To maintain a comfortable temperature in the home and reduce heating costs, it is necessary to insulate the floor in a wooden house. There are several technologies for the procedure. The choice of material depends on the stage of construction or renovation and the financial capabilities of the owner.

MINERAL WOOL

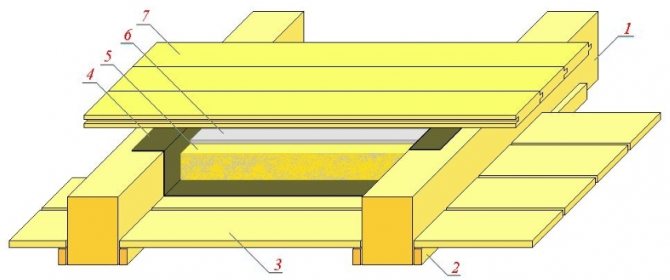

The next step is to install the insulation. Mineral wool is usually used for wooden floors. First, a vapor barrier is spread on the boards, attaching it to the bars with a stapler, then the insulation is laid in rows. If the insulation boards are 2 or more rows, then the seams between them should not be on top of each other. To exclude cold bridges, the second layer of insulation must be put in a checkerboard pattern to cover the seams of the first row. Mineral wool is laid flush with the lags, and again covered with a layer of vapor barrier material on top. Then the floorboards can be mounted.

It is believed that an air gap must be left between the insulation and the boards. In order not to be mistaken, insulation with mineral wool should be carried out according to the instructions on its packaging. The main disadvantage of warming with mineral wool slabs is that mice are very fond of living in it. Rodents settle there, build nests, breed. It is almost impossible to get them out of the underground space. Although the press writes that mice do not live in modern eco-samples of such a heater, since boric acid is used in the production of the material. Another disadvantage is that if the vapor barrier layer is used incorrectly, the insulation gets wet and loses its heat-shielding properties. There are many videos on the net where you can see that a lot of water flows out from under the mineral wool. Therefore, the proper use of vapor barrier requires increased attention.

What determines the microclimate of the underground room

Before solving the question of how and how to insulate the underground in a wooden house, remember the heaps (prizes). Our ancestors built them along the perimeter of old wooden houses, not only to sit on them basking in the sun. Filled with sawdust heaps of wood insulated the lower part of the hut, protected the lower part of the walls from moisture, prevented the soil around the house and the cellar from freezing.

The quality of insulation and dryness of the underground, its year-round operation within the temperature range of 5 - 10 (0С) is directly related to:

- with effective insulation of the foundation, basement, which will prevent the walls of the underground from freezing in winter;

- with their reliable waterproofing and removal of atmospheric, soil moisture from them;

- with ventilation of the underground space itself;

- with competent insulation, vapor barrier and waterproofing of the underground itself, the underfloor with living quarters.

Only by observing all these requirements will we get a warm and dry subfloor in a wooden house. In the following version of the underground insulation system, we will consider the use of traditional and modern materials, their methods of application outside and inside.

Ventilation of the underground

You need to think about ventilation at the design and construction stage. Ventilation holes (air vents) in the underground, we make in the foundation (tape, monolithic, in wooden zabirki - partitions between the pillars) against each other.

Their number, diameter and location must meet the requirements of paragraph 1.47 of SNiP 2.08.01-89 "Residential buildings", International residential code-2006 IRC2006 R408.1). For orientation, for an underground with an area of S = 50 m2, you need 10 - 12 round vents with a diameter of 11 cm.

Advice! If everything is correctly calculated, the insulation, vapor barrier and waterproofing of the foundation, basement, underfloor flooring have been correctly made, then the air vents are not closed for the winter. They are only protected from rodents with a metal mesh.

