Home / Boiler automation

Back to

Published: 20.06.2019

Reading time: 5 min

0

991

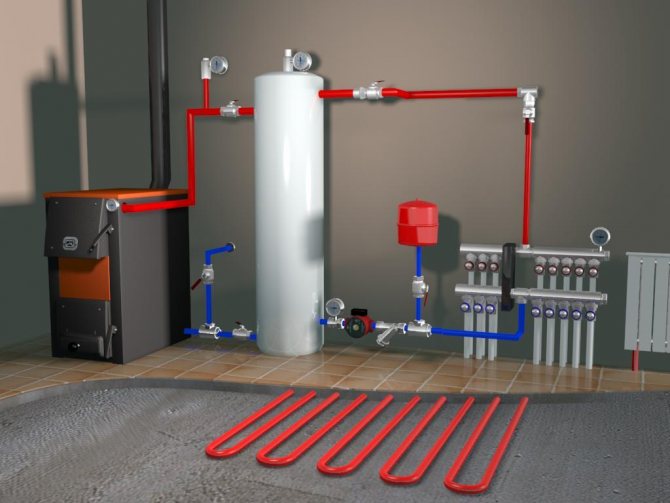

In order for an autonomous heating system to work correctly and economically, it is necessary to install a heat accumulator for boilers. This allows you to significantly reduce costs not only for fuel, but also it becomes more profitable to maintain a house.

Before choosing the necessary heat accumulator for your heating system, you need to study the principle of operation, where it can be installed and which heat accumulator is suitable, because they are of different types.

Photo: stovesonline.co.uk

- 1 What is a heat accumulator

- 2 Principle of operation

- 3 Varieties of accumulating models

- 4 When you need a heat storage

- 5 Where to install in the heating system

- 6 Is it possible to do it yourself

- 7 Top 5 best heat accumulators

- 8 Rules for safe operation

What is a heat accumulator

A heat accumulator is a buffer device that accumulates excess resource, equipped with nozzles for connecting heat generation circuits. What he saved is then used in the heating system during the interval of the planned main fuel loads.

If you have correctly selected and connected the device, then this makes it possible to significantly reduce the cost of purchasing fuel (up to 50 percent), so you can switch instead of 2 downloads per day to 1.

The buffer device, in addition to having the function of accumulating heat, also protects the cast-iron boiler from possible cracks when the temperature drops in the water supply system.

Subtleties of assembling a heat accumulator

To simplify the task of assembling a heat accumulator with your own hands and to reduce the cost of this process, you should use the following recommendations:

- Instead of a factory coil, it is quite possible to use a flexible metal corrugated pipe;

- The metal container, if desired, can be replaced with a refractory plastic one - but to maintain its shape, such a structure will have to be installed in a lattice frame;

- Small-sized heat accumulators fit well into the underfloor heating system;

- If you need to heat a large room, it would be better to use a factory heat accumulator, the parameters of which were calculated and tested by specialists on professional equipment.

