Ceramic kilns

In this case, not ceramic kilns for firing are considered, but units specifically for ceramics. Products made from this material have high strength, which they acquire when exposed to very high temperatures.

This oven is a ceramic product specially designed for this type of heat treatment. They come in different designs, with different temperatures and may differ in thermal sources. You can buy them, but there are craftsmen who can make them on their own.

Advantages and disadvantages

- The main advantage of a ceramic stove is its uniquely high power. Keep in mind that this indicator has a direct relationship with the size of the device, therefore, the oven must be purchased competently and sensibly assessing your needs.

- Forget forever about ugly, outdated and blackened stoves from time to time - you can decorate your ceramic device at will as you want.

- You can paint the stove by hand, tile it with designer tiles or even make a mosaic on it - everything is limited only by the limits of your imagination.

- Those who like to cook, and especially those who like to grill, should pay close attention to a stove of this design - it has the opportunity to fry fish, grilled chicken, chops and many other products, pampering yourself and your family with delicacies.

Minuses:

- Of the disadvantages of ceramic stoves for heating a house, one can single out the fragility of the structure - the cladding can be broken quite easily, therefore you should always treat it with caution.

- The downside is the high price of a quality product - the cost of models of European-made ceramic stoves can go off scale, and the purchase of such a device can significantly hit the wallet.

Firing equipment classification

Firing equipment can be classified according to several parameters depending on user requests.

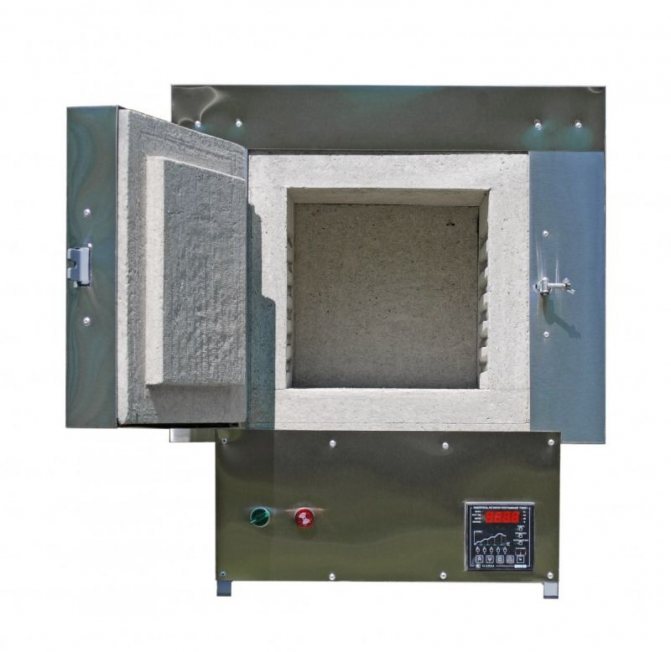

Location of heating elements:

- chamber (heating elements inside the container);

- muffle (heating sources are located around the chamber made of a fire-resistant muffle).

Energy source type:

- gas (maximum temperature 1100-1300 0С);

- electrical (termodist 1200-1400 0С);

- using solid fuels.

Loading type:

- front-loading;

- top loading.

Type of environment inside the chamber (applies to industrial devices):

- general purpose (air environment);

- vacuum (as a medium - airless space);

- with a protective gas environment (gases such as hydrogen, helium, nitrogen, argon are used).

Chamber or muffle? Nuances of choice

When choosing a kiln for firing, usually take into account the expansion and production volumes. For more or less large-scale activities, camera equipment is used.

Ceramic muffle kilns have become more widespread. Let's dwell on them in more detail.

These devices are distinguished by their simplicity of design and reliability. The range of operations that can be performed using this simple equipment is wide:

- Remelting of valuable and precious metals and alloys. The muffle furnace guarantees no interaction with the flame and the introduction of impurities.

- Metal processing using high temperatures: aging, cementation, hardening, annealing, tempering.

- Working with ceramic products. In such a furnace, an even tone of the ceramic surface can be obtained. Relevant for art products.

- Drying of dielectrics inside the oven (microwaves are excellent for drying electrically conductive materials).

- A sad function is cremation. Yes, these are the ovens that are used for this purpose. They can be burned to mineral constituents (ash).

- Laboratory research and experiments.

- Medical use (for high temperature sterilization).

Muffle kilns for ceramics firing have long established themselves as unpretentious, ergonomic, with decent functionality. It is also possible to choose such a furnace in the case when the buyer has a lot of requirements for the firing device.

