How to properly insulate the walls of a bath

The procedure for warming a wooden frame

It is necessary to take care of the insulation of the walls of a wooden bath at the stage of its construction. For this there is a mezhventsovy heater for the bath. It is laid between the logs of a log house. Such heaters have a natural base of felt, jute, hemp hemp, linen tow. Natural insulation provides natural air exchange in the room.

Jute fiber does not rot and does not absorb moisture. Long-lasting insulation is linen-jute felt, which combines the strength of flax and the water-repellent properties of jute.

- When erecting walls, insulation is laid between the crowns.

- After the complete assembly of the log house, the joints of the logs are sealed, sealing the insulation with a special caulk.

- The sealed joints are covered with a sealant.

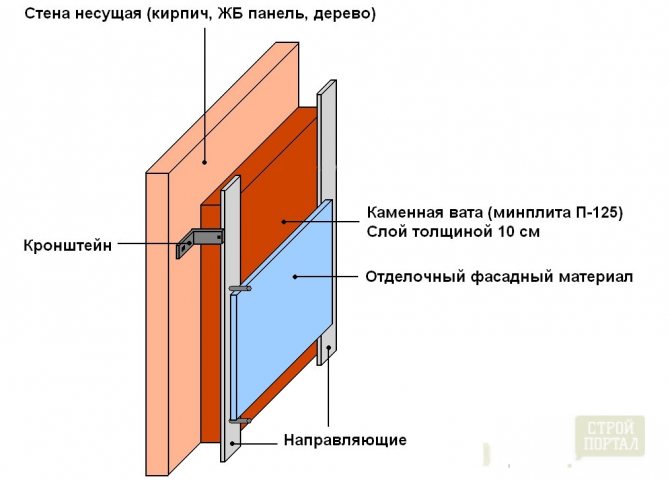

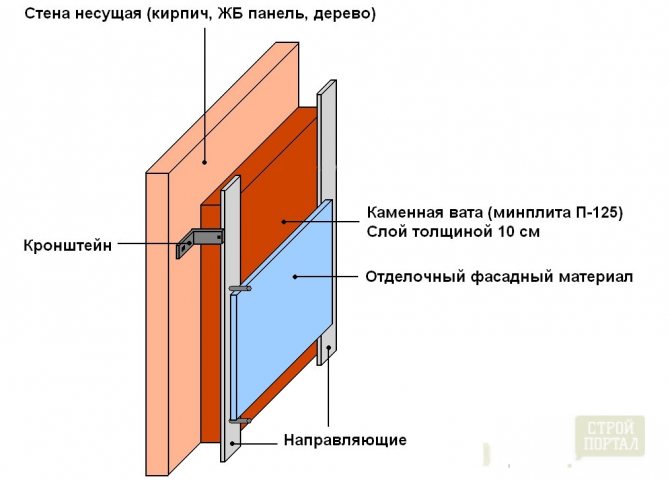

How to insulate the walls of a bathhouse made of bricks or foam blocks from the outside

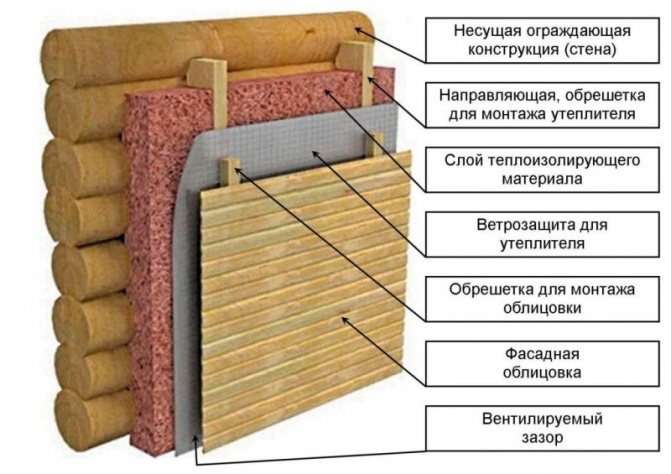

It is possible to insulate the walls of a brick bath from the outside using a ventilated facade device. A frame is mounted on the walls, then a heater and a waterproofer are attached. The work is completed by sheathing the frame with materials for the facades of buildings - siding or plastic clapboard.

