Comparative characteristics of fuel

The fuel cost is presented in the table (average prices):

| Name | Price including delivery in Moscow (volume from 20 tons) | Shipping price from the warehouse (volume from 1 ton) |

| Sunflower husk pellets | From 53 $ (3500 r) per ton | From 68 $ (4500 r) per ton |

| Light wood pellets from 6 mm | From $ 101 (RUB 6700) per ton | From 109 $ (7200 r) per ton |

| Light wood pellets from 8 mm | From $ 95 (6300 r) per ton | From 103 $ (6800 r) per ton |

| Birch fuel briquettes | From 87 $ (5800 r) per ton | From 89 $ (5900 r) per ton |

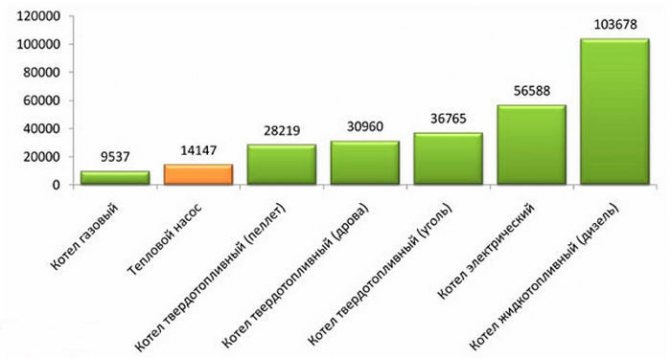

Comparative characteristics of heating costs are shown in the photo.

It is noticeable that when using granular fuel, the cost of maintaining the system is slightly higher than using gas equipment, but much lower than any other devices operating on a standard type of fuel.

How to determine the quality of fuel pellets

The cost of raw materials depends on the quality, the class of pellets, the average prices of pine pellets start at $ 90 (6000 r) per ton, and peat fuel is estimated at $ 83 (5500 r) per ton. The cost of pellets for heating depends on a specific region, supplier, but in general, the spread does not exceed 500 rubles per ton.

The quality of the pellets determines the efficiency of the heating system. You can visually determine the indicators of fuel raw materials.

What to look for:

- Dust. If there is a lot of dust in a bag or package, this indicates a substandard product.

- The evenness of the surface of the granules without cracks and blisters indicates compliance with the processing technology and product preparation.

- Colour. It should be even without centers of lightening, darkening. If the shade of the granules is gray, then they have been lying for a long time and the quality will be low.

- Granule length. The European standard that manufacturers adhere to is 25 mm. But fuel cells can be longer or slightly smaller, size does not affect the overall combustion efficiency.

- Smell. Good quality fuel should have a sweetish aroma - it appears during processing and drying. If there is a smell of rot, burnt product, harsh chemistry - the manufacturing process is disrupted, it is better to refuse granules.

Advice! The alternative fuel product may smell like the raw material it is made from. Therefore, sunflower husk pellets sometimes smell like oil, wood pellets - with shavings, peat - with smoke.

Pellet classification

According to the technological classification, products are divided as follows:

- White. This is a premium class. Well dried wood without bark is used in the manufacture. The ash content of the fuel is not more than 0.5%, therefore, granular products are used for all types of solid fuel equipment. The ash removal process is carried out once a month, the heat generation is 17.2 megajoules per 1 kg of products.

- Industrial pellets. These are granules, in the production of which raw materials are used with dust, soil, bark, and other inclusions. Ash content is high, heat generation is also 17.2 MJ / 1 kg of fuel. The regularity of cleaning the combustion chamber is more frequent, the parameter is indicated in the technical documentation for the granules.

- Agropellets. Fuel that has been assigned a standard class. Sunflower husks and buckwheat are used as raw materials. Distinctive features - dark color, low heating capacity (no more than 15 MJ / 1 kg), high ash content. But there is a plus - a reduced cost. Alternative fuels are used at thermal stations and in boilers with an automatic cleaning function. Otherwise, the ash will have to be cleaned every day.

Important! When choosing pellets for heating, it is necessary to evaluate the individual characteristics of the region. In areas with a developed agricultural economy, the use of agropellets will be an inexpensive option for generating heat, and wood pellets are cheaper in areas with wood processing enterprises.

