Steam room, washing or dressing room

Steam room insulation

The steam room is the room with the highest temperature. In the Russian bath, 60-90 degrees are optimal, in the Finnish - 70-110. In addition, the baths are often burned down. This means that the materials used in the construction should:

- withstand this temperature (and humidity);

- do not emit toxic substances when heated;

- do not sustain combustion.

The limitations are significant. The types of insulation will be discussed below, but it is already clear that the choice is extremely limited.

If an environmentally friendly insulation strongly gains moisture (while losing its properties), you also have to take care of its high-quality insulation between the layers of the hydro and vapor barrier. And in order to prevent rotting of the tree, which is most often used to finish the steam room, it is necessary to leave ventilation gaps between the vapor barrier and the same clapboard or imitation of a bar.

From what has been said, it is already clear that the steam room is insulated from the inside. The ceiling part requires special attention, because light steam tends upward to the ceiling, where the main heat loss occurs in the absence or improper insulation. The vapor barrier is laid in two layers.

Foil is often used as it in the steam room, because it is capable of reflecting infrared radiation and returning it to the room (like in a thermos). In addition, it is an excellent vapor barrier because it does not allow water to pass through at all.

Another problematic place is the outlet of the stove chimney. It must be properly insulated and the ceiling must be protected from overheating. A high threshold to the steam room and a low, but wide door will help to keep warm.

Insulation of the washing

Insulation of walls in a washing room in a bath. The washing room differs from the steam room in that the temperatures are lower and the humidity is higher. Nevertheless, the problem of saving heat is also relevant for soap. Insulation methods are no different from a steam room, except that there is no need for a double vapor barrier.

But there is a need for good ventilation. The floor in the sink is often made of tiles. If desired, it is insulated with a "warm floor" system. Less steam accumulates under the ceiling than in the steam room, but there is no need to leave space for heat loss here, so the ceiling of the washing room is also carefully insulated.

The dressing room, although it is not directly exposed to steam and water, still refers to rooms with high humidity - the proximity to the steam room and the washing room affects. Therefore, all recommendations regarding the choice of heaters and the need for insulation apply to it.

The dressing room also needs insulation so that it does not become the refrigerator that will take heat from other rooms. The scheme of an ordinary pie may not be needed if you use polyurethane foam as insulation in the dressing room - it does not need to be fixed to the wall and insulated from moisture and steam.

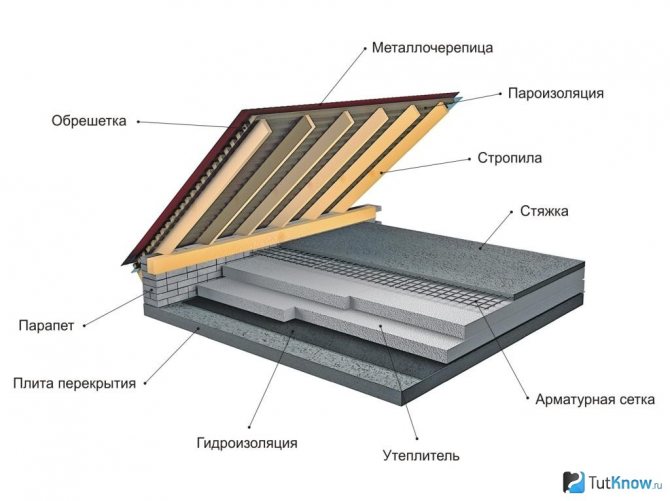

Thermal insulation of the bath roof with foam

You can use foam as insulation over the steam room only in the second layer: if a layer of clay is applied to the ceiling, expanded clay is poured or mineral wool is laid, the foam plastic can become the next layer of the cake. But in this situation, it is necessary to make the ceiling vapor protection very high quality, otherwise the vapor will "get stuck" in the lower layer of thermal insulation. Ventilation in the room should also work at "five" - to remove this very steam. So, if there are other options for insulating the roof of the bath, use them.

In order to clearly demonstrate how effective the foam is in comparison with other materials, we found the following data: foam with a thickness of 6 cm in terms of thermal insulation properties replaces:

- mineral wool 11cm thick;

- tree - 19.5cm;

- dry foam concrete - 50cm;

- brick wall 85cm;

- concrete 213.2cm.

Impressive. It is so? But for thermal insulation of a bath, foam plastic should be used either for external insulation of walls and facades or for insulation of premises without high temperatures.Please note that under the ceiling in the wash compartment, the temperature often reaches + 90 ° C, which is almost critical for foam.

What are the advantages of the frame structure

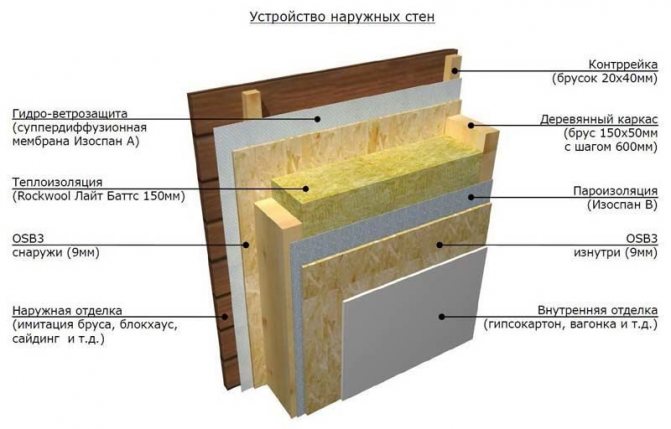

Arrangement of the inner part of the wall of the frame bath.

- The frame structure will turn out to be about two times cheaper than a sauna built from logs. Savings arise not only due to the use of inexpensive materials, but also when choosing a simpler type of foundation. There are significant savings in time and labor. For example, to build a frame bath with your own hands in the warm season, it will take several weeks and one or two assistants to make it more convenient to conduct the work process.

- The construction will not shrink, therefore, the bath is finished immediately after the completion of the construction process, so you will not have to postpone the use of the bath for its intended purpose for a year, or even more.

- Insulation of a frame-type bathhouse allows you to end up with a room that resembles a thermos, which can retain heat for a long time, since there is not a single gap through which the wind would pass.

- The modern materials used to insulate the bath are highly resistant to fire (they will not catch fire), so the likelihood of occurrence is significantly reduced.

- Excellent thermal insulation can significantly reduce the heating time of the bath. It takes only two to three hours for the bath to warm up entirely. This is very little, because it will take at least twice as long to warm up a wooden bath. Hence, we can conclude that there is also savings in firewood for kindling, during the year a large percentage of saved firewood will be obtained.

- The frame structure allows the use of external cladding, which makes it possible to give the bath a unique look, to distinguish it among the buildings, or, conversely, to fit into the style of other adjacent buildings.

Ventilation in a frame bath: rules for creating

Properly organized ventilation will secure good air exchange, which guarantees a comfortable microclimate, reducing the likelihood of mold and putrefactive lesions. In a frame bath, it is advisable to create a supply and exhaust system, which includes:

- supply openings for fresh air - it is better to place them below, closer to the stove;

- exhaust openings - located at the top, opposite the supply openings. Dampers are installed on them to adjust the intensity of the removal of warm air.

What kind of bath, wall insulation from the inside or outside?