The procedure for arranging a ventilated facade is as follows:

- Treat the wall surface with an anti-fungal primer.

- Install the aluminum profile vertically at a distance of 0.8-1 m from each other.

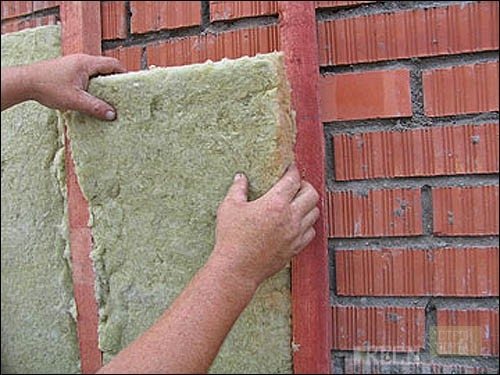

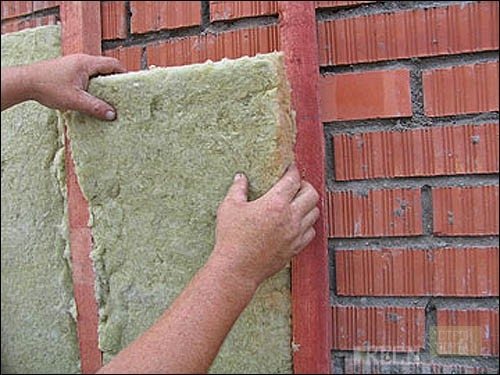

- Fill the space between the profiles with a layer of insulation.

- Close the joints between the plates of thermal insulation material with tape or fill with adhesive.

- Secure the waterproofer with rails.

- Install horizontal guides from the profile for further fastening of the facing material.

- Sheathe the finished frame with finishing material for cladding the facades.

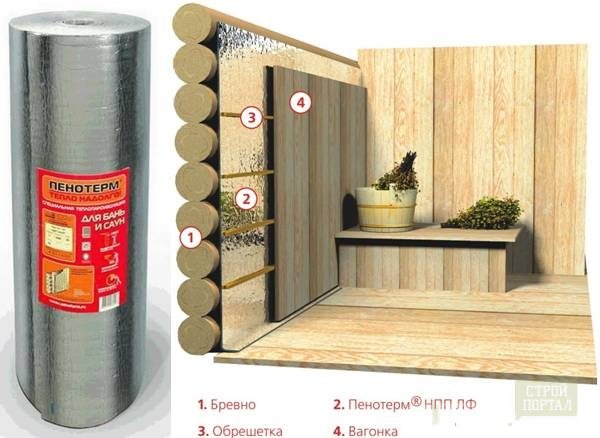

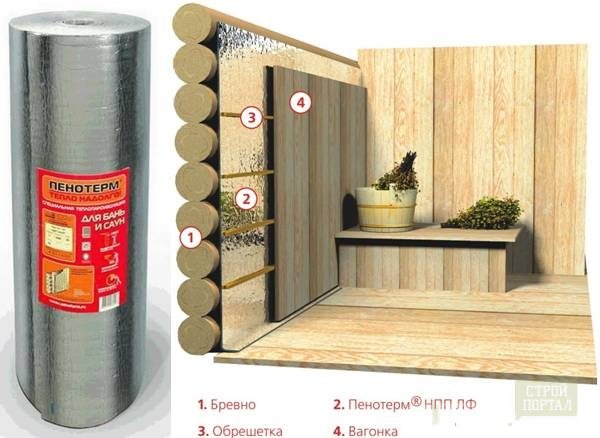

Wall insulation technology inside the bath with Penotherm thermal insulation

- The insulation is attached to the walls of the bath vertically. The wooden surface does not require preparation.

- Unwind the roll and cut the required number of strips with an allowance of 10 cm to the height of the walls.

- Secure the material with a stapler with the foil side inward. The material is overlapped.