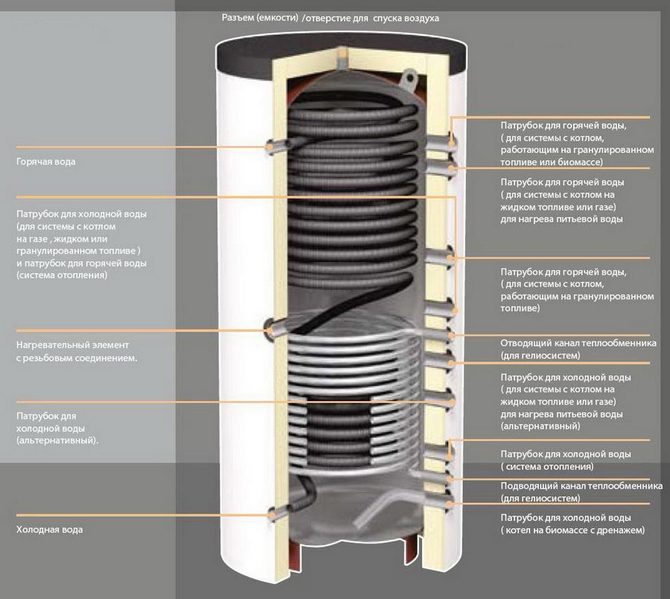

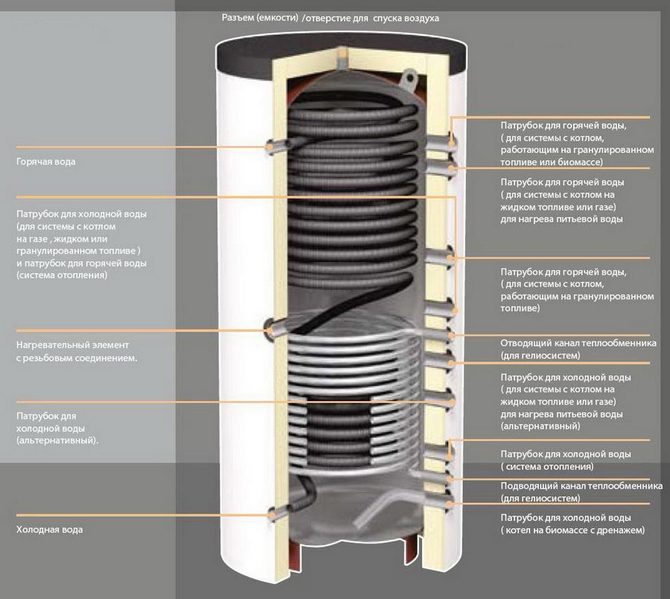

When choosing a heat accumulator for a heating system, it is imperative to check whether it has a sufficient number of nozzles so that it can be connected. This is a very important factor - the lack of outlets will not allow combining the tank with hot water supply or underfloor heating, not to mention alternative heating equipment, such as solar collectors.

