To whom in Russia floors are good

Warm bath floors were invented a long time ago, by the ancient Greeks, and were improved by the ancient Romans. However, retaining the Greek name for this invention - hypocaust.

From the point of view of convection and efficiency of the entire heating system, the hypocaust can be called the optimal design. However, this design also has disadvantages, and significant ones.

Preparatory work

When building a foundation, it is necessary to consider a drainage system. Take out the drain pipe. Install a ladder; this is the node through which all the water in the room will be supplied to the waste water tank.

The ladder is protected with a grill. Building the foundation. Perform preparatory work for the installation of a floor heating system.

- The floor for the bath should be well insulated, therefore, the foundation is filled with expanded clay or crushed stone. The thickness of the backfill is 20 cm. All materials are well compacted.

- A waterproofing membrane is laid on the surface. The sheets are overlapped by 15 cm. The membrane is placed on the walls.

- A coating of insulation is formed on the waterproofing; mineral wool, basalt or polystyrene plates. The insulation is covered with waterproofing.

- Reinforced mesh is laid.

- Form a frame for the floor slope. Manufacturers offer structures made of metal rails. They are attached to a circle. Its diameter must match the size of the drain hole. The circle is placed on the drain hole. The slats are lifted and reinforced on the lower surface of the wall.

- A concrete solution will be poured over the created frame.

- Form a rough screed. Its thickness is 10 cm. After drying, the coating is treated with mastic with an antiseptic. Protect the floor from moisture and mold.

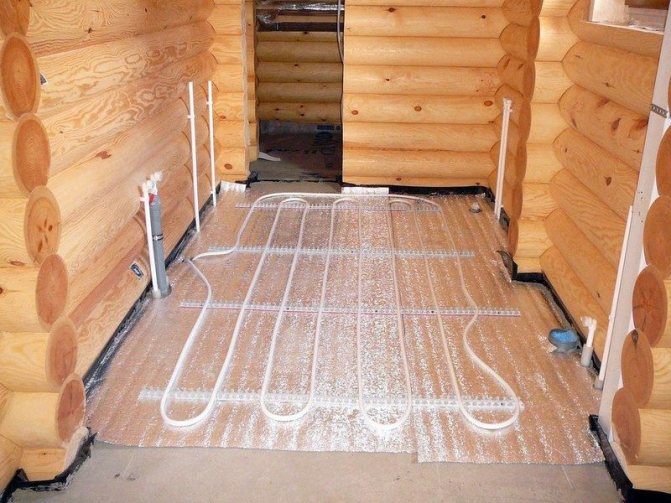

Basalt slabs are laid on the rough screed. They are protected from condensation with plastic wrap. A damper tape is reinforced along the lower perimeter of the wall. A reflective foil screen is placed on the floor.

For the water "underfloor heating" and for cable sections, you will need fasteners. It is recommended to install a MAK mesh, mounting tape, tires with a locking device.

We recommend: How to connect a warm floor from the stove?

disadvantages

- First of all, the high cost and low maintainability. And the initial installation is a very troublesome process.

- The second drawback is the excessive tendency to dry out the air. In the bathhouse, with its high humidity, one could not be afraid of such a phenomenon. But if we are talking about a rest room and a dressing room, then ensuring optimal air humidity for a person becomes a real problem.

- The third drawback is the impossibility of vertical temperature zoning. If in an ordinary bath, if necessary, to cool down, it is enough to move lower (this rule is true, not only for a steam room), then in a room with a hypocaust you cannot count on this - the floor is hotter than at medium heights.

- Well, and the fourth serious minus is the wood's dislike for running out in humidity and heat. It seems to be warming up and drying, but in fact it turns out that the wood, baked on one side and moistened on the other, rots less, but dries up and warps.

From all that has been said, we conclude: warm floors in a bath are good not with wood, but in combination with other, less classic flooring materials, for example, tiles.

On the other hand, it is very tempting to feel a warm floor under your feet. But is there any point in all this trouble? Indeed, in a small bath, it is enough to splash on a wooden crate covering a concrete floor or tiles - comfort, and quite decent, is provided.

General information about the system

The water in the pipes of the water circuit will be heated from the stove

For underfloor heating in the bathhouse, the installation of a boiler is not required, since the heating will come from the stove. To do this, a heat exchanger should be made from a metal tank above the firebox.