- Do not cut off excess material along the length, but wrap it on the floor. This installation method will allow condensate to drain.

- Glue the seams with metallized tape.

- Install a wooden lathing for the subsequent installation of the lining.

- Install wooden lining.

Insulation of the walls of a brick bath from the inside

The principle of installation of internal thermal insulation of the walls of a bath made of bricks or foam blocks is the same as outside.

The difference is that a wooden crate is mounted inside the bath, and not a metal one.

After laying the insulation and waterproofing membrane or film, the crate is sheathed with wooden clapboard.

Do-it-yourself warming of the walls of the bath, done according to all the rules, will help keep the heat in the bath and preserve your health.

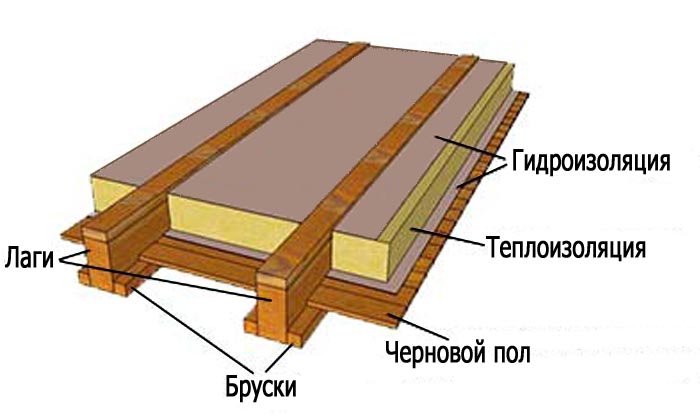

Floor insulation

When you are thinking about high-quality thermal insulation, then you probably have a question about whether it is worth insulating the bath from a bar from the side of the foundation. In fact, it is not just worth it, but it must be done, otherwise the cold will quickly penetrate into the room through its lower part.

With wooden floors, the boards are usually laid in two layers, and the space between them is filled with thermal insulation. The concrete base is more durable, it can be faced with ceramic tiles, and expanded clay or expanded polystyrene sheets for thermal insulation. The "warm floor" technology can also be used, when electromatics are attached.

Thermal protection method

There are two ways to insulate the base - before and after laying.The first method is applied before pouring the cement. Heaters are laid on the outside of the foundation wall above the ground and underground (if there is a tunnel). Insulation of the underground part of the foundation block, in contact with the ground, is additionally covered with a protective layer. If the foundation block is shallow, its base is also subject to thermal insulation.

After casting the cement mortar, in addition to finishing with heat-insulating material inside the room, a blind area is laid - the outer layer that holds the base. Before filling the blind area, a heat-retaining layer is laid under it.

Often builders use formwork instead of an insulating layer. The structure is mounted not from wood, but from expanded polystyrene. Therefore, it does not need to be removed after the concrete has dried. It is a good thermal insulation material, does not deteriorate under the influence of environmental factors. Unfortunately, wooden boards are prone to rotting.

The second method is used after the construction of the building. In fact, it is equivalent to warming the height of the basement. The base, as with internal insulation, is protected by a blind area. This method is simpler, more economical, but less effective, since it is applied only to the front side of the foundation.

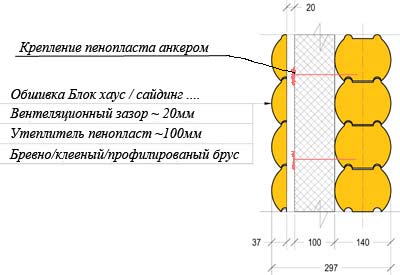

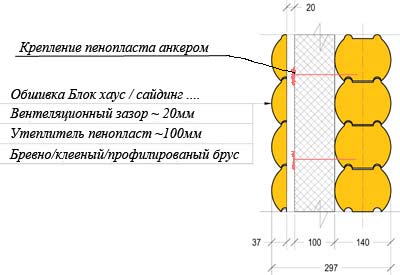

Features of warming a frame bath outside

If you need to insulate the walls of a frame bath, then it is best to use foam for this. In this case, the lightness of this material plays a decisive role. Although there are other advantages, for example, hydro-repellent properties and low thermal conductivity.