Pellet classes description

White pellets

Pellets of premium grade - this is what buyers often call them. They are light in color. This color is achieved by removing the bark from the wood before crushing and properly drying the wood. Premium grade pellets are usually made from softwood or hardwood sawdust. White pellets have a very big advantage over their competitors - low ash content. The ash content of white pellets is 0.5% and below. For example, the Pelletron boiler, when used, is cleaned only once a month. Premium pellets, which account for more than 95% of the total pellet production, can be burned in any boilers and stoves designed for standard or premium fuel.

Industrial pellets

The color of such pellets is already darker. This is due to the presence of bark and other non-combustible residues (earth, dust) in the pellets. The ash content of this category of pellets starts from 0.7%. The calorific value of such pellets, for the most part, is no different from the "white" pellets. But you will have to clean the boiler more often. The frequency of cleaning will directly depend on how high the ash content of the fuel is.

Agropellets

Such pellets are made from buckwheat shelling waste, sunflower seeds. These pellets are very dark in color. Their ash content is 3% or more. The main plus of agricultural pellets is their price. They are much cheaper than all of the above. As a rule, they are used for combustion in large boilers. In this case, the boilers are cleaned once a day, or a pellet boiler with automatic cleaning is used.

The main characteristics of pellets

Dealing with the type and classification, one can understand what pellets are - they are waste of wood processing, agricultural crops, peat, coal. Granular fuel is obtained in the process of pressing waste under high pressure (more than 300 atmospheres) and elevated temperatures. The raw mass is passed through certain forms, from where it comes out in the form of capsules, granules. Particles of the substance stick together without the use of chemicals, so heating a house with pellets is considered one of the most environmentally friendly. Standard size of granule thickness is 6-10 mm, length is 20-30 mm.

What is the peculiarity of the use of granules - pellet heating is performed by pressing, therefore, it emits much more heat energy. For example, in comparison with other fuels, 1 ton of pellets replaces 0.5 ton of diesel, 480 m3 of gas or 1.6 ton of firewood. Choosing encapsulated raw materials reduces the amount of waste in the form of ash. Some minus in the high cost, compared to firewood, but here you have to choose - buy firewood for sawing or bags of granules.

On a note! In addition to wood, bark, coal, peat, agricultural waste, household solid waste is used for manufacturing - such granules do not have high heat transfer, but are cheap and therefore are quite suitable as a reserve stock.

Pellets: what is it?

Externally, fuel pellets look like cylindrical granules. Waste of wood and agricultural production is pressed into them. Their sizes are standard:

- Diameter - 6-8 mm.

- Length - from 5 to 70 mm.

- Humidity - 7-10%.

"Loose" granules are convenient when using feeders in boiler rooms

Due to this indicator, they are successfully used in pyrolysis boilers. If we compare it with firewood, then the efficiency of boilers using such fuel is 1.5 times greater.

But the size of one pellet depends on the material used for the production, the type of raw material and the scope of use.

Note! Abroad, this type of fuel is actively used, especially for automated boiler houses. Pellets have found their distribution both in domestic and industrial use. In terms of their thermal conductivity, pellets are compared to coal. In addition, this fuel is environmentally friendly.

Well-dried pellets work more efficiently

Pellet manufacturing technology

Solid fuel boilers for long burning for home heating

Raw material passes through several stages in the process of preparation and receipt of the final product:

- Splitting up. The procedure for grinding waste allows you to obtain a fine-grained composition of granules whose dimensions do not exceed 2x25x25 mm. This is to facilitate drying.

- Drying. There are several ways to carry out this stage, it all depends on the type of equipment used in production. The basic rule is that after drying, the moisture content of the raw material should not be more than 10%.

- Additional grinding. A hammer mill is used, which crushes the granules into fractions up to 4 mm in size.

- Moisture enrichment. The substance is passed through a screw mixer and absorbed with moisture.

- Pressing. Presses of various types are used, through which the mass is passed, leaves the sieve and is cut with a knife - the process is automated, the temperature regime is maintained within +100 C.

- Cooling and packing.

Important! If, during the pressing process, the temperature regime exceeds +120 C, the material loses its combustible properties - this reduces the heat transfer of the pellets.