Air in the rubble filling of the columnar foundation of a wooden house

EXTRUDED POLYSTYRENE FOAM

There are other ways to insulate wooden floors. For example, when foam is used instead of mineral wool or its variety is extruded polystyrene foam. Its advantages are low coefficient of thermal conductivity, lightweight, waterproof, long service life, resistant to deformation. The main disadvantage is that it burns well and emits pungent smoke. However, this material is also readily used by homeowners for insulating floors, including wood floors. The disadvantages include the fact that it can also be gnawed by mice. Although they will not live in it, they will simply harm. To protect the expanded polystyrene from mice, laying on the boards of an ordinary roofing material, even better than used, will help. There is no information that rodents eat roofing material. They are scared off by the material itself, and the persistent smell of bitumen coming from it. Therefore, in order to protect the insulation from mice, it is imperative to put a layer of this roofing material in front of it.

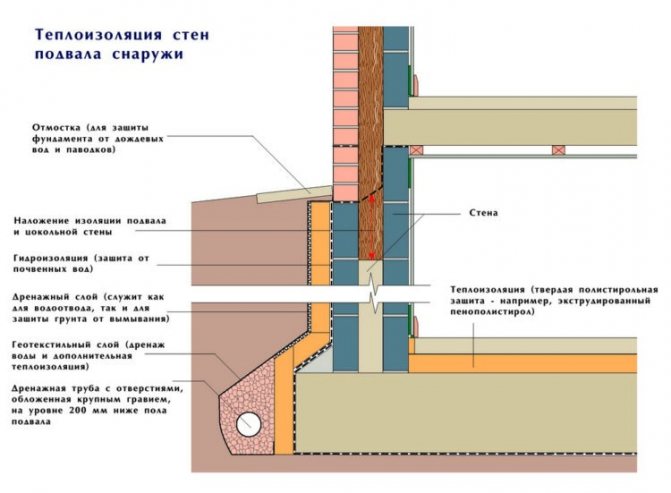

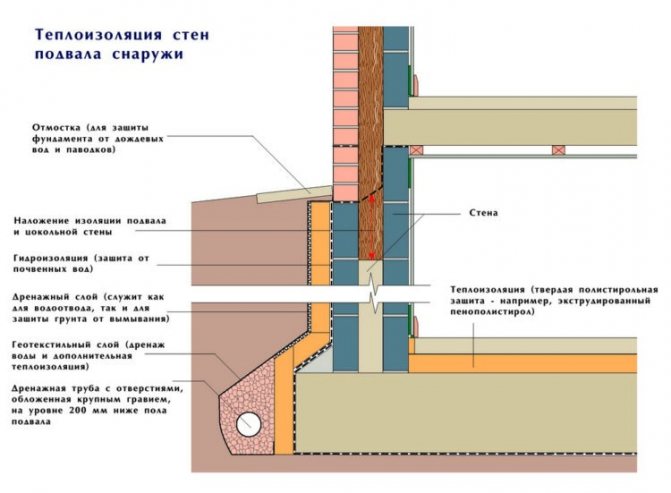

Stages and rules of external insulation

It is important to know these points, as they directly affect the quality and durability of the basement finish. It:

- Work should only be carried out in dry weather. Since the work on insulation and waterproofing of the cellar can take several days (everything will depend on the number of workers and the pace of work), it is best to carry out such events in the summer or early autumn.

- You will need to insulate the entire wall as a whole - from the foundation to the ceiling (floor). If you insulate only part of the base, then this will do nothing.

Preparation for the process:

- Remove blind area.

- Dig a trench around the entire perimeter of the house. Its depth should be at the level of the basement floor. The width is such that it will make it easy to carry out the work.

- Clean the walls from the remnants of building materials and old finishes. It is also important to remove dirt from it.

- Inspect the wall surface for cracks and chips. If such are found, then they should be sealed with a mortar of cement and sand. After the solution hardens, further work can be continued.

- If the surface of the basement walls will be finished with foam, then the base will also need to be leveled so that the sheets lie flat.

- After preparation, the surface should be primed. There should be several layers. Only after it is completely absorbed into the base can you continue to work.

- The waterproofing material can be fused onto walls after applying a primer.

- Next, you can carry out work with insulation.