A question that torments many bath owners when they think about insulating it. In fact, everything is not as complicated as it seems. If you are already familiar with the concept of "dew point", then for a bath it is not very relevant - this is a room that is used from time to time, and when used, the temperature and humidity jump sharply and high. Because of this, the dew point slides back and forth when you heat the bath, splash water on the stove when it cools down and ventilates.

Therefore, the main task of the owner is to create proper ventilation in the bath and thorough drying of the premises after the bath procedure. And it is also worth putting insulation that does not deteriorate from dampness and dries out easily.

At least first of all, the insulation is installed from the inside, because by insulating from this side, you will not spend energy every time on heating the entire thickness of the walls, which have cooled down to the outside temperature in winter since the last visit.

And when they are insulated from the outside, they end up inside the "pie". And no matter what kind of walls we are talking about - they all cool in the cold. If the internal insulation is not enough, then you can take on the external one, with one condition: you need to leave a gap between the waterproofing and the cladding in order to get a ventilated facade.

IMPORTANT! For external cladding, it is better to use a membrane as waterproofing that will release vapors from the insulation, but will prevent the penetration of street moisture.

In addition, there is a specificity in the material of the walls: block baths, due to the hygroscopicity of the blocks, need external cladding, it is almost always combined with insulation from the outside. But wooden baths are not insulated from the outside, for fear of decay of the walls.

The warmer the bathhouse itself, the less firewood will be consumed to heat it and the longer it will retain heat. In general, bath insulation is a complex process. And the rest room, steam room and dressing room can be insulated in completely different ways: due to their constant microclimate. So how to properly insulate the bath? Let's figure it out.

So, how to insulate a bath from the inside, depending on what material it was built from.

Penoplex

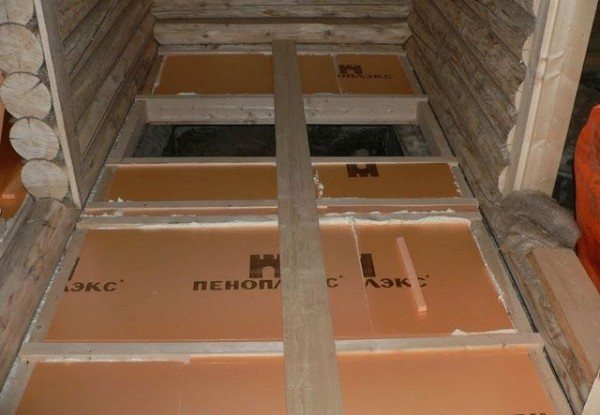

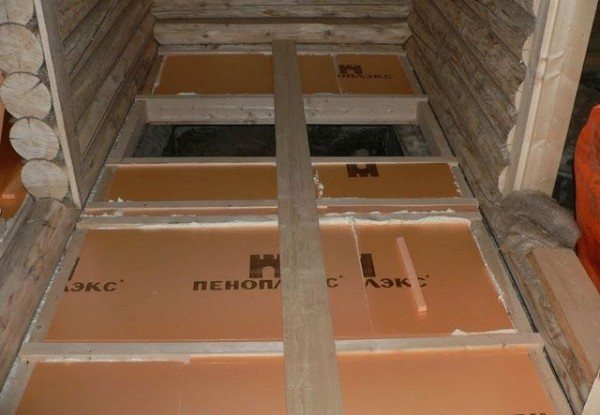

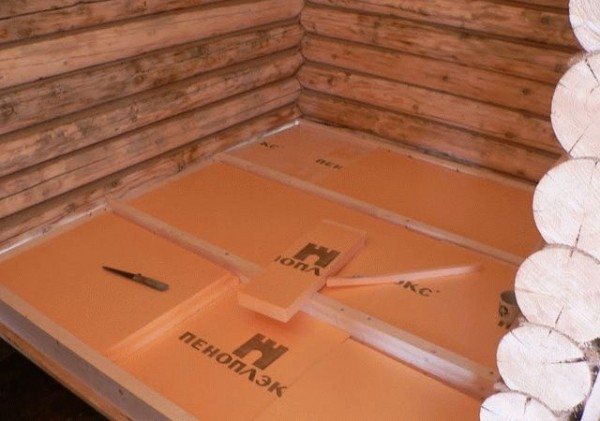

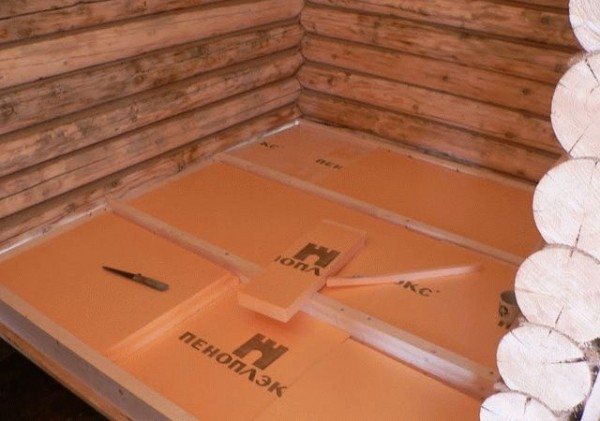

The material is a close relative of polystyrene, but is devoid of its shortcomings. It is more expensive, but it is highly durable, quality and moisture resistance. The thermal insulation performance of these materials is the same.

The choice between them is carried out depending on the installation method and the expected load. When installing heavy furniture and laying insulation under the screed, extruded polystyrene foam is preferred. It will definitely not wash out under load (with the right choice of strength grade).

Thermal insulation of the floor in the bath with penoplex allows you to do without vapor barrier and waterproofing. If possible, they should be used (especially in places with the highest humidity), but this is not a mandatory event.