Factory technology

The factory technology for the production of pressed granules can be divided in stages:

- Large initial crushing of raw materials;

- Drying;

- Grinding of crushing results;

- Dry base water treatment;

- Pressing;

- Cooling.

- Packaging of finished granules.

In the first stage of production, raw materials are fed to crushers for grinding... Output material dimensions 25 × 2 mm. This allows you to dry the processed raw materials in special dryers, then crush it again.

Raw materials with excess moisture are pressed worse and the resulting pellets are not suitable for combustion. Therefore, drying is a stage that cannot be ruled out.

Drying has two types: belt or drum. It is selected purely depending on the raw material and the desired output result. The drying process is the most energy-intensive in the entire production. However, this process cannot be avoided.

The raw material prepared for the press should not exceed 4 mm... For crushing them, special crushers are used. Among them, the most suitable are hammer mills. A good product at the exit can be identified by its weight: about 150 kg per m³ is a sign of excellent quality.

The required moisture content of the material for pressing is 10% ± 1%. With strong overdrying, the raw material is saturated with steam or water.

As a result of pressing, pellets are obtained in the form of cylinders with a diameter of 6 to 25 mm. Since freshly made pellets have a temperature of 70–90 ° C, they must be cooled before filling. Industrial fans are used for cooling.

The finished chilled pellets are often stored in silos and warehouses, but for a longer preservation of their qualities, it is recommended to place them in large bags.

Purification of water from a well from iron is quite real. Read how to equip. How to choose a heat pump for home heating, in our article.

Check out all the benefits of solar panels for home heating at https://klimatlab.com/otoplenie/alt_energiya/solnechnye-batarei-dlya-doma.html

Devices for the use of fuel pellets

Wooden pallets are used for heating (as well as made from other types of raw materials) in devices specially designed for these purposes. These are boilers, fireplaces with their own characteristics and features.

Fireplaces for loading pellets

They are used for heating individual rooms or houses with an area of up to 20-25 m2.

The average power of the devices is 6-15 kW, there are three types of devices:

- convection heating air;

- with a circuit for hot water supply - they can heat water;

- combined - used for heating water and air.

On a note! Combined fireplaces can work on pellets, briquettes, wood fuel.

Boilers for loading pellets

These are pellet heating systems with a capacity of up to 100 kW, therefore, they are used in houses with an area of up to 100 m2, they allow the formation of circuits with a liquid heat carrier for underfloor heating or an autonomous heating system. It is recommended to install boilers in basements or specially equipped rooms, as well as in detached buildings.

The efficiency of boilers depends on the type of equipment; there are devices on sale that work:

- only on granules;

- on pellets, wood or briquettes;

- combined types of equipment that allow the use of any type of solid fuel.

Worth knowing! The power and efficiency of the boiler depends on the type of fuel used. The parameters are prescribed in the product data sheet.

Pellet boiler arrangement

The main difference between the equipment is in the small volume of the combustion chamber due to the flow of the main processes not in the chamber, but in the convection part of the units.

Other distinctive features include:

- Special type burners with high efficiency.

- Long service life. With the correct operating technique, boilers serve for at least 20 years.

- High degree of equipment automation. Automation helps to establish the regularity of fuel supply, set the heating temperature.

Experts advise choosing devices with a capacity of 15-100 kW for a private house, but you can use the formula for 10 m2 you need 1 kW of thermal energy, plus a margin of 15-20%.

Advice! If you need a heating device in a room with a capacity of less than 15 kW, it is wiser to put a fireplace.

Benefits of pellet heating

The advantages include the following indicators:

- no need for regular maintenance of boilers;

- there are no unpleasant odors in the combustion process;

- high efficiency;

- convenience of storage and transportation of fuel;

- the ability to establish hot water supply in the presence of a water circuit (available in almost all boilers);

- ease of installation - you can do it yourself.

Combined heating boilers for a private house

Important! The efficiency indicator is influenced by the calorie content of the pellets for heating. The highest level is for wood raw materials, lower for pellets from household waste. To store fuel, you need to equip a well-ventilated compartment protected from water and snow.

Disadvantages of pellet heating

The disadvantages include:

- The high price of boilers. The equipment costs a lot more than gas or electrical appliances.

- The need for ash removal. It all depends on the boiler model, but even in old types of equipment, the ash pan should be cleaned no more than 1-2 times a week.