It is possible to insulate the frame bath from the outside with the help of foam plates, even without the skills to work with this material. Insulation just needs to be glued to the wall or fixed with self-tapping screws, and plaster or decorative facade cladding should be applied on top. The lack of foam in its fragility, which is why you need to be especially careful when working with this material.

Mezhventsovoe insulation and sealing of cracks

Over time, wooden buildings must shrink, which becomes the reason for the appearance of gaps between the crowns. Those, in turn, open the way for drafts, so the first stage of the struggle is to seal them.

The initial stage of mezhventsov warming takes place during construction. Beams (including profiled ones) and round timber are laid with tow tape or jute. Subsequently, this will be an internal insulation between the wreaths.

In addition to the internal, there is also the external, which has to be updated periodically. The resulting cracks can be filled with tow, jute, natural moss, or you can use modern materials, but only those intended for wood.

IMPORTANT! Plumbing sealants, putty and polyurethane foam are not suitable for sealing cracks in a log or timber bath.

They are inelastic, designed for a constant gap size (and in a tree it changes), they have poor adhesion to wood, insufficient heat resistance, harmful emissions, and other disadvantages. Over time, they crumble out of the cracks.

The cracks on the outside of the timber or log are sealed with wood sealants in such a way that the sealants will dry from 2 to 5 weeks, and the walls must be protected at this time from the sun and rain.

What materials can be used for thermal protection

Previously, builders used sand, expanded clay, and earth to create a heat-shielding shell. They were poured around and between the excavated foundation blocks. Expanded clay and sand have thermal insulation, waterproofing, drainage properties.

These materials reduce the force of soil pressure on the wall, which allows their use on clay soils. Such measures were explained by the lack of an alternative or financial opportunity.In addition, sand, expanded clay layers can be poured on their own without the involvement of a construction team.

Later, in addition to natural thermal barriers, mineral wool was used. This material is heat-resistant, but has several disadvantages:

- need additional moisture-resistant protection, because they are prone to getting wet;

- they are mounted on a frame base, since they do not have the necessary rigidity;

- subject to subsidence, which negates the thermal insulation characteristics.

Due to the problems of mineral wool, a new type of insulation has appeared - bituminous mastic. This mixture is used to cover micro-slots, gaps, cracks in the foundation, protecting it from moisture, partially insulating it.

The next step in the development of building heat insulators was foam plastic. The material is very resistant to temperatures, loads and accidental damage, easy to install. From above, this material must be treated with plaster, because under the influence of direct sunlight, the material turns yellow and loses its quality. In addition, rodents spoil it.

At the top step in the development of heaters is polyurethane foam (or its analogue - expanded polystyrene). It possesses not only heat-insulating, waterproofing qualities, but also noise-insulating ones. This material:

- durable;

- sealed;

- steam and waterproof;

- reliable;

- depending on the form of use, it can be seamless;

- has low thermal conductivity.

The weak side of polyurethane foam is its susceptibility to destruction by exposure to sunlight.

The range of thermal insulation is diverse. The choice depends on the budget allocated for the construction of the bath, the planned operation time of the building, and the time frame.

Insulated foundation

Why carry out a similar procedure

Before dealing with cladding, wall and foundation insulation in the bath, you need to understand why this is needed. Thermal insulation allows:

- Keep the room warm.

- Prevent moisture damage to the base of the building. The liquid, penetrating into the micropores of the foundation under the influence of temperature changes, expands small holes, forming cracks.

- Increase the rigidity of the base.

- Warm up the floors of the building.

- Reduce heating costs.

- Normalize the room temperature.

Insulation is not needed when the bath is being built without a foundation (mobile or lightweight construction).

In addition to its practical use, the basement insulation is necessary to give the building a finished look.