Features of the device of ceramic furnaces

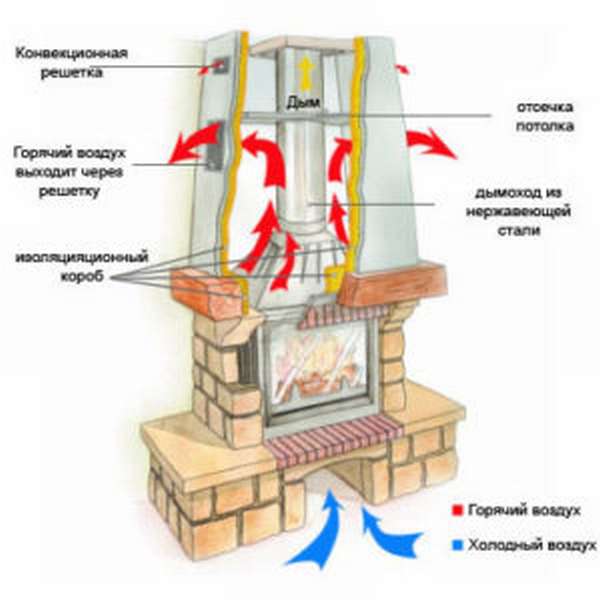

As you know, the principle of operation of the classic stove is as follows: the heat obtained as a result of burning wood heats the air in the stove chamber, which causes the so-called natural draft - a high pressure zone, due to which there is a harmonious circulation of cold and hot air. So, gradually, the whole room warms up.

The device of the fireplace stove directly depends on its type - there are open and closed types of fireplaces.

- In the first case, the fire is kindled in a specialized niche, and no protective doors, as in the furnace, are provided - the maximum means of preventing a fire here is only a protective screen. A significant drawback of such a device is the inability to preserve heat for a long time and heat the entire room with high quality - but on the other hand, you can admire the living fire for a long time right in the middle of the house.

- The second type of fireplaces - closed-type devices, can warm up the room much more reliably and faster - their efficiency is several times higher than that for open fireplaces. Such fireplaces can also be purchased with panoramic decorative doors, which makes them the best option for those who value quality and comfort, and do not want to give up beauty.

If we are talking about such an amazing miracle of technology as a ceramic-lined fireplace stove, you can once and for all forget about the problem of poor-quality heating of the room and tastelessly cooked food.

- With the help of a ceramic oven, you can do anything you want, even use it to bake clay crafts - the power of the oven mechanism is enough for this purpose as well.

- The material for finishing the furnace is a high-quality and beautiful ceramic material with refractory properties - you do not have to worry that one day it will crack from temperature changes - everything was carefully thought out by the developers.

- The present function of secondary afterburning will help to keep the flame at the same level for a long time without human intervention.

- It also provides for the automatic removal of soot and dirt, which makes this technical innovation a unique find.

Advantages of muffle kilns

The main feature of this type of equipment is the use of a muffle as an insulator for material (or product) and fuel (or products of its combustion). The muffle is the shell that protects the heated material and is the main working space.

Unit advantages:

- Wide temperature range (100 to 1450 degrees Celsius).

- Variety of used protection (air, atmosphere, or vacuum).

- Use of any energy carrier available to the buyer (you can connect to the power grid, you can use the gas main).

Such ovens can be of any size, with a different volume of the working chamber and with a different type of bookmark.

For travelers and for summer cottages

Electric ceramic stove is perfect for outdoor use. It is stationary and easy to carry with you. Heating occurs from an electric spiral due to heat transfer from the walls of the furnace. These days, these ovens come in a variety of designs.You can choose both a laconic style of execution and an oriental design. The stoves have a high cost, but it is justified by at least two properties: high power (it all depends on the size, but even a small stove has good thermal characteristics) and environmental friendliness (ceramics is clay, a completely environmentally friendly material that does not contain impurities and synthetic additives) ...

In such electric ovens, you can cook barbecue, grilled chicken, bake fish, bread cakes and much more. They can even heat a small room. Summer residents will especially appreciate all the advantages of this device, because outside the city people spend a limited amount of time (season or weekend), and it is very convenient to take a small stove with you, which will both heat and feed.

About tiles

The tiled stove is a truly luxurious building, even dilapidated, see fig. However, facing with tiles is definitely not one of those works that can be performed by studying the technology according to the descriptions; this business is even more delicate, requiring experience and accuracy than facing with natural stone.

