Building a house is an important process in which you need to take into account many nuances. Every year, more and more requirements are imposed on the construction of housing, especially in terms of achieving energy and fuel savings. Modern materials can significantly help in this, however, they should be chosen correctly. For example, recently, such material as penoizol has received positive reviews and competes with the more popular ecowool and expanded polystyrene. What are its features? And why do you need to insulate your house at all?

How to insulate a house?

Let's start by answering the last question. In any house or apartment, especially in those that were built in Soviet times, heat losses are too great - they can reach 40%. In the end, you have to spend a lot of money on heating your home, since heat leaves our homes through the outer walls, floors, windows, doors, and also the roof. Modern methods of insulation, for example, insulation with penoizol, allow solving a number of important issues:

- The optimum room temperature will be maintained throughout the year.

- The walls will be protected from moisture, condensation accumulation, which means they will be reliably protected from mold and mildew.

- The acoustic properties of the building will improve.

- The level of noise insulation in the room will be higher.

- The hygienic condition of the room will be much better.

- Lower energy costs.

- The erected house will be more durable and economical to operate.

Of course, even insulating houses with penoizol will not completely protect the premises from heat losses, but at least they will be minimized. In addition, it is important that the installation of the insulation material is carried out competently and professionally in compliance with the technology.

Penoizol: what are the features?

As a rule, ecowool, polystyrene are most often used as insulation, but today penoizol is also becoming quite popular. It has many advantages, each of which plays a role in forming such a good opinion of the material. Firstly, penoizol is completely uninteresting to rodents and microorganisms, so you don't have to worry that the walls will gradually be eaten from the inside. It is noteworthy that if this material is mechanically affected, it will turn into dust. The second important point is that penoizol receives positive reviews due to its breathable structure and good thermal insulation properties. Due to the presence of capillary moisture transfer in the material, it can be safely used in wooden construction, while the appearance of mold is excluded. All excess moisture will be eliminated by the capillaries of the insulation. The third positive point is that compared to ecowool and glass wool, the material we describe is hermetic, it literally fills all the pores and details in its path.

The porous structure is the key to reliability

The studies carried out allowed us to bring together all the features that Penoizol has. Its characteristics are as follows:

- The resistance coefficient is 40% higher compared to mineral wool and cellulose insulation, which means that the level of heat loss will be minimal.

- Penoizol is not afraid of moisture, which can destroy wood and lead to defects in the walls or roof. The material has a porous structure, so all the accumulated moisture dries out instantly, which means there is no reason for worry.

- Average insulation sags for 10-12 years, respectively, there may be cracks in the walls or floor.If insulation with penoizol is chosen, then this can be avoided, because it fills all the pores, and its service life can reach 70-80 years.

Penoizol characteristics table

Among all traditional heaters, users distinguish penoizol, the characteristics of which allow it to be classified as high-quality and practical building materials

.

Penoizol characteristics as insulation:

| Thermal conductivity | The thermal conductivity of foam glass and penoizol are similar: 0.031-0.041 W / m * s. |

| Moisture resistance | Penoizol absorbs 10-20% of moisture per day, which evaporates without affecting quality. |

| Biological resistance | The material is not afraid of bacteria and rodents. |

| Fire resistance | The insulation is assigned to the groups G-1 (burns poorly), V-2 (does not melt), D-1 (does not emit smoke) and T-1 (non-toxic). |

| Chemical resistance | Penoizol is resistant to aggressive environments. |

| Vapor permeability | Constructions sprayed with penoizol "breathe" due to the hygroscopicity of the material. |

The table shows the most important qualities of a heat insulator, thanks to which the home becomes warm, comfortable and safe.

However, among the characteristics of penoizol as insulation, such important details stand out:

- the cost of penoizol is comparable to the cost of mineral wool and lower than the price of foil insulation;

- the material is universal and has a high level of adhesion - the composition of penoizol allows it to be used for structures of complex and carved shapes;

- during installation and during further operation, penoizol does not emit hazardous chemical compounds;

- penoizol has high noise absorption rates;

- because of its softness, penoizol (pictured) closes all existing cavities and crevices;

- the approximate service life of penoizol is from 30 to 50 years.

Where is Penoizol used?

The modern homeowner is always faced with the choice of quality and reliable materials, especially when it comes to thermal insulation. Penoizol received positive reviews precisely due to the fact that it is a unique combination of price and quality. In addition, this material can be used to insulate both the floor and the roof both in new buildings and in existing buildings. Penoizol is a urea foam with a cellular structure. Due to its excellent physical and chemical characteristics, the scope of the material is wide enough. The material is released in the form of liquid foam, so it can easily fill all cavities in which it quickly solidifies. For wall insulation, you can also choose sheet foam.

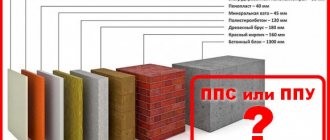

Polyfoam or penoizol

According to customer reviews, penoizol is the most profitable and practical means for insulating premises.

Penoizol is safer and has low thermal conductivity compared to foam. The fact that knowledge and equipment is important for the installation of penoizol does not stop buyers, since its characteristics are better than that of foam. If the budget is limited, you can buy polystyrene, since it is cheaper than penoizol, but it is better not to skimp on insulation.

As soon as they do not call penoizol - "liquid foam", KFP, "Mipora", "Mettemplast" - but no one will undertake to say exactly what it is, where it is used and what properties it is characterized by. But this product, if you know about all its features and subtleties of the technology of use, will help to solve a lot of problems, and with minimal costs.