From it it will be possible to lay water heating on the floor in those rooms where it is needed. Additionally, you will need to install a pump to circulate water in the pipes.

Since it will not be possible to install a volumetric heat exchanger in the furnace, an additional storage tank should be placed near it and connected with steel pipes to the heat exchanger. To reduce heat loss, insulation is laid on the floor, which can properly reflect it and the rooms will have the required temperature.

The main problem with a water heated floor from a stove is the impossibility of adjusting the temperature. For heating, it is recommended to heat the floor up to 40 degrees, but in the bath the water heats up more and it will be necessary to additionally install a mixing unit.

To protect the floor itself from moisture, a standard cement-sand screed is used, and tiles are used as the floor covering.

Before installing the system, you need to familiarize yourself with the pros and cons, which are shown in the table:

| № | Dignity | disadvantages |

| 1 | There is no electromagnetic radiation unlike the electrical system. | In winter, it is necessary to drain the water so that the pipes do not break from frozen water or the stove must be constantly heated. The best option is to change the water to antifreeze. |

| 2 | Ecological cleanliness and harmlessness to health. | To heat the storage tank, a lot of heat is required, due to which the stove will be less efficient in its main purpose. |

| 3 | Comfortable conditions are maintained in the bath, the floor remains warm. | For floor heating in several rooms, a large heating medium should be installed, due to which the warm-up time will be increased. |

| 4 | Profitability. |

Underfloor heating can be made using several types of materials and devices, which are presented in the table:

| Name | Dignity | disadvantages |

| Concrete screed - ideal for a bath. The filling is simple and does not require any special skills. | Saves money on building materials, and due to cement, the floor will be resistant to moisture. | It will be possible to use the floor a month after pouring, and if the pipe is damaged, you will have to remove the entire screed to be able to determine the place of the leak. |

| Polystyrene boards are easy to use. | Each board already has a foil layer to reflect heat, and they are also equipped with places for fixing pipes. | It is necessary to additionally fill the screed. |

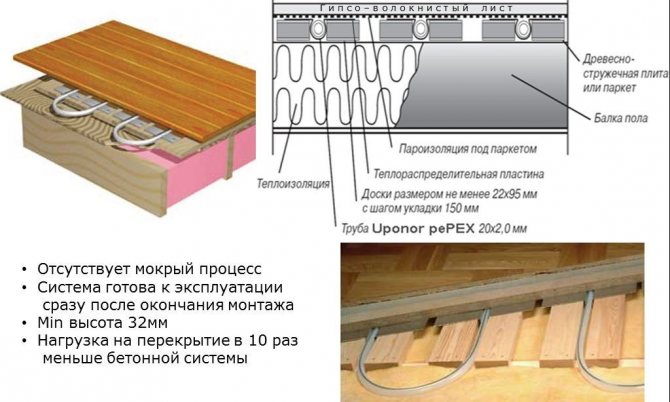

| Heating pipes in a wooden floor. | High maintainability. | Accurate calculations are needed to determine the laying of the pipeline. |

Any thermal material can be used for thermal insulation of the system: mineral wool, expanded clay, polystyrene and other types.

Advantages of underfloor heating in a bath

Has a heated floor in the bath and advantages, in addition to those mentioned. They manifest themselves only when it comes to large areas and when heating is installed in the bath, which allows it not to freeze out in winter during long interruptions in operation.

It is easier to say this: for bath complexes or large premises, you can think about how to make a warm floor in a bath. For small banks, this is simply an unnecessary waste of money and effort. Although the final decision is, of course, up to the developer.

Electric floor device made of infrared mats

The most optimal solution for the independent installation of a floor heating system in the washing room of a Russian bath is the installation of infrared mats.Such a floor heating scheme allows to achieve a high tightness of the structure and is distinguished by electrical safety. In addition, the gentle operating mode allows the use of such floors in structures with wooden elements. The height of the entire floor heating structure will be only a couple of centimeters. It usually takes only 5 days to install the system and install the flooring.

How to fill the floor in a concrete bath with your own hands

After the standard preparation of the base, a roll of thermal film is rolled out on the floor.

The infrared electric floor heating system in the bath is laid in the following sequence:

- After the standard preparation of the base, a roll of thermal film is rolled out on the floor. For reliability, it is fixed to the base with adhesive tape.