- Heating with pellets is more expensive than a system with a gas boiler.

- Interruptions in the delivery of granules are possible.

Important! When choosing a boiler, it is necessary to look at the adaptation of the device to the conditions of the region of operation. Not every boiler from a foreign manufacturer will withstand power surges and work in an increased mode (in severe winters).

Advantages and disadvantages of pellet heating

The advantages of pellet heating include the following:

Solid fuel boilers for long burning for home heating

- The installation of a solid fuel pellet boiler does not require a permit, as for gas equipment.

- The unit does not require any special maintenance. It is enough to clean it from ash 1-2 times a month if there is no automatic cleaning function.

- During operation, the solid fuel heater does not emit harmful compounds and does not pollute the atmosphere.

- The efficiency of solid fuel heating equipment is 75-95%.

- Fuel is easy to transport and store. The only condition for the storage space is that it must be dry.

- Some boiler models can not only heat the house, but also solve the problem of hot water supply.

- The unit can be installed by hand without the involvement of specialists.

But pellet heating also has disadvantages:

- In comparison with gas and electric boilers, pellet units are more expensive.

- Models without an auto-cleaning system must be regularly cleaned of ash. Usually the frequency of this procedure is once a week.

- If we compare the cost of gas and pellet heating at home, then the latter type will cost more.

- Imported pellet boilers do not tolerate power outages and harsh winters, so they fail prematurely.

- In some localities it is not so easy to buy pellets.

Making pellets with your own hands

The process can be difficult, you need special equipment.

The master will come in handy:

- crusher, but not when using sawdust, husks - this raw material is sold crushed;

- granulator with cylindrical or flat die;

- aerodynamic or drum dryer (you can make it yourself from an iron barrel);

- secondary crusher.

Important! If the master has a flat die granulator, no crushers are required. The crushing process takes place in a granulator.

How to make a do-it-yourself granulator is shown here.

It all starts with the preparation of raw materials and here you need to follow the rules:

- The raw materials must be clean without impurities. The whole mass should be sieved.

- Humidity not more than 12%. Before starting work, the raw material is dried to the desired value.

- The absence of lignin and resins is a bad indicator. The more components, the faster the granulation will be, the fractions will not fall apart after manufacturing.

- A special drum is used for drying.

And now there are several ways to make pellets, depending on the feedstock.

Sawdust pellets

The algorithm of actions is as follows:

- dry the mass to the desired moisture content of 12%;

- sift sawdust through a sieve to eliminate mechanical impurities;

- run the mass into a hammer mill;

- if the moisture content of the material is below 8%, treat the raw material with wet steam;

- compress the granules and let cool;

- pack in paper bags.

It remains to store the fuel in a dry and ventilated shed.

Straw pellets

High ash content of raw materials is a minus, but increased energy efficiency and low cost are pluses, therefore straw is often used for the preparation of pellets. However, there is a difficulty with the equipment - for straw, a large-sized crusher is required, which must be purchased or made by yourself. Both waste from grain processing and raw materials from cut reeds are loaded into the crusher.

The equipment is used the same as in the previous example, and the fuel is used for fireplaces, stoves. The difference is the need for frequent cleaning of the ash pan, however, high efficiency and a very large amount of heat make up for the disadvantage.

Peat pellets

How to do:

- dry raw materials in natural conditions;

- to clear the mass of stones, impurities, plants;

- grind the entire substance;

- dry the mass to the desired indicator of 12%;

- re-run the mixture into the chopper;

- pass the mass through a press and process the final product with hot dry steam;

- chill granules to cure and can be used.

The use of peat granules is wide - they are used to enhance the effect when applying mineral fertilizers and purify water from oil if it gets into the tank.

Pellet production at home

The process of producing pellets at home is quite complicated, but quite feasible, with special equipment.

Equipment for the production of pellets at home:

one.Wood shredder or chipper - provided that the raw material is wood, sawdust or husk. This is not an obligatory component, since it is possible to purchase ready-made crushed raw materials.

2. A drum or aerodynamic dryer, for the manufacture of which a metal barrel is perfect.

3. Secondary crusher, which grinds raw materials into sawdust.

4. Granulator with a flat or cylindrical matrix.