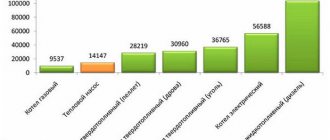

A heat pump is an interesting thing, but expensive. The approximate cost of equipment + external circuit devices is from $ 300 to $ 1000 per 1 kW of power. Knowing the "handiness" of the Russian people, it is easy to assume that more than one hand-made heat pump works in the vastness of our vast and diverse homeland. Most often, there are home-made devices that were made by "refrigerators". And this is understandable, because the heat pump and the freezer work according to the same principle, it is just that the system of heating plants is focused on collecting heat, not removing it, and the compressor is used with a higher power.

Read about how it works here.

What can be a source of heat for a heat pump

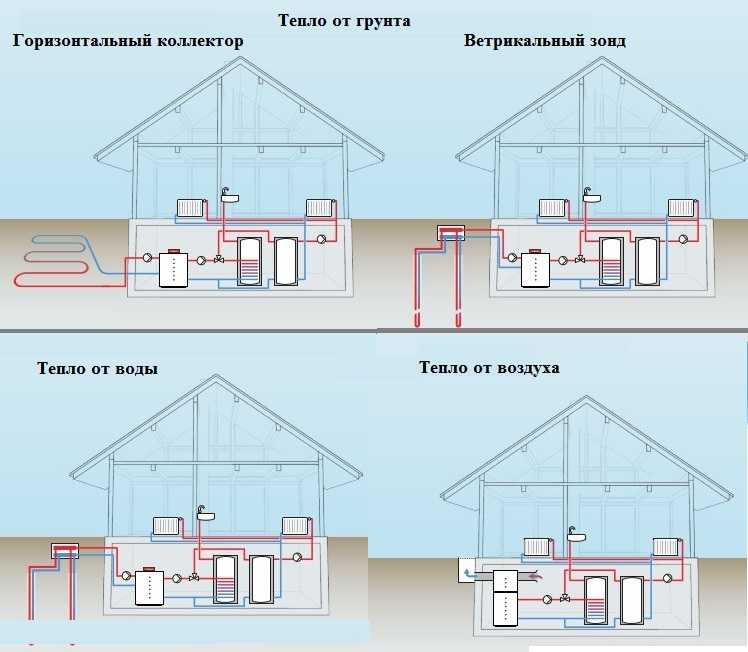

Heat for heating the room can be taken from the air outside. But here difficulties in operation will inevitably arise: temperature fluctuations, even average daily, are too large, not to mention the fact that the heat pump shows normal efficiency at temperatures above 0o C. And how many regions do we have such a picture in winter? In the spring, and even then not early, and not throughout the territory, and not all the time.

Any environment can be a source of heat for your heat pump-heated home

A heat source located in the water looks much more acceptable. If there is a river, a lake or a pond of a decent depth nearby, this is just great: you can simply drown the pipeline. It is only important that fishermen with donks do not fish there.