It is important to take care not only of warming the base. The base also needs processing

Choosing a heater

This is the first step on the way to comfort, helping to figure out how to insulate a sauna inside from a bar. The most environmentally friendly can be called: tow, moss, flax fibers, expanded clay. But if you prefer more modern thermal insulation, then attention should be paid to basalt wool, perlite, as well as such popular materials as polyurethane foam or expanded polystyrene.

But it is almost useless to use plaster for wall insulation, and all because of the constantly changing air humidity, leading to deformation and cracking of the plastered layer. Moisture-absorbing materials are also highly undesirable. Therefore, if someone tells you how to insulate a bath from a bar from the inside with cotton wool, felt or tack, then in no case follow such recommendations, you will definitely go wrong. As soon as the insulation picks up moisture, it ceases to retain heat, that is, it becomes completely useless.

What materials are suitable for bath insulation

- To keep warm in a heated bath for a long time, it is necessary to insulate the walls of the bath from both sides. Heaters for internal thermal insulation must be environmentally friendly and meet sanitary standards.

- Mineral wool heaters have a low thermal conductivity.It has high hygroscopicity, therefore it needs reliable waterproofing. For interior decoration, its use is undesirable. Under the influence of high temperatures, mineral wool releases harmful substances. When using mineral wool indoors, waterproofing is necessary not only to protect the material from moisture, but also as a barrier against the ingress of harmful vapors into the room.

- Polystyrene also emits harmful substances when heated. For this reason, it is not used for internal thermal insulation of a bath.

- Finnish sauna heater SPU Sauna-Satu has a high thermal insulation capacity. It is produced in slabs with a size of 600x1200 mm. Thickness 30 mm. The material does not support combustion. Does not absorb moisture. Due to the fact that the material does not emit harmful vapors when heated, the SPU Sauna-Satu insulation is recommended for indoor use. In particular - for finishing the steam room and sauna. Installation is carried out directly on the wall without a lathing device.

- Thermal insulation of the walls of the bathhouse from the outside pursues the goal of protecting the building structure from atmospheric influences - cold air and precipitation. The insulation technique is chosen depending on the building materials from which the bath is built. For outdoor insulation, almost any type of insulation is suitable.

- To insulate the walls of a frame bath, you should choose a material with a low weight, so as not to create unnecessary stress on the walls.

- Foil thermal insulation Penotherm NPP LF is produced especially for finishing the steam room. This insulation is made of foamed NPP polypropylene, laminated with aluminum foil on one side. Combines the qualities of heat and waterproofing. The material is resistant to high temperatures. Has a thickness of 3 to 10 mm.

- For insulation of brick walls, which has a high thermal conductivity, a material with a thickness of 8-100 mm is required. For wooden baths, insulation with a thickness of 3 to 5 mm is suitable.

- For the device of steam and waterproofing, special materials are used. The GEXA company produces Izospan films and membranes. The correct waterproofing device helps to maintain the properties of the insulation and prevents the formation of condensation.

Mineral insulation or cellular insulation?

Layout of mineral wool.

Now let's look at materials that are great for outdoor thermal insulation of baths. These include products created on the basis of 100% natural fibers: wool felt, moss, hemp, linen tow. Such materials for caulking are environmentally friendly, they are easily compacted in the process of work, and provide excellent air exchange.

Quite often, red moss is used for log cabins, which does not rot. As a rule, the length of its fibers is 15-30 cm, which is very convenient. Moss called cuckoo flax and sphagnum are also used. All these materials are available and cheap: a forty-kilogram bag of such building moss will cost only three hundred rubles.

It is popular for warming baths and jute, which is used for warming crowns, for caulking the entire structure. For log cabins, jute felt, felt from a mixture of flax and jute, flax wool are also suitable. These materials are elastic dense strips that are easy to fit and completely cover the seams between the logs.

Their cost is also low: a jute cloth with a length of up to 20 meters costs about 100 rubles, a roll of flax will cost 520-750 rubles.

Important! The process of warming (caulking) is carried out at the stage of assembling a wooden frame, the grooves and gaps are warmed after the completion of construction work on the roof. This process is carried out at least twice, with the second time - a year after the construction of the bath.

Layer diagram for warming a wooden bath.

