Relevance of the issue

As you know, warm air always rises. If, during the construction of the building, the insulation of the ceiling was not taken care of, then you will lose 30-50% of the heat. For example, if you used four cubic meters of gas during the day, then 1.2-2 cubic meters. meters will go to "heating the street" (or attic).

Uninsulated ceilings are the main reason for the formation of condensation on their surface, which contributes to the emergence and development of fungi or mold. If this has already happened, get ready for an expensive repair, and it costs several times more than carrying out work on the insulation of the ceiling.

In order to choose the optimal material and method of insulation, the following factors must be taken into account:

- Construction (features) of the ceiling and roof.

- Climatic features of the region (pay attention to the air temperature outdoors and indoors at different times of the year).

- Physical properties of the material used.

In addition, you should know that there are internal and external ways to insulate ceilings. The effectiveness of each of them is determined individually.

Insulation of the ceiling in a wooden house with mineral wool

Minvata is divided into three types: glass wool, slag, basalt or stone wool - all of them have found application in the construction of wooden houses. Glass wool is used for cold attic floors, stone wool is used to insulate ceilings both from the inside and outside, and slag wool is used to insulate pipelines, septic tanks, and outbuildings.

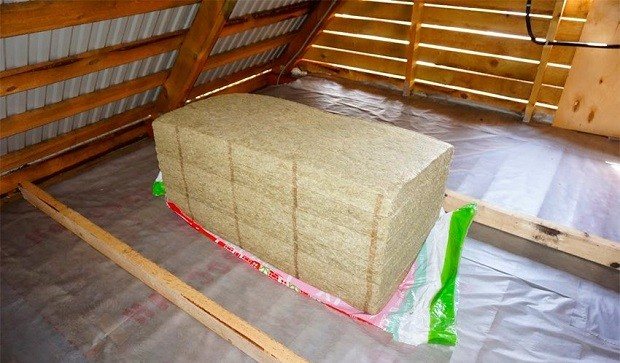

Before insulating a wooden ceiling in a private house, do calculations of the thickness of the insulation, filling area... Each roll or package of insulation boards has an indicator of the geometric dimensions of the insulation, R-value or coefficient of thermal conductivity. Determine the required amount of material, then purchase hydro and vapor barrier materials, insulation, fasteners, which are usually included in the insulation kit, purchase tools and protective equipment.

If a attic unheated, then roll material moisture resistant glass wool will fit, it is laid on the floor of the attic between the floor beams, the distance between the beams is 58 cm, the height of the beam is 100-150 mm. For central Russia, 150 mm thickness of ROCKWOOL Thermal insulation is enough.

Insulation moisture resistant it is laid on the floor of the ceiling without vapor barrier, provided that the room under it is dry.

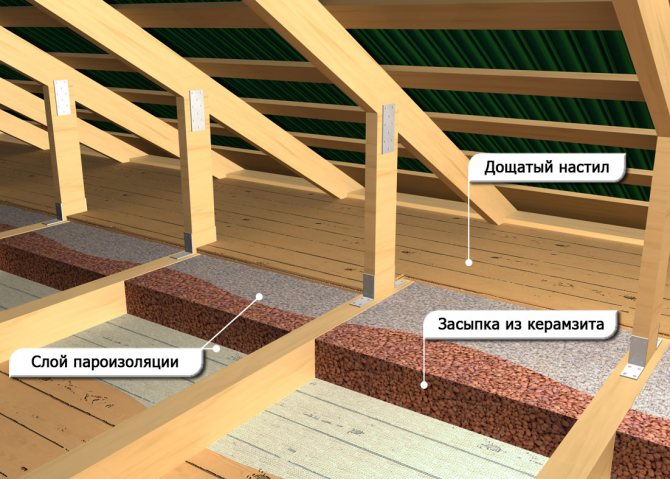

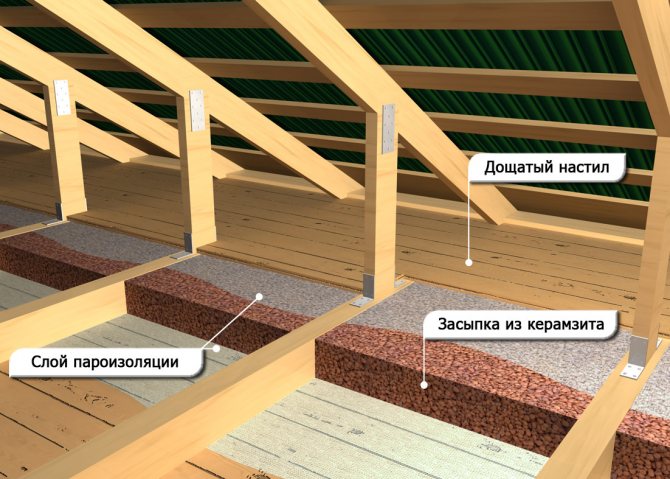

Then, if they intend to use the attic for storing things, they lay vapor barrier film, nail a 20 x 45 mm rail on the lags, for the ventilation gap and lay the floor. Sometimes the question arises: what is the best way to insulate the ceiling in a wooden house, if it is an attic? The best solution - natural materials: cellulose, sawdust, expanded clay.