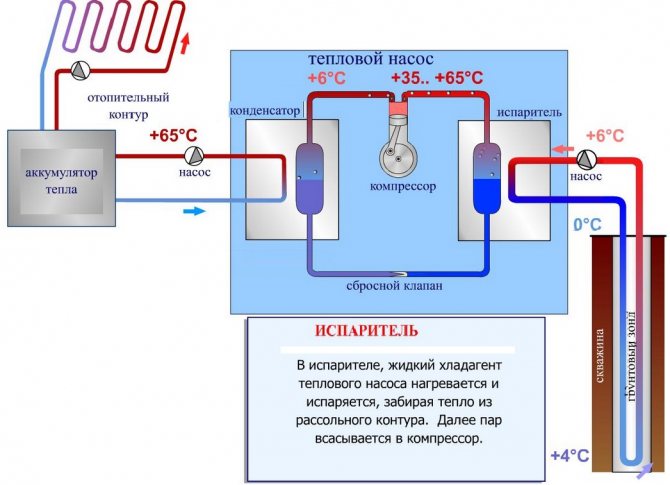

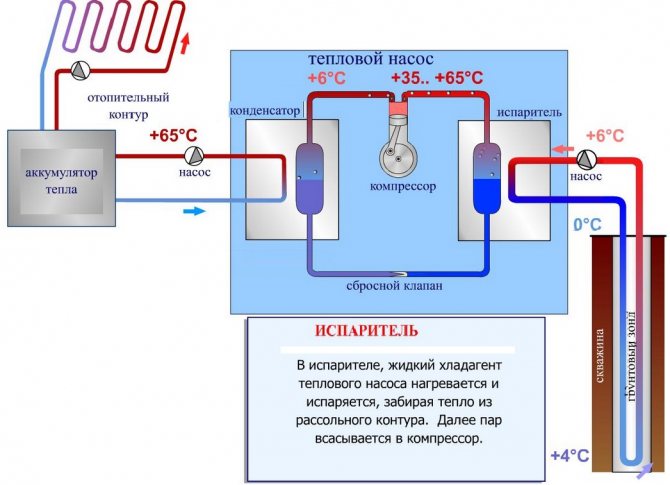

Another good option is a well, but there is a possibility that the water level will drop and you will have to look for another source. But so far everything is fine, it will work well: the average water temperature in the underground horizons is 5-7 oC. This is more than enough for the operation of the heat pump.

You may be surprised, but you can also use the sewerage system - the temperatures there are higher than in the wells. The pipeline can be placed in a cesspool or well, but on condition that it is covered with water at all times. And the pipe will need to be chemically resistant.

A horizontal underground collector is an extremely laborious task: it will be necessary to remove the soil from several hundred square meters to a depth below the freezing point. These are very large volumes that cannot be mastered alone or even with an assistant. And, as practice has shown, in our climatic conditions such systems are ineffective: winters are too harsh.

With vertical collectors, things are no better - you will hardly be able to do without drilling equipment. The number and depth of wells depend on the soil: the range of possible heat removal from a meter of a well is very large. From 25 W / m in dry crushed stone and sandy soil, up to 80-85 W / m in wet crushed stone and sandy soils or in granite. Accordingly, the difference in the length of the wells is 3 times and more.