Operating principle

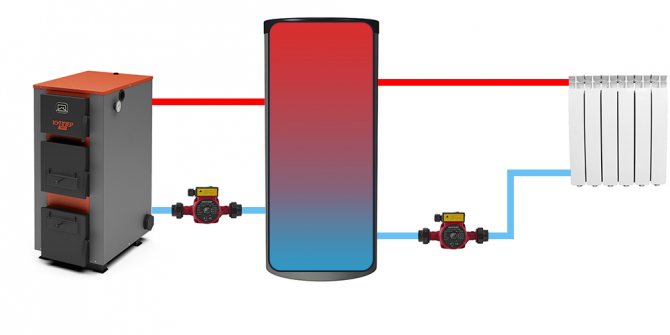

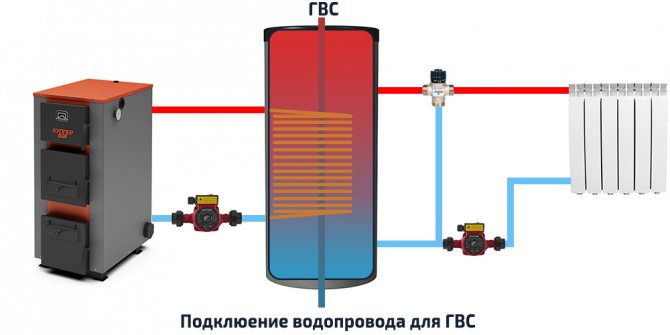

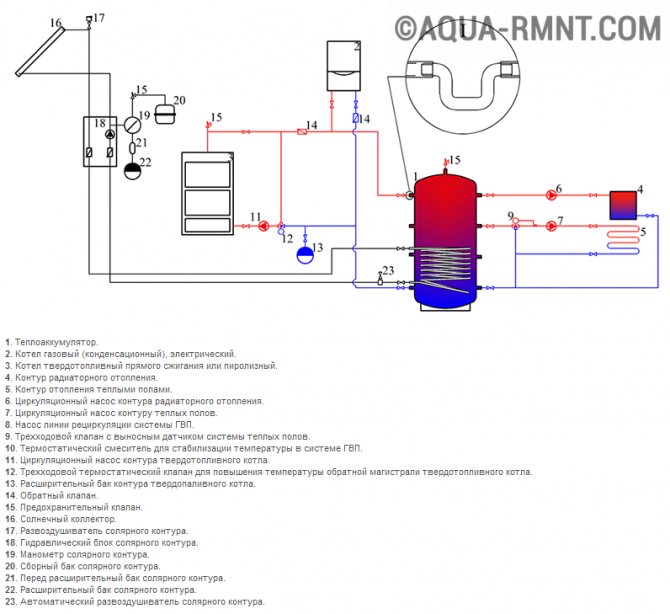

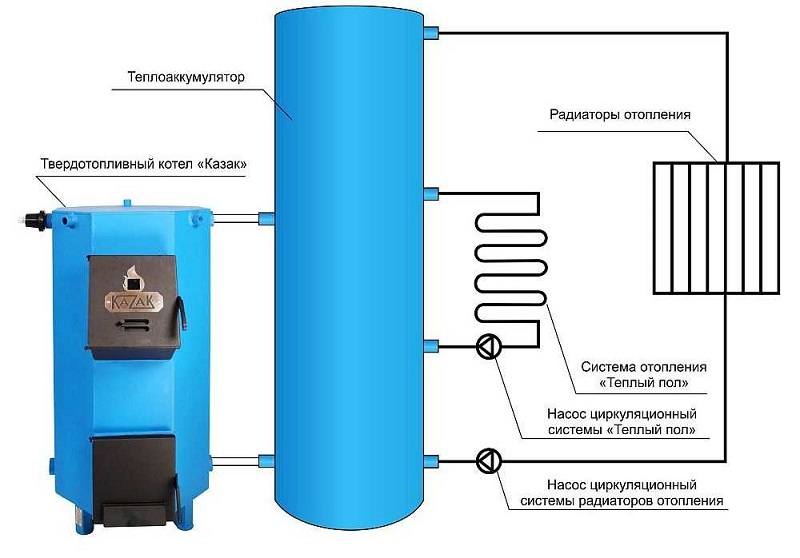

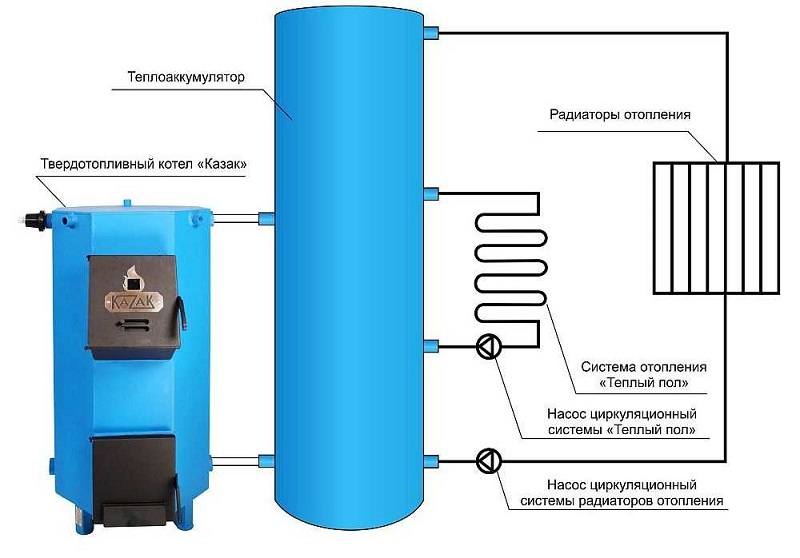

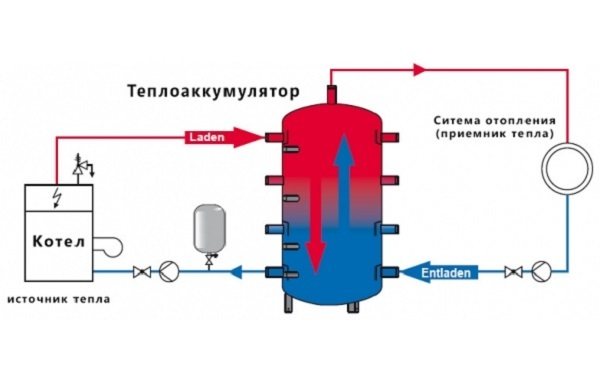

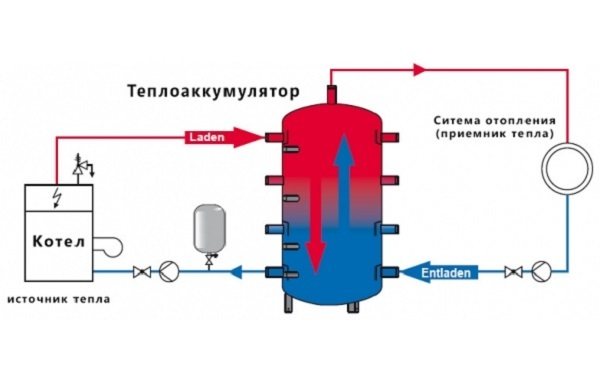

The heat accumulator for boilers has a simple operation scheme. From the unit of any type of fuel, a pipe is brought to the upper part of the device through which hot water enters the storage tank.

When the water cools down, it goes down to the ring pump, which feeds it back into the main pipe, and the water returns to the heating device for the next cycle.

If you install a heat accumulator, this will prevent overheating of the water when the unit is operating at maximum power, will provide heat exchange and economical fuel consumption. Therefore, the load on the heating system decreases, and its service life increases.

The boiler with any type of fuel has a stepwise operation, from time to time it turns on and off, reaching the required temperature. The work stops, the heat carrier being in the tank is replaced by a hot liquid.

It has not cooled down because there is a heat accumulator for the heating boiler. If it happens that the boiler turns off and becomes inactive until the next fuel loading, then the radiators will still be hot for some time, and the water in the tap will also be warm.

Device and principle of operation

The heat accumulator is a buffer tank, which is made in the form of a cylinder made of stainless or black steel.

Heat storage device

As a rule, two cycles are distinguished in the operation of a solid fuel boiler with a heat accumulator:

- In the first cycle, two fuel fillings are made, then, they are burned in the maximum power mode. In this process, all excess heat accumulates in the battery, and does not fly out into the pipe.

- There is no need to heat the boiler, since the optimal temperature regime is maintained due to the transfer of heat from the tank.