Styrofoam or extruded polystyrene foam

Work on the insulation of the outer wall with the help of these materials can be carried out on your own. Such work does not require special skills and knowledge. These materials are the most common today, which are used as insulation.

Basement walls are insulated with extruded polystyrene foam plates

Process:

- Calculate the wall area and determine how many insulation slabs are required for work.

- It is important to add about 10% per battle to the result obtained.

- Prepare a solution.

- Apply glue evenly to the foam board and glue it to the base. It is necessary to start carrying out such work from below. Each row is attached to the base with an offset from the previous one.

- After finishing, you need to grease the seams between the sheets. This should be done with a cement mortar. Also, if necessary, you can cover the entire surface of the plates with such a solution.

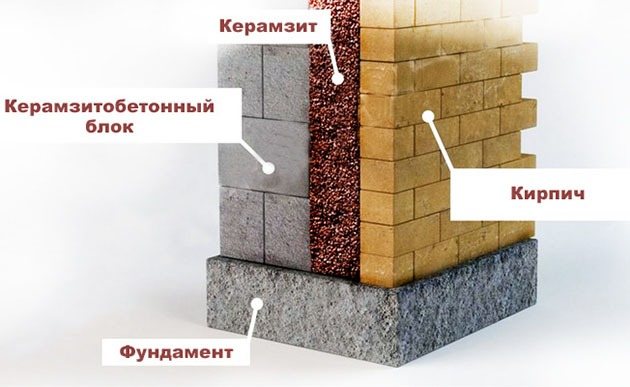

Expanded clay

This material is free-flowing, and therefore work on its installation can also be carried out on your own. The disadvantage of such insulation is that it is necessary to make a layer that is too large, since its thermal conductivity is lower than that of foam. The recommended layer is 10-20 centimeters.

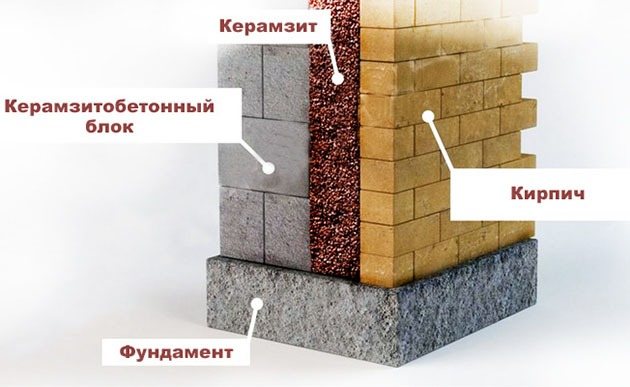

The scheme of warming the walls of the basement with expanded clay

Work order:

- Another wall is being erected at a distance of 20-30 cm from the basement wall. You can make it out of bricks.

- Gravel is pouring along the bottom.

- Drainage is laid and diverted away from the building.

- Expanded clay is poured into the gap between the walls.

- The second additional wall outside must be waterproofed too.

After that, expanded clay is tamped and a concrete screed is made on top of it. It is also important to put waterproofing under it. You can refuse to lay insulation.

Important! For the interior decoration of the basement walls, you can use the same material as for the exterior. Only the use of expanded clay in this case will not be effective, since it will take away the useful area of the room. Usually, insulation from the inside is carried out using polyurethane foam.