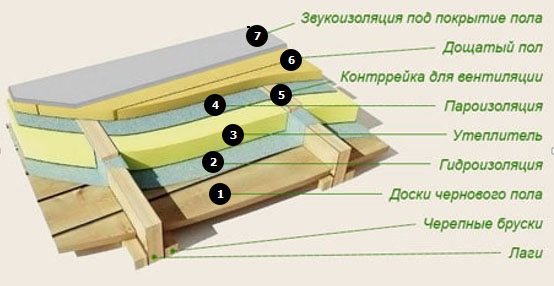

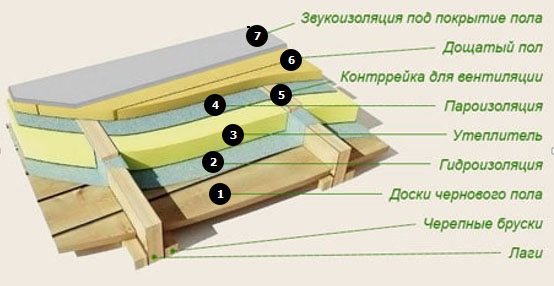

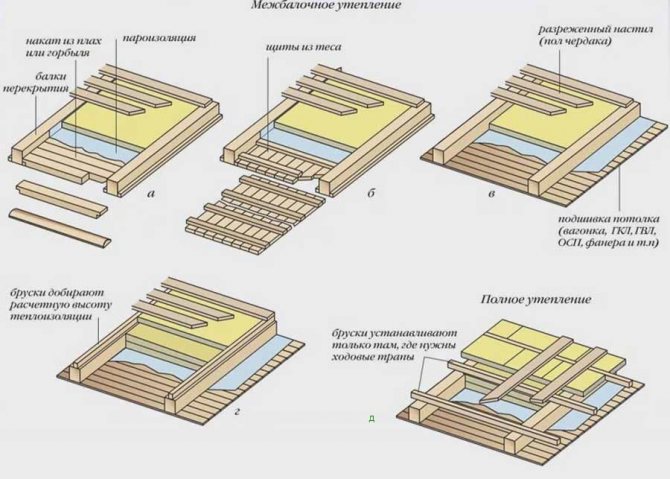

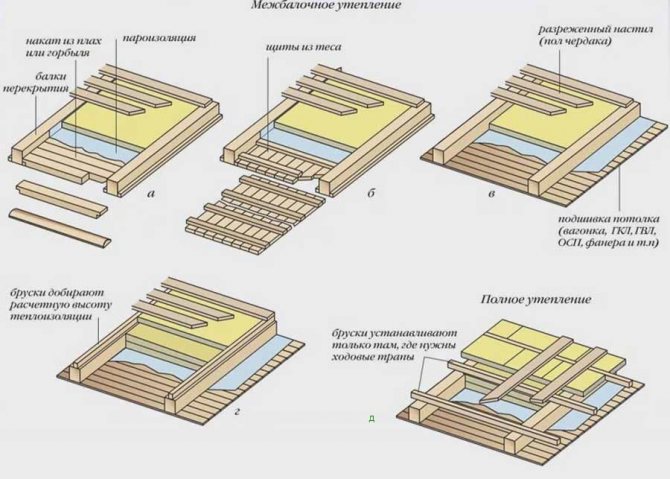

Here is a classic scheme for insulating a ceiling in a wooden house with your own hands from the attic side.

Here, work on insulation begins with the installation of a waterproofing film (2), you can also use a vapor barrier "Izospan" or a simple plastic film.

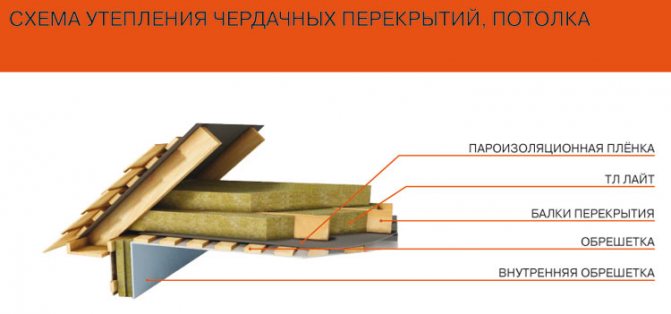

When planning an attic, additional living space, it is better to insulate the ceiling in a wooden house basalt, and hydro and vapor barrier is needed if there is a kitchen or bathroom under it. Insulation (3) is placed between the overlap logs, covered with Izospan vapor barrier film (4) on top, and then a counter batten (5) is nailed to the logs to create a ventilation gap.

Instead of a batten, you can nail in a felt sound-absorbing damper strip and place a floorboard on it. The diagram suggests using a rough plank floor (6), then a lining under the laminate (7) and then a finishing floor.

Materials for performing work on insulation of ceilings

To date, the following materials can be used to insulate ceilings:

- Expanded clay is a lightweight, durable, refractory material that retains heat well and has excellent sound insulation performance.

