If you are going to make a fireplace with your own hands, you should first study the theoretical part of the process

If you think about the arrangement of your private house or suburban area, then many begin to think about how to install a fireplace. And in the event that you have read the instructions for installing a brick stove structure, and realized that it is unrealistic to carry out this in your house, then you can find an alternative option. Why won't a brick fireplace work? The answers are different, perhaps a bad facade or you do not want to occupy extra square meters, but you want to create home comfort. And here a homemade metal fireplace can help us, which is very easy to make with your own hands.

Design features

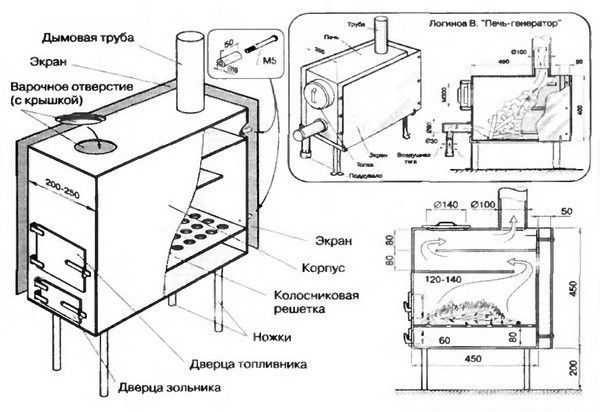

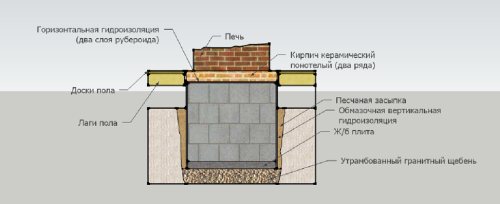

Iron wood fireplaces have an interesting design. The firebox, which looks like a chamber, stands on a special support or stand. There is no need to install an additional foundation for this heater, but due to the heavy weight of the unit, a reliable foundation must be provided.

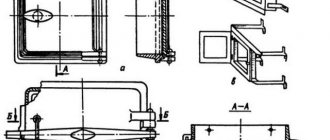

Metal fireplaces with side and top chimney connections

The firebox is connected to the chimney, which removes all combustion products from the heating system. To harmoniously fit the device into the interior of the house, its outer surface can be lined with refractory materials.

copper

Non-ferrous metal fireplaces are more expensive than cast iron or steel. But they allow you to bring warm copper shades into the interior. A bronze fireplace is less prone to corrosion and rust. And the plasticity of the material allows you to make parts of any complexity and filigree from it, which allows you to make the fireplace a real work of art.

By purpose, metal fireplaces are divided into the following groups:

heating devices. This is the most common group of fireplaces that perform only the main function - heating the room;

fireplace stoves. The top surface of such ovens is a hob. Thus, you can even heat food on small fireplaces or, for example, boil a kettle;

brazier. It turns out that this is also one of the varieties of metal fireplaces. The main function in such open-top structures is to cook food on coals or wood with low combustion;

decorative fireplaces. They do not give much heat, but in metal decorative fireplaces you can watch the play of live fire. There are very compact models of decorative fireplaces, suitable for installation in the smallest niches.

Varieties of aggregates

Depending on the method of placing the installation in a heated room, the following metal fireplaces are divided:

Built-in metal insert

- wall-mounted;

- corner;

- hinged;

- central;

- built-in.

In this case, there are different units depending on the shape and size of the firewood chamber. The firebox can be cylindrical, conical, parallelepiped or other geometric shape.

Features of a metal hearth

The metal fireplace is one of such installations that can replace the classic counterparts. There is no particular need to install an expensive foundation for it. With their compact dimensions, such fireplaces freely heat all available rooms of the house.