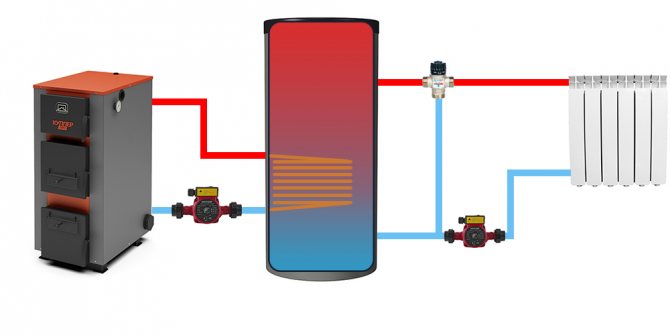

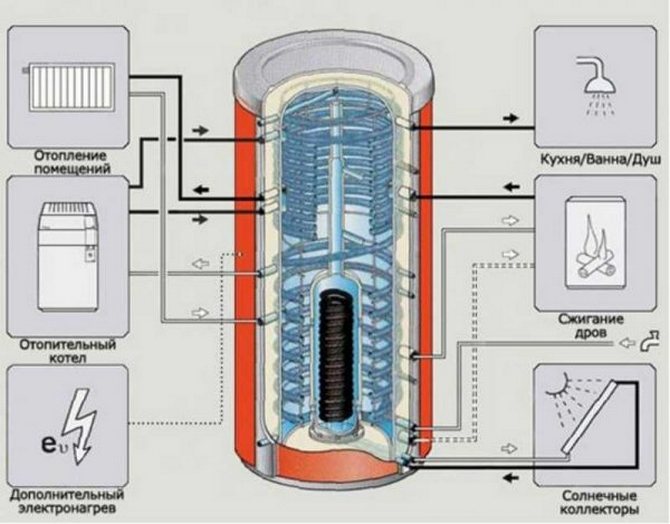

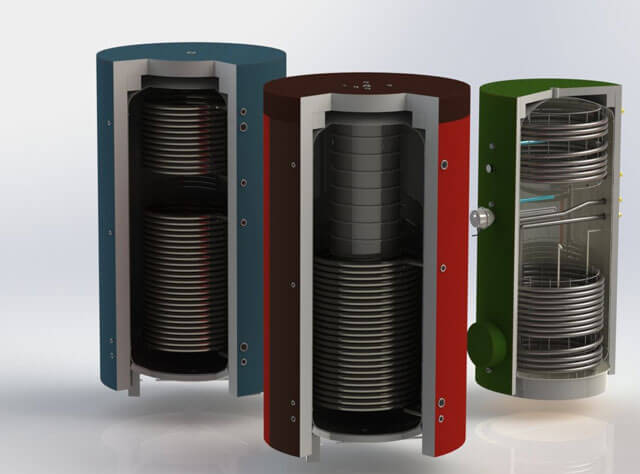

Depending on the design, the following types of buffer tanks are distinguished:

- empty (no heat exchanger);

- with one or two heat exchangers;

- with the presence of built-in boilers of a smaller diameter, which are used to ensure the autonomous operation of the hot water supply system.

There are several threaded holes in the steel body of the tank, thanks to which the heat accumulator is connected to the boiler.

Varieties of accumulating models

The storage devices function in the same way, but differ in their design, therefore, the following types of storage device are distinguished:

- hollow (does not have an internal heat exchanger);

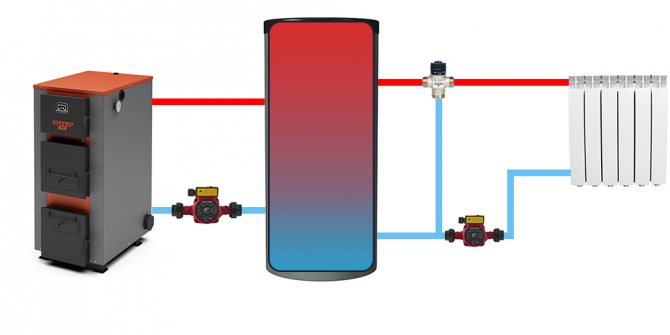

- with 1 or 2 heat exchangers (ensures correct operation of the unit);

- with built-in small diameter boiler.

Hollow heat accumulators are the simplest ones and have a low cost. They can be connected to one or more units. It is also possible to install an additional heating element that operates on electricity. The heat accumulator guarantees good heating of the living space, reduces the likelihood of overheating of the heat carrier and ensures the safe operation of the system. The heat storage unit with one or two coils is an advanced type of device with a wide range of uses. The heat exchanger, which is located at the top, collects heat energy. The one at the bottom intensively heats up the buffer tank.

A thermal buffer unit is much more expensive than a hollow one, but this is fully justified. The device significantly increases the functionality and efficiency of the system. An accumulator with a built-in tank accumulates the excess heat generated and supplies hot water.

Benefits of using heat accumulators

The installation of a heat accumulator is aimed at achieving the following goals:

- The boiler can be heated at any convenient time;

- The laying of each next batch of fuel can be postponed for some time;

- The amount of fuel used to heat the building will be reduced.

A buffer tank (heat accumulator) built into the boiler allows maintaining a comfortable microclimate in the house and at the same time reducing fuel consumption for heating. If such a system is supplemented with sensors and thermostats, then the savings will be maximum - when a certain temperature is reached, the heat supply to the heating circuit simply stops.

The energy generated by the boiler will be stored in the heat accumulator until it is needed. As soon as this happens, heat will begin to flow directly into the heating, bypassing the boiler. Increasing the battery capacity will extend the autonomous operation of the heating system.