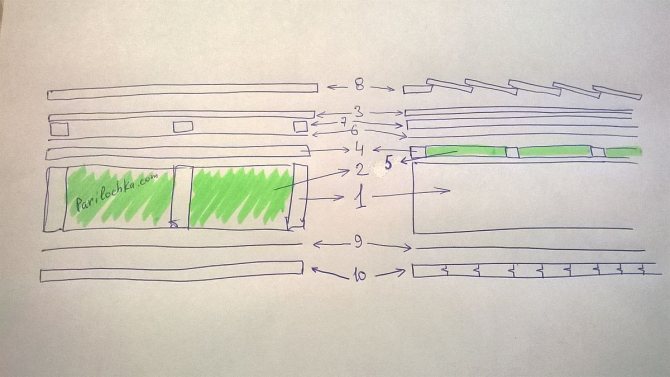

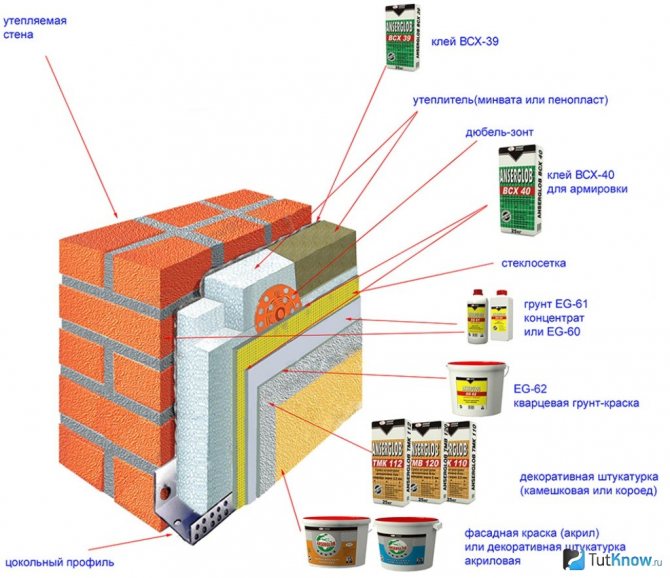

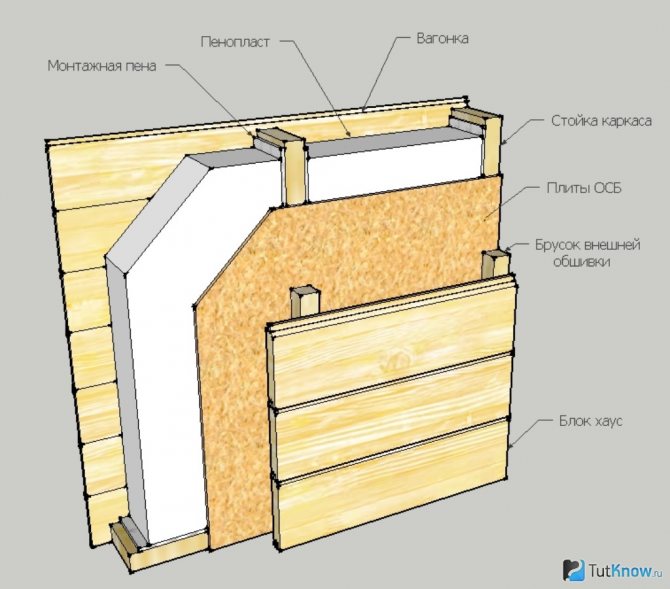

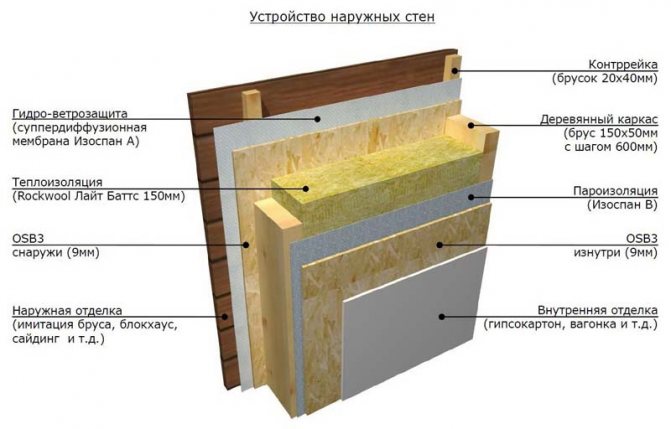

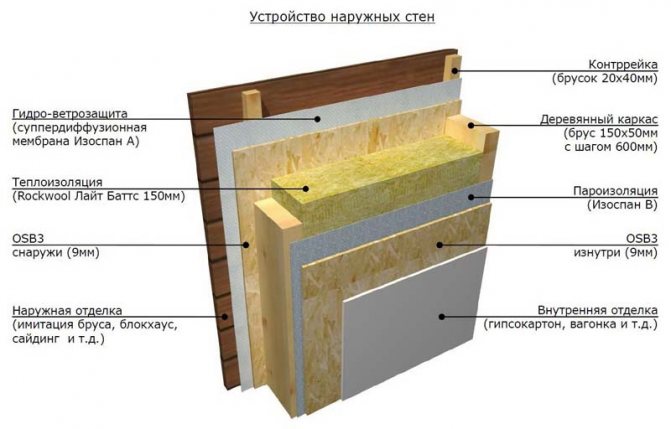

Wall cake of frame bath

Floor covering device.

Very often, when we talk about a wall, a picture of brickwork appears in our head, but nowadays a wall is not just stacked bricks or concrete, but a very complex, multi-layer structure.

The wall can be made in several layers, each of which will consist of a certain building material, combining insulation, bricks and other materials necessary for the work.

An example of a properly made cake would be the following combination of layers:

- A bar with a minimum thickness of 150x50 for the frame.

- Mineral insulation, which will be located between the frame racks (you can use rolls or mats of mineral wool).

- OSB board with a minimum thickness of 15 mm.

- The lathing is horizontal.

- Insulation required for horizontal lathing.

- Vapor barrier (or wind barrier), it is permissible to use a multifunctional membrane.

- The lathing is vertical type.

- External finishing.

- Vapor barrier material.

- Lining (or drywall) for interior decoration.

Stages of warming the bath outside.

The outer covering must be laid on the crate to create a ventilation gap (condensation will evaporate and not accumulate). It is unacceptable to place the external finish directly on the membrane in order to prevent the insulation from sticking to the finish and its subsidence.

After the frame has been erected, it is necessary to carry out interior decoration using boards with a thickness of about 2-3 centimeters. It is best to use wood that will not rot in high humidity, such as linden, aspen, larch. The selected sheets are nailed to the vertical beams. For the decoration of a very part, a wooden lining is used, which also helps to strengthen the entire structure, and not only creates a pleasant appearance.

As a vapor barrier material, it is allowed to use a special film or parchment. The film is placed with foil to the side of the room so that it warms up faster. This material is simply necessary for a frame-type bath in order to avoid the ingress of moisture or condensation on the internal walls.

Insulation is applied to the vapor barrier to ensure the required level of thermal insulation. The waterproofing is attached directly to the beams. Next, the external walls are sheathed using DSP or OSB sheets, attaching them to the beams. The outer walls of the bath are sheathed with lining, siding, block house, boards to give the structure a proper look.

Steam room insulation

The most important room in the entire bath is, perhaps, the steam room. Its main task is to maintain hot steam for a large amount of time. It is this steam that has a beneficial effect on the body of a person who often visits the bathhouse, therefore it is simply unacceptable for the hot air to leave the steam room too quickly, after which it becomes cold in it. To avoid this, it is necessary to pay great attention to the arrangement of thermal insulation. Thermal insulation of the steam room must be carefully thought out and done correctly, only then the room will be able to reliably retain heat.

The step-by-step instructions for insulating the steam room from the inside must be strictly followed. If the thermal insulation of the steam room is not carried out properly, then this can cause a lot of problems in the future. With poor thermal insulation, the oven will slowly and poorly heat up the air, which, moreover, will cool very quickly. At the same time, the concentration of steam in the steam room will be small and clearly insufficient for normal bathing procedures. Another unpleasant moment with poor insulation is the inevitable appearance of mold and the rapid decay of the wooden components of the bath structure.

Advice! Foil insulation on the walls helps to keep warm for longer, since the foil has certain reflective characteristics.

When making the choice of building materials for thermal insulation, it is necessary to take into account their stability and safety when exposed to high temperatures prevailing in the steam room. It is best to choose basalt roll products that are successfully used for insulation, and aluminum foil is used to provide vapor barrier.

Before you start warming the bath, you need to prepare the internal surfaces. For this, an inspection of the ceiling and walls is carried out, all protruding elements, foreign inclusions are leveled, mold and mildew are removed. Then all surfaces must be treated with an antiseptic composition intended for steam rooms.

In order to insulate the steam room, they use not only insulating materials directly, but also many others, designed to correctly perform certain functions. The use of various materials contributes to the creation of a kind of "sandwich", which consists of several layers, including waterproofing, thermal insulation and insulation of the bath from the inside, vapor barrier and inner lining.

The thermal insulation of the steam room begins with the waterproofing layer. It is necessary mainly because the outer walls, upon contact with hot air, become covered with condensation, as a result of the formation of which fungus, mold and rotting appear on the walls. To prevent this from happening, the surfaces must be covered with any material intended for waterproofing, for example, foil or plastic wrap.

