To increase the efficiency and benefits of the bath, it must be insulated with high quality.

After all, high heat loss leads to the appearance of bridges of cold, which not only lowers the overall temperature, but also circulates cold air, which can lead to colds.

For thermal insulation of baths use different types of materials, including waste from sawing wood (sawdust).

In this article, we'll cover:

- what is the difference thermal and steam conditions baths and houses;

- how walls, floors and ceilings are insulated with sawdust;

- how sawdust insulation differs from insulation other materials.

Differences between the thermal and steam regime of a bath and a house

Despite the fact that many people perceive the bath the same structure as the house, its insulation differs from the insulation of a house due to serious differences in thermal and steam conditions.

For more information about home insulation, read the article Home insulation.

In a residential building, humidity rarely reaches dangerous values, leading to the appearance of mold and rot. However, in the bath, the humidity exceeds this threshold many times.

In addition, it is possible to arrange a ventilation system in a residential building using a recuperator, this will allow you to constantly supply fresh heated air to the rooms. In the bath this type of ventilation unacceptable.

After all, warm up the air so that it did not cool the inner space of the steam room rooms without intensive heating from the stove is impossible, and the recuperator will only slightly raise its temperature.

Therefore, during the use of the bath for its intended purpose part of excess moisture absorbs into walls, penetrating very deeply.

It is very important that the moisture accumulated in the walls can escape not only inside the room, but also outside, leaving immediately into the atmosphere. For this reason, it is extremely undesirable to build the walls of the bath from materials that do not allow moisture to pass through well, and it is also impossible to use insulation, which impedes free movement water vapor.

Due to its ability quickly absorb and release moisturewithout losing its thermal insulation properties, sawdust is the most successful material for warming a bath.

After all, they not only do not interfere with the movement of water vapor, but also to some extent are a regulator that prevents a strong drop in humidity in the material of the walls.

Due to uneven moisture changes wood breaks, and bricks, cinder block and concrete crumble... Therefore, it is necessary to use a material that not only does not interfere with the movement of water vapor, but also regulates the moisture content of the walls.

Advantages and disadvantages of sawdust insulation

It should be said that today it is difficult to find a cheaper material for insulation than sawdust. They can be bought cheaply in areas where woodworking is active or at any sawmill. The environmental friendliness of the material speaks for itself. Using sawdust mixed with clay or cement gives results no worse than rock wool. The sawdust is light in weight, so it does not put a lot of stress on the attic floor. They do not emit an unpleasant odor, do not cause allergies, do not irritate the eyes and the respiratory tract, such as, for example, mineral wool.

Sawdust is the cheapest and most environmentally friendly material for insulation.

Transporting sawdust to a cold attic is easy. They can be delivered there in small portions and this task can be easily done by one person. Sawdust can easily fill hard-to-reach places - crevices and curved gaps.

It should be noted that sawdust is a combustible material. Therefore, fire retardant components are used for their use. In addition, there must be protection against rodents - mice and rats. For this, fluff lime is added to the solution.

How to insulate a steam room?

These operations are in many are similar to the same actions in ordinary houses, so we will provide links to articles where you can get useful information, as well as the main differences.

After all, it is necessary not only to know what and how to do, but also to understand why it is so correct.

This will help you find the most suitable solution in certain conditions, when the measures recommended in the article are inapplicable either because of the construction of the wall, or because of the inaccessibility of material or the impossibility of performing certain works.

For more information on sawdust-based insulating compounds and binders, click here.

Thermal insulation of the ceiling of the bath with sawdust with clay, cement

Due to the high humidity in the bath, the ceiling must be equipped not with hydro, but vapor barrier.

Otherwise, the sawdust will contain constantly condensation and they will quickly lose their thermal efficiency and then begin to decay.

As a vapor barrier can be used:

- roofing material;

- glassine;

- kraft paper;

- cellophane;

- polyethylene;

- aluminum foil.

Vapor barrier film laid between the boards ceiling and insulation, and the film should go onto the walls.

If the budget allows, it is better to make a vapor barrier from aluminum foil, it will not only protect the insulation from moisture, but also increase it thermal insulation properties.

After all, the foil reflects infrared rays, due to which part of the thermal energy returns to the steam room and participates in heating the air.

Moreover, you need to use a mixture sawdust with lime and clay, because other binders are not suitable for warming the ceiling of the bath.

During washing, part of the moisture, despite the vapor barrier, will pass to the insulation and settle on the sawdust as ash, therefore, the bottom edge of the insulation layer will often be damp.

PVA will not allow sawdust to effectively absorb moisture, therefore the dampness will transfer to the boards ceiling, because of which they quickly rot and require replacement.

Cement and gypsum are afraid of high humidity, therefore they will collapse, and after them the wood will begin to disintegrate.

Clay is devoid of these shortcomings, therefore, after the end of washing moisture will be evenly distributed throughout the insulating layer and will begin to evaporate, leaving through the attic.

In addition to binding individual sawdust, clay also acts as an element, accelerating the spread of moisture throughout the insulating massif, in addition, after the loss of excess moisture, the clay will again bind the sawdust together.

Minimum thickness insulation layer 10 cm, optimal 20–25 cm. In addition, it is necessary to establish high-quality ventilation of the roof, otherwise moisture rising from below will not be able to effectively escape into the atmosphere.

When you are going to insulate the ceiling of the bath, you must understand that do this job effectively it is possible only from above, that is, from the side of the attic or upper floor.