- Sawdust is an environmentally friendly and inexpensive material.

- Polyfoam is one of the best options for ceiling insulation, which has a lot of positive characteristics.

- Mineral wool is lightweight, non-toxic, but costs much more than other insulation materials.

- Ecowool is a high-quality but expensive material.

- Clay - has excellent thermal insulation properties.

Each of the listed materials has its own advantages and disadvantages. If you need insulation for the ceiling in a wooden house, but you do not know which one is best for your situation, do not rush to buy the most expensive material. To get started, carefully study the information provided.

Ceiling insulation with tiled and block materials

Most modern insulation materials are available both in the form of soft rolls and in the form of stiffer slabs. These are all types of mineral wool (primarily basalt wool) and ecowool. Also, in the form of plates, foam and polystyrene foam are produced. More often than others, basalt wool slabs are used to insulate the ceiling.

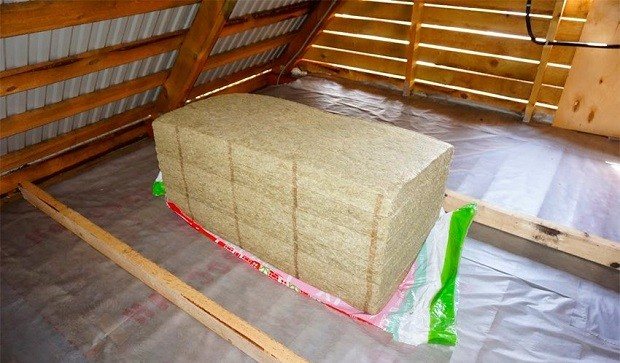

Basalt wool - insulation with basalt, more precisely, with hard basalt fibers inside, has excellent thermal insulation properties and high ductility. To insulate the attic from above, it is better to use basalt wool in the form of slabs, and from below - in the form of rolls.

The technology of warming the attic with basalt wool slabs is simple, does not require a lot of time and great physical effort. First you need to completely clean the surface of the attic, freeing it from dust, dirt and foreign objects. If the wooden structures of the attic are open, it is best to treat them with antiseptics to protect them from mold and mildew.

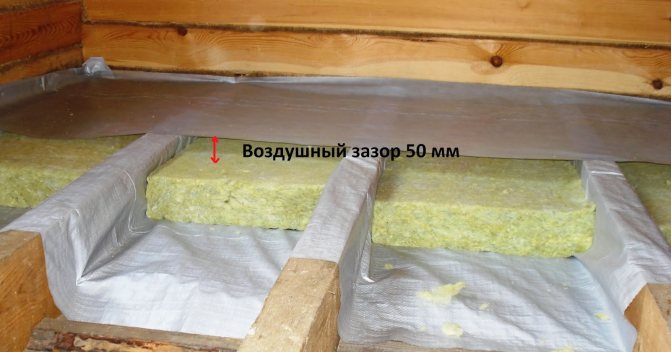

Then a vapor barrier film is laid out in the attic, with the obligatory observance of an overlap of the laid strips of 7-10 cm and gluing all joints with tape. Basalt wool slabs are laid between the ceiling beams. If the ceiling design does not allow laying basalt wool slabs between the beams, then before laying it is necessary to fill the mounting rails in the attic, observing a step of 0.5-0.7 cm less than the width of the insulation slabs.

On top of the insulation slabs, they are covered with a waterproofing film, on top of which, in order to ensure the ability to move freely along the ceiling, a subfloor is mounted from old boards.

According to a similar scheme, the ceiling is insulated with any tiled or block heat insulators, incl. and homemade, made from a mixture of hay or straw and cement.

Insulation of ceilings from the inside

The main disadvantage of the presented method of insulating ceilings is the fact that you have to fix all the elements above your head, and this is a very uncomfortable position.

An important point! If the house has already been renovated, then the presented method will be irrelevant for you. Experienced experts recommend that you be engaged in insulation of ceilings even at the stage of internal work, in the process of building a house (or during a major overhaul).

The sequence of insulation of ceilings from the inside:

- 1. If there are gaps in the ceiling, be sure to remove them with polyurethane foam. Large holes must be caulked beforehand.

- 2. In order to exclude the appearance of condensation, it is necessary to attach a vapor barrier film to the ceiling. To carry out these works, you need a construction stapler.

- 3. The next step is to lay the insulation material. Do this so that you feel comfortable, and the pieces of material fit snugly against each other, preventing warm air from leaking out.

- 4. Installation of ceiling coverings is in progress.

The listed stages of insulation work are designed for the use of ecowool and glass wool.If you decide to use polystyrene (materials similar in structure), then after fixing the vapor barrier film, pieces of this material are glued to it, and another layer of film is applied on top.

The final stage of these works includes fixing the ceiling sheet or hemming the ceiling with specially prepared boards. Pay attention to the fact that experts in this industry recommend insulating the ceiling in a room from both sides at the same time.

The best materials for outdoor insulation

The industry produces a wide range of insulation materials. Each of them has its own properties, positive and not quite qualities. First of all, environmental friendliness is important - they should not harm health.