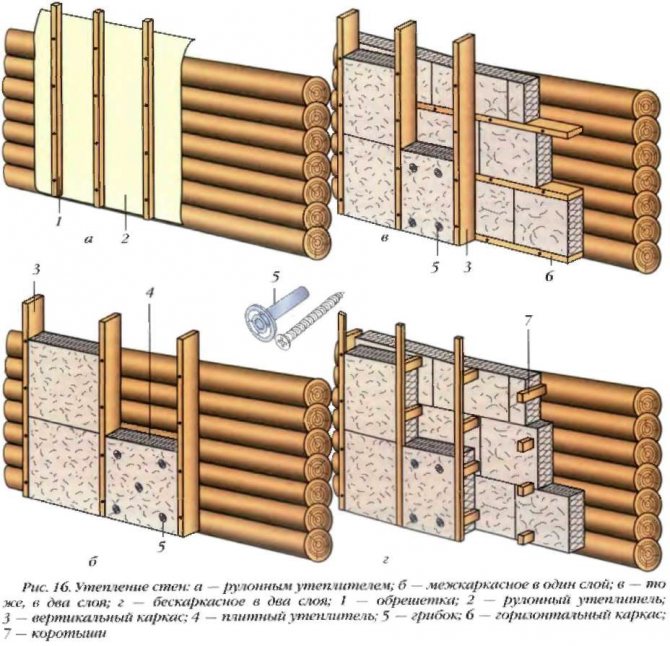

Mezhventsovy insulation for walls made of logs

Next, a layer of thermal insulation is mounted. Its installation begins with the fact that clean, unpainted paper is attached to the surface, with the help of which harmful substances are prevented from escaping into the air. It is necessary to fasten the sheets of paper very carefully, making large overlaps. This will minimize the loss of hot air in the steam room.

How to insulate the ceiling

Do-it-yourself ceiling insulation in a bath is an extremely important stage, since it is through it that a significant part of the heat can go away.Insulation for a bath, at the same time, can be different:

- Expanded clay.

- Penofol.

- Ecowool.

- Mineral wool.

- Sawdust.

- Penoizol.

A step-by-step instruction with a video will tell you how to properly insulate the ceiling in a bath:

Vapor barrier

The importance of vapor barrier is to prevent water vapor from wetting the insulation, which, because of this, loses its thermal insulation properties.

In the case of foil, the task becomes more complicated: it not only does not allow steam to pass through, but also must reflect most of the infrared radiation. More information about foil can be obtained from the link given above, where we considered the thermal insulation of the steam room.

The physical properties of the material used as a vapor barrier should not change with strong heating.

It also includes the requirements for environmental friendliness for insulation.

Bath wall construction with vapor barrier.

Experienced builders advise using a 50 mm thick roll Ursa for wall insulation. It is laid between the uprights, located vertically, with alternately nailing the rails to them. In some places, it is allowed to nail directly to the outer boards, but this can only be done with the help of special nails, which have a rubber washer under the head.

The negative for a frame bath is the formation of moisture in winter, when it is hot in the bath. It is for such moments that a vapor barrier is needed. At the moment, the best option is a plastic wrap, which should be placed under the inner lining.

It is important to note that a high-quality vapor barrier lining is required for the steam room. A good example of this type of vapor barrier is aluminum foil, vapor barrier film, glassine and other materials. For this room, it is undesirable to use roofing material or roofing felt because of the specific smell that will be released when heated.

Thus, a wall cake is obtained, consisting of the following layers:

- outer lining layer;

- glassine layer;

- insulation layer;

- a layer of polyethylene film;

- inner lining layer.

It is very important that a small gap of 5 cm is formed inside the wall.

Features of bath insulation

The service life of the bath or sauna itself with significant heat loss in general decreases... If nothing is done, a high level of humidity will remain in the room at all times. So wooden structures will simply rot. In addition, it adds unpleasant pungent odor, which is also unlikely to be pleasant.

First of all, it is necessary to create thermal insulation for the steam room floor. Soil is being dug in this room.

to a depth of 500 mm from the estimated level of the finished floor. This is done during the construction phase. The bottom of the excavated pit is leveled according to the level. After that, a layer of washed sand up to 50 millimeters thick falls asleep. Then foam mats are laid, the thickness of which can reach 200 millimeters, a layer of cement-sand mortar poured over the foam... Usually, a 1: 1 ratio is used. Foam crumb is used with a thickness of 50 millimeters.

In addition, a layer of cement-sand mortar 1: 1 is poured from above again. But this time - with vermiculite, the thickness of which usually also does not exceed 50 millimeters. Reinforcing mesh with cells of 100 × 100 millimeters fits on top. Finally, it all ends with a layer of concrete, 50 millimeters thick. Iron and level the upper part. Wooden floors with holes or slots for water drainage should only be installed after all the previous steps have been carried out.

Waterproofing is done between a layer of solution with vermiculite and a layer of concrete, if the base of the floor of the washing compartment of the bath is arranged according to the same principle. Be sure to fit two layers of bikrod or roofing material.Special hydrophobic impregnations concrete is waterproofed. Now they can be found in a large assortment in any hardware store.

Electric underfloor heating can be installed in the upper part of the floor to create the most comfortable indoor environment. Autonomous water heating pipes can also be lay in the base of such a structure... There is no need to install a wooden floor if the sauna already has electric underfloor heating. Ceramic tiles are laid on top of the concrete base. Further, there are removable wooden gratings on top of the floor.

Thermal insulation of walls in the bath and their decoration

The "pie" scheme is similar both inside and outside: if a non-sprayed insulation is used, then

- the first layer to the wall is the crate;

- followed by a layer of insulation;

- then a layer of vapor barrier;

- ventilation gap (for example, using lathing);

- external or internal wall decoration

Since we are talking about baths, the majority, of course, prefer wood. If not in the whole bath, then at least in the steam room. This could be:

- lining;

- imitation of a bar;

- block house.

It is optimal to use larch or aspen in a steam room, but it is better to leave conifers for the washing room - in the steam room they can cause a burn, and in the washing resin it will protect the tree from decay if moisture gets too much. However, in washing rooms, tiles are often used for interior decoration - ceramic, made of natural or artificial stone, porcelain stoneware. There is also a cheap option with plastic panels, but I don't want to recommend it - because of the smell.

It does not matter that a frame sauna will be an inexpensive option for a bath, it can be given a very expensive and exclusive appearance, and it is not necessary to do with simple painting of the walls. Thanks to the large number of modern building materials, you can give the walls of the bath a decent appearance. The walls from the outside can be finished with thermal panels, facing bricks, vinyl siding, block houses.

Here, the imagination of the master is important, who can make a beautiful and functional room from the frame version of the bath.

Laying technology

Bars are first attached to the wall. Later it will be necessary to insert a heat insulator into this crate, the thickness of which will be equal to the thickness of the bars. The bars should be as thick as the insulation is expected to be. The vapor barrier is most often aluminum foil. Then the lathing is installed under the "lining".

The "lining" itself is best fixed horizontally, since the condensate formed on the vapor barrier will be able to drain down without obstacles, because the lathing will be attached vertically.

It is important to measure what the actual width of the insulation is. The bars must be filled at a distance of 1 cm less than the width of the insulation. Then the latter will fit snugly, preventing the cold from penetrating.