- Next, an adhesive solution is applied over the infrared heating mats for laying the floor covering. In this case, you need to try to ensure that the heating film is completely covered with a layer of solution.

- Then the floor covering is laid on the mortar - ceramic tiles, porcelain stoneware, clinker tiles.

- The underfloor heating system can be used immediately after the adhesive mortar has completely hardened for laying the floor tiles. Usually the glue curing time is indicated on the packaging.

Varieties and features

Discarding the classic scheme of a hypocaust with a stove in the basement, we can say that there are two main types of underfloor heating - water and electric.

Water floors

I would like to feel the warmth under my feet in the bath everywhere, including in the washing room and in the steam room - the solution would be a heated water floor in the bath. It is quite costly during installation and is practically not repaired - any repair, in fact, comes down to replacing the entire structure. But it has the lowest operating costs. And he is also not afraid of moisture, so he is good in a washing and steam room. So this is the most versatile option.

The heat carrier of a water-heated floor is most often water. Antifreeze or ethylene glycol is sometimes used. In any case, such a floor requires an autonomous heating boiler.

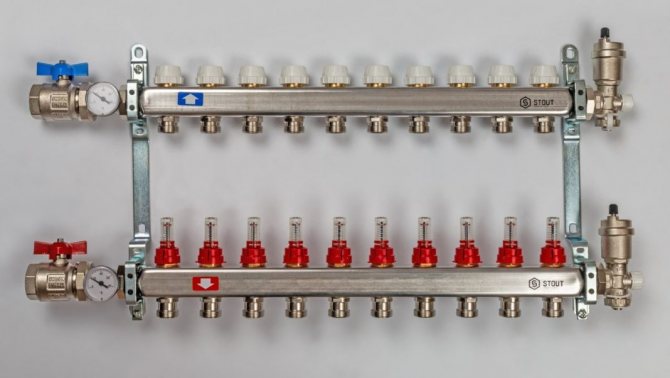

In this case, the boiler is needed directly in the bath. The idea of diverting the mains from the main cottage heater is usually bad and unprofitable. The system must not be allowed to freeze in winter. To adjust the entire underfloor heating system, you have to install a collector box - so the system turns out to be very cumbersome.

Some craftsmen recommend feeding the water floor system from the sauna stove. This cannot be done. Let me explain why.

- Firstly, you should not take away the heat needed to heat the stove.

- Secondly, the stoves are heated irregularly, and the water circuit just needs a clear periodicity - freezing is destructive for it. So there must be a separate boiler for the water floor.

Electric floor

Lighter in weight and easier to install, it is worth recognizing the electric floor heating system. A warm floor in a bath with your own hands is the easiest way to do just this. Electric floors are of two main types. First, in the form of mats. The second, in the form of a heating wire, is laid, like water pipes, in zigzags.

Electric underfloor heating systems are simple. Roll mats are easy to repair and easy to install. However, they are completely unsuitable for washers and steam rooms. Even with all the precautions.

More precisely, at the time of using the steam room, these systems must be de-energized for safety reasons. And, taking into account the human factor, it is easier not to put them in humid rooms at all.

A significant disadvantage of electric floors is the high cost of operating costs and the need for increased electrical power. But they are very light and are not afraid of frost. It is worth mentioning the ease of adjustment and changing the heating mode.

Varieties of heated floors

The installation of a water floor will cost more due to the purchase of a boiler, pump, fittings, copper or plastic pipes

Bath floor heating systems are divided into the following types:

- Water heating system for floors. The design consists of a closed circuit in which the coolant circulates through the pipes. A pump is used to transport it. The coolant can be water, ethylene glycol, an aqueous solution of antifreeze and the antifreeze itself.

- The second underfloor heating system is powered by electricity. Usually, factory electric floors or infrared mats are used for these purposes.

Each floor heating scheme has its own advantages and disadvantages. For example, installing a water floor will cost more by purchasing a boiler, pump, fittings, copper or plastic pipes. However, operating costs will make it possible to compensate for the costs in 6 years. The construction of electric underfloor heating will cost a little less, but high electricity tariffs will not allow you to save money during operation.

In addition, it is quite difficult to make water heating with your own hands. We need preliminary calculations and competent design. In addition, water heating is usually laid in a concrete screed, so it is very difficult to find a leak in case of damage. Repair work in this case will be very time consuming and expensive, because you will have to dismantle the entire screed, especially if the structure is large, for example, 6x5 m.