Each of the heaters will make the house warmer, less accessible for the penetration of extraneous noise. The main difference lies in the price and laboriousness of installation.

It is essential that the insulating layer does not create unnecessary stress on the ceiling structure and does a good job of retaining heat. Also, it should not accumulate condensation on itself and be resistant to fire.

The material used for insulation is divided into 4 categories:

- bulk - this group includes ecowool, expanded clay, sawdust;

- slab - this is expanded polystyrene, mineral wool dense sheets, cork plates;

- roll - all varieties of mineral wool;

- sprayed or bulk - here we are talking about penoizole.

Let us consider in detail the characteristics of the main materials used as insulation.

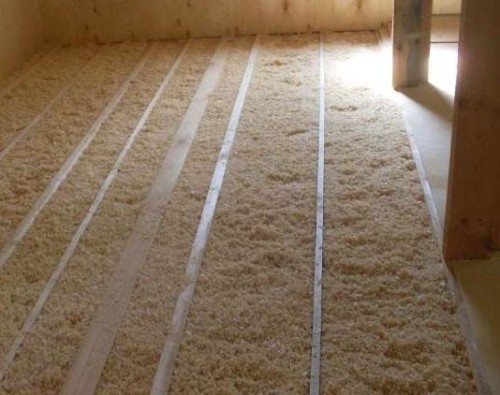

Sawdust as insulation

Despite the fact that there is a great variety of new materials, the relevance of sawdust remains the same. They are readily available, cheap, and the quality is not inferior to expensive heat insulators.

You need sawdust stored for no more than a year, dry, odorless and mildewless, medium in size. The volume of the material is determined based on the area to be insulated.

Alternatively, the sawdust is soaked in a solution of copper sulfate. After that, drying will be required, and then a mixture of wood material and cement is prepared.

A cement mortar is made in a ratio of 1:10 - 10 buckets of sawdust are added for every one and a half buckets of liquid. The output is a bright gray and wet mixture. It is subsequently distributed along the plane of the ceiling. The recommended height of the insulation layer is 20 cm.

Before laying the mixture, the entire area to be insulated is cleaned of dust and other contaminants. Then it is treated with an antiseptic solution, covered with waterproofing

To improve the adhesion of the thermal insulation to the ceiling surface, the layer can be slightly trampled, it will be compacted and it will retain heat better. When the solution of chips and cement dries up, you can walk on it.

Sometimes lime or gypsum is added before mixing sawdust with cement mortar. This makes the insulation invulnerable to rodent attacks, and increases the degree of its fire safety.

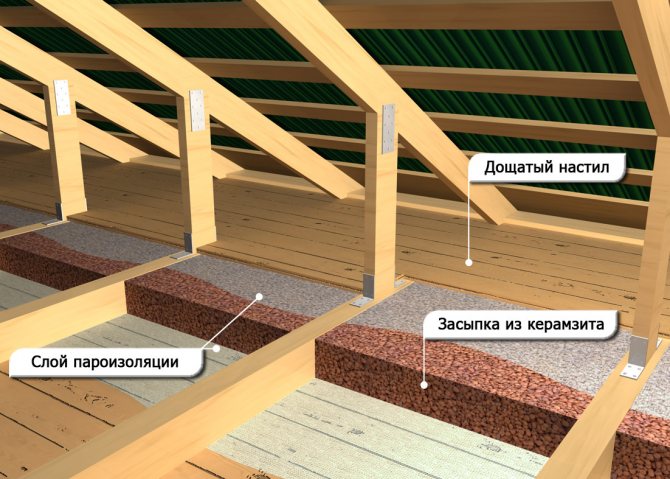

Insulation of the ceiling with expanded clay

Another old, but not entirely forgotten method of insulation is a layer of expanded clay on the ceiling. The full environmental friendliness of the material attracts, since expanded clay is just high-strength balls obtained from fired clay.

The material is durable, resists deformation well, absorbs moisture, which subsequently evaporates. An attic insulated in this way is always dry, which is why wooden structures last longer.

The thermal insulation characteristics of expanded clay are still lower than those of the latest generation of insulation materials.

If there is another one above the insulated room, the space between the logs should not be filled to the full height. A two-centimeter gap between the insulation and the surface of the future floor will exclude contact of the latter with the granules. Therefore, when walking, there will be no extraneous sounds.

Fine and medium-sized material is better suited.Before laying it, the surface is cleaned of all strangers, covered with glassine or a special membrane.

Expanded clay is poured over the waterproofing layer. Further, it is advisable to cover the surface with a board or plywood. You can also use OSB plates. An option such as a cement screed is also suitable.

Expanded polystyrene plates for ceiling

The heat-retaining properties of expanded polystyrene are much higher than that of bulk materials. Since the slabs are lightweight, they exert minimal stress on the ceiling structure.

It is easy to work with this material. It is easily cut, so it is not difficult to fit it under the openings. There are sheets of different thicknesses on sale.

Since this insulation does not allow air to pass through well, it must be separated from wooden structures with a vapor barrier material. Otherwise, condensation will surely appear.

Slots at the joints are also disadvantages of this method of insulation. Heat is lost through them, so you cannot do without the use of polyurethane foam.