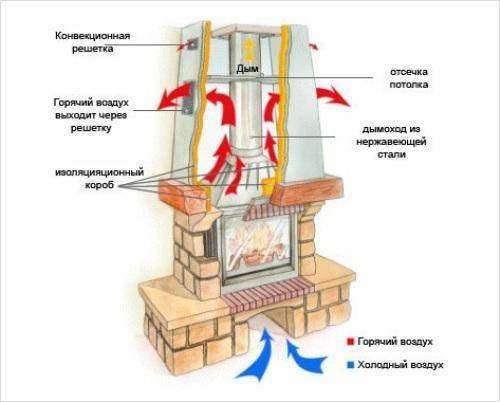

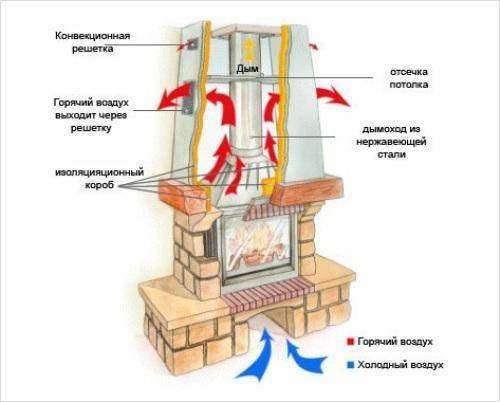

Diagram of the principle of the fireplace.

The brick hearth is attributed to the inventions of European civilization, and the metal prototype is considered a native of Japan. In Japanese homes, such hearths are not uncommon.Most fireplaces from the Land of the Rising Sun are small in size and provide high fire safety to such an extent that they are located next to partitions.

They are made from a variety of metallic materials: steel, copper and sometimes tin, galvanized and blackened. What metal to use for the fireplace is already determined by the preference of the owner of the dwelling.

Designer decoration is no stranger to metal products, providing them with different styles and unexpected combinations of geometric shapes. The variety is also noticeable in the shape of the hoods and in the way of fixing the chimneys that remove hot exhaust gases.

Advantages and disadvantages of devices

A metal fireplace with wood has the following advantages over other types of heating devices for a private house or summer cottage:

What does a metal firebox consist of?

- high efficiency;

- low weight of the unit;

- no specific maintenance required;

- ease of installation;

- lightning-fast heating of the room;

- can be installed anywhere.

Despite all the advantages that the user of wood-burning fireplaces receives, these devices have a number of disadvantages. First of all, it is very easy to burn yourself on the stove, since the body heats up very much during the heating. Also, this device cools down quickly enough, which contributes to the uneven distribution of heat in the room.

Advantages of a metal furnace

The metal furnace structure is practically not inferior in the degree of heat transfer to a brick analogue. Of course, the unit cannot be used for large rooms, because its power is not enough to warm up the whole house. However, for one or several small rooms, this is quite enough.

A metal fireplace has long ceased to be an ordinary iron box. Modern appliances are endowed with grace and nobility, because the lines of rough metal are smoothed out by an interesting decor, and the configuration of the stove can be very diverse.

Photo 1 A fireplace made of metal is a decorative highlight of any interior.

The main advantages of a cast-iron hearth are not bulky dimensions, ease of use, as well as the ability to choose the necessary, functionally significant, technical characteristics. The weight of such a unit is much less than a brick analogue, therefore it is easier to assemble and, if necessary, moves. Also, there is no need to build a powerful foundation for installation.

Another indisputable advantage of this type of fireplace is a simple constructive device, combined with high productivity rates. During the heating process, fuel is consumed sparingly, because metal tends to warm up many times faster than other materials.

In addition, you can study the photo article on our website in more detail, where you can get inspired by the ideas of rooms with a fireplace.

Simplicity in care is also important. Cast iron fireplaces can be easily cleaned of soot, for example with baking soda or citric acid. If the firebox door with glass is looked after in the standard way - with window polish.

Photo 2 If required, a cast-iron fireplace can be a portable device and can even be placed in a steam room, but this will require a specially equipped place.

It's important to know! Ordinary tooth powder can remove soot from firewood. It must be diluted with water and the darkened areas must be polished. Then wipe with a damp cloth.

Despite the indisputable advantages of a metal hearth, it also has disadvantages. The main ones are a high degree of fire hazard and rapid cooling of the furnace device, after the termination of the furnace process. Refueling with flammable materials must be carried out with gloves, otherwise any inaccurate contact with the hot metal will cause burns.

What kind of fuel should you use?

For heating a summer cottage or a country house, it is best to use dry wood. In this case, give preference to aspen. A special type of metal aggregates is the stove, which uses pellets as an energy source. They are loaded into the firebox in the required volume, and the heating intensity is regulated automatically or using a manual control unit.

What kind of wood is better to heat

Also, some types of metal units can operate on gas. These devices are safer for heating, but it is impossible to make them yourself.

Types of iron stoves for summer cottages

Modern stoves that run on wood and are made of metal bear little resemblance to a "potbelly stove". Metal stoves for the home are usually divided into two groups:

- Classic ones that work on a direct combustion system.

- Heating, designed for long burning.

This or that system can be present in steel ovens, which are designed for cooking or heating. There are a large number of such ovens on the market, among them the following are worth noting:

- The bell-type stove is a heating stove, it uses the principle of convective movement of gases that move through the channels and then go out into the chimney. Instead of the hob, an open oven is installed, which is located directly under the hood. This helps keep food hot for a long time. The firewood is loaded horizontally; the firebox door is made of fireproof glass.

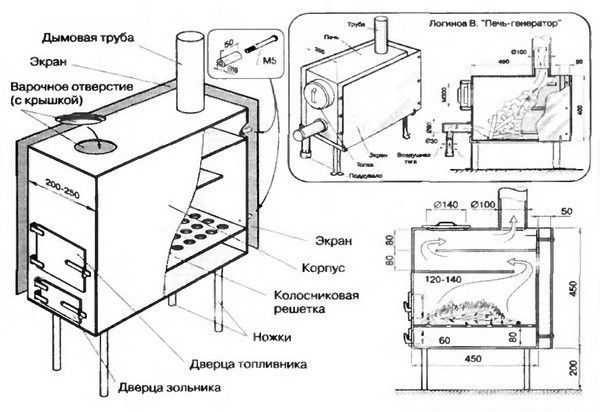

Direct combustion furnace. Most often these are small-sized models, for example, Thermofor or Cinderella. The design performs two functions at once - it heats the room and helps in cooking. The thermal power of such a "baby" is 4 kW or a little more, which allows you to heat a room up to 50 m2. There are models that are equipped with electricity generators, which increase the voltage generation and power of the furnace. For example, the Indigirka cooking stove, which runs on wood, and not only heats the house, but is also suitable for charging gadgets.

Gas generating furnaces. Perfect for summer cottages, since the structures are economical and compact in size, have a high level of efficiency, which reaches 80%. For the long-term operation of this type of stove, it is necessary to equip the chimney and heat it with high-quality wood. Gas-generating stoves work due to the fact that firewood (or another type of fuel) is loaded into the combustion chamber, ignited, and then the door is closed. Fresh air flows through the telescopic pipe, which sinks lower when the amount of firewood decreases. The air supply process is regulated by a damper. The kiln has an average life of three days. If the gas generating stoves have a water heating mode, you can save on the use of firewood.

Required materials for a homemade fireplace or stove

In order to make a stove with your own hands for heating a private house or summer cottage, you need to use the following materials:

- metal sheet 5 mm thick. This will be needed for the construction of a combustion chamber and a chimney;

- metal sheet 0.5 mm - for making an ash pan with your own hands;

- metal elbows for chimney;

- stainless steel pipes for the construction of a chimney;

- grate;

- solid door for the combustion chamber;

- various fasteners;

- stand for the case (corners and slats can be used).

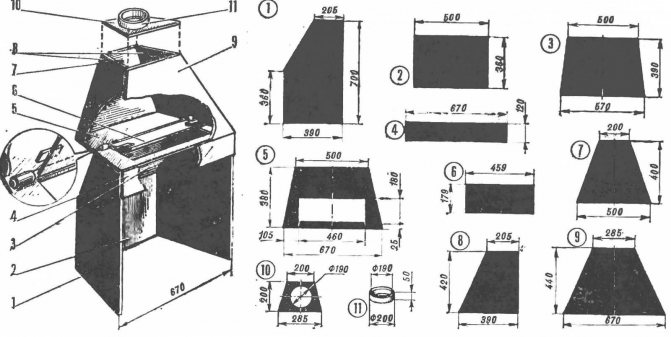

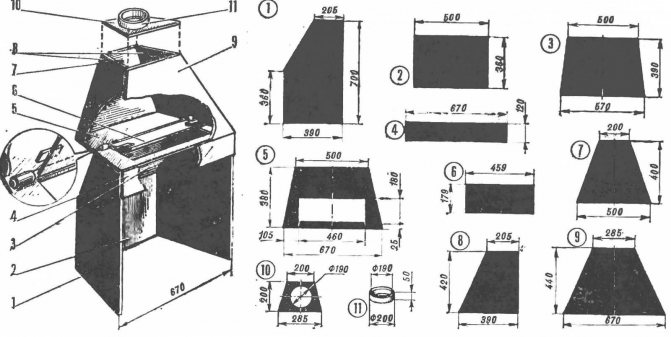

Scheme for making a homemade metal fireplace

Do-it-yourself fireplace with a cast-iron firebox

After preparing all the necessary materials, you need to start designing the stove. It is best to draw up drawings before the assembly process with your own hands, which will greatly simplify the installation of a heating device in a private house or summer cottage.

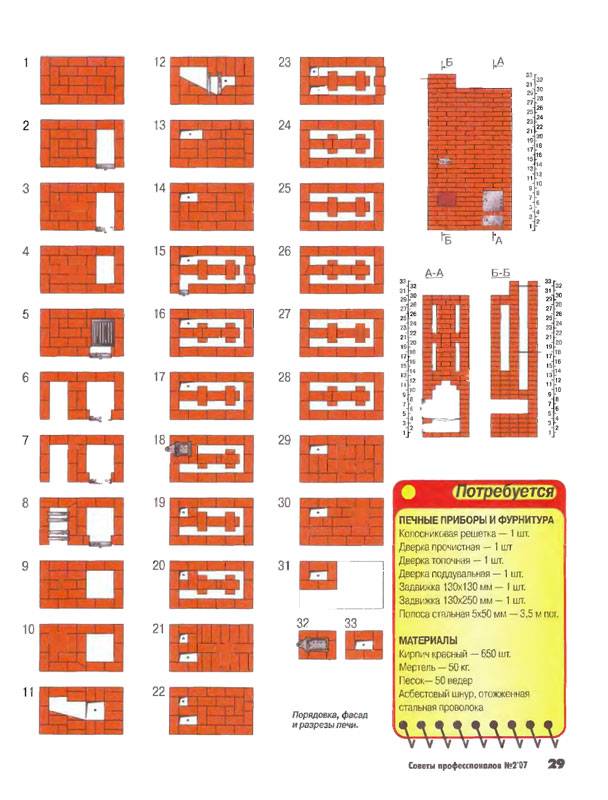

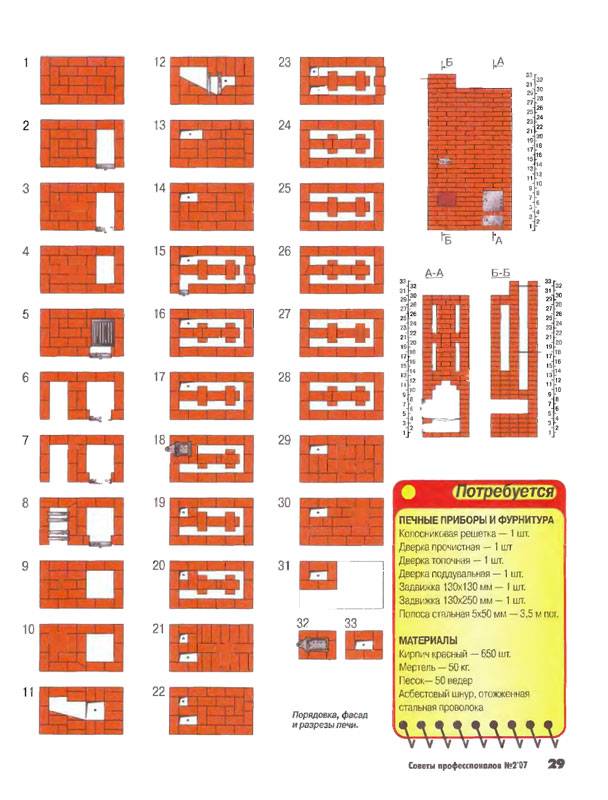

How to lay the oven with your own hands

In order to avoid mistakes during laying, order is used.

After the foundation is ready, you can start laying the stove. Before that, it is necessary (if you are not a professional stove-maker) to prepare in advance the ordering of the stove or fireplace. This "document" allows you to determine almost exactly the amount of brick that will be needed for the entire furnace, as well as to prevent any inaccuracies and shortcomings in the masonry process.

The stone kiln is made of red refractory bricks. It is also called chamotte. Thanks to special processing, it acquires qualities and characteristics similar to those of natural stone. In addition to bricks, the furnace should also consist of a strong mortar, which holds the bricks together. You can make it yourself using clay, sand, water, cement or lime.

The choice of these or those components depends on what quality clay you are using. So, if your clay is normal, then it will be enough just to soak it with water, and such a solution is suitable for stove masonry. If the clay is oily or skinny, then other elements will need to be added to it. For oily clay, binders will be needed, for example, sand, lime or cement. If she is skinny, then you will have to add oily clay.

http:

https://youtube.com/watch?v=78fqp8T0NoM

How to check the quality of clay with your own hands?

To do this, you will not need to resort to some kind of chemical experiments and other complex tests. All you need is a container of water. You need to put a certain amount of clay into it (no more than half a kilogram). After it has softened, it will need to be mixed in water. This is done with an ordinary stick. It is by looking at it that you will determine how oily or, on the contrary, skinny the clay is. After stirring, take out a stick or a jar and watch. What happened to her? If the clay sticks to the stick in large pieces, then it is oily, if the clay layer on it is small, and it slowly slides off it, then the clay is normal. The skinny clay does not stick to the stick, and you will take it out of the water in exactly the same condition as you put it in the liquid earlier.

Another option is to mold 2 small balls, one of which will need to be crushed into a cake. Both figurines should be placed in a dry, dark place for 2-3 days. There they will dry, and then you can check what kind of clay they were made of. If they are not cracked, then the clay is either skinny or normal. More precisely, you can determine by hitting the ball on the floor. The scattered ball is made of skinny, and the surviving one is made of normal clay. If there are cracks, then it is greasy.

http:

Thus, do-it-yourself fireplaces and stoves can be made of brick or metal.

How to make a heating stove yourself?

Do-it-yourself step-by-step instructions for building a wood-burning stove for a summer cottage or a private house: From metal corners, make a rectangular frame with legs, which will act as a base for a heating unit. Then attach it securely to the floor. Lay a sheet of metal on top of the frame.

Drawing of a metal heating stove

Build a box of sheets of metal that will act as a firewood chamber. The firebox should have double walls in order to increase the efficiency of the stove. Also divide its inner surface into two parts and install the damper. In the first compartment, the process of burning firewood will take place, and in the second, the accumulation and removal of smoke.