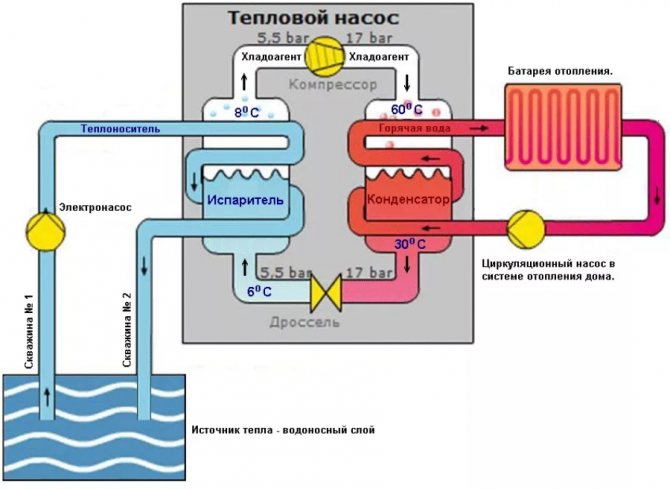

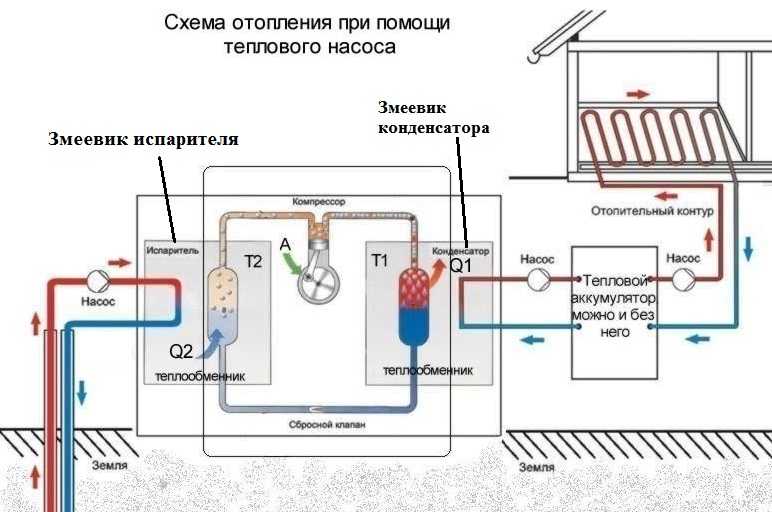

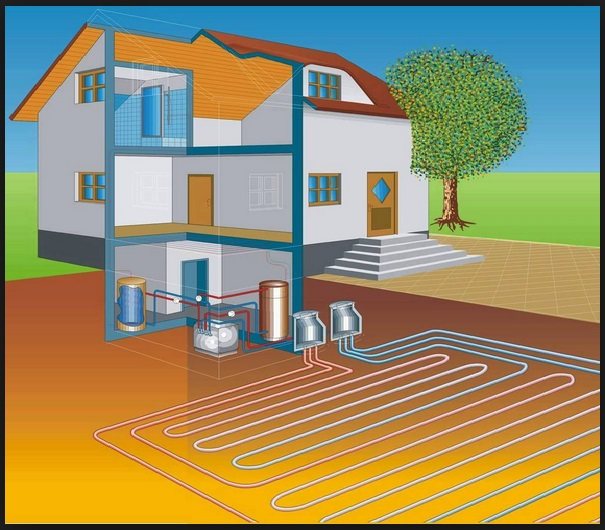

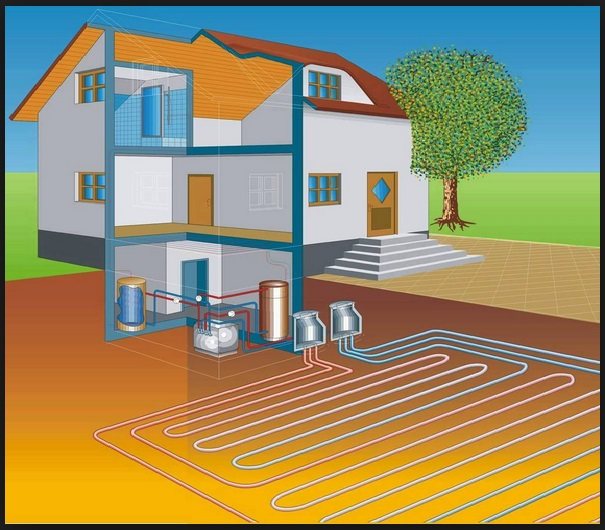

Here is a diagram of heating a house with a heat pump. When using, as in the described example, two wells and in the absence of a closed loop, the distance between the two wells must be at least 20 meters. And you need to take into account the direction of the flow so that cold water from the pump does not lower the temperature in the "donor" well

In the described example of a homemade heat pump, the heat source is a well with a good water flow rate. Water arrives so quickly that it covers the consumption for household needs and is enough to transfer the required amount of heat (the required water flow rate was calculated and the pump was selected accordingly). But the source of heat for this modification can be any of the ones described above, except for air.Having decided on the heat source, it will be possible to make a heat pump for heating a house.

Types of heat pumps

In order to clearly understand what a heat pump is, you need to know what is the heat carrier for it on the contours of its structure outside and inside the house. These coolants classify this device.

Water-air

The most efficient systems for heating are water-water systems. This efficiency is due to the fact that the temperature of the water used at great depths is constant and has rather high indicators. To obtain energy from this type of source, they can use:

- wells and wells, with the help of which groundwater is pumped;

- open water bodies, which include rivers and lakes;

- waste water that has been used in industry for technology.