If the distance is correct, the insulation is held tight. To be sure, you can attach it with stainless screws and washers. The tightness of the heat insulator is extremely important. After all, if moisture forms under it, it can lose its properties. All joints must be glued with aluminum tape.

Foil is rightfully considered the best vapor barrier. Its advantage is that it can retain moisture, as well as reflect heat into the room, which is especially important for a bath. By choosing foil, you can save time to warm up the bath. It will become easier to maintain the temperature. This will reduce the load on the oven.

The vapor barrier strips should overlap by 5 cm, not less. The joints must be glued with foil tape. The vapor barrier is attached to the bars with staples. The joints are also glued with tape so that moisture does not get on the thermal insulation.

When the "pie" is assembled, another crate made of strips is stuffed onto the protruding bars. It is intended for mounting fastening materials. It also serves for the installation of interior decoration of the walls of the bath.

Wall construction rules and procedure

A frame wall in a bathhouse has many advantages. So, for example, these include its lightness, ease of installation and a relatively low price. But a rather serious disadvantage of buildings erected from such walls is the fact that they do not keep heat well. It is possible to correct such a defect by carrying out additional insulation of such walls.

The wall cake in a frame bath consists of vertical racks fastened with various fasteners, as well as various finishing materials and heat insulators. At the same time, the structure diagram of such a wall should, in any case, remain unchanged. So, in particular, a vapor barrier must be installed inside such a wall. Only after its installation is the insulation for the frame bath mounted on the walls, which is closed, in turn, with a finishing material.

The main task of vapor barrier in such a structure is to protect the wooden elements of the building from the effects of excess moisture.

The vapor barrier installed for this purpose allows you to protect the bath from rot and distribute the effect of moisture on it, evenly creating a special microclimate under the insulation.

If you are just building a frame bath, then wall insulation should become one of the most important operations in its construction. The fact is that only a properly assembled "sandwich" will allow the frame wall to reliably protect the premises from wind and heat loss. If you make a mistake in the process of insulating your bath, it will remain cold even if you heat it well.

As for the device of the described wall, the frame bath has a kind of wall cake, which includes:

- inner lining;

- vapor barrier;

- crate;

- insulation;

- specialized membrane layer;

- external cladding.

In this case, the thickness of the walls of the frame bath in this cake is a determining parameter. Due to the fact that recently insulation materials have been created that work much more efficiently, this parameter tends to be reduced, but earlier the builder tried to make such a wall as thick as possible in order for it to better keep heat in the interior of the building.

For a building such as a frame bath, the wall thickness should be at least 18-20 cm.

In this case, the specific value of this parameter may vary depending on the insulation material used in the construction process. At the same time, unlike a brick wall, the frame wall practically does not change its weight when using a thicker insulation, which allows the use of a light strip type of foundation during construction.

When erecting the walls of a frame bath with your own hands, you should seriously think about how exactly you will insulate it. The fact is that each of the layers described above plays its own special role in the process of preserving heat, therefore there are nuances in the installation of each of them, which must be taken into account in the production of finishing and construction work.

So, for example, frame walls, as well as insulation and vapor barrier of a bath can be carried out in two different ways: inside and outside. The best option is a combination of these two methods, since in this case the wall will be protected both from the inside and from the outside. In the same case, when you live in a relatively warm area, it will be more complete to insulate your building from the inside.

From a technical point of view, the installation of insulation does not present any particular difficulties, since almost all types of modern heat insulators are produced ready-made, and you just have to install them in place using the instructions supplied with the insulation kit. If you use old methods of insulation, for example, with the help of shavings or slag, you will separately have to clarify how to insulate the walls in a frame bath with their help.

In addition, it is worth separately learning how to build the floor and walls of a frame bath. The fact is that it is best to insulate the same floor during the construction of the building, and not to open it for additional work on the installation of thermal insulation. Usually, the floor is insulated with the same materials as the entire structure, for example, mineral wool, but expanded clay can also be used for this, pouring it under the floor boards in the space between the logs.

Separately, it is worth mentioning this type of bath insulation, as a warm floor. It is carried out by installing heating elements powered by electricity, or using the energy given off by hot water. In this case, you will have to equip the floor in your bath using a separate technology, but as a result you will be able to regulate the level of heat on your floor, as well as provide the building with additional heating options.

Before installing the insulation in a frame bath, experienced builders recommend carrying out electrical wiring and arrangement of other utilities.

The fact is that it is not recommended to open the frame walls several times, as this negatively affects their durability. It will be optimal when you perform all the necessary operations only once, while hiding all the wires and pipelines in a non-combustible and moisture-proof box.

The effectiveness of the insulation of frame structures directly depends on the choice of the type of insulation material. At the same time, any heat insulator in a bath must be able to withstand high temperatures with a significant level of humidity. It is also imperative to pay attention to the fact that the material used as insulation does not emit toxic substances when heated.

Modern heaters are natural and artificial. Artificial ones are the most common because of their high technical characteristics and low cost. Natural environmentally friendly ones can be used in the process of warming a traditional Russian bath or a Finnish sauna.

As for specific types of insulation, the following are presented on the construction market:

- Mineral wool slabs. They are made from fine fibers formed from melted rocks or from the metallurgical industry. The air voids formed in the process of weaving the fibers during the formation of this material perfectly retain heat, which gives such plates excellent thermal insulation properties. In addition, they do not burn and do not emit toxic substances when heated, and are not afraid of high humidity.

- Reed slabs. This type of insulation is absolutely environmentally friendly and also has excellent thermal insulation qualities. Its thickness is 15 cm, which is just perfect for the construction of frame walls. It is mounted in a manner similar to the installation of mineral wool insulation, so you can use it to insulate your bath yourself. However, this material burns, so it is necessary to pay special attention to its anti-perneal impregnation.

- Gypsum-sawdust mixture. This type of insulation is good because you can very easily make it yourself, for this it is enough to mix 10 parts of well-dried sawdust with 1 part of cement or gypsum. As a result, at the end you will have a good thermal insulation material at a very low price.

- Polymer-based materials. These are polystyrene foam, polyurethane foam and the like. They have the following advantages: low cost, ease of installation and processing, low weight, excellent thermal insulation properties and absolute resistance to moisture. However, they burn well, are afraid of high temperatures, and can give off unpleasant odors when heated. In this regard, it is recommended to use them only in those places where there are no high temperatures, namely in the dressing room, sink, rest room.

The choice of a specific type of insulation material directly depends on several factors, the main of which is the climate in the area where you are going to build a frame bath. In addition, the type of heating you intend to use is also worth considering. So, for example, gas heating allows you to regulate the level of air heating in the bath rather subtly, in this regard, synthetic insulation can be used to insulate most of the rooms in the bath.

In the same case, when you cannot choose a heater for your bath on your own, you should seek advice on this from an experienced specialist. He will help you choose the necessary material, and also tell you some of the intricacies of its installation on a frame wall.

Frame wall cake with additional insulation.

Before starting the construction of a frame bath, you need to make sure that the wood used in the work is completely ready. It must definitely be well dried. The species of wood can be any, in this matter you can rely on your own preferences. The main thing is not to use birch in work, which rots very quickly, and all other types of trees are suitable for work. Most often, the choice falls on linden, larch or aspen, which are distinguished by low thermal conductivity and duration of shape retention.