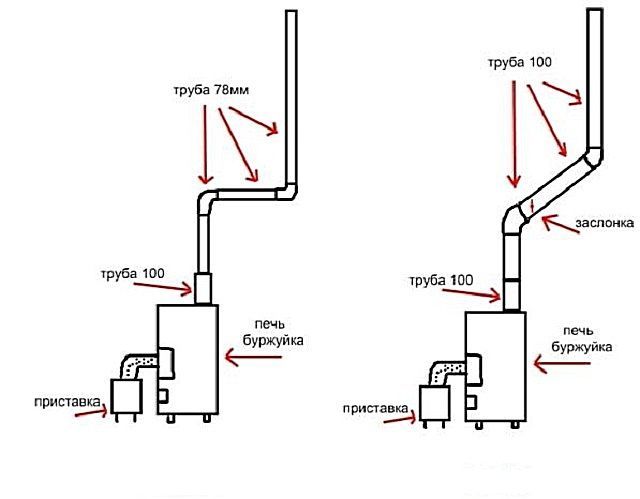

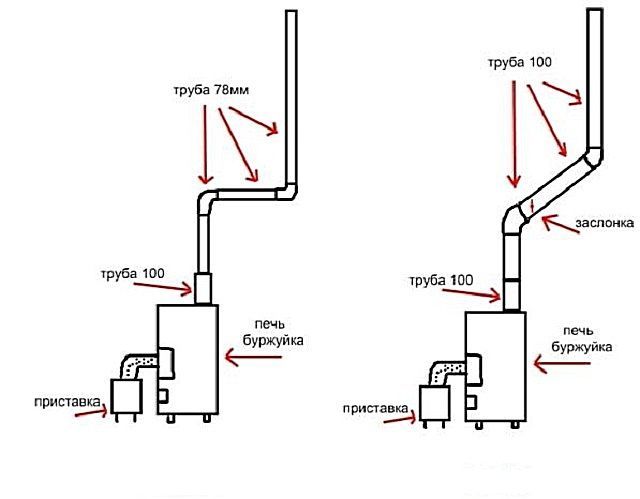

Install the doors on the firebox, then install it on the prepared base. When the firebox is ready, proceed with the chimney arrangement. It can be made from pipes. They need to be joined together with the help of sockets, and all seams must be lubricated with a heat-resistant sealant. Use your knee to make the curved section.

Chimney for a homemade stove

Fix the chimney to the wall with clamps and brackets. So that the finished stove has a high fire safety, carefully insulate the nodes of the chimney transition through the ceiling. Do this with basalt cardboard and glass wool.

Cover the wall behind the fireplace with heat-resistant material. Perform the same operation for the floor near the heater.

At the bequesting stage, you can tile the stove. Homemade wood stoves should be placed in a place where a constant flow of air can be ensured.

Also, make sure that no flammable materials are placed near the heating unit.

What type of fireplace and type of insert you choose for yourself

Choosing the type of future fireplace. Fireplaces are built into the wall, wall and corner. If the thickness of the wall allows you to make a smoke channel for the fireplace in it, such a fireplace is called built-in or closed. If the walls are thin, then the smoke channel will protrude from it.