Lay the material as follows:

- The base is cleaned and a vapor barrier is placed on it.

- Give the polystyrene sheets the desired geometry and dimensions.

- Lay out the material, pressing it tightly to the base.

- Fill the joints with polyurethane foam.

- Excess frozen foam is removed.

If the attic is going to be used, a finishing coating in the form of a reinforced concrete screed at least 50 mm thick is laid on the slabs.

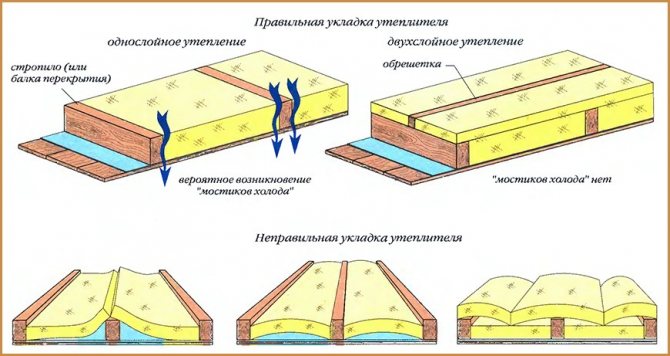

If the insulation is carried out in two layers, the second layer is laid in such a way that the sheets are displaced by about half of the bottom sheet. This will prevent the appearance of cold bridges.

Although expanded polystyrene is of unnatural origin, it does not emit harmful substances during operation. This material does not rot, does not corrode, does not contribute to the appearance of fungus, mold.

The average service life of the material is 20 years. Negative property - fragility, instability to chemical reagents.

Rolled mineral wool

Mineral wool in rolls has the lowest density - 1-11 kg / m3. This is due to the fragility of the fibers. If you make the material tight, it will not roll. Mineral wool is a non-combustible material.

Since it is easy and convenient to lay, this material is most often used. With its help, you can insulate the ceiling in a wooden house, both outside and inside. It will not be very expensive.

The fibers in the glass wool are arranged randomly, which provides both high thermal protection and sound insulation. There are separate lines of materials that absorb sound vibrations.

When installing this type of insulation, protective equipment is needed, since the dust generated during operation is dangerous for the skin and respiratory tract

As a minus, low moisture resistance can be noted. This material should not be tamped, since the air contained between the fibers will go away and the thermal conductivity will significantly decrease.

The styling technology is also simple:

- The surface of the overlap is cleaned, necessarily removed or hammered to the full length, nails sticking out of wooden structures.

- Lay a vapor barrier film.

- Lay the mineral wool, trying not to leave gaps.

- Cover the mineral wool with a polymer film or foil material.

If you plan to periodically walk in the attic, you need to arrange a wooden flooring, securing it in such a way that it does not put pressure on the insulation layer.

Some types of mineral wool contain phenol. However, if the temperature limits are not exceeded, this hazardous substance will not be released.

Features of insulation with penoizol

Penoizol is a liquid foam. It belongs to those materials that cannot be used without special equipment. It is poured or sprayed, based on the type of installation.

In addition to equipment, you need a protective suit.It is difficult to get the job done without professional skills.

The main advantage is that the material fills not only all the cracks, but also microcracks. In addition, it is safe, non-flammable, and rodents are not interested in it. The structure of the material contains many air bubbles, which guarantees excellent insulation.

Sometimes penoizol is used as sound insulation. The 5 cm layer absorbs about 95% of the sounds. Manufacturers claim that certain types of material can last 70 years

Schematically, the technology looks like this:

- a vapor barrier is laid on the surface;

- fill the gaps between the beams with penoizol with a layer of about 25 cm;

- lay a layer of roofing material or other similar material;

- plank topcoat is laid.

Negative quality - fragility, mechanical stress to the material is contraindicated. The high cost also cannot be attributed to the advantages of penoizol.

Sawdust - high-quality insulation?

For a more detailed analysis of the question of how to insulate the ceiling in a wooden house, it is necessary to consider the main methods of carrying out these works using different materials.

The use of wood sawdust for external insulation of ceilings is time-tested.

This is an inexpensive and moderately effective method, for the implementation of which the following components are required:

- Water.

- Cement.

- Polyethylene or vapor barrier film.

- Dry sawdust (optimal size - medium).

Experts recommend using cement in a ratio of one to ten (in relation to sawdust).

The whole process consists of the following steps:

- 1. The surface is prepared: debris is removed, the cracks are sealed, and the film is laid.

- 2. A mixture of cement with sawdust is prepared. Water is added gradually.

- 3. The resulting mixture is being laid (layer height 15-20 cm).

Here is a great video from the real owner of the house, who decided to insulate the ceiling with sawdust. See what he says in the end:

Note! The above work should be carried out no later than July-August, so that the mixture of cement and sand dries well before the cold weather. The main disadvantage of the presented method is that the tree tends to rot, and the entire protective layer can be destroyed by rodents and insects.

