you can use polystyrene or expanded polystyrene with a thickness of 5-10 cm.

Pros of using penofol

It is important to know all the positive aspects of using this material:

- It can be laid in rooms where it is damp, for example, in a cellar (basement). When installing, separate membranes for waterproofing are not required.

- Besides the fact that you get a coating that retains heat well, sound insulation is a bonus. This quality of material is relevant for multi-storey buildings with noisy neighbors.

- Penofol is recommended to be used in combination with other heat insulators, then its properties only increase. A good example is the use of the desired material in baths. A layer of aluminum foil in the steam room helps to keep the temperature high.

- Even at high humidity and high temperatures, penofol will not emit fumes that could harm human health.

- The material is considered thin, which is good when laying it on the ceiling. The height of the ceilings practically does not change, other heaters make the room visually smaller, since they recede a few centimeters from the ceiling.

- Penofol is offered for sale in rolls. It can be easily cut, you can lay it down in a short period of time.

- It is often used in rooms where there is a great fire hazard. The material does not burn, which makes it irreplaceable.

- For private houses, it is taken in order to insulate the basement floors, and also because mice do not gnaw it.

Which Penofol is better to use?

The material demonstrates high thermal insulation properties despite its low thickness. How does he do it? Now we will explain briefly. The basic principle of thermal insulation is a combination of two types of insulation. Foamed polyethylene consists of air bubbles enclosed in a thin polymer shell. The cells are tightly connected to each other, so that water and air do not penetrate into the structure. Accordingly, heat transfer is also blocked.

The second feature of technical insulation is the presence of a reflective layer. More than 40 years ago, the ability of precious metals to return thermal radiation was experimentally proven. However, they conduct heat well. This is why PE foam and aluminum cladding work together so well!

Consider the thermal conductivity of insulation. With values in the range of 0.037–0.051 W / m · ° C, polyethylene foam is comparable to the popular mineral wool. Whereas the usual ceramic brick masonry in dry conditions has a thermal conductivity of 0.56 W / m · ° C.

The 14 micron aluminum coating returns up to 97% of thermal radiation. That is, the room is warmed up by reducing heat loss. It remains to calculate the energy savings.

Reviews of owners of private houses

Home owners speak positively about this material. Citizens note that they choose floor insulation with penofol because of the light technology. You can do the work yourself, the main thing is to follow the instructions for use.

Many people note the durability of the sought material. When insulating a surface, it is difficult to make a mistake, even when sealing joints. Penofol also received positive reviews due to its low cost. Compared to other insulation materials, it has an affordable price for most citizens.

So, we found out what penofol is and how to insulate rooms with it.

Materials used

Going to a building materials store, you can see how wide the range of products in question is. Each heat insulator differs in its dimensions, characteristics and installation method. The choice of this or that material depends on the personal wishes of the owner and the characteristics of the floor covering.

Mineral wool

For thermal insulation of a cold wooden floor, mineral wool is often used. The heat insulator is produced in the form of elastic mats and panels. The process of its installation is carried out in one layer.

Insulation mineral wool

The main advantages of the material include:

- high noise and heat insulation performance;

- long service life;

- resistance to fire and high humidity;

- acceptable cost;

- security;

- resistance to mechanical and chemical factors.

Polyurethane foam

The material is ideal for thermal insulation of the floor from below. Its peculiarity is that it contains pores that are filled with air and gas. Polyurethane foam is lightweight, but at the same time perfectly retains thermal energy. Possesses maximum resistance to the formation of fungus and mold. It does not lend itself to decay and the influence of acids.

Insulation Polyurethane foam for the floor

Polyurethane foam is laid using a special technique, and it is also characterized by excellent adhesion to the surface.With the help of this material, it is possible to carry out floor insulation of various shapes without forming joints.

This heat insulator for floor insulation from below is considered the most popular. Due to its special structure, a low level of vapor permeability and heat conductivity, fire resistance is achieved. The material is also distinguished by its reliability and resistance to the influence of mechanical and chemical factors.

Insulation foam for the floor

Styrofoam has a long service life, while retaining its thermal insulation properties. Its main disadvantage is that it absorbs a small amount of liquid, which has a detrimental effect on certain properties.

You can make the floor warmer in a wooden house with the help of penoplex. It is distinguished by its light weight and homogeneous polymer composition. Thanks to this, there is no load on the base of the house. The heat insulator is made by means of extrusion - forcing soft raw materials through molding recesses of special equipment.

Penoplex insulation for the floor

The heat insulator is highly reliable and resistant to low temperatures. It will show its thermal insulation qualities for a long time and will create reliable protection against moisture penetration.

Thermal insulation of a wooden floor can be done using expanded clay. It is a free-flowing material characterized by a porous structure. The heat insulator is produced by firing slate or clay in a special furnace.

Expanded clay insulation for the floor

Expanded clay is a durable and environmentally friendly material. It is characterized by high levels of sound insulation, fire and frost resistance. But expanded clay has one drawback - after a while it becomes too dense due to its own weight and loses its thermal insulation qualities.

How to insulate from the basement

It is extremely necessary to insulate the basement in a private house. Thanks to this, it will be possible not only to reduce heat loss, but also to protect the house from dampness and destruction in the future. For carrying out thermal insulation work, you can use penoizol, polystyrene, but mineral wool can be used to seal up the ceiling from the side of the basement. With the help of foam, the floors and walls of the basement are insulated.

The first step is to prepare the surface. And to do this, remove all debris and dirt, walk with an antiseptic and a primer. This will protect the surface from rotting, and will also make the material adhere more firmly to the surface. Fastening a heat insulator is a simple matter that even a beginner can handle. You need to apply glue to the surface of the heat insulator, and then immediately apply it to the ceiling.

On the video floor insulation in a wooden house from the basement:

Floor insulation from below in a private house is a necessary measure to create a comfortable and warm environment. The main thing in this matter is to choose the right thermal insulation material. And although the choice is very wide today, you need to choose the insulation that will be convenient in terms of installation, will suit your operating conditions and will become a reliable protection against heat loss.

How to insulate

The most effective and reliable way of installing a heat insulator from the bottom of the floor is laying on logs - transverse beams, on which the floor covering will be concentrated.

The insulation process is not difficult if you follow the following procedure:

- Fix the beams to the foundation with a step of 1-1, 2 m.

- Fix chipboard or thick plywood on the boards. Use self-tapping screws for fastening. This stage is important for the installation of the thermal insulation layer.

- Place the selected heat insulator on the surface between the beams. The thickness of the layer to be laid can be different, so the dimensions of the transverse logs must be taken into account.

- Lay a layer of waterproofing on top of the insulation. Most often, plastic wrap is used. This does not always need to be done, since there are a number of heaters that have an increased level of moisture resistance.

- At the final stage of installation, a wooden covering is installed. It can be old or new material.

On the video floor insulation in a wooden house from below with penofol: