Heating in a greenhouse: choosing an economical system

Ecology of consumption. Homestead: Heating a greenhouse in winter is probably the biggest expense. Let's consider how to organize heating of the greenhouse in winter, if possible, without investing large funds.

Without a doubt, a greenhouse on a personal plot is a necessary structure.

This building, irreplaceable for the gardener, acquires even greater value when the possibility of heating it is provided.

Growing early vegetables, greens, strawberries and seedlings, and with year-round use of a heated greenhouse - and obtaining such products in winter - isn't this an obvious benefit?

Especially for those who earn in this way: vitamins in winter and early spring are not cheap and the demand for them is great.

The ability to harvest 2-3 crops makes this business even more profitable.

The cultivation of tropical and ornamental plants has now become a fashionable hobby. And to provide them with the appropriate climatic conditions throughout the year is possible only in a greenhouse or winter garden, where there is heating.

How to build a greenhouse with heating? or make heating in an existing one?

Which way to choose?

The most popular options are as follows:

- biological systems;

- with solar panels;

- electric;

- water;

- steam;

- gas.

This also applies to industrial greenhouse structures. A conventional heater is no longer suitable for this solution. It will heat, but only in one of the available places. Some areas will simply remain cold unless special fans are used.

If a structure is created in the form of a home oven, then attention should be paid to the power indicator. A too weak boiler leads to a high probability that not only the greenhouse will freeze, but also the house itself.

It is also necessary to take into account the distance at which the greenhouse and the house are from each other. A home oven is simply inconvenient to use if this distance is more than 10-15 centimeters. The operation of a water boiler will lead to the fact that the entire system will have to be constantly heated, otherwise it will defrost.

How to make greenhouse heating efficient and cost effective? To do this, you need to take into account several main rules. The most important factor is the size of the greenhouse, then the most suitable time of the year for construction should be chosen. Finally, it is worth taking a closer look at the materials from which the greenhouse building is being erected.

It is best to do such work in the spring and summer. Then there will be more time to prepare for the cold weather. Biological heating is perfect for small spaces. Water heating is available to organize in almost any building, because you can place boilers and stoves anywhere.

How to make heating in a greenhouse?

There are many ways to heat a greenhouse with your own hands. For these purposes, different schemes are used:

- stove heating greenhouse

- greenhouse gas heating

- electric heating of the greenhouse

- steam heating in the greenhouse

- hot water

For example, when laying the foundation of the greenhouse, you can fix the electrical circuit in it using heating cables for underfloor heating. This option practically does not take up the space of this building, while ensuring good heating of both air and soil.

But the use of electric heaters is not a very convenient solution.

The fact is that in the absence of normal air circulation, the greenhouse area will warm up unevenly, i.e.That is, if one part of the space turns out to be excessively overheated, then the heat will not reach the other at all.

You can normalize the movement of the air flow by installing a fan. However, the very process of its operation also leads to air cooling. There is one more negative point here - electricity costs will increase significantly.

To make the heating of the greenhouse with your own hands rational, to create comfortable conditions for the growth of plants, especially if you are heating the greenhouse in winter, you should choose a type of it that will provide full heating of the soil and air.

How to choose a heating unit?

To equip heating a greenhouse with a large area, you will need a furnace with a water circuit. It is built independently or purchased from the manufacturer. The courtyards can lay out a heater with their own hands, inside which a coil is placed: a steam outlet and a pipe for collecting condensate are removed from it.

A foundation is required to equip the furnace. The coil is placed in the combustion chamber or in niches: in this case, the walls are built double. The heating unit is made from barrels, gas cylinders, metal cabinets and boxes. The steam generator is located on the sides of the firebox.

To make the heating in the greenhouse completely autonomous, firewood, coal, waste oil, and manure are used as fuel. You can install a heating element in the furnace, supply electricity to it, but this will require permission from power engineers, heating will be expensive.

If finances allow, it is better to buy stoves or boilers in specialized stores. Aggregates are selected depending on the power and on the area that needs to be heated.

- A potbelly stove with a 4 kW water circuit can heat a greenhouse with an area of 30 m2.

- "Cinderella" produces 6 kW. It can be installed in a booth of 60 m2.

- Buleryan has a large firebox. Burning time at full load is 10 hours. Its power is 6 kW. The unit is installed in a greenhouse of 50 m2.

Recommended: How does electric steam heating work?

These units run on wood. They have a metal body that acts as a heating device. Stoves require a chimney. Its length in the greenhouse is up to 3 m. Combustion products pass through the chimney, which additionally heats the soil and plants. For heating large areas, the manufacturer has provided these models of units with a water circuit.

It is recommended to equip the greenhouse with steam or water heating. Steam heating will be more efficient than water heating. Its efficiency is higher, but there is a risk of burning the vegetative part of the plants or their root system. It is necessary to properly distribute the steam lines throughout the greenhouse.

Heating system selection

When choosing a greenhouse heating system, consider:

- building dimensions

- heating method of the residential building itself

- their financial capabilities.

Each option has its own advantages and disadvantages.

It is important that the heating system matches the type of greenhouse.