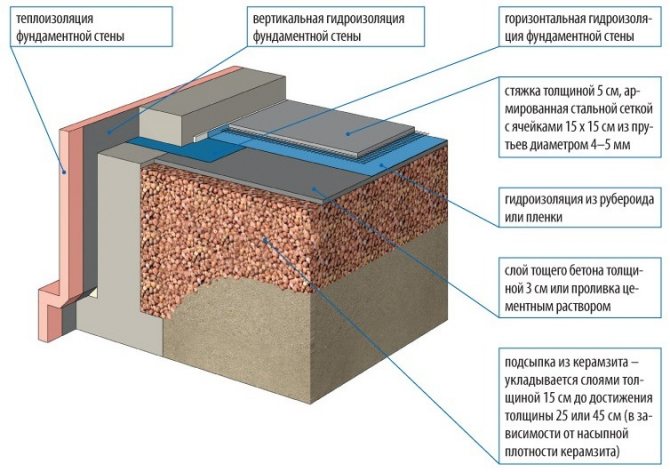

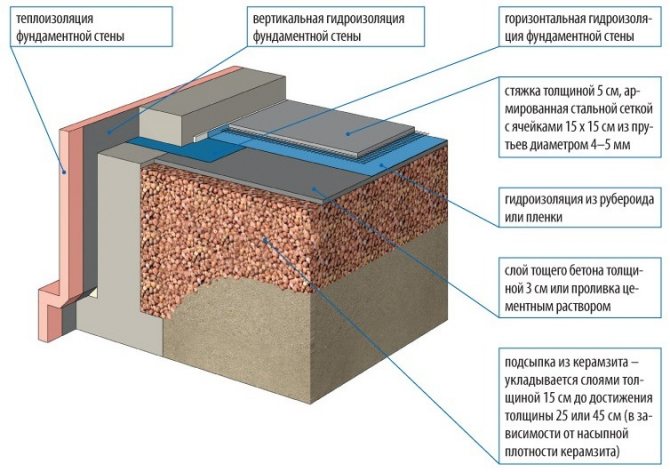

Floor and its insulation

Not only the basement walls should be waterproofed and insulated. Such work should be carried out with the floor. They are made using the same material that was used for the walls. To fill up expanded clay or lay foam plastic should be between the logs, pre-covering the floor with a waterproofing material. From above, you can also put a film under the main floor so that moisture does not enter the room.

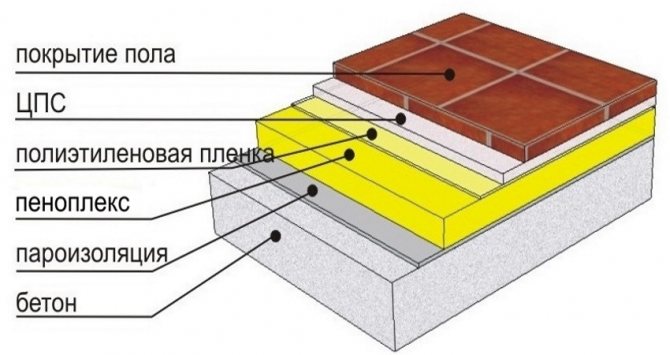

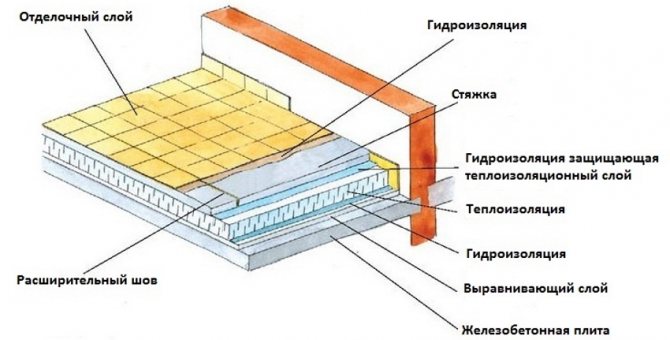

Floor insulation scheme in the basement on the ground

If there is no lag system on the floor, then it can be done on your own using a bar. It is also recommended to pre-waterproof them with a solution that will prevent the appearance of mold and mildew. The timber should be placed at a distance of 50 centimeters from each other, connecting them with planks. On top of the first layer of waterproofing, you can put insulation, if necessary. After carrying out such work, the main floor is mounted and finished.

KERAMZIT

Expanded clay remains the most environmentally friendly insulation today. These are clay balls filled with air. Depending on the size of the fraction, expanded clay is used both for use in cement mortars for their insulation, and for well laying of buildings. They fall asleep both between the logs and in the attic. In this material, mice definitely do not live and cannot even spoil it. They just ignore him. The disadvantages of expanded clay are as follows: to ensure reliable protection of the floor from the cold, a sufficiently thick layer of material is required; when wet, it loses its heat-shielding properties.