For external insulation of brick and concrete buildings, mineral insulation is used, which are soft slabs or mineral wool mats.

Such plates have in their structure flexible and thin fibers from mineral melts. All wool is divided into stone and slag, a similar classification depends on the material of manufacture.

The main advantages of mineral insulation are:

- incombustibility;

- environmental friendliness;

- the material does not absorb moisture, does not rot;

- has a low cost (500-1000 rubles per package).

In addition to mineral wool, glass wool is also used, which is distinguished by excellent thermal insulation properties, strength, and elasticity.

Among the products based on plastics that are suitable for external insulation of baths, one can distinguish foamy and cellular (foam), porous, honeycomb (honeycomb). Most often, polystyrene foam is used, which is distinguished by its strength, density, and low thermal conductivity.

Of the modern materials for warming baths, foam glass can also be noted, which, despite the rather high cost (up to ten thousand rubles), is one of the best materials. This insulation absorbs sounds, is easy to process, non-flammable, waterproof, very strong and durable.

Features and technology of warming the basement of the bath

Bath insulation from the inside must be started from the floors. However, before that, it is imperative to carry out the insulation of the foundation. If this is not done, then no matter how insulated and reliable the floors of your bath are, cold air will still penetrate inside.

If we consider the foundation from the point of view of possible heat loss, then it can be divided into 2 zones: the underground part and the basement. Accordingly, the insulation of the basement of the steam room can be done in 2 ways. The underground part is insulated with a layer of expanded clay, the height of which should be approximately 2 times greater than the thickness of the walls. Then the plinth from the outside is sheathed with mineral wool or extruded polystyrene foam.

Technologically, the insulation of the foundation is not particularly difficult. It is acceptable to use 1 of 2 possible options. Warming of the foundation is carried out up to the level of soil freezing. This parameter is determined separately for each region. When installing heat-insulating material to a great depth, the effectiveness of the use of insulation is significantly reduced. In the corner zones, the thermal insulation layer must be increased by 1.4-1.6 times.

If the foundation is insulated with extruded polystyrene foam, there is no need for additional laying of a protective coating for the waterproofing layer, which would protect it from mechanical damage.

In the process of preparing for pouring the foundation, the trench and the formwork for pouring the foundation are made wider than the calculated dimensions by the thickness of the sheet, and even better than 2 sheets of polystyrene insulation. Insulation is attached to the surface of the foundation after removing the formwork. The part of the foundation that rises above the ground can be trimmed with decorative stone or tiles directly over the thermal insulation material. This completes the warming of the basement of the bath.

Internal insulation of a bath from a bar

Foil is used as heat and vapor barrier

Correctly and conscientiously made log house insulation allows you to use the bath without interior decoration. In summer, there will be no problems, but in winter it turns out that the temperature in the steam room drops rapidly, cold air flows from the cracks into the dressing room, and the stove requires a lot of firewood. These problems are removed after interior decoration. You can start internal work after the log house has shrunk, the roof and the rough ceiling have been installed. If you accept the inconvenience, the internal insulation of the bath can be done later, after a few years.

For interior decoration, non-combustible materials are used, wooden structures are treated with antiseptics and fire retardants.The work is carried out in the following sequence:

- Finishing caulking of the walls, caulked seams and cracks are sealed with a sealant, the surface is treated with antiseptics and fire retardants.

- A crate of timber with a section of 50x50 is hung on the walls and the rough ceiling, the bars are placed vertically with a step corresponding to the width of the insulation.

- An inorganic insulation is placed in the formed cells, the upper edge of the bar should protrude 2-3 mm. As a heat insulator, you can use mineral wool, foam glass or penoplex.

- A layer of vapor barrier is laid on the protruding edges of the lathing, the resulting gap provides ventilation of the insulation. The vapor barrier can be paper-based foil or metallized film, the joints are sealed with foil tape. This tape is used to seal the corners, joints of door and window frames.

- The finishing is done with a clapboard, the surface is treated with acrylic or oil impregnation. In the washing section, the walls can be sheathed with plasterboard under the ceramic tiles.