It is known that heating film greenhouses, for example, requires more heat than heating polycarbonate greenhouses - a material that is itself a worthy thermal insulator.

It is necessary to consider the features of the system. For example, some of them, due to their high cost, are completely unsuitable for standard, small greenhouses. Other systems require professional installation and adjustment.

This is especially important when it comes to heating industrial greenhouses that use advanced technologies such as heat pumps, infrared heating and others.

Having made a decision about home-made heating of the greenhouse, the first step is to "feel" the whole technology of the process, to take into account all the pros and cons of the selected heating system.

It is necessary to correctly calculate the heating of the greenhouse in order to achieve the most rational distribution of heat in a given room.

Now, briefly about each heating method.

Heating

For year-round use, a polycarbonate greenhouse with a rigid foundation and a metal frame, equipped with a heating system, is also suitable. To properly build a greenhouse, it is best to place it longitudinally from the west or east, away from tall trees, as this will allow more light to penetrate inside. Greenhouse vents are best done on the south side.

After the location of the future structure has been determined, it is necessary to prepare a foundation for it. The most common materials for it are:

- concrete;

- brick;

- timber.

Since the concrete strip foundation is the most popular and reliable solution, it is best to stop at it if possible. The most common size of this structure is 6 meters long and 3 meters wide with a height of 2.5 meters, which, as you can imagine, is a fairly compact option. A greenhouse of this size is easier to heat, and there is enough space for vegetables in it for a farm whose harvest volumes do not strive for industrial ones.

To install a concrete foundation at a depth of half a meter from the surface of the earth, formwork made of wood with a height of 20 cm is used, into which concrete is poured. Further, reinforcement with metal rods with a diameter of up to 6 mm is performed, and fasteners for the frame are also installed. Concrete hardens, as a rule, in about a month.

After the foundation is ready, you need to start assembling the frame. Most often, structures of this type have a gable or arched roof shape - everything here depends on personal preferences, since the use of polycarbonate, due to its flexibility, allows both options to be implemented.

The greenhouse frame can be either wooden or metal, but the second option is preferable due to its greater durability, provided that galvanized steel is used and preliminary anti-corrosion treatment. The wooden frame, in turn, is more environmentally friendly and suitable for the use of nails, but in conditions of high humidity, the likelihood of rotting wood is high.

The metal frame can be purchased disassembled in a specialized store or made by hand from a galvanized profile. It is best to purchase or make your own frames with a distance between the arcs of no more than 1 m to give the structure the necessary rigidity. The installation of additional stiffeners will also help this.

The assembled frame is screwed to the foundation on pre-concreted special fasteners, and then polycarbonate sheets are attached to it using self-tapping screws. For constructions that are used year-round, an 8 mm cover is best suited, since it is thick enough to retain heat and transmits light to maintain a plant-friendly environment inside the winter greenhouse.

After the actual greenhouse is ready, you can proceed with the installation of the heating system. Here you can apply various types of air heating: various heaters, air heaters, stoves. But the most effective is the use of water heating, since it allows you to uniformly maintain the required temperature throughout the entire territory of the structure.

To heat the winter greenhouse with the help of water, pipes are laid in the ground, and a boiler is installed in the vestibule. You can also use a wood-burning stove for additional heating.The advantage of this type is also the fact that the main problem associated with heating the greenhouse in winter is not cold air, but frozen soil. And, since in this case there are pipes in the soil that will warm it up, so you can make the cultivation of crops in it as comfortable as possible.

As you can see, growing vegetables and other plants in winter is quite possible -. This is so difficult to do - first of all, you need standard construction skills and a little ingenuity. Moreover, if the work is done efficiently, the structure will serve for many years. Thus, we can conclude that a winter greenhouse with your own hands is quite real.

Water heating

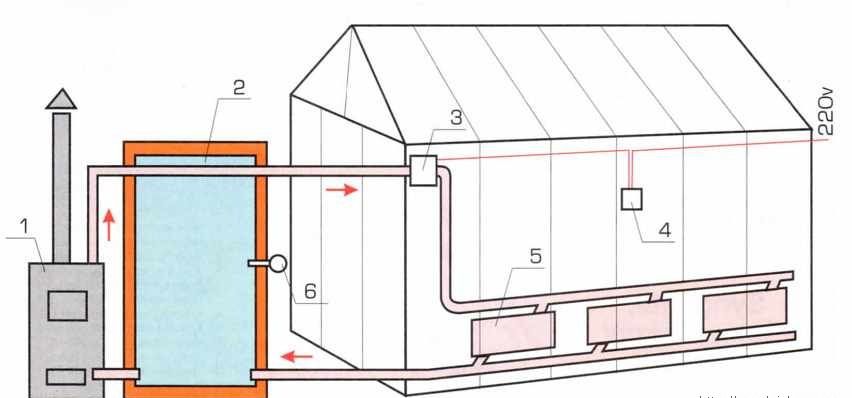

Installation of water heating of the greenhouse is possible, operating both on electricity and on gas.

The heat source is hot water circulating through pipes that are laid inside the greenhouse or under the floor.

The scheme and principle of operation of water heating of a greenhouse is as follows: a coolant (heated water) circulates through pipes closed in the system, which, having given off heat to the atmosphere, enters the boiler again, where it is reheated.