It is much easier to make a cable electric floor with your own hands, but in terms of maintainability it is no better than a water one. It is much more profitable to make an electric floor heating system in the wash compartment using infrared mats. Even if one of the constituent elements fails, the entire system will continue to work. This floor heating scheme has earned numerous positive reviews and for the fact that the height of the screed in this case will be minimal.

Underfloor heating base

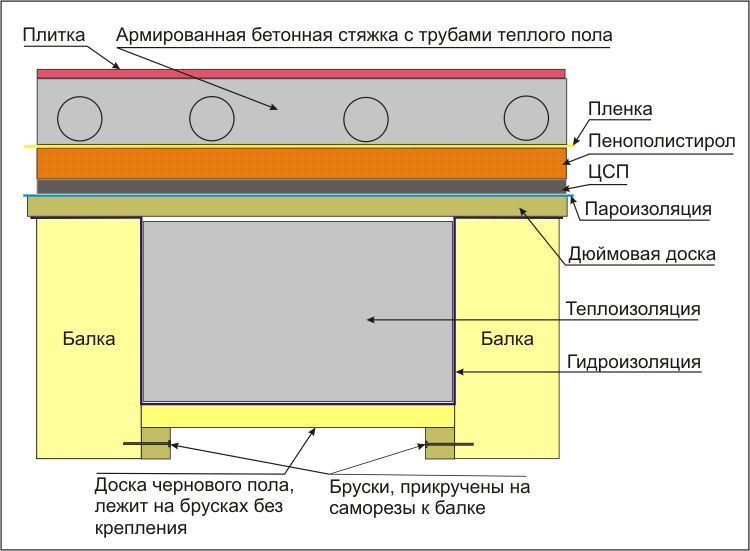

The best option for underfloor heating in a bath is a concrete floor. Wooden floors will also work. The main thing is not to forget to insulate it - there is no point in heating the subfloor.

It will not be possible to combine a warm floor and crevice water removal. Underfloor heating can be done only where there is drainage along the slope into the ladder. In the rest room and dressing room, of course, there is no such restriction.

The slope in the bath room is made with a screed. With a screed thickness of more than 3 cm, a reinforcing mesh is used.

If you are going to lay tiles on top of the heaters, then the concrete floor is definitely the best base - if only because of the rigidity of the structure.

When pouring the screed layer in which the heaters are located, a damper tape must be laid along the perimeter of the room - it plays the role of a compensator during linear expansion from temperature changes.

Floor insulation can be very diverse. Cork, expanded clay, foam glass. If you do not want to once again make the floor heavier and fill the heating element with concrete (screed), this is especially important for infrared heating elements, then you should use special foam polystyrene plates - they have channels for fixing elements of the heating system.

The distance between the turns of the floor elements must be maintained according to the manufacturer's recommendation, but not more than 40 cm. A larger distance will give uneven heating.

The location of the furniture in the room should be taken into account. There should be no heating elements under it. This is an unnecessary waste of heat and unnecessary damage to furniture.

It is good to lay something foil under the warm floors. And the dampness from the basement will not go, and as a heat reflector will do.

System types

Before doing heating in a bath from a floor stove, you need to study the types of systems:

- Under the concrete screed. Heating pipes are poured with a layer of concrete, which protects them from any mechanical damage, exposure to moisture. Ceramic tiles are laid on top of the screed, which transfers heat well.

- Under the wood flooring. The tubes are placed on the base and then covered with a protective cover over which a wooden floor is laid.

The second option for laying heating circuits can be divided into three types:

- Rail system. Pipes with circulating water are laid around the rails, which guide, hold them motionless.

- Polystyrene system. Special polystyrene slabs with pipe recesses are laid on the subfloor. The heating circuit is then assembled.

- Modular system. On the rough floor, special mats are laid out, which have fasteners for pipes. A protective layer, wooden flooring is laid on top.

The main drawback of structures is low resistance to prolonged exposure to moisture.

More about water systems

Water systems are laid in a snail or wave. The first method is more difficult, but gives a more uniform heating.

Do not forget that the system of water-heated floors needs a circulation pump - it will not work by gravity. Before filling the system with a solution (covering it with a coating), be sure to pressurize the system (check it under pressure) - then it will be troublesome to open and eliminate the leak. Splices and fittings along the laying route are not allowed, they are only possible in manifold cabinets.