Tiled stoves and fireplaces

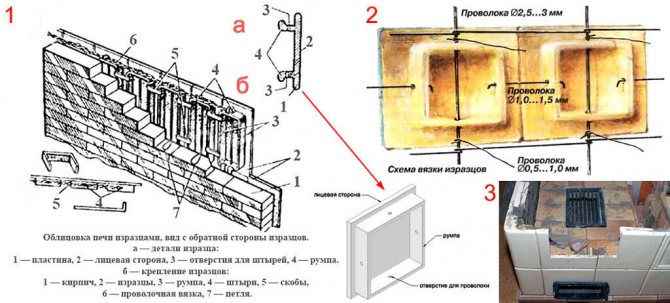

Tiles are generally prepared from the same kaolin mass as quality tiles. To agree on the TKR and improve the heating technology of the stove, the tiles are molded box-shaped with a cavity - a rump, pos. 1a on the next. fig. - which is filled with sand during the lining process. Mountain sand is needed with rough grains and a minimal admixture of clay, it does not swell from cyclic heating, does not bake and does not cake. Tiles are placed on a greasy clay masonry mortar; clay is used white, sand is the same mountain. Add half a glass-glass of table salt to a bucket of the finished solution.

Facing the stove with tiles

Before facing, the tiles are laid out and the layout is sorted out, as in the case of a wild stone, achieving evenness of the rows. The sizes of the tiles have been standardized by GOST since 1947, but the tolerance is quite large, approx. 1.5 mm. Less is impossible to achieve due to the properties of the material itself. With a cladding height of 10 rows, the gap between the seams can reach 15 mm, which, you yourself understand, is in no way permissible.

Note: the basis of large art panels on tiles is laid out and adjusted by hand in the factory. Therefore, tiled panels are very expensive, but they are put in place without a layout.

Facing with tiles is carried out in order, tying the tiles with steel pins and wire. As a rule, the stove is lined with tiles in the order of its construction, and the lining must always be ahead of the masonry, as shown in pos. 3. In this case, the tiles are knitted with anchor loops, as in pos. 1b. Some craftsmen (qualitatively - few) know how to tile running ovens with tiles; in this case, the mating is done with anchor pins, pos. 2.

For home comfort

The ceramic stove is an absolutely unique unit when viewed as an element of interior design. The lining of such a furnace can be made of various materials: natural or artificial stone, ceramics. These materials have decent heat storage properties. After heating, they will give off heat to space for a long time. Traditional metal stoves have 1.5-2 times less heat transfer than ceramic ones, and therefore cannot create such a unique, cozy, warm and attractive atmosphere in the house.

Types of cladding for fireplaces and stoves

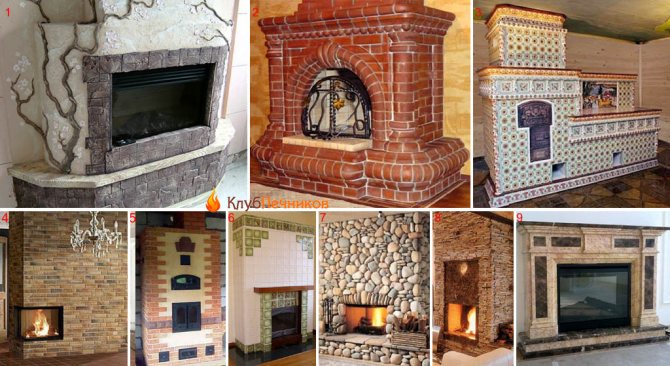

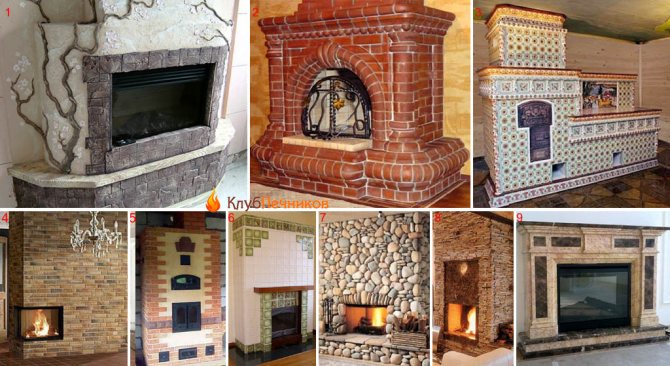

External finishing of metal stoves on the one hand is easier, because the metal is ductile, elastic, and the exfoliated lining can often be corrected on the fly. On the other hand, it is more difficult due to the large TCR of the metal and the high temperature of the furnace body.Therefore, metal ovens are most often painted with heat-resistant enamels; one, but a significant exception will be considered below, but we will deal mainly with brick heating and cooking appliances. It is not easy to fulfill all the above conditions, but the stove business has existed and developed for millennia. Stove makers, like all high-class craftsmen, are sane people, so as a rule, modern technologies that are suitable for their work are not rejected. Therefore, for amateurs, the choice of methods for facing a fireplace and / or stove with their own hands is quite wide, see fig. and the list is below:

Types of cladding for fireplaces and stoves

- Plastering with simple or decorative plaster;

- Finishing with facing bricks;

- Facing with tiles;

- Clinker tile finishing;

- Facing with ceramic terracotta tiles;

- Facing with majolica;

- Facing with natural stone;

- Artificial stone decoration;

- Facing with marble and other ornamental minerals.

Tile and kerogranite

Often, fireplaces with stoves are faced with tiles and porcelain stoneware. The reason is the relative cheapness of materials, the simplicity and availability of the technology for their installation. But, generally speaking, tiles and porcelain stoneware are not the best facing materials for heating devices, it is difficult to match them according to TCR in a given temperature range, and the values of their heat capacity and thermal conductivity in this case are far from the required ones.

Calibrated white kaolin tiles from the inside can be used to decorate decorative fireplaces, installing them in the same way as terracotta tiles, see below. If the stove is finished with tiles, additional metal support elements are required, see eg. video below. But this is not entirely good - details with a large TCR appear in the structure of the cladding, therefore, the stove must be previously heated many times.

Video: decorating the stove with tiles on homemade corners

Porcelain stoneware is suitable for cladding heating appliances of the same kind in the same ways, but the tiles must be taken from it of zero caliber. There are other publications on the properties of porcelain stoneware, but in this case it is important that the initial mass was deformed minimally during firing, which means that the shopping center at the place of operation will withstand.

What is the difference from a traditional Russian oven?

Ceramic stoves for the home have absorbed all the best that the ancient Russian traditions of heating rooms can give. They warm up quickly, give off heat to the surrounding space for a long time, and have the function of preparing tasty and healthy food. But modern technology has gone very far. Now this device is more complete and supplemented with such functionality as a water circuit in the structure, ensuring absolute safety (excluding the occurrence of dangerous situations that cause smoke or fire), an additional stove or oven for cooking. Considering the sophisticated design, the ceramic stove has unrivaled aesthetics.

Stove Store

The address: Moscow, Bulatnikovskaya street 20, office 17.

Telephone:

+7(495)902-57-82

Office and warehouse working hours from Monday to Friday from 9.00-18.00

Are you sure that a heating device should not only be functional, but also truly beautiful? In this case, a refractory ceramic furnace offered by a world renowned manufacturer is a worthy choice. Beautiful design and high quality are among the most important advantages.

Convenient design and optimal dimensions are what you can count on in every case. At the same time, the possibility of creating an ideal layout remains. The ceramic furnace features a robust body and the use of fire-resistant materials ensures that any risks are eliminated. The ceramics used to add beauty help to eliminate the risks, as a result of which a beautiful interior can be created completely safe for you.

High efficiency, economical fuel consumption are also possible. Take the chance to bring warmth to your home, forget about the winter cold by choosing the best stove. A varied assortment is the basis for a successful choice.

Variety of options

Manufacturers have taken care of the durability of such important equipment, but have not forgotten about the appearance. Yes, the basis is always safe and durable components: cast iron, stone, ceramics, steel. It's all inside. These materials are widespread because they are resistant to external factors, durable, durable and come in an affordable price range.

As for the outer cladding, it is quite interesting. The leading manufacturers of ceramic stoves for the home are Italian companies, while Italians know a lot about art and sophistication. A lot of materials are used: tiles, fire-resistant glass, ceramics, environmentally friendly paints, unique tiles.

Customer reviews speak for themselves - everyone is happy. Yes, the price of such a device will not be low, but the high cost includes aesthetic pleasure, trouble-free operation of the stove without problems for many decades, safety, high quality guaranteed by European brands and extensive functionality.

What to start from?

There are ovens in which the degree of heating is high (up to 2000 degrees), medium (up to 1400 degrees) and low (up to 500 degrees), obviously, the first thing you have to decide on is the temperature you need for your work.

The second criterion for choosing a furnace will be its power, it is calculated based on the size of the products you make. Loading can be top circular and front.

According to the type of fuel used, a distinction is made between gas ceramic stoves, electric and solid fuels, such as wood stoves.