A larger number of pipes allows you to lower the water heating temperature. It should be noted that the pipe system tends to heat up rather slowly.

The boiler is the main element of such heating for greenhouses. His choice is due to a specific situation.

In the area where the gas pipeline is laid, it is gas boilers that are often in demand, as the most economical option.

Despite the fact that the heating works from the mains, the following happens: the water heated in the boiler is supplied by means of a circulation pump to pipes that can be laid along the walls of the greenhouse or between plants.

When installing a water heating system, copper, steel and plastic pipes are used. The latter are just what you need in this case. They are lightweight, affordable and do not rust.

The circulation of water in the system is usually forced, which is facilitated by the installed pump, less often - natural.

When connecting thermostats to pipelines and radiators, it becomes possible to maintain a certain temperature automatically.

When laying pipes for subsurface heating, it must be borne in mind that steel is not suitable for these purposes. Corrosion of the metal will destroy and disable such a heating system.

The disadvantages of water heating in a greenhouse include the complexity of the installation of the pipe system, the high price and the need for constant monitoring.

The positive side is that there is a simultaneous heating of air and soil.

Connection to an existing heating system

Before doing anything, you need to make sure that the boiler can provide the required pressure.

In addition, it makes no sense to connect to an existing system if the greenhouse is located at a distance of more than 10 m from the house.

And since the pipes laid to it must be insulated, then it will cost quite a lot. It is also necessary to take into account the fact that most of all heating is necessary for the greenhouse at night. Just at this time, controlled heating systems can lower the temperature. It is important to consider the priority of connecting to the greenhouse.

Infrared heating

For infrared heating of greenhouses, use:

- infrared lamps for greenhouses

- infrared heaters

If we take into account the fact that such an energy carrier as electricity is the most expensive, then it becomes clear why the plen heating system is gaining momentum.

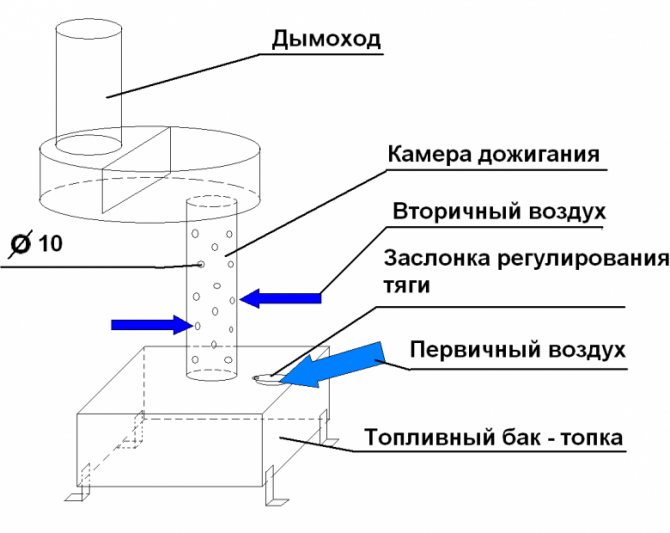

Sawdust oven ↑

Sawdust is an option for heating raw materials. This is a waste of woodworking production, you can buy it very cheaply, and in most cases the owner of the workshop will be just happy to get rid of the garbage.

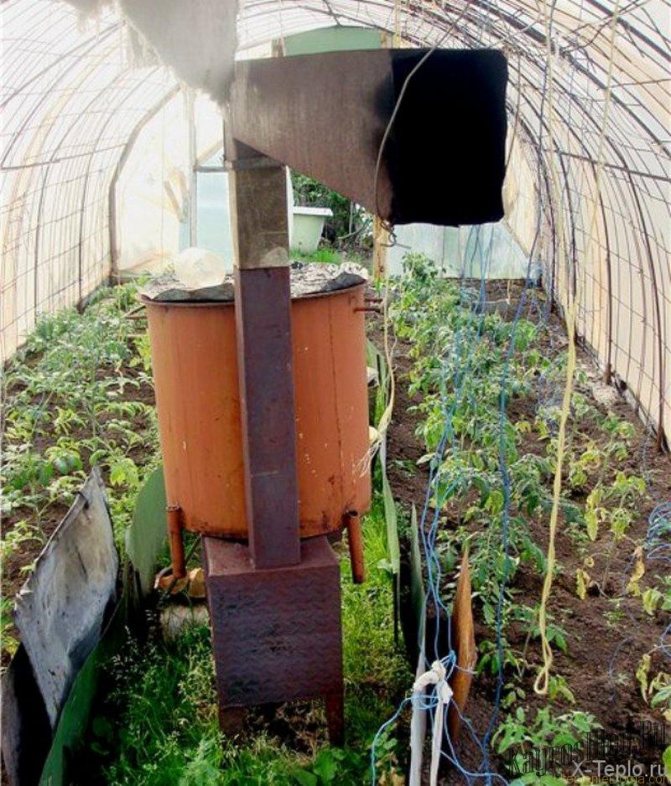

You can use the Buleryan stove to heat the greenhouse.