When you need a heat storage

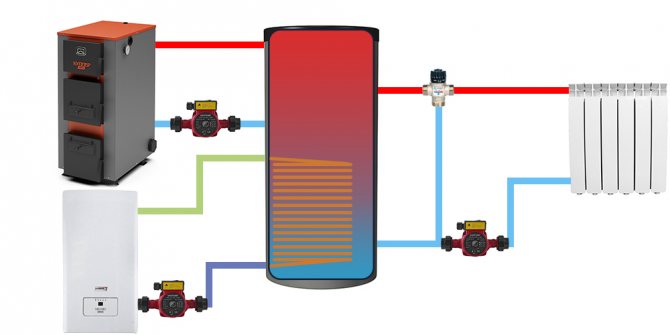

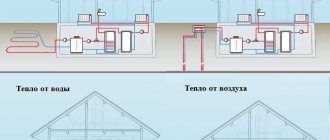

The heat accumulator is applicable to different types of boilers.Basically, it is used in the solar system, with solid fuel and electric boilers. The system with collectors allows you to use the energy of the sun every day in everyday life. If you do not use a heat accumulator, then the complex will not work fully, because the energy from the sun is supplied unevenly.

Photo: termocom-spb.ru

Accumulators are used in heating systems with solid fuel boilers. The buffer device allows you to provide heat at the moment the unit goes into passive mode. The tank must be large in order to store a significant amount of heat, and then use it rationally.

When working with electrical equipment, the tank must be placed in the immediate vicinity of the boiler. It is worth noting that this heating option takes up a lot of space, it requires a separate room and is very costly - it can pay off only in 2-5 years.

Significant energy costs can be reduced if the buffer tank has good capacity, using the equipment at night or on weekends.

Ways to connect the heat accumulator

The connection of the heat accumulator depends on how the coolant circulates in the heating circuit:

- If the water in the system moves under the influence of gravitational forces, then the heat storage device must be located as close as possible to the heating boiler.

- If there is a circulation pump, the location of the buffer tank is irrelevant.

The temperature in the room where the heat accumulator will be installed must exceed 10 degrees. A self-made buffer tank for a solid fuel boiler should be located below its level or level, but not higher. In addition, when installing the device, care must be taken to provide free access to it, allowing for repair or maintenance work.

Can I do it myself

You can assemble a heat accumulator for heating boilers with your own hands. To do this, you need to take a steel tank or purchase stainless steel sheets with a thickness of more than 2 mm, weld a container in the form of a cylinder (vertical tank).