Thermal insulation materials

The market for building materials offers a very wide range of products to improve the energy efficiency of a home, including wood. Each industrial product has its own characteristics of use, differs in the laying process and is used strictly under certain conditions. The ceilings of wooden buildings are usually insulated with expanded polystyrene, sawdust, mineral or basalt wool or expanded clay granules.

Expanded polystyrene

Expanded polystyrene boards are a great option for arranging thermal insulation of suburban real estate. The insulation is lightweight and does not pose any danger to the environment. Expanded polystyrene is often confused with polystyrene foam, but the production technology of these thermal insulators is radically different, as are the thermal insulation qualities of materials.

List of main benefits:

- Expanded polystyrene is almost not subject to crumbling, unlike polystyrene, and its service life is much longer;

- The material has an increased level of moisture resistance in comparison with mineral wool;

- The thickness of the expanded polystyrene slabs is significantly less than that of basalt wool with equal heat saving rates.

The disadvantages of a thermal insulator include its ability to burn and a relatively high price. Expanded polystyrene is unacceptable to use in wooden houses where mice and rats are found, as they like to reproduce in it, equipping passages and burrows.

Sawdust

Sawdust is a material of natural origin, characterized by a very low weight and completely safe for the environment and human health. Thermal insulation of the room with sawdust is one of the most budgetary methods, since the material for the work can either be asked for in the wood production or bought at an extremely pleasant price.

The main disadvantage of this insulation is its high fire hazard, since the fleeting effect of fire or high temperature is enough for it to ignite. Over time, such material dries up and cakes, and serves as a haven for rodents.

Expanded clay

Expanded clay is another popular insulating material for floor and ceiling treatments. It looks like clay granules with many pores. It retains heat well and is cheap. Its main plus is the longest service life in relation to analogues.

The insulation is highly durable, fireproof and not affected by moisture.

Mineral wool

This type of insulation is very popular among consumers. It is her that owners of private households prefer to acquire. The positive qualities of the material include:

- increased heat saving characteristics;

- ease of installation indoors;

- does not support combustion;

- has a long operational life;

- the cost of the insulation is affordable;

- remarkably insulates the room from extraneous sounds from the outside.

The disadvantages of mineral wool include:

- low indicator of its environmental friendliness;

- ability to absorb moisture;

- over time, the material loses most of its useful properties.

The use of expanded clay

The presented material in many respects is one of the best for use as a material that retains heat in the house.

It will not be eaten by mice and insects, it is designed for a long period of operation, does not rot and has excellent sound insulation.

For the installation of insulation, in addition to expanded clay, you will need:

- Drywall / Boards.

- Vapor barrier film.

- Scotch.

The whole process of installing insulation materials can be divided into the following stages:

- 1. Preparation of the coating. Garbage is removed, the joints are glued, and the film is laid.

- 2. Expanded clay is poured. The height of the cover must be at least 20 cm.

- 3. Vapor barrier film and boards are laid on top.

By the way, here is a very revealing video in which a foreman with many years of experience shares his thoughts on ceiling insulation with expanded clay:

Some owners of wooden houses lay expanded clay so that its height is 30-50 cm. Of course, the thicker the protective layer, the better the heat will be retained, but do not forget about the loads on the floors. This amount of expanded clay has a decent weight, not every structure is able to withstand it.

Ceiling insulation technology from above

It all depends on what kind of insulation will be used. If mineral wool or expanded polystyrene plates are used (which is inexpensive), then on a prepared basis it is necessary to make a crate. It's just that wooden slats with a cross section of 50x50 mm are nailed to the flooring every 1 m.

The distance (1 m) is not easy to choose. This is the width of the mat of mineral wool and PP slabs. After all, the main requirement for thermal insulation processes is to create a layer without cracks and gaps, which during operation will become cold bridges. Therefore, the insulation must fit snugly against the elements of the sheathing. If from one of the edges of the structure the step between the slats is less than 1 m, then the insulation is cut to the required width.

Insulation of the ceiling structure outside with mineral wool

The main article is insulation with penofol.

It is necessary to approach the insulation of the ceiling structure in a wooden house with polystyrene (expanded polystyrene plates) and mineral wool taking into account the thickness of the heat-insulating layer.Since the thermal conductivity of materials is different, it is recommended to lay mineral wool with a thickness of 100 mm, PP slabs not less than 50 mm. That is, for polystyrene, the laid crate is just right. For mineral wool, it will be too small. Therefore, on the installed rails, you need to punch one more on top.

Mineral wool has one drawback - it is a hygroscopic material that absorbs moisture well. Therefore, a waterproofing membrane is stretched along the crate, which will protect the insulation. The strips are laid with an overlap with an offset of 10-12 cm. The laying direction is across the laid load-bearing beams. And after that, boards are stuffed on top, because walking on a mineral wool means crushing it and reducing its strength and thermal performance. In this regard, foam is stronger, plus it does not absorb moisture. But it is not recommended to walk on it either, so you will have to lay OSB boards or plywood sheets on top, or boards.

Thermal insulation of the ceiling from the outside with foam

As for expanded clay, it is simply scattered over the surface of the flooring, after having filled the restrictive elements along the perimeter of the latter. It can be all the same slats, stacked vertically in three rows. The thickness of the expanded clay layer of 150 mm is more than sufficient.