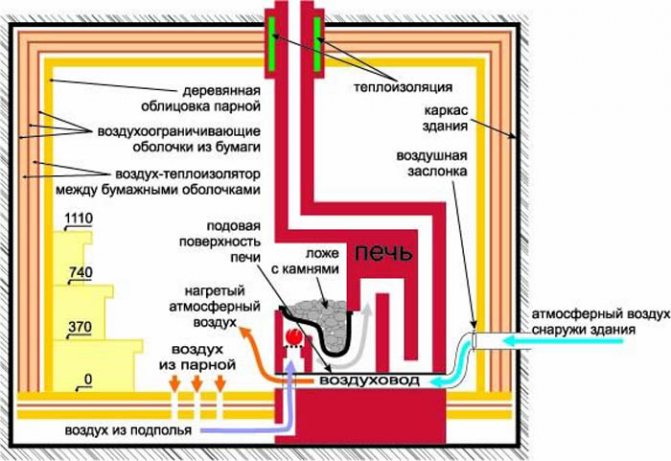

Heating by air from the oven

To ensure floor heating with air from the stove, you will have to install a special stove. In it, the lower part should warm up more. Such ovens are called "double-deck hood". The scheme of its work is as follows.

After laying firewood in the firebox and lighting it up, the heated air begins to rise up and rests against the dome of the bell. After that, it begins to go down and flows through the partition and enters the lower part, where it gives off thermal energy.

Based on the foregoing, a simple conclusion can be drawn that furnace devices of this design are more efficient. They give off heat energy practically to the floor and heat it up. Bringing the temperature level to a comfortable level for people to stay in the steam room.

Despite the external complexity of the work on the construction of a water floor in the bath, it is possible to do it yourself without the involvement of third-party craftsmen. It should also be noted that the heating of a bath using a warm water floor system is significantly lower than that of an electric one. When constructing a warm water floor, you need to be prepared for the fact that an emergency situation, for example, a leakage of the working environment, will require opening the floor and screed to restore working capacity.

Electricity as it is

Electric underfloor heating is of several types. The heater can be in the form of a wire - two-core or single. A two-core is more convenient to install, it does not need to be ringed, it fits in one direction and a plug is simply placed at its end.

The single-core wire is laid with the expectation that both ends must be brought to the controller. Don't forget about the temperature sensor. Its installation is also required and it is made in the floor between the cable turns.

The system with a single-core wire is easy to install, but it has a significant drawback, it gives high electromagnetic radiation. When using a two-core wire, the electromagnetic radiation is much less due to the opposing magnetic fluxes.

For floors made in the form of rolls or mats, the electromagnetic radiation is significantly lower. But there are restrictions on their use.

The power of heat mats ranges from 150 to 450 W per square meter of surface. For bath floors, 250 W per square meter is considered optimal.

Scheme of water floors

There are no special difficulties in the construction of a warm water floor in the bath.

A warm floor for a bath consists of the same units as a warm floor intended for living quarters. That is, it includes:

Heating circuits through which the heated working medium moves.

Mixer (collector), it separates the liquid along the circuits. It also contains water heated from the oven, with a cooler one.The thing is that the stove is not able to heat water up to a certain temperature. Often, the temperature of the working environment does not allow it to be placed in the heating circuit and therefore has to be mixed with cold water.

Heat exchange block. It transfers heat from the stove to the coolant. Module constructions are described below.

For the arrangement of the heating system, plastic or metal pipes are used. Only, in this case, one must remember that when laying them, it is required to use a single piece of pipe. When laying the heating element, it is not permissible to use fittings or other forms of connection. Such joints increase the likelihood of a leak, to eliminate which you will have to open the floor covering and screed. The order of laying the heating system in the bath is practically the same as the sequence of laying the warm floor in the living room. But, some subtleties still exist.

Bath, refers to rooms with high humidity. This means that only materials that resist corrosive processes should be used in the installation of underfloor heating systems. These can be either polymers or corrosion-resistant steels.

A concrete slab should be located at the base of the pipelines through which the coolant is supplied from the sauna stove. To reduce the loss of thermal energy between the pipes and the concrete base, it is required to lay a layer of insulation. For this, it is permissible to use foamed polyethylene with a foil surface. You can use polystyrene, penoizol or mineral wool.