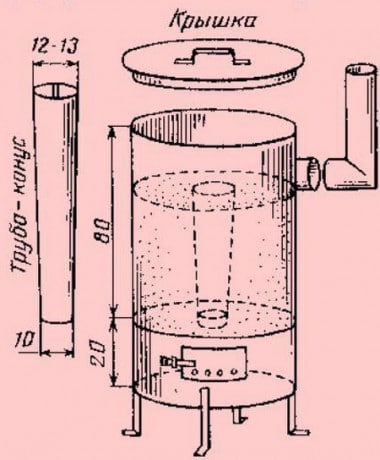

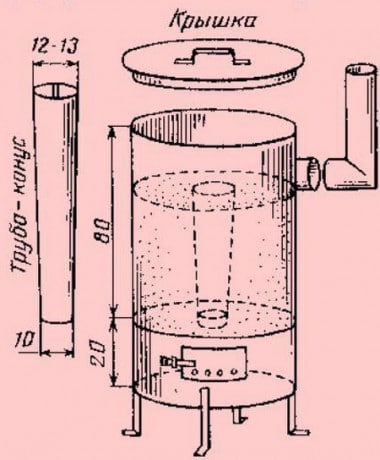

An old tin barrel (preferably two), a propane gas cylinder, a piece of pipe of a suitable diameter, or something like that will do.

- A hole is cut in the side of the barrel and a chimney is welded in. It should be horizontal.

- A hole is cut on the bottom about 2 times smaller than the diameter of the bottom itself. The second barrel is cut into two parts, of which the lower one is approximately 25 cm high.

- We weld the legs from a suitable durable material. Two barrels are connected and welded. The seams must be neat.

- A cover is being made. The remains of the second barrel are used for it.

- It remains to install the stove and connect it to the chimney.

An unnecessary barrel or cylinder will make a wonderful stove.

To put the furnace into operation, we make a cone. Any material (wood, tin, etc.) will do. The narrow section should fit freely into the hole in the bottom of the top section.

The cover is removed, a cone is inserted, closing the hole at the bottom, sawdust is poured. They must be well tamped when falling asleep. When the container is 2/3 full, the cone is removed.

A small amount of wood chips and paper are put into the firebox. You can add a little gasoline or diesel fuel. The main thing is that the sawdust starts to burn. After that, the lid is closed and the oven starts to warm up. The traction is regulated by means of the door.

Depending on the size of the stove, the operating time will vary, but on average, the sawdust will need to be filled in no more than twice a day.

You can do without the bottom barrel. A hole is simply made at the bottom to ignite sawdust.

Air heating

It is easier to build air heating of a greenhouse with your own hands than water heating.

In this method, air is used as a heat carrier.

It is pumped between the walls of the boiler and the furnace, while heating up, and then it is distributed through the air duct system.

A polyethylene perforated sleeve is laid around the perimeter of the entire room. Warm air enters through it, which evenly heats the soil.

The advantage of this method is the rapid heating of a greenhouse of any area.

The disadvantage of this heating system is that you have to constantly monitor the humidity in the greenhouse. This heating method contributes to a sharp decrease in it.

Technical methods

It is very rarely possible to implement the most ideal method - the installation of a greenhouse over a heating main, therefore, ovens, gas, electric heaters are used, suitable even for a large greenhouse. The following heating groups can be distinguished:

- air;

- water.

Air heating uses air as a heat carrier - with the help of furnace designs, pipes it is directed to the right place. The most primitive way is to heat greenhouses with a piece of pipe. It is laid so that one end is inside the greenhouse, the other is outside, a fire is made under it.

Ovens

You can buy a ready-made solid fuel stove or build a do-it-yourself greenhouse stove. For her, you need to make a brickwork, a foundation. The chimney must necessarily go outside.

A brick stove or the simplest design - a "potbelly stove", should be placed in a separate area or with a firebox outside so that smoke does not get onto the plants. A solid base is also required - concrete or brick. It can be buried or on the surface. The minimum distance to the walls of the greenhouse from the ends of the stove must be at least 250 mm. The chimney is made horizontal, passing along the building, its upper part should be at a distance of about 150 mm from the bed, shelving.

A potbelly stove can be welded from sheets of metal or you can take a sufficiently thick steel barrel and cut holes in it for storing fuel, cleaning from ash. The main nuance of such a heater is a chimney for removing burning from the greenhouse. It should stretch along the entire room, can lie, be suspended or buried in the ground.

Buleryan

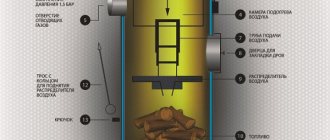

The basis of the device is a pyrolysis oven or a gas generator. The fuel smolders with a limited air flow, pyrolysis gas is released, it is burned out in another firebox. Smoldering continues very slowly, ensuring a stable temperature.

The fireboxes have large pipes welded around them, through which the heated air goes inside the greenhouse. The stove is installed on a solid base, the chimney is led out. This is the most economical and efficient type of heating.

Wood heating

When choosing a heating option for a greenhouse, taking into account what is happening with an enviable regularity in the growth of tariffs for electricity and gas, it is worth paying attention to an alternative method - heating the greenhouse with wood.