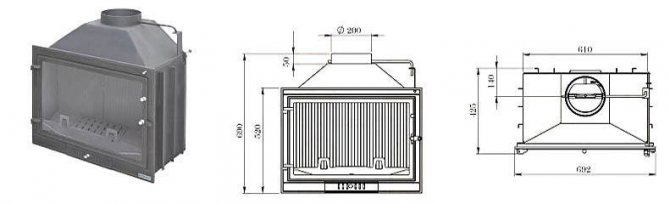

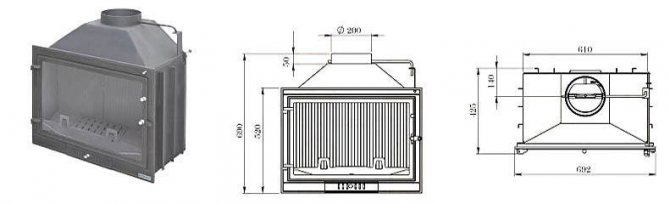

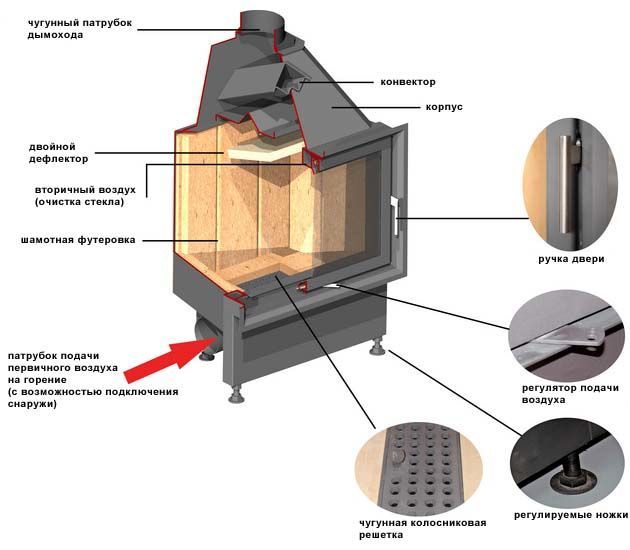

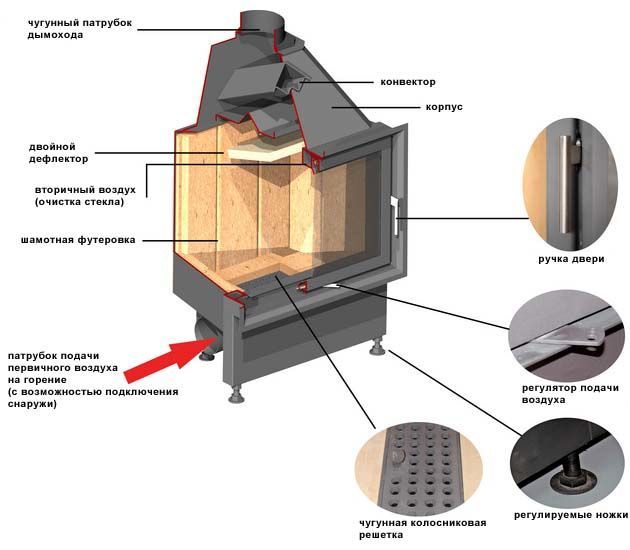

Fireplaces of this type are called back-to-wall or semi-open. There will be a corner fireplace in the corner of the room. Choosing the type of fireplace insert. Furnaces are made of brick and metal (steel or cast iron). Fireplaces with metal inserts are widespread. Many firms offer ready-made cast iron fireboxes. Having bought one, you only need to overlay it with brickwork and you will get a fireplace.

Many craftsmen make fireplace inserts with their own hands from sheet metal (steel, copper, or cast iron). Metal fireboxes are more durable and they greatly facilitate the construction and operation of the fireplace. The choice of sizes for the future fireplace depends on the area of the room. The area of the fireplace fuel chamber should be in the range from 1/50 to 1/70 of the floor area of the room. Suppose the floor area is 20 square meters, then the area of the fuel chamber should be within the range of 0.4 square meters. up to 0.285 sq.m. For example, let's choose the area of the fuel chamber equal to 0.4 sq. m.

The dimensions of the fuel chamber (width, height, depth and section of the chimney channel) are proportional to the width of the window.

If we designate the width of the firebox window with the letter A, the height of the window H, and the depth of the firebox B, then the height should be about 0.7 of the width (H = 0.7A), and the depth about 0.55 of the height (B = 0.55H). The cross-sectional area of the chimney should be 10 times smaller than the area of the fuel chamber. Next, we find the width of the fuel chamber window, it will be equal to 1.04 meters.

Having the width of the fuel chamber window for a room of 20 sq. meters, you can calculate the remaining dimensions: H = 0.728 meters, B = 0.4 meters, and the cross-sectional area of the smoke channel will be 0.04 sq. meters.

For better heat transfer, the side walls of the fuel chamber are tilted by 45-60 degrees, the rear wall is allowed inside the chamber by 20-22 degrees, starting from 1/3 of the height. To improve traction, the upper part of the fuel chamber is narrowed, forming a neck.

To avoid backdraft, which causes the fireplace to smoke, arrange a smoke tooth. In front of the fireplace, it is necessary to provide for an underfloor platform with a width of 0.5 meters, which is installed for fire prevention purposes. Above the smoke tooth, it is necessary to provide for the installation of a damper that will block the smoke channel. We will consider the rest of the subtleties when describing the manufacture of a fireplace with our own hands.

Artificial plasterboard fireplaces

Artificial plasterboard fireplaces

Artificial plasterboard fireplaces

The most popular and easiest to implement option. The only difficulty for a beginner may arise at the stage of designing a metal frame, you just need to practice a little.

Drywall is extremely easy to handle and install. You can effortlessly cut the sheet into blanks of the required shape, bend drywall and perform other necessary actions.

Do-it-yourself drywall fireplace

First step. Make a frame using wood beams or metal profiles.Assemble a box with dimensions 130x120x30 cm from plasterboard sheets. The box must be without bottom and back walls. Use a sharp knife or hacksaw to cut drywall. Glue the parts of the box with assembly glue.

Frame

Frame sheathing

Second phase. Prepare a plasterboard base of 150x40x20 cm. Install the finished "foundation" near the wall. For added security, glue the box to the floor with mounting glue.

Stage three. Glue the previously assembled fireplace structure to the "foundation". Place a mantel of a suitable size on top.

Stage four. Make a decorative chimney 80x15 cm from drywall and wooden slats (frame). Determine the height yourself - from the mantel to the ceiling surface. Glue the chimney to the wall and directly to the fireplace. Do this part of the design at your discretion, if you wish, you can do without it.

Fifth stage. Gently glue the skirting board to the “foundation” and to the main body of the structure. In the case of the main part of the structure, the plinth should be glued under the mantelpiece. Here it is better to place it in steps, using products of different widths to obtain a beautiful smooth transition.