Why do you need to insulate the basement?

The constant presence of the foundation under the influence of moisture can lead to the following problems:

- Concrete will quickly collapse, as moisture will penetrate into its pores, and then expand under the influence of low temperatures. This can lead to cracks and other defects in the base.

- A low temperature will be constantly present in the basement, which will make it unsuitable for use as a usable area.

- Moisture can lead to mold or mildew on the walls.

- Since the air in the basement will be constantly humid, this can also be reflected in the increased humidity of the rooms located above it. Mold can also appear there.

Important! Due to such problems, the owner of the house will not be able to fully use the basement and make living quarters there. Dampness will deteriorate furniture and food. It will also be bad for a person, since constant dampness can negatively affect his health.

WOODEN FLOOR INSULATION

Sometimes builders use a combined method of insulating wooden floors, pursuing 2 goals at once - to keep it warm and so that there are no mice. This is achieved in the following way. Roofing material is first laid on the shields installed between the logs, followed by a layer of expanded clay, leaving a few centimeters for laying polystyrene foam. This material blocks the access of cold air from the ground and protects the room from the penetration of mice from below. Even if the rodents make a hole in the shields and roofing material, then they will definitely not be able to advance further than expanded clay.

From above, having leveled and tamped a layer of expanded clay, lay expanded polystyrene. Again, it is believed that it is better to leave a ventilation gap of a few millimeters between the insulation and the floorboards.

This insulation also does not allow cold air to pass through. The gaps between the lags must be filled with polyurethane foam, which, after drying, must be cut off with a knife. To prevent the expanded polystyrene from moving during foaming, it is better to press it down with some kind of load, for example, bricks. The foam will dry and fix it firmly.

Next, the floorboards are installed directly, then any floor covering. This "cake" keeps the room warm and prevents the outside air from cooling the floors.

Thermal insulation of a wooden floor in this way includes: a board from 2 cm below, then a layer of roofing material, then expanded clay, followed by expanded polystyrene from 3 cm, at the end a floorboard from 4 cm.You will also need a lot of used engine oil or an antiseptic and several cans of polyurethane foam. The thickness of these materials is sufficient to maintain a comfortable temperature in the room. The main thing is not to leave gaps when installing an insulating layer, which must either be foamed or clogged (caulked) with tow.

VIDEO

VIDEO

What to insulate in the basement?

Partial waterproofing of the basement walls and floor will not completely solve the problem. The floor and ceiling should also be protected from moisture. At the same time, experts note that ceiling insulation can be done only if necessary. In this way, you can achieve better heat retention in the basement.

In the basement, first of all, the walls and the floor are insulated. Ceiling - in some cases.

Few people know that basement insulation should be carried out not only from the outside, but also from the inside. This article will tell you how to insulate the basement from the outside. This method of insulation will help create a barrier not only from moisture, but also from cold. If you only insulate the cellar from the inside, then this will not guarantee that moisture and cold will not penetrate inside. Also, in this case, mold and mildew may appear on the walls between the insulator and the concrete.

Inside, you will need to insulate the cellar if absolutely necessary. If you correctly insulate the walls of the basement from the outside, then the internal work can be omitted.

Is it possible to insulate the floor using penofol as the only insulation?

Due to the high quality of heat insulation, this material is well compatible with any type of screed. If you do not have the opportunity to use other types of materials for floor insulation, you can use penofol without the risk of getting low quality thermal insulation.

When creating the same environmental conditions, the heat saving coefficient of penofol grade B, which has a thickness of 4 mm, will be comparable to:

- clay brick masonry 2.5 bricks thick;

- sand-lime brick masonry with a thickness of 3.5 bricks;

- 38.4 centimeters of aerated concrete;

- 49 centimeters of expanded clay concrete;

- 6.7 centimeters of stone wool;

- 4.6 centimeters of styrofoam.