For external cladding, it is better to use pine or larch, and for internal cladding, all tree species will do, but in most cases, aspen is used.

After all the work is completed, the outer boards must be covered with an antiseptic, and the inner lining, if possible, sanded and then varnished for furniture, preferably in two layers. A special impregnation will also be advisable, which is necessary for all rooms, except for the walls in the sink and the steam room.

The lower harness will be stronger if it is made of a strong beam, a beam with a section of 10x10 cm will do.It will need to be connected in the corners and fastened with nails. The resulting lower strapping must be securely fastened; for this, the corner posts must be installed on steel pins, so they will not move.

Do-it-yourself floor insulation in the bath - which insulation to choose and how to install

For many years, the builders of baths did not pay special attention to floor insulation, because they did not have sufficient knowledge about thermal insulation. The materials used at that time quickly deteriorated, which entailed numerous repairs of the baths - now everything has changed dramatically.

Why is it so important to insulate the floor in the bath

Old bathhouses with leaking floors are still actively used by summer residents and residents of the southern regions. For those who happened to be born in the middle and northern regions, it is better to think about floor insulation. Despite the fact that warm air naturally rises upward, a large part of it is lost when it comes into contact with the cold floor.

A large temperature difference between the upper layers of the steam room and the cold floor in a room intended for taking periodic bath procedures can adversely affect human health. To eliminate heat losses, as well as to speed up the heating of the bath room and create an obstacle to the cold from the outside, it is required to put high-quality insulation for the floor in the bath.

How the floors differ in design

Insulation should be carried out on "dry" floors with a wooden or concrete base, which means that they should not have leaks. Water drainage is carried out by making the floor surface at a slope of 10 ° towards the drain gutter or dirty water drain hole. Thereafter, the wastewater flows into the catchment area, and then into the aeration sites or gutters. If everything is done correctly, then the water will not spoil the insulation in any way, and the thermal insulation will last a very long time.

Materials used for insulation

So, everyone can ask himself the question - "What is the best way to insulate the floor in the bath?". Armed with modern craftsmen and those who want to make the floor insulation in the bath with their own hands, there are both new schemes and new materials. Concrete floor slabs or logs are often used as the basis for the usual buildings of country cottages. In both the first and second cases, the insulation will fit, taking into account the peculiarities of the base. Based on its technical characteristics, the type of insulating material will be selected.

Expanded polystyrene (polystyrene) is a versatile material, so it can be used to insulate wood and concrete foundations. Nevertheless, foam insulation of the floor in the bath is often carried out on a wooden base. This ultra-light material does not absorb moisture accidentally seeping through the wood. As a result, the bases are lightweight, and the material itself is very easy to process, while waste is minimized.

Glass and mineral wool are most often used for thermal insulation of concrete floors. If you apply them to wooden floors, you will need to install an additional layer of waterproofing after the insulation layer. If this is not done, the insulation will begin to accumulate moisture, which will lead to a deterioration in thermal insulation.

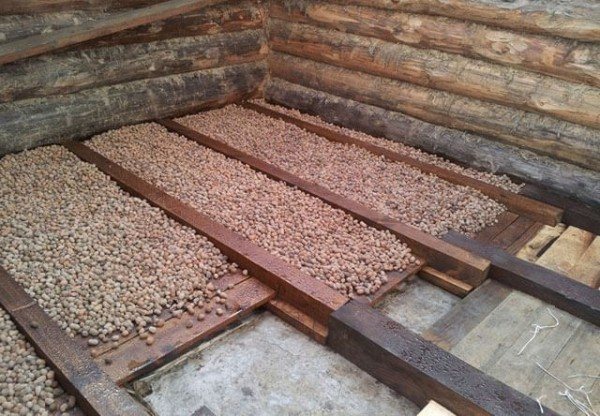

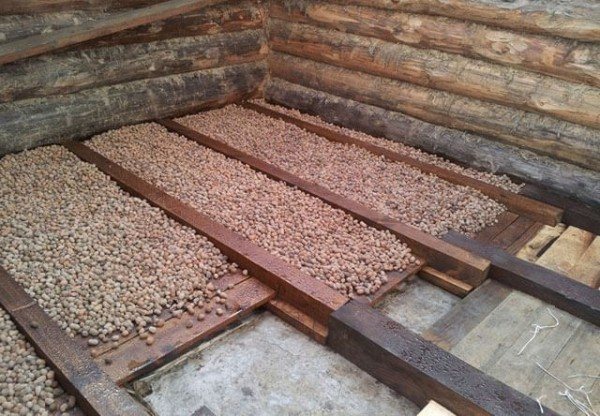

Warming of the floor in the bath with expanded clay is carried out according to the same principle as when using mineral wool. They have similar heat engineering characteristics. If the floor is wooden, then you will need to install an additional moisture-proof layer. Loose material is not easy to use as insulation on sloped surfaces. Therefore, so that expanded clay does not roll down the floor with a slope of 10 o, it is moistened with a liquid cement mortar. Another method: to carry out the pouring of the mixture of expanded clay insulation proposed above, followed by pouring a cement screed.

For warming the floors on the logs, a foamy heat insulator Aisinin is used. Another option is to use boiler slag. It is covered with a 30 cm layer, 25 cm of foam concrete on top, and after -10 cm of half-pan. The height of the thermal insulation layer is determined based on the climatic conditions of the area in which the bath is being built.

Another good insulation is perlite. This dusty sandy insulation is combined with water and cement before use. It acts as a light interlayer between two layers of concrete screed.

Preparation of perlite insulation

To mix dusty sand, you need to choose a room where all doors and windows can be closed at the time of preparation of the solution.

- The material is mixed in a deep container with water in a 2 to 1 ratio until smooth.

- In the resulting solution, you need to slowly pour cement (grade M300 or higher), in a volume that is half the dimensional of all components. An ordinary bucket can act as a measured one.

- After that, you need to pour in an additional half a bucket of water. Each step must be accompanied by sufficient mixing. At the final stage, another half liter of water is added.

- First, you need to remove the finishing layer and fill the cranial bars around the entire perimeter of the room at the bottom of the beams. A rough floor will be attached to them in the future.

- Unedged boards of poor quality are cut into pieces in such a way that when they are laid on the bars, small gaps remain between the board and the beams.

- The fixed boards form a subfloor, on which a waterproofing layer is subsequently laid - when working with wooden floors, this is an indispensable element. The best choice would be a membrane that acts as a vapor barrier. The film is laid in such a way that the entire surface of the subfloor with beams is protected, as well as the walls to a height of 20 cm. The film can be fixed with a construction stapler, and the edges of the insulation sheets must be glued with vapor barrier tape.

- There are two options for further actions - to lay another rough floor layer on the vapor barrier and then insulate, or immediately install the insulation.

- From the decision of how to insulate the floor in the steam room of a wooden bath, it will depend on what kind of vapor barrier to put on top under the final flooring. As an option, roofing material can become an alternative to the membrane, the joints of which are meticulously fastened with mastic based on bitumen.

- To isolate the lumen around the drain pipe from the insulation layer, polyurethane foam is used.

The resulting mortar should be different from conventional plastic mixtures intended for smoothing irregularities and finishing. The output should be a crumbly plastic mixture, which can be covered with a continuous 10 cm layer of the lower layer of the concrete screed. The perlite insulating layer hardens after 5-6 days, after which you can start pouring the upper finishing layer from cement mortar. The waterproofing layer and the reinforcing mesh are placed as desired before the finishing leveling layer, they are not mandatory.