So what is penoizol and is it interesting for us in terms of domestic use, especially if we focus on such an important indicator as the ratio of the final result and the funds spent? Let's consider all the main pros and cons of penoizol.

The basis of this material is a polymer (carbamide resin, purified in a special way), which contains various additives (primarily a plasticizer).These include substances such as foaming agent, hardener and water. The technology for preparing penoizol has its own specifics, but this is a topic for another article. We will deal only with its advantages and disadvantages.

It is worth noting that opinions about this material are very contradictory, and there is not so much information. And this is understandable - the products on the market are quite new. Therefore, we will restrict ourselves to summarizing all the reviews that are in the public domain.

pros

By such a parameter as the coefficient of thermal conductivity, penoizol surpasses the common one. Its value can vary in the range of 0.033 - 0.048 W / m · K, since the value depends on the density of the material (from 8 to 28 kg / m³). This means that under the same conditions of insulation, CFPs can be laid with a thinner layer, which does not significantly affect the decrease in the usable space in the room.

The poured mass forms a continuous structure. Consequently, there are no joints, overlaps and gaps in the insulation layer, as is the case when using plate and roll products. Accordingly, there is no need to seal them (sealing the base).

Due to the fluidity of penoizol, they can treat any areas - hard-to-reach, with complex geometry or relief. When insulating a private building, it is especially difficult to finish the places of passage through the walls (floors) of various communications, the location of pipes on the roof, and so on.

The absence of fasteners ensures the integrity of the waterproofing layer, eliminates the likelihood of the formation of so-called "cold bridges". Therefore, indirectly, the level of heat loss decreases even more.

According to some experts (with reference to the specialized scientific research institute of the Russian Academy of Sciences), the service life of the material is unlimited. Although in practice (taking into account the "youth" of the product), this has not been confirmed in any way - only theoretical calculations.

Penoizol does not melt, does not ignite, does not emit smoke - it only charred.

Its structure is such that it belongs to the category of "breathable", so unpleasant "surprises" in the form of mold or mildew do not threaten the base material.

The possibility of reinforcing the layer by introducing additives of mineral origin into the mixture.

Low cost - from 790 rubles / m³. This is enough for insulation of about 15 - 20 m² (depending on the thickness of the fill).

Minuses

Like all foams, it does not have high mechanical strength. Therefore, insulation with penoizol is automatically accompanied by a surface lining of the applied layer. And the point here is not in its appearance. For example, when decorating a garage, this is not essential. The reason is the fragility of the material. "Unprotected" penoizol quickly crumbles, and there will be little sense from such insulation.

The complexity of the insulation of frame structures. If the mass is poured between the capital partitions, then they are not deformed under its weight. Consequently, penoizol fills the entire cavity to the maximum. And with insulation, when the walls of the formwork are not rigid enough, they can "play". After some shrinkage of the CFP, this will lead to the formation of voids, and then it will not be possible to correct the situation. Although this can be avoided. For example, by maintaining the temperature in the room at a constant and constant level, thereby regulating the rate of evaporation of moisture. But this is feasible only with internal work.

Penoizol emits harmful substances, and intensively. This is one opinion. The other is only partially, and then only until the filled mass has completely hardened.

Restriction in use - it is not recommended to use it for insulating the buried parts of structures The same applies to various types of screeds (equipped with a "wet" technology), since moisture is partially absorbed into the material, which impairs its properties as a heater.

The complexity of independent work. The main difficulty is in strict adherence to technology, and this requires certain knowledge and experience.

But this is basically a theory, and in some respects it is not entirely confirmed. After all, there is still no practice of using penoizol on a large scale, and for a long time. Accordingly, there is no accumulated statistics, specific recommendations for the use of this material, taking into account all the nuances of this insulation technique. Therefore, before making the final decision on the advisability of acquiring and installing with your own hands, you need to think carefully about everything. Better yet, consult a "pro".

For the sake of fairness, it is worth pointing out that many manufacturers advertise other types of penoizol - crushed (packed in mats), sheet. But this is already somewhat different, and more like a regular one (in granules or slab).

Among the many heaters that exist on the construction market today, sprayed materials stand out favorably, in particular - penoizol. Let's consider it from all sides and find out if it is possible to make thermal insulation with this substance on our own.

Wall insulation: what to consider?

Penoizol insulation for walls is the most optimal solution, because it:

- does not burn;

- resistant to mold, fungus, rodents;

- vapor permeable, that is, excess moisture comes out;

- durable (service life is at least 50-70 years).

Due to its excellent thermal insulation properties, it is not only convenient, but also beneficial to insulate a house with the help of penoizol, since it is easy to install and keeps heat well. Penoizol can be laid in two ways - in the form of plates or thick foam. In this case, it is important that the resistance to vapor permeation of the inner layer is higher than the resistance of the outer walls.

Secondly, you should not choose a film, foil, roofing material as a vapor barrier material, since there will be no air gap between the walls of the building and the outer area. To increase the efficiency of using this insulation, it is best to combine it with wood, concrete, brick or plaster. When laying the slabs, a gap between them and the wall should be avoided.

Fields of application of liquid foam

Inside houses, liquid foam is used less frequently than for outdoor insulation. Most often, with its help from inside the premises are equipped with:

- attic floors in panel houses;

- inter-rafter spaces;

- sloping areas of rooms;

- insulation of two parts of the walls that fit tightly to each other;

- formwork;

- false walls;

- wood floors;

- hard-to-reach sections of the walls.

Also with