Furnaces of the Buleryan type are very suitable for this purpose. Their use allows you to organize the heating of the greenhouse in such a way that night trips for the next laying of firewood are not required. The room heats up quickly, and the temperature is maintained at a predetermined level for a long time.

One load of firewood is enough for 6-8 hours. The body of the stove does not heat up, which completely ensures safety.

You can build a stove for heating greenhouses with your own hands, as an option, a stove with a horizontal chimney.

Its structure is as follows: a brick firebox is made in the vestibule, and in the greenhouse, in its entire length, a chimney is laid under the shelves. It is through it that carbon monoxide passes and leaves the room through the pipe on the other side.

The heat generated at the same time heats our building.

Combined heating method

Combined boilers are widely used. They are convenient in that they make it possible to instantly react to changing operating conditions.

At the same time, the disadvantages of one heating method can be successfully covered by the advantages of another. For example, a power outage will not be taken by surprise if heating is provided that operates on wood, gas, or coal.

When there is a duplicate source of heat, you can safely calculate the future profit from a rich harvest.

Which method to choose for heating the greenhouse, everyone decides independently.

To choose the optimal heating method, which is so necessary in a suburban area, a structure, you should very carefully calculate each available option. And in the end, to understand for yourself what kind of heating is better for a greenhouse, more economical, more profitable and more convenient. published by econet.ru

P.S. And remember, just by changing your consumption - together we are changing the world! © econet

Did you like the article? Write your opinion in the comments. Subscribe to our FB:

Greenhouse heating: ways to heat the greenhouse in winter and early spring

The road is a spoon for dinner, and a green cucumber - for the new year. This addition to the Russian proverb is not controversial. No amount of conservation can replace vegetables grown in our own greenhouse.

However, just the desire to create a "vegetable island" on the site is not enough. Heating the greenhouse in winter is a major stumbling block for beginners.

Which heating method is easy to implement and not too expensive? What technical innovations do greenhouse owners use to grow seedlings, vegetables and flowers? What are their pros and cons? We will give answers to all these questions in our review.

Types and methods of heating in greenhouses

All methods of heating greenhouses can be divided into auxiliary and main ones. Ancillary products include solar radiation and biofuels. Everyone knows about the energy of the sun's rays, which create a greenhouse effect. The use of biofuels should be considered in more detail.

The decomposition of organic matter is accompanied by the release of large amounts of heat. Knowing this, experienced greenhouses in the cold season lay horse, cow or pig manure under the beds.To slow down the rate of decomposition, it is mixed with straw or sawdust. Above, a homemade "bioaccumulator" is covered with fertile soil and plants are planted. A week later, the process of heat release by organic matter begins. It lasts for several months. As a result, the earth warms up evenly, and the seedlings start growing together.

Economical and environmentally friendly solar and biomass heating methods have their drawbacks. In early spring, the energy of the sun's rays is not enough to fully warm up the greenhouse. Biofuels start to "work" only when the temperature is high enough to be created by another heat source. These reasons explain their subsidiary status.

Do-it-yourself heating of a polycarbonate greenhouse in winter. Types of polycarbonate greenhouse heating in winter

To choose how to heat the greenhouse, in addition to financial possibilities, one should take into account the climatic conditions of the area, the size of the room and the type of crops grown. Cold-tolerant plants such as spinach, dill or celery require minimal heating, while thermophilic tomatoes, cucumbers and peppers need a higher temperature and constant heating of the greenhouse.

Stove

The basis of stove heating is a solid fuel stove or boiler fired with coal, wood or briquettes. Furnace combustion products, harmful to crops, are discharged through a chimney that goes outside.

- Advantages of stove heating:

- inexpensive energy materials;

- simple device and operation;

- fast heating of the room;

- the ability to make it yourself.

- Disadvantages:

- the need for frequent fuel filling;

- lack of process automation;

- uneven heating of the room;

- reduction of air and soil moisture.

In the absence of a greenhouse humidification system, a wide container with water can be placed to prevent drying out of the plants.

Making such a candle is pretty simple, and the performance is just excellent. for a greenhouse of 20 squares, 3 or 4 such heaters will be enough to survive the night spring frosts without problems

Important! For safety reasons, it is necessary to constantly monitor the normal operation of the chimney and periodically clean its internal surfaces from solid particles that have settled from the burnt fuel.

Potbelly stove

One of the simplest designs has a fairly common solid fuel stove - a stove. It consists of an ash pan and a closed combustion chamber and is a standard metal stove equipped with a straight chimney.

During the combustion of fuel, the walls of the stove are heated, and the greenhouse is filled with heat. At the same time, the use of a fan will help protect the plants closest to the stove from overheating.

Brick oven

The circulation of fluid in the system can be forced or natural. Many people prefer the first option, because in this case it is unlikely that the heating medium will freeze, for this they use a mixture of horse manure and chopped straw, which prolongs the decomposition period, or compost from household waste. Under the influence of various microorganisms, organic components begin to decompose with the release of heat.

The main sources of heating for greenhouses

Efficient polycarbonate greenhouse heating can be created in several ways:

- Solid fuel stove;

- Gas boiler;

- Electric cable;

- Infrared heater;

- Heat gun;

- Heat pump;

- Solar liquid collector.