And yet, it is important to choose the most suitable insulation for the floor in the bath - which is better - opinions differ. According to numerous reviews of experts and home craftsmen, expanded polystyrene does its best job. It is easier to handle, easier to stack, inexpensive, and the leftovers can always be used for other purposes.

The technique of laying insulation on the floor

The technology of laying the insulation is similar for all types of baths - it is located in the gap between the solid layers with additional insulation made of a special film. For wooden baths, everything is very simple - the insulation is placed between the wooden layers - rough and final. But if the bath is on piles - how to insulate the floor? We will answer right away - very easy. Insulation is placed on the base layer of the cement screed and the leveling layer is poured.

Method of warming wooden floors of a bath

It is optimal if the floor insulation in the steam room and other premises of the bath is carried out during the period of its construction. But provided that the floors were laid with high quality and do not leak, you can perform thermal insulation after. How to insulate the floors in the steam room of a bath?

The procedure is performed in several stages:

When all the manipulations with the location of the insulation are completed, you can lay the finishing layer of the wooden floor, remove the remaining insulation and close the joints with plinths.

For ventilation of the wooden floor, a small gap should be left under the finishing layer - about 3-4 cm.

How to insulate a concrete floor in a bath

The concrete floor can be poured either directly onto the ground or onto the concrete slabs below the floor. A waterproofing layer is laid on this rough screed. For these purposes, either a roll coating or 3 layers of coating mastic is used. Alternatively, both of these types of insulation can be combined.

Styrofoam, expanded clay, sheets of mineral wool or other heat-insulating materials of the owner's choice are placed on top of the insulation. In this case, it is worth considering the technical characteristics of a particular type of insulation in order to correctly calculate the layer thickness and the required amount of material.

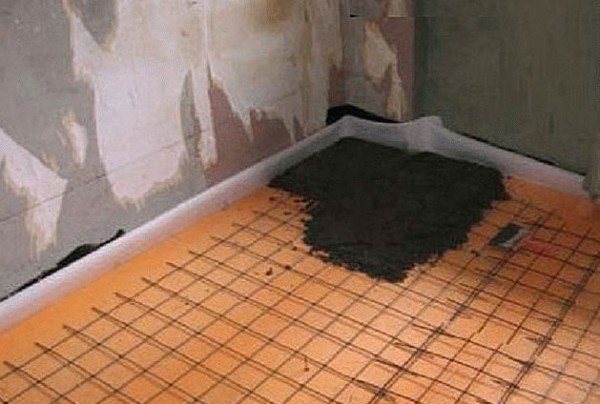

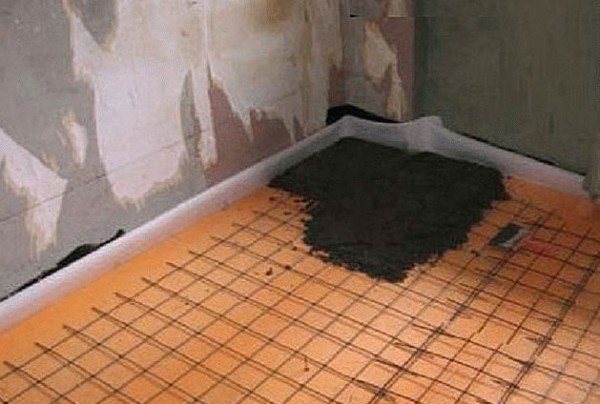

Next, reinforcement is performed - that is, a reinforcing mesh is installed on top of the insulation on alabaster-cement or plastic fasteners, into which a layer of cement screed is poured. Subsequent finishing of the concrete floor is made at the request of the owner.

The subtleties of warming individual rooms of the bath

Since the purpose and intensity of use of the bath premises vary, many are wondering what kind of floor insulation is required in the dressing room. Since this is a rest room, the insulation in it does not need to be supplemented with waterproofing. Basically, water is poured directly onto the floor only in the washing room, where waterproofing is indispensable.

The steam room is used most intensively in the bath, where the preservation of heat is very important. But whether it is necessary to insulate the floor in the steam room additionally - everyone decides for himself.It is recommended to raise the floor in the steam room above the general level by 10-15 cm, which will make it possible to lay another layer of thermal insulation on the finished floor and put an additional floor on the logs. This approach will reduce heat loss and speed up the heating of the steam room.

Thus, the technique of floor insulation in the bath is briefly outlined by us in this material, so that everyone can roughly imagine the estimated volume and complexity of the work. It is worth noting that when calculating the amount of thermal insulation materials, you need to rely on the weather conditions at the location of the bath.

Do-it-yourself floor insulation in the bath: insulation for the floor on piles, which is better, expanded clay, polystyrene, the better to do in the steam room and dressing room, is it necessary to insulate the floor in a wooden bath, photos and videos

How to choose a heater?

| Insulation type | Where to apply | |

| reed slabs | Insulation of the rest room and dressing room. They are completely unsuitable for insulating steam rooms and washing rooms - they are flammable. | |

| peat slabs | ||

| chipboards | ||

| Styrofoam | A good insulation for the ceiling of a bathhouse that has a second floor (everywhere except for the steam room), but inside in hot rooms it is highly discouraged to use it because of phenol emissions. | |

| extruded polystyrene foam | For the floor, usually the second layer after expanded clay, it is suitable for roof insulation. | |

| foam glass | For a bath, an excellent option, because the material took the best from foam and mineral wool. | |

| mineral wool | For internal insulation of walls and ceilings, only basalt wool and stone wool for baths and saunas from Rockwool are suitable - they comply with the standards for the content of phenolic substances, which are usually impregnated with mineral wool. More information in the article about which insulation is better. | |

| glass wool | Worse than mineral wool tolerates high temperatures, it can be insulated with everything except the steam room. | |

| expanded clay | For floors and ceilings, the layer should be more than 20 cm, the fractions should be mixed to fill the voids. | |

| foil and foil insulation | They have two qualities: vapor barrier and IR reflection. They are used most often in a steam room, but can be used wherever there is a need to create a "thermos". | |

| classic mezhventsovy insulation | red moss | Traditional materials for insulation of log cabins and baths from a bar. Rodents and birds take them to their nests. During insulation work, the plant material dries up, which complicates the already long and painstaking work. They need caulking periodically. |

| cuckoo flax | ||

| sphagnum | ||

| wool felt | ||

| hemp hemp | ||

| linseed tow | ||

| jute | ||

| modern mezhventsovy insulation | flax | Modern hybrid materials preferred for caulking wooden baths. They fill the gaps between the crowns well and quickly. It is enough to carry out the work once and the repeated caulking may not be necessary at all. Find out more: We put a log house or timber? Mezhventsovy heater for a bath: which one to choose, which one is better, natural or modern? |

| flax-jute felt | ||

| jute felt | ||

| fluffed spruce or pine wood | ||

As you can see, there are more than one correct options, so you always have a choice. Finally, one piece of advice: when purchasing insulation, carefully consider its technical characteristics and the availability of certificates confirming its safety for humans in high temperature conditions.

How to insulate the floor in the bath with your own hands

Until recently, many did not know how to properly insulate the floor in the bath, so that the heat-insulating material does not rot, bacteria and fungus do not multiply under it. Therefore, they simply left gaps between the boards, where the water flowed down. But the precious warmth was quickly dissipated. Now people have learned how to make the right thermal insulation in high humidity conditions.