Polyurethane foam is the best of all. But it has two drawbacks:

- It costs much more than all other materials.

- For its application, special equipment is required, consisting of two cylinders and a compressor, plus hoses with a nozzle.

Thermal insulation of the ceiling with expanded clay

Before insulating a wooden ceiling with polyurethane foam, you need to weigh the pros and cons. The only thing to add is that manufacturers now offer mini installations. They include two cylinders in which the insulation components have already been pumped in under pressure, that is, the compressor is no longer needed. The equipment weighs 30 kg.

Apply polyurethane foam in a small layer (within 2-3 cm). In air, the colloidal mass immediately solidifies and becomes strong. So you can walk on such a warm floor in the attic without fear of damage. In this case, the heat-insulating layer is a continuous coating without seams, gaps.

Thermal insulation of the ceiling outside with polyurethane foam

Mineral wool

The nature and the first stages of these works are the same as in the case of sawdust. After surface preparation, cotton wool is laid, cracks and holes are blown out (large ones must be caulked), and then, all this is covered with a film. You can put boards on top or make a screed.

Some experts advise doing combined protection. For this, the first layer of foam (its analogs) is laid, and the second, of mineral wool. Further stages are carried out according to the above scenario.

Useful video

Let's watch a useful video about ceiling insulation in a house without installation work:

Having familiarized yourself with the materials and methods of insulating the ceilings of wooden houses, we can state that for insulating dry rooms, it is possible to do without additional sealing films.

For wooden houses, including summer cottages, the best insulation is moisture resistant, which does not require additional protection from moisture. Basement-type rooms are best insulated with polyurethane foam. To supplement the thickness of the insulation, it is better to use backfill, because they are better at filling voids in especially difficult places.

Ceiling insulation with clay

Clay is as much in demand today as it was a hundred years ago. Its main advantages are durability, reliability and ability to retain heat well. Clay is used as a heater only together with sawdust.

After preparation of the coating, a vapor barrier film is laid, on which a solution of clay and wood sawdust is applied (layer thickness 10-15 cm). At first, it is necessary to control how the solution dries.All cracks must be filled with clay.

Representatives of the older generation (especially rural residents) still remember the times when clay mixed with straw was used as insulation. But today such a solution is practically not used.

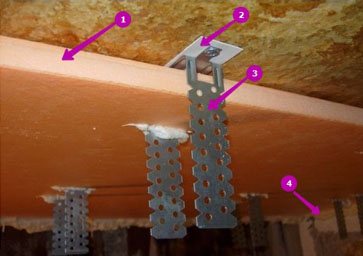

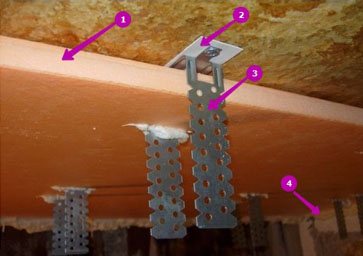

Insulation of the ceiling between floors in a wooden house

Insulation of the ceiling of the first floor in a wooden house is interfloor insulation... Here, the requirements for the thickness of the insulation are not significant, because if some of the heat penetrates into the rooms of the second floor, then it will be useful for heating.

Here the choice of insulation is based on two-component qualities: heat and sound insulation. These qualities are possessed by high density insulating materials. The technology of insulating the ceiling in a wooden house with high-density slabs is somewhat different from the traditional one: laying insulation in the space between the floor joists.

Note. A damper pad (2) is placed under the suspension (3), damping percussive sounds. "Penoplex" - dense polystyrene, fixed with liquid nails to the wooden ceiling of the floor, all cracks and gaps are filled with a foam seal (4), which is also a damper between the wall and the ceiling. Add a plasterboard suspended ceiling here - you get excellent thermal and sound insulation protection. By the way, instead of a gypsum plasterboard ceiling, stretch ceilings are used, which greatly simplifies installation.

Thermal insulation of the ceiling of a wooden house is possible both during construction and in operation. If you find that the ceiling is not sufficiently insulated due to voids formed due to shrinkage of the insulation, then you can always fill the voids with bulk material - cellulosewhich is lightweight and completely harmless to health.

Cellulose insulation not susceptible to mold, fungal diseases, moisture resistant and durable. For insulation of interfloor floors, it perfectly fills voids, especially in hard-to-reach places, does not cake, has high coefficient of thermal resistance... Fall asleep with a layer of 150-200 mm.

How to insulate the ceiling of a wooden house with basement rooms

Many wooden houses are built on concrete, brick, aerated concrete, expanded clay concrete plinths covered with lightweight concrete slabs, which are the ceilings of garages and ancillary basements. A simple way to insulate such premises is polyurethane foam ceiling covering using foaming components and a special tool for applying a heat-insulating coating.

Such a covering can also be done on a wooden floor. The method is beneficial in that it does not require costly preparatory work. Foamed polyurethane fills all voids and cracks. Perhaps the disadvantages of the method are:

- Lack of this technology in remote areas;

- Intolerance to UV rays;

- Expensive compared to other methods.