Indeed, when insulating from below, it is impossible to create a normal vapor barrier, so the sawdust will be saturated with a large amount of moisture, which will damage not only them, but also the ceiling sheathing.

Interior wall decoration

The way to insulate the walls of the bathhouse and the house directly depends on their design.

For more information about the insulation of the walls of the house, read the article Wall insulation.

The main difference is that in the absence of a high-quality ventilation system that can quickly ventilate the room after the end of washing, the walls must protect with a vapor barrier from the inside.

First of all, this applies to houses made of logs, beams or boards, including frame houses. Indeed, due to high humidity and poor ventilation the wood is heavily filled with water and swells so much that structural damage is possible.

In brick baths, poor ventilation leads to rapid destruction of the inner surface walls, because of which they begin to crumble.

Least of all, high humidity harms the concrete walls, but after a few years they also begin to slowly collapse, sprinkling from the inside.

Therefore it is necessary first of all, arrange ventilation, which would create air circulation covering the entire room.

Especially effective in the baths of the forced ventilation system, because they allow you to quickly ventilate the steam room and remove excess moisture.

However, the vapor barrier cannot fully protect walls from high humidity, therefore, on the outside, nothing should interfere with the evaporation of the liquid and its escape into the atmosphere.

Because of this, the walls of the baths cannot be insulated with foam, polyurethane and other similar materials.

And the use of mineral wool will not give the expected effect, because she is afraid of even a slight increase in humidity.

Therefore, as insulation for walls you can use the formulations based on sawdust, lime and clay / cement as a binder.

It is undesirable to use PVA and gypsum as a binder, because the glue is much less water vapor permeable, and gypsum is afraid of even a slight increase in moisture. In all other respects, the walls of the bath are insulated in the same way as in ordinary houses.

Heat and waterproofing of the floor

About the main methods we talked about floor insulation here, so further we will talk only about the differences that arise when working in a bath.

The main problem that arises when insulating a bath floor is in very high humidity.

Therefore, it is necessary to exclude any contact between the insulating material and water. This can be done in two ways:

- the creation of a waterproofing screed;

- adding liquid glass to the composition of the insulating solution.

Waterproofing screed preferable if the base can easily withstand the additional weight.

Therefore, this method is most often used on concrete floors.

However, it can be used on wooden floors too, but only in small rooms, because the bearing capacity of wood is much lower than that of reinforced concrete.

If the subfloor is made of wood, then you can insulate it with a composition with liquid glass, as well as cover with a thin layer of waterproofing.

It is advisable to use liquid glass as a waterproofing material, because bituminous waterproofing afraid of high temperatures... You can also use polyurethane and rubber based polymer waterproofers.

If you need the most effective insulation, then a mixture of sawdust and lime is used, and clay or PVA is used as a binder.

After the warming mixture has solidified, leave for a while (depends on the type of binder, clay - for a month, PVA for two days), after which it is covered with a vapor barrier (cellophane / plastic wrap or aluminum foil).

Then a layer of waterproofing is poured and only after that the boards are laid. Moreover, on such a base, the subfloor is laid without fastening, therefore it is advisable to use a tongue-and-groove board. If the floor is tiled, then a 10 cm thick screed is poured over the vapor barrier.

Ceiling preparation

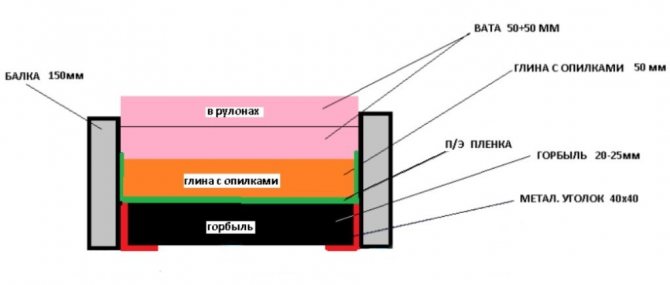

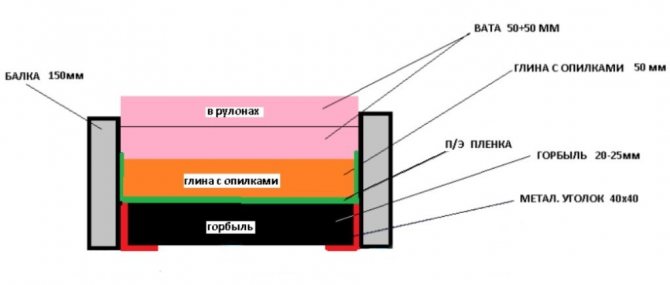

Clay insulation scheme

Of course, only prepared floors can be insulated. There are several ways to do this:

- filing with bars 50x50 mm;

- the use of edged boards;

- filing with a tongue-and-groove board.

The use of bars is considered to be the cheapest option, because.they are not sewn up solid, but with a gap of 20 mm. These slots will then be filled with a clay mixture. They are joined along the length on the beams. It is important to fix the bars correctly and securely. To do this, you can use nails at least 10 cm or wood screws at least 9 cm long.

Boarding with a board takes much less time, saves energy, but financially it turns out to be much more expensive, especially if a grooved planed board is used. On the other hand, if the flooring is leveled immediately, then the ceiling in the room is smooth and beautiful. Additional work with it is no longer required. Usually, in this way, the ceiling of the bath is insulated with clay.