Sixth stage. Install your artificial firelight inside the plasterboard structure.

Seventh stage. Finish your faux fireplace. Do what you want here. For finishing, you can use water-dispersible paint, wallpaper, foam tiles and other suitable materials.

Fireplace decoration. Possible variant

False plasterboard fireplace

Operation and maintenance rules

The metal fireplace is quite easy to use and does not require any special maintenance measures. During operation, the main thing is to comply with fire safety measures - to avoid falling out of burning fuel and so on. When servicing the fireplace, be careful not to touch the walls of the product. It is recommended to use fabric gloves to load fuel and open the door.

In order to maintain the device, it is necessary to regularly clean the furnace and chimney from soot. Overgrowing of the chimney with soot will impair natural draft - this can lead to smoke entering the room. Also, it is impossible to carry out wet cleaning of the device - this will lead to increased corrosion, the fireplace will take on an unpresentable look.

Chimney device

For the installation of the chimney, a steel pipe with a diameter of at least 200 mm and a wall thickness of 2.5 mm is usually used. Sometimes modern modular stainless steel chimneys are used for this purpose, made as a sandwich panel.

The steel chimney is installed using electric arc welding. The turns of the smoke duct are realized by using steel bends of the appropriate diameter. It is recommended to minimize the number of turns during installation. A large number of turns will impair traction. Passages through building structures are sealed with non-combustible materials (basalt wool and other materials with similar properties). It is also recommended to insulate the transit areas passing through the attic with non-combustible materials.

On the upper part of the chimney, a cap and a fungus are mounted to protect it from atmospheric precipitation.

Types of fireplaces by location

- Built-in - their entire structure (firebox and chimney) is placed in the wall, which saves room space. Under and the portal of the fireplace is arranged above the floor level, and a brick floor is arranged in front and on the sides of the portal, while the bricks are placed on the edge.

- Attached - can be installed anywhere in the home. The only condition for installation is the presence of a fireproof wall or partition. Sometimes the chimney is attached to the chimney of an existing stove above the dampers. In this case, the stove and fireplace can be used both simultaneously and separately.

- Island - can be installed at some distance from the walls, for example, in the center of the room on a square or round area, towering 35-50 cm above the floor level. A square or round smoke collector is installed above the stove, made of sheet metal chimney. An example of island fireplaces is a metal hearth made by hand from a barrel or pipe 80-100 cm in diameter.

Metallic elements can be:

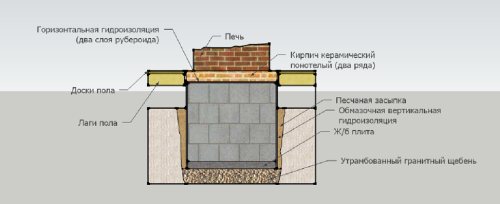

Diagram of the foundation for the fireplace.

- matte black;

- shiny black;

- completely smooth;

- with a corrugated pattern;

- decorated with a decorative stamp;

- with a minted design and other decorations.

A metal fireplace can work independently, or it can be combined with other materials, such as:

- natural stone;

- brick;

- tile.

Finishing

In absolutely all cases, the resulting fireplace will have to be decorated outside. It can be simply painted over with a layer of glossy or matte paint. Here you need to remember the elementary laws from the physics course. Dark bodies emit more energy, and since our task is to remove energy, then black colors will be in priority.

The fireplace can be decorated with special refractory materials. These include ceramic, artificial and natural stone tiles. When gluing tiles, you should remember about the thermal expansion of the metal, so the joint gap should be slightly increased.

With the possibility of making a fireplace yourself, you have a lot of opportunities to realize your old dream exactly in the form in which it interprets itself. Desire and work in a certain sequence will serve to ensure an excellent result.

A beautiful fireplace that brings warmth to the house is the dream of every owner of a private house. In addition to warmth, the fireplace also brings an atmosphere of coziness and zest to the interior. As a rule, they prefer to put brick fireplaces in their houses, but it is not always possible to install such a unit at home, since there may not be enough space or strength for it to care for it.

An excellent alternative to a brick fireplace can be a metal one, which has a lot of advantages, as well as location options, besides, it can be easily built with your own hands. In this article, we will touch on each of the above points.