A heat pump that uses energy extracted from an open-type reservoir will require the lowest cost. In this case, you will need to load pipes with a coolant and lower them into the water. In the case of groundwater, a more expensive structure is used, since its implementation is already more difficult. To dump water, you need to build a well. This water will pass through the heat exchanger.

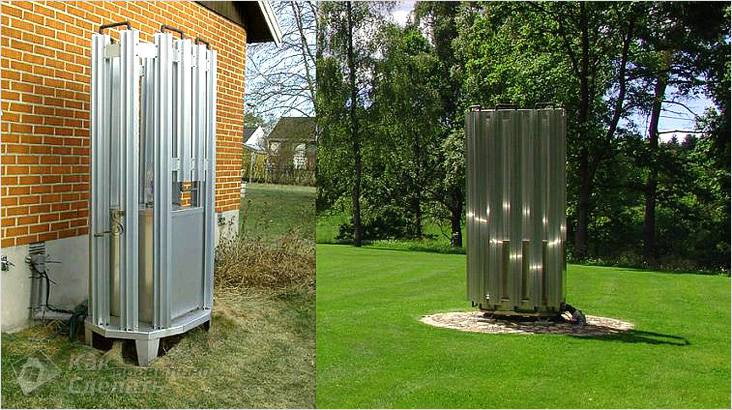

Air-to-water or air circuit

An air-to-water heat pump combines pros and cons. The advantages include the uselessness in the development of wells of great depth and work associated with soil cleaning. The disadvantage of these devices is its low power in the cold season, which affects its lowest efficiency among other models. To use this device, it is required to mount the appropriate equipment on the house roof.

Air source heat pump

The advantage of this design can be attributed to its ability to reuse the leaving heat from the premises, which heats the heat pump in the form of smoke, water or air. In winter, alternative heating will be required in order to eliminate the lack of heat.

Ground-water

A heat pump of this type is also a very efficient source of energy for heating. This is due to the fact that the heat that is obtained from the ground 5 meters deep has constant values in temperature and is not affected by changes in weather conditions on the surface of the earth. On the external circuit, the coolant is a special safe composition called brine, which is safe from an environmental point of view.

The external circuit used for this type of heat pump can be horizontal or vertical type.

The pipes used for this system must be plastic. Horizontal execution requires a large area of land. After the pipes are laid under the ground, this plot of land cannot be used for agricultural needs.

It is allowed to grow a lawn or plants of the same age. For vertical execution, it will be necessary to develop several wells, the depth of which ranges from 50 to 150 meters, since at such a depth the soil has a stable and high temperature. Such a device is called a geothermal pump. To transfer energy from such depths, special probes are used.

From the operating experience of a do-it-yourself heat pump

As practice has shown, the performance of the presented option is low: 2.6-2.8 kW. There is no need to talk about the high efficiency of this heat pump: on an area of 60 m2 at -5 oC outdoors, it itself maintains + 17oC. But the system was considered and installed under the boiler - radiators, at an input temperature of + 45oC, simply cannot give out more. The system in the house worked old and the number of radiators was not increased, but so far in the cold they were warmed up by a stove.