Although, in monetary terms, this method is not much more expensive than the construction of additional logs and the laying of roll insulation or the installation of tile insulation. It's up to you, but this method is more and more popular:

- Lack of preparatory work costs;

- High speed of work execution;

- Excellent heat and sound insulation properties.

Rolled insulation

The process of insulating the ceiling of a wooden house in this case is slightly different from all of the above methods:

- 1. The first stage includes surface preparation, driving nails into it (not completely) and zigzag thread tension.

- 2. Rolls are laid.

- 3. The vapor barrier film is fixed.

- 4. The nails are driven to the end to better press the insulation.

- 5. Boards or drywall are nailed on top.

An important point! If you work with rolled insulation (mineral or glass wool), be sure to use protective clothing, glasses, gloves and a bandage for your nose and mouth so that harmful particles do not get on your skin, eyes, nose, etc.

When performing this work, be sure to make sure that there are no cracks anywhere.

Installation process

The ceiling in a wooden house is attached to the floor beams, through which the heat quickly evaporates upward. To avoid this, two possible methods are used - laying the insulating layer from above or from below. In regions with a rather harsh climate, it is possible and desirable to use both at the same time. This will significantly increase the heat resistance of the house.

Insulation from below

This method is used in cases where the surface is sewn up with plasterboard, plastic, clapboard, and so on. It should be borne in mind that the height will drop significantly. Ideally, all work should be done before the room is renovated. Materials required for work:

- waterproofing film;

- Scotch;

- polyurethane foam;

- thermal insulation.

Ceiling insulation in a wooden house begins with filling all the cracks in the corners between the walls and the ceiling with foam, if necessary, first sealing it. This procedure will significantly increase the tightness of the living space. After drying and expanding, the excess foam is removed using an ordinary clerical knife. Then the obligatory waterproofing is done.

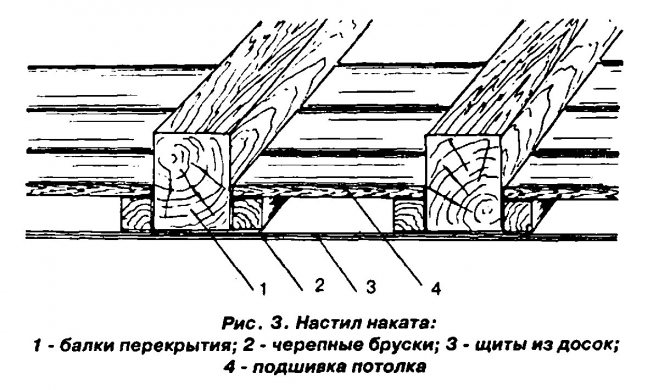

Wiring diagram of wooden floors

It is important that the film is laid correctly, that is, it waterproofs the room from the external environment and vaporizes the room from the inside. In this case, it will fulfill its function and the room will "breathe". Waterproofing can be installed either in whole strips of film, or in small pieces. In both cases, the joints must be glued with tape. The film is attached to the ceiling lathing with a stapler.

The insulation layer is fastened either with a self-tapping screw (applicable for polystyrene or expanded polystyrene), or using a wire stretched crosswise, pressing the material to the ceiling (in case it is a mineral plate). You need to press hard, otherwise you will not be able to get the desired effect. After completing these works, it is advisable to close the insulation with another layer of waterproofing. As a result, the ceiling in a wooden house will work like a thermos. Only then do further editing begin.

Helpful hints

If you decide to do ceiling insulation, be sure to study the presented tips from professionals.

- Before starting work on the insulation of the ceiling, be sure to check the condition of the roof. If there are gaps, cracks, etc., first eliminate them, and only then proceed with the insulation of the ceiling.

- If you decide to insulate the ceiling from the inside, combine these works with indoor repairs.

- Do not try to blow out large cracks with one polyurethane foam, seal them first.

- For internal insulation of the ceiling, it is quite enough to use polystyrene, the thickness of which does not exceed 5 cm.

- Laying roll materials must be carried out together, even an experienced specialist will not be able to simultaneously hold the threads and insert cotton wool.

- When performing work on insulation of ceilings, always try to lay the material so that the joints overlap and the gaps are closed.

This article explains in detail how to properly insulate the ceiling in a wooden house so that the work performed is of high quality and efficient. If you have carefully studied the information provided, then you will not have any serious problems in the process of insulating ceilings.

Some helpful tips

- There is a foam ceiling tile - it in itself quite well protects from the cold.

- Do not dwell on ceiling insulation. Walls and floors can also allow heat to pass through.

- If you have difficulties with do-it-yourself insulation, it is better to contact the masters who will do everything correctly.An unreliably insulated ceiling is practically useless.

- Plasterboard lining requires the use of a galvanized iron profile. Why is this needed? If you do not do this, you can soon suffer from a fallen structure.

- In a wooden house, it is better to insulate the ceiling in the summer months, so that excess moisture has time to evaporate by autumn and cold weather.

Insulation of the ceiling in a wooden house will protect the room from the inside from heat loss. If the ceiling is not insulated, all the work should be done immediately upon arrival.