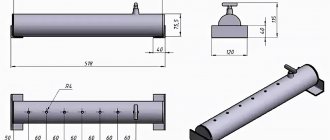

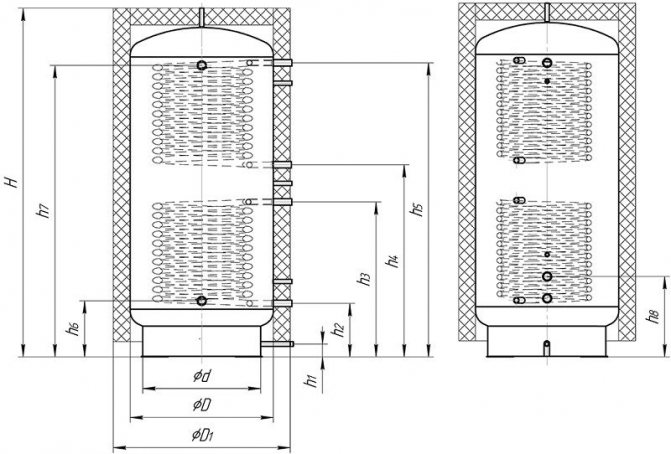

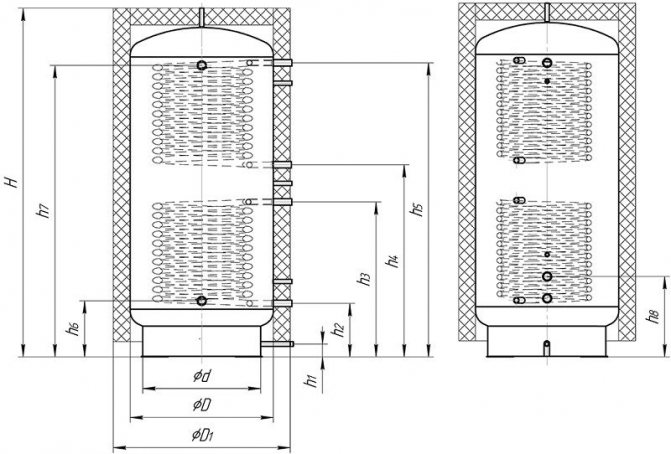

Battery drawing

A copper pipe with a diameter of 2-3 cm and a length of 8-15 m is required. It must be bent in the form of a spiral and placed inside the tank. Here, the battery is the top of the container. Connections for outgoing hot water and incoming cold water are installed in the tank.

Photo: builditsolar.com

For an open heating system, a cube-shaped steel tank is suitable.

It is imperative to check the tightness of the container by filling it with water or lubricating the welded seams with kerosene. If everything is fine, then it is necessary to insulate the home-made device, which will allow the liquid in the container to be hot for as long as possible.

The unit is insulated as follows:

- The outer surface of the container must be well cleaned and degreased, covered with anti-corrosion agents.

- Provide thermal insulation. You can wrap the container in foil film.

- Provide openings for branch pipes and connect the container.

- A thermometer, a pressure gauge and an explosion valve must be installed on the buffer tank.

It is better not to use polystyrene for insulation. In cold weather, mice start up in them, looking for a place for wintering.

Do you need a buffer tank for Stropuva boilers?

Well thought out regulation of air supply to the furnace ensures high efficiency and maximum long-term operation of the boiler on one fuel load. Thanks to the innovative principle of top combustion and the design features of the Stropuva solid fuel boilers, they do not generate excess heat, as a result of which there is no need to use a heat accumulator.This is a huge advantage of Stropuva boilers, since the cost of equipping a heating system with their help is much less than the cost of arranging heating a private house with the help of heat generators from other manufacturers.

Top 5 best heat accumulators

______________________________________________________________________________________

| Model | Characteristic | Benefits |

| S-TANK АТ PRESTIGE - 500 (Belarus) | Weight - 105 kg. Diameter - 78 cm. Height - 157 cm. The volume of the tank is 500 liters. | · Ease of maintenance and easy installation; · Water heats up quickly; · Protected from overheating; · Multifunctionality; · Compatible with different sources of heat supply. |

| HAJDU PT 300 (Hungary) | Height - 1595 mm. Weight - 87 kg. The volume of the tank is 300 liters. | · Works in a closed system, with pumps, heat and solar panels; · You can install heating elements; · Simple installation, construction and maintenance; · Good thermal insulation. |

| HAJDU AQ PT 1000 (Hungary) | The volume of the tank is 750 liters. Weight - 93 kg. Diameter - 79 cm. Height - 191 cm. | · Ergonomics; · The presence of thermal insulation; · Removable insulation and casing; · Compatibility with various boilers; · Long-term operation. |

| S-TANK АТ AT-1000 (Belarus) | Weight - 131 kg. Height - 2035 mm. Diameter - 92 cm. The volume of the tank is 1000 liters. | · The device is thermally insulated on top (70 mm); · For convenient connection, the branch pipes are turned at an angle of 90 ° and are located at different heights; · There are 4 holes of 0.5 inches for temperature control pressure gauges and sensors. |

| S-Tank AT 300 (Belarus) | Weight - 65 kg. Height - 1545 mm. Diameter - 500 mm. The volume of the tank is 300 liters. | · Goes well with any type of boilers; · Insulation has high fire resistance; The tank is protected from the outside by a casing (plastic or cloth, · The top of the tank is painted with heat-resistant paint. |

______________________________________________________________________________________ Heat accumulators for heating boilers of Russian production have proven themselves well in the market. They are not inferior to foreign counterparts, they also have high quality and long service life, and the price is much lower. Famous models of protective devices are produced by brands: "Prometey", "Vodosystem", "BTS", "Gorynya", LLC "RVS-engineering", "Teplodar".