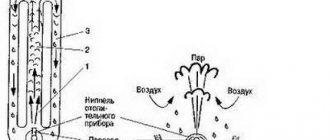

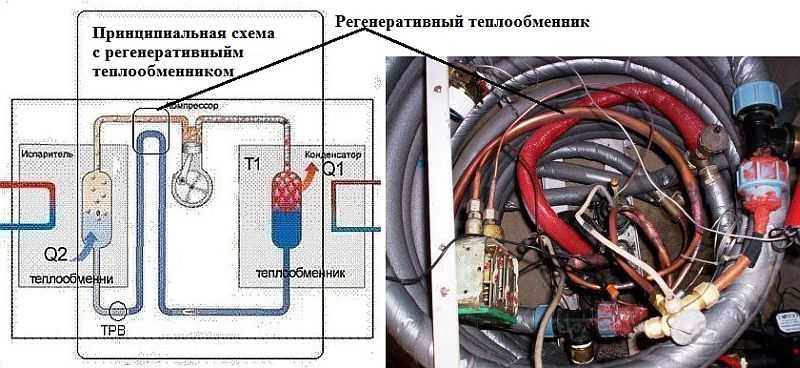

If a regenerative heat exchanger is added to the structure, this will increase the efficiency by 10-15%. Given that the costs are low, you can do it. You will need two copper pipes 1.5 meters each. One with a diameter of 22 mm, the second - 10 mm. A 4-core conductor (length 3-4 meters, diameter 4 mm) is wound onto a thinner one to increase the heat exchange area, its ends are soldered to the tube so that they do not unwind. The wire wound tube is gently inserted into the larger diameter tube. It must be installed between the compressor and the evaporator. The refinement is insignificant, but it significantly increases the efficiency. True, under certain conditions it is unsafe: warm freon can get into the compressor, which will lead to its failure.

Improvement of the circuit: you can add a regenerative heat exchanger, which will increase the productivity by about 15-20%

The second option for increasing efficiency, safer and no less effective, is to build in an additional heat exchanger for heating water or glycol.

What to look for if you decide to make your own heat pump. There are a few things that can only be learned from experience:

- The starting currents of this particular installation were very decent. There were not always enough network resources to run the installation. Therefore, if you make a serious installation, it is better to take a three-phase compressor, and supply a three-phase input, respectively. Yes, not cheap, but for a stable start of a single-phase compressor, an electronic stabilizer of decent power is required, which cannot be called cheap either.

- A heat pump on a finished radiator system will not give a normal room temperature. They are designed for a different coolant temperature, which these installations, especially home-made ones, are extremely rarely able to give. Therefore, either upgrade the system (adding at least the same number of radiator sections), or install water floors.

- If there are three rings of water in a well, this does not mean that it has a large debit. You need to know how much water he is able to give with its constant selection.

Video

The following video provides details on the features of heat pumps:

https://youtu.be/jU5ueYQY-88

More information about the device of a homemade pump in the following video below:

In recent decades, home owners have acquired a fairly large selection of heating systems. It is no longer necessary to connect to centralized networks and use traditional sources. You can choose equipment that works on alternative energy, but its main drawback is its high cost. Do you agree?

However, if you build a heat pump with your own hands from an old refrigerator, the system can be significantly reduced in cost. And we will tell you how to do it.

In the article, we have selected the simplest solutions and provided them with detailed drawings and diagrams. Therefore, it will not be difficult for a home craftsman to understand them. In addition, here you will find step-by-step instructions for the manufacture of heating equipment. And the videos posted will tell you about the design features of the heat pump and the features of its connection.

Outcomes

Undoubtedly, the cost of a heat pump from an air conditioner is several times lower than ready-made factory options, even those made in China. But there are a lot of nuances here: you need to take care of the source and amount of supplied heat, correctly calculate the length of heat exchangers (coils), install automation, provide guaranteed power, etc. But if you are able to solve these problems, then it is undoubtedly beneficial. Let us give you some advice: in the first year it is very desirable to have back-up heating, and testing and trial run, it is better to carry out in the summer, so that there is time to revise the unit before the start of the heating season.

What is a geothermal pump

How the heat pump works

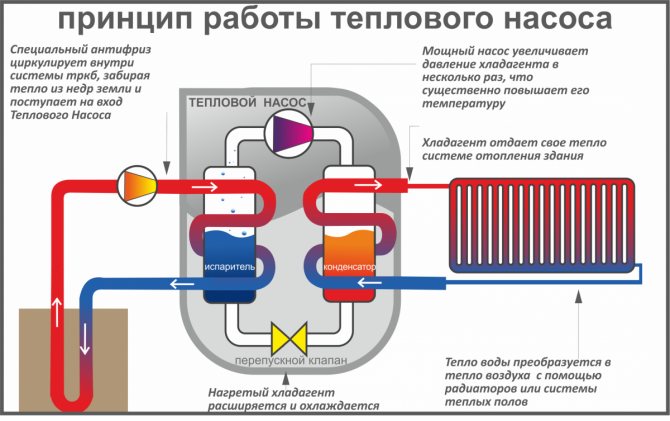

First you need to understand what a geothermal pump is, and on what principle it works, because it is he who is the heart of the entire device we are describing.