Stove heating

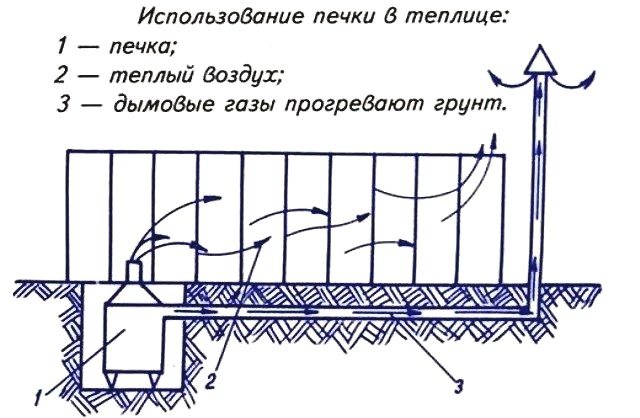

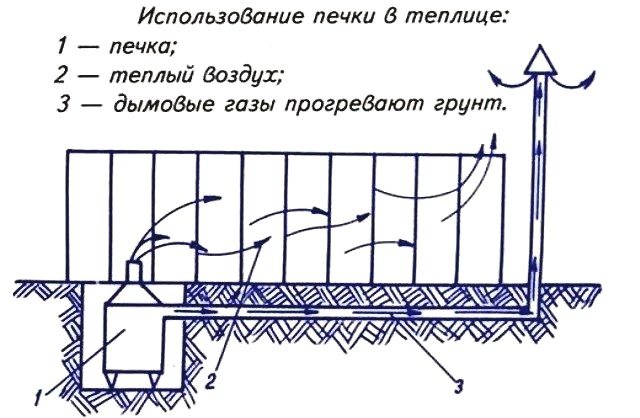

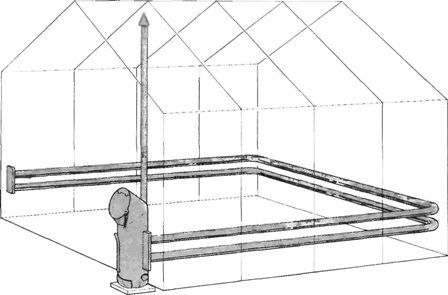

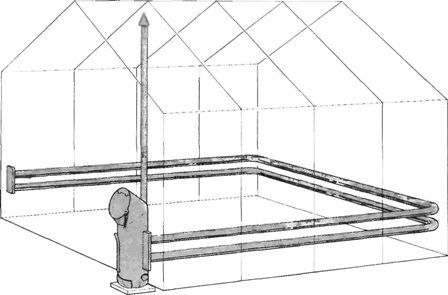

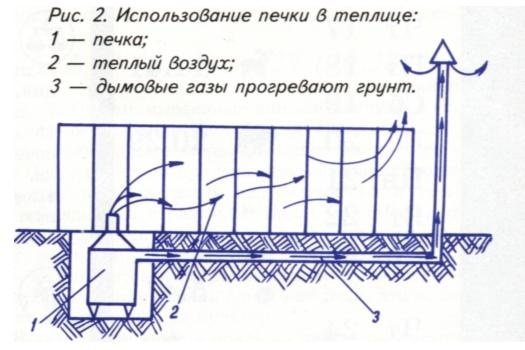

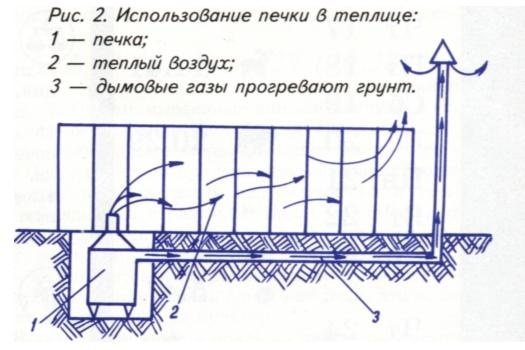

Heating a greenhouse with a stove is an old-fashioned way of maintaining a positive temperature. Despite its considerable age, it is still relevant. The idea of the method consists in laying a long channel from the furnace buried in the ground, through which hot gases move. They warm the soil, and the red-hot stove body radiates heat into the air.

This method has several advantages:

- Low price and availability of solid fuel;

- System autonomy;

- Minimum maintenance costs.

There are also disadvantages to stove heating:

- The process does not lend itself to automation;

- The soil is warmed up in a narrow area along the smoke channel.

A modern option for heating greenhouses with solid fuel is the Canadian Buleryan stove. In its firebox, the process of burning firewood is slow. Due to this, the frequency of fuel loading is reduced (2 times a day), and the heat output becomes uniform.

Types of heating with a stove

There are several different ways to heat vegetation with ovens.

Heating the room directly by the stove.

This implies the use of one or more heating elements (ovens), reasonably dispersed around the perimeter of the entire structure. In such a situation, the vapor-air mixture (air) is heated, as in the case of natural - solar heating of the structure. There are two types of heating of this kind.