Do I have to do this

Bath floors are constantly exposed to unfavorable conditions: high humidity due to water ingress and temperature, especially in the steam room.This negatively affects the strength of the floor material. This environment is ideal for the development of fungus, mold and disease-causing bacteria. All this does not contribute to healing and relaxation, although bath procedures are intended for this. But the selection of the right raw materials and quality installation will help to avoid these troubles.

The combination of a high room temperature and a cold floor can make a person sick. And the heat will disappear much faster. This means that much more fuel will be needed to maintain the desired temperature. And this does not save the budget in any way.

Therefore, the floor covering in the bath must be insulated. And this will have to be done in all rooms: a steam room, a changing room, a rest room, a washing room.

Only "dry" wooden and concrete floors are insulated, that is, the bases of which do not leak. The drains in them merge due to a 10-degree slope to the side where the gutter or special hole is located. There is a drainage tank through which it all flows into the sewer or ditch. If this system is done correctly, the insulation will last a long time.

The choice of heater for the sauna

A log structure is usually located on concrete slabs or logs. In both cases, thermal insulation is done, taking into account the characteristics of the base. These data allow you to choose the right thermal insulation material.

Floor insulation with universal foam polystyrene is allowed for both concrete and wood floors. This material does not absorb water. Its undoubted advantage is its low weight, due to which the total mass of the structure remains practically unchanged. Also polystyrene is easy to use. Styrofoam has similar properties.

The concrete base in the Russian bath is predominantly insulated using mineral wool and glass wool. They do not tolerate moisture well, therefore they lose all their thermal insulation properties when wet. You can also use expanded clay. Its technical characteristics are very similar to those of mineral wool, despite the different appearance. But it's not easy to work with him. It is not easy to fill in a layer of insulation while maintaining the required floor slope of 10 degrees. Therefore, it is mixed with a weak cement solution.

Also, the floors are insulated with boiler slag, foam concrete, polpan, penoplex.

A material such as perlite is also used as thermal insulation. It is mixed with water and cement mortar. When it completely solidifies, it has a porous structure. Perlite is usually located between the top and bottom screeds of the concrete floor.

How to insulate the floor in a Russian bath from the inside with your own hands

The method of insulation depends on the insulation used and the material from which the floor is made in different sections of the sauna.

Use of perlite

Perlite is a silty volcanic sand. With a light breath of wind, it scatters, so you can work with it only in a room without a draft. Close all doors and windows tightly before proceeding. Thermal insulation of the floor in the bath with perlite must be carried out at the construction stage. Otherwise, you will have to dismantle the top screed of the concrete base.

All work on floor insulation in a washroom or steam room using perlite consists of several steps:

- Pour insulation into a deep container. Fill it gently with 2 to 1 water. Wait for the mixture to settle. Then mix well and gently.

- Add here 0.5 parts of cement of a grade not lower than M300. Stir again.

- Add another 0.5 parts of water to the resulting solution. Stir and pour in the same amount of liquid again. Mix everything very well. The resulting solution must be dry and crumbly. It needs to be stirred until it becomes plastic.

- After that, spread it in an even layer over the lower concrete screed in a layer of 100 mm. Then let the coating harden. This will take about 5-6 days.

- Once everything has solidified, install the leveling top concrete screed.

As a unit of measurement, you can use a bucket, the volume of which will be equal to 1 part.

Thermal insulation of a wooden floor in a steam room and a washing room

Naturally, it is best to carry out thermal insulation work even at the construction stage. But, if for some reason this did not happen, then you will have to dismantle the final flooring.

To insulate a wooden floor:

- Nail the skull blocks along the entire length of the lower edges of the beams on both sides.

- Take the planks and cut them slightly smaller than the gaps between adjacent beams. Place them on the cranial bars. In this way, you will form the first layer of the subfloor, on which you need to cover the waterproofing material. This is a prerequisite for a wooden floor. Ideally, use a waterproofing membrane that will also prevent steam from entering. When laying it, cover all joists at the bottom of the floor with an overlap of 200 mm. Fastening is done with a construction stapler, and the joints are sealed with vapor barrier tape.

- Lay insulation on the waterproofing, on which it is recommended to lay another layer of waterproofing material, for example, roofing material. Bituminous mastic is used for gluing it at the seams.

- Fill the space between the drain and the insulation with polyurethane foam.

- At the last stage, cover the finished floor, remove the protruding vapor barrier and nail in the baseboards.

Leave a small gap of 300–400 mm under the finished floor for ventilation. So, the tree will constantly dry out.

Insulation of a concrete floor with tiles

The waterproofing material is laid on the bottom slab of concrete slabs on the sub-floor layer. It is not necessary to use a roll of insulation. You can apply a coating paste in three layers. Both materials can be combined.

For a concrete base, mineral wool, extruded polystyrene foam or expanded clay can be used as insulation.

Special plastic or alabaster-cement supports are placed on the heat-insulating material. A reinforcement network is laid on them. Further, the upper floor screed is poured and finishing work is carried out.

Underfloor heating device

Underfloor heating is one of the most effective insulation methods. This is achieved by using water, infrared or electric heating. Its installation takes place in several stages:

- Cover the layer of thermal insulation with reinforced mesh, on which you put special mats or an electric cable.

- Lay them evenly so that the entire floor area is heated equally.

- The mats are fixed with glue.

- Finish up with ceramic tiles.

The floor is heated with pipes filled with hot water. In this case, only high-quality metal-plastic, polyethylene or copper pipes can be used. Installation of temperature sensors, thermostat and pump is mandatory. This greatly complicates the insulation process. In order for the water in the pipe system to heat up, they must be connected to a water heater, for example, an electric boiler.

When creating a warm floor, you must clearly save the step-by-step instructions:

- Prepare the floor surface for installation work. There should be no chips, protrusions or cracks on it.

- Cover with insulation material.

- Use a special tape to go around the perimeter of the floor. It will not allow the floor to deform under the influence of high temperatures.

- Lay the reinforcement network, and distribute the pipes with the heat transfer fluid along it. There must be a distance of 100 mm between the pipe and the wall. They must lie freely so that high temperatures do not deform them.

- Connect the piping to the heating using inlet and outlet headers. Using the sleeve and the winding, firmly fix the places where the pipes are connected to each other.

- Check how the system works at maximum water supply.Make sure there are no leaks anywhere.

- If everything is in order, then you can lay a rough screed, on which, after hardening, a self-leveling mortar is laid.

- Finally, cover the floor with an absorbent layer and topcoat.

Requirements for the insulation of different sections of the bath

The end result largely depends on compliance with the requirements for flooring in different parts of the bath:

- The sink floor is exposed to copious amounts of water. Therefore, good waterproofing is a guarantee of the quality and durability of thermal insulation.

- The rest room and dressing room can do without waterproofing material.

- It is not necessary to raise the finished floor to insulate the floor in a steam room. You can build another floor on top of the logs, and equip it with good insulation. Thus, two problems will be solved at once. The floor is insulated and rises to the 10-15 cm required according to the rules. Thus, the steam room shrinks and heats up faster. This method of insulation can also be used if the bathhouse was equipped in a trailer or built on screw piles.

Thermal insulation of the bath floor, although a rather time-consuming process, is mandatory. Thanks to this, the time in the sauna will be comfortable, and the heat will be used rationally.

How to insulate a wooden and concrete floor in a bath. What materials to use. Photo and video.