It's not a secret for anyone that above-zero temperature is always maintained in the thickness of the earth. The water under the ice is in the same state. In this relatively warm environment, a closed pipeline with liquid is placed.

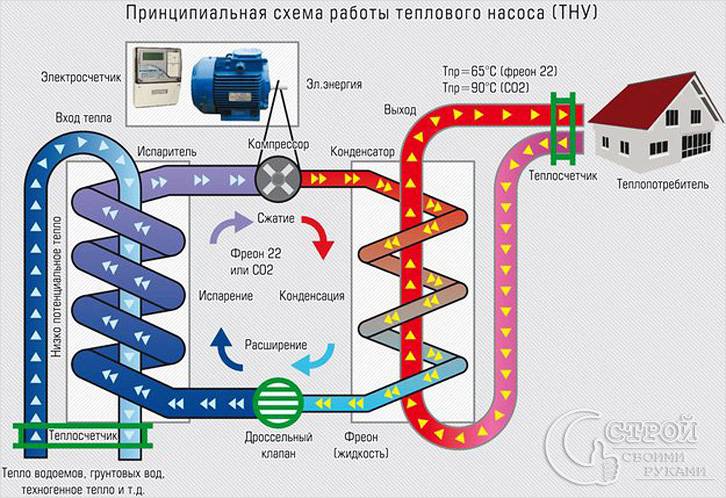

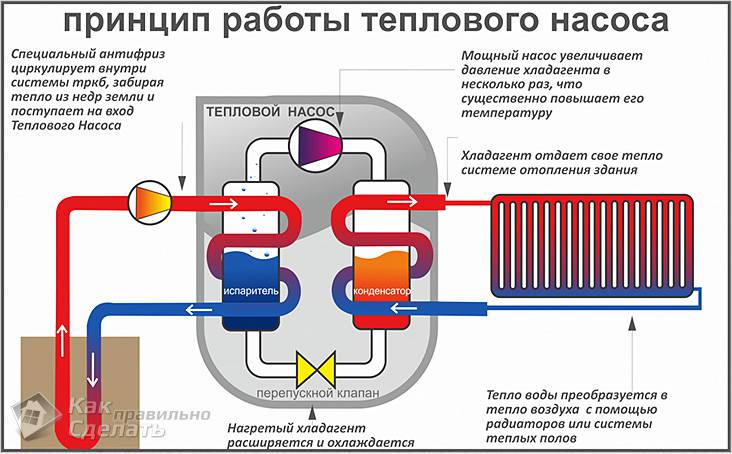

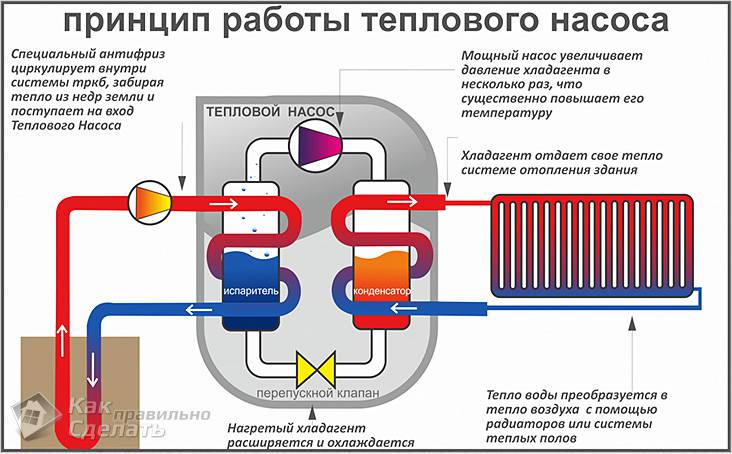

The operation scheme for heat pumps is quite simple and is based on the reverse Carnot principle:

- The heat carrier, moving along the external circuit, heats up from the selected source and enters the evaporator.