- the use of several mini-ovens that run on liquid or solid fuel, and they are located at an equal distance to each other and serve as direct sources of heat. The convenience of this method lies in the fact that, if necessary, the summer resident will be able to move without problems - move such stoves to the necessary place that is more in need of heat. As for the disadvantages, it is the need for a constant, round-the-clock presence of at least one person in the country - to maintain the fuel combustion process (throwing firewood, adding oil, etc.) and adjusting the set temperature (to avoid overheating). In addition, several such heating devices need proper and high-quality removal of combustion products, as well as frequent ventilation or blowing of the greenhouse through the use of artificial or forced ventilation of air in the room;

Advice: for a more ergonomic distribution of warm air inside the polymer structure, you can use electrical appliances - blowers or fans, which will direct, "dissipate" the warm vapor-air mixture inside the room.

- using one large stationary oven is a fairly good and productive method of heating vegetation. It can be located both near one of the polycarbonate walls and in the middle of the building, and the second method is much more preferable, but for its implementation, a hole should be cut out and subsequently sealed for an emergency "release" of heat. It is clear that it is not enough to cover the entire perimeter of a rather large polycarbonate greenhouse, one, even the largest, stove is not enough. So, elements of heat dispersion over the area of the building will be required, that is, pipes with hot air removal. The main thing to remember with this heating method is the correct placement of such pipes - 15 cm (minimum) from the polymer walls, as well as the presence of small hatches along the entire length of the pipes (for their periodic cleaning). In order to increase the performance of this system, in several places it is possible to install "accordions" - radiators, because this will greatly help to reduce the consumption of liquid or solid fuels and the preservation of heat in some cases.

Both the first and second methods of heating a greenhouse room require frequent airing or switching on forced ventilation, as well as periodic cleaning of the stove (stoves). Among other things, you should correctly calculate the capabilities of polycarbonate walls - thin and low-grade materials may not withstand such a temperature drop and deteriorate.

Water heated oven.

The organization of such a polycarbonate greenhouse heating system, although it is considered quite laborious at the initial stage (direct construction), but the efficiency of the fuel is much higher than that of other methods.

To build this system, the furnace itself is needed, and it is quite powerful (large) - it can be made of metal or brick - it does not matter, and installed outside the room or in the vestibule (if there is one). In the upper part of the building, a metal vessel with water is attached under the ceiling, to which a branch pipe is welded through the firebox. A closed loop of auxiliary elements is connected to this pipe - pipes that distribute hot water around the perimeter of the room.

This method is good due to the fact that there is no need to often open and close the polycarbonate greenhouse, thereby letting in cold air there, but it is worth noting that a sufficiently large amount of firewood will be required to maintain the set temperature.

Heating the room by warming the soil.

This method is considered the safest for plants and the polycarbonate walls themselves. After all, the plants do not overheat, the polymer coating is not threatened by the immediate proximity of heat sources, and the formation of condensation on the walls and leaves of garden crops is minimal.

Since this method is considered the most popular and productive among "experienced" summer residents, it is worth considering in more detail.

Rating of greenhouse heating options

In conclusion, we will make a comparative analysis of the considered options for heating greenhouses.

The easiest way to organize heating is with gas boilers and solid fuel stoves. Gas installations can be easily automated and, without auxiliary heat sources, create a comfortable microclimate for plants.

Buleryan stoves are not very convenient in operation (the need for periodic manual loading of firewood). Their main advantages are low fuel costs and high heat transfer.

In second place, you can put infrared emitters, cable heating systems and solar collectors. They are relatively inexpensive, easy to install and operate automatically. However, in terms of the cost of energy spent on generating a unit of heat, they are significantly inferior to gas and firewood.

Heat guns occupy the third place in our ranking. They are easy to maintain, can operate in automatic mode, but are not economical. Heat pumps are located in the same niche. Despite the minimal cost of energy, the price of these installations is high and the payback period is very long (8-12 years).

Heating options

You can find many ways to insulate the ground and warm up the air in the greenhouse - from industrial installations to self-laying foam and insulation material.

The main power supply for most heaters is:

We will analyze the most popular designs, highlight the pros and cons of each - you just have to choose the one that suits your greenhouse.

Electric heaters

Among the variety of these heaters, several groups stand out: operating on the principle of the sun (infrared emitters), heating the air (heat guns), heating the soil (heat mats).

- easy to install by yourself;

- only an outlet is needed for power supply;

- easy to remove and rearrange to another place;

- big choice.

- do not warm up the air and soil at the same time;

- you need to take care of protection from moisture so as not to damage the electronics;

- a large greenhouse needs several emitters.

Tip: To get rid of moisture, you can use an exhaust fan (install it in advance).

Warm floor

It is also powered by electricity and completely covers the base of the greenhouse. You need to remove the earth, put in the insulation material and the cable, then fill the beds again - and the heating is ready.

- the soil is evenly heated - up to 40 ° С;

- soil heating is automatically regulated;

- economical - this is a simple system in which there is only cable and insulation;

- you install it yourself, even if not related to construction and design.

- it is necessary to monitor the humidity so as not to damage the cable;

- does not warm up the air.