- There it exchanges energy with a refrigerant (usually freon).

- Freon boils, turns into a gaseous state and is compressed by a compressor.

- Hot gas (it heats up in the range of 35–65oC) enters another heat exchanger, in which it gives up its heat to the heating or hot water supply system of the house.

- The cooled refrigerant becomes liquid again and returns to a new circle.

Helpful hints

At all stages of building a house, starting from the design stage, it must be remembered that TN is an inertial system. It can be compared to a massive Russian stove, which was usually heated once a day while cooking. Then the accumulated heat heated the dwelling until the next morning.

Walls made of heavy logs have a fairly high degree of thermal inertia. Simply put, they slowly cool down when it gets colder at night. Good thermal inertia for thick stone walls and heavy concrete or bricks.

Polyfoam and foam concrete have good thermal insulation properties. But due to their low specific gravity, they have low thermal inertia. A heat pump in a building with walls made of such materials with a sharp drop in the outside air temperature will not always be able to “pump” enough heat from the outside into the “warm floor” heating system.

You also need to consider other factors:

- To reduce heat loss or not freeze pipes at all in the pipeline between the house and the wells or the collector, it is necessary to lay them to a depth below the freezing level. In Crimea, 0.75 meters is enough, and at the latitude of Moscow - at least 1.5.

- The biggest heat losses are usually through windows. Therefore, triple glazing is not a luxury at all, but an economically sound building solution. The ideal option is to use glasses that can reflect infrared rays.

- In the case of using the option of 2 wells for the intake and discharge of water, the distance between them must be at least 20 meters.

- It is better to try a homemade TN first in a utility room or garage. Installation of underfloor heating in a residential area will require additional costs. Find out the ordering by the link for the corner fireplace.

How to make a heat pump with your own hands

Some guidelines for creating these devices are described below:

- First of all, you should start purchasing a compressor, for example, such as in an air conditioner. As a rule, it is attached to the wall.

- Making another important part of the product, the capacitor, is quite realistic to do with your own hands. To do this, you need to bend a copper pipe (the diameter should not be less than 1 mm) in the form of a coil, and, already in this state, place it into the depth of a metal or plastic case. As a body, you can use a tank of suitable size. By

After the installation of the coil is completed, the parts of the tank are welded, and the necessary threaded connections are installed. The evaporator is also most often mounted to the wall. Hint: to make a high-quality coil, it is best to wind a copper plumbing pipe over a cylindrical base of the desired thickness, for this you can use a gas cylinder. To achieve the same distance between the turns, use a perforated aluminum corner, on which the coil turns are attached. - The final installation of these parts, namely soldering a copper tube, pumping freon, etc., should be done exclusively by a highly qualified professional worker. Doing this without proper experience can damage the equipment and significantly increase the likelihood of personal injury.

- The next step is to connect the structure to the building's heating system.

- After that, you should proceed to the installation and connection of the external circuit. This process has its own characteristics, which differ depending on the type of heat pump. Important: before starting the heat pump, you should diagnose the electrical wiring in the house and the electricity meter. If described is dilapidated and outdated, then replacement will be required. Acceptable power, which the electric meter has, can be considered a mark above 40 amperes.

It is worth noting that the operation of a heat pump in heating a house does not always fully satisfy all the requirements of the owners. Usually, this is due to the fact that the thermodynamic calculations were performed incorrectly. The result of such an error is a low-power system, or the system turns out to be too powerful, and this is due to excessive consumption of electricity.

To select a system with a suitable power, you should calculate the heat loss of the building, and many other calculations. This calculation should be performed by an experienced design engineer.