Tip: to accurately avoid freezing the beds, raise them about 40 cm above the ground.

Water heating

It works in the same way as home heating - hot water moves through a pipe and heats the ground. You can conduct it directly from home, or install a separate boiler. Place pipes around the perimeter of the greenhouse and between the beds.

- it is quite cheap to install such heating;

- you can build this system yourself;

- heats up the soil and plant roots well.

- almost does not warm the air;

- may not cope with severe frosts.

Solar heating

Sunlight is the most natural heating for plants. Install a collector or special panels on the roof of the greenhouse to retain the meager heat that the sun provides in winter.

- convenient for residents of the southern regions.

- for the system to work, it is necessary to constantly clean off the snow;

- the greenhouse should be in the brightest place of the site;

- more suitable for glass greenhouses;

- even if you collect the daytime heat to the maximum, a sharp night cold snap can nullify all work;

- expensive equipment.

Stove heating

Many people still put potbelly stoves or homemade stoves in greenhouses, despite the fact that this is an old-fashioned way. If you are attracted to such a system, you can buy a stove of the required size and make autonomous heating.

- easy to use;

- you can make it yourself and adjust it to your greenhouse;

- you can choose a stove for the available fuel - coal or wood;

- economical way.

- fuel must be added constantly;

- the design is quite cumbersome, it is difficult to move it to another place;

- the air heats up unevenly - it's too hot nearby, it's cool in the far corner;

- will not be able to maintain a high temperature if a severe frost hits.

Air heating

Provided by large installations that drive warm air through the greenhouse. This is a complex equipment, therefore, it is installed by specialists during the installation of the greenhouse.

- evenly distributes warm air over the top;

- does not burn leaves with hot air.

- cannot be installed by yourself;

- does not warm up the soil;

- expensive equipment.

Biological heating

This organic matter - most often horse manure, which is laid in the ground. It is necessary to remove the soil from the garden, fill it by one third with manure and fill it up again.

- manure maintains a temperature of 60-70 ° for up to 120 days;

- warms up the soil well;

- additionally fertilizes, moisturizes the beds, nourishes the roots.

- difficult to get;

- cannot be replaced with ordinary humus, as it quickly loses heat;

- more suitable for southern regions.

Conclusion: how best to heat the greenhouse

In order for a modern polycarbonate greenhouse to produce crops even in winter, it is most profitable to install electric heating.

The most popular are infrared emitters: they are easy to install, they do not require constant attention and complex maintenance. In addition, they mimic sunlight, which will benefit the plants.

When buying a greenhouse, decide in advance whether you need it in winter or not. It is much easier to heat it in the spring - the ground thaws faster than outside. With the first plus, you can already start planting.

Heating the greenhouse with a homemade stove

My husband is a welder. Therefore, it was decided to make the simplest potbelly stove - from a 200 liter barrel.

It is done as follows.

The barrel is laid on its side, a hole for the pipe is cut from above. The bigger it is, the better. We made a hole for a pipe 180-200 mm. This is the optimal size.

The outlet under the pipe can be made in the middle or shifted to the rear edge.

Next, we weld on the legs, about 20-25 cm long. The barrel should not lie on the ground. It's more convenient to operate this way. And such a stove will not heat the earth, but the air in the greenhouse.

Legs are made from scrap material. Pieces of fittings or water pipes, or something like that, will do.

You also need to make a door for storing firewood. It should not be small, otherwise you will be tortured with the constant tossing of logs.

We made a door almost the entire width of the bottom of the barrel. To make it easy to open, you need to weld two small overhead hinges.

During operation, the door gets very hot, so it is advisable to make some kind of handle so that you can pull on it.

And of course, you can't do without a bolt or latch. So that the doors can be locked in the closed position.

I especially want to tell you about the pipe through which hot air flows. It should be made as long as possible. Ideally 4-8 meters.

The pipe is installed at an angle and runs along almost the entire length of the greenhouse. We hung it on the rails. Such a strange design allows you to heat the greenhouse in every part of it.

How much firewood is needed

A homemade stove can be heated with any fuel. The two main types are firewood and coal. She does not disdain either old boards or used oil. Anything that burns, you can throw into it.

During the winter-spring cold season, we spend about 1.5 cubic meters of firewood on heating a medium-sized greenhouse.

It is necessary to add firewood to maintain the microclimate in the greenhouse every 2-3 hours. At night, of course, I don't really want to get up. You have to force yourself. We set the alarm clock and take turns going to throw up firewood.

Different cultures need to maintain different temperatures. For example, for growing cucumbers, the air temperature should be 26-28 ° C. Peppers require a temperature of 30-35 ° C. For tomatoes, keep the temperature at 25-27 ° C. Greens are the least capricious to temperature extremes and grows quite well at 5-15 ° C.

Waste to income

Many greenhouses buy fertilizer from the store, use chemicals or gypsum. Although it is more profitable and useful to use the ash that remains after heating.

The best ash comes from burning aspen, pine and birch. It is rich in potassium, magnesium and calcium. It is not advised to use oak and ash ash.

If you have sawdust left, you can throw them not only into the firebox, but use it as a soil ripper. And also as a protection against the formation of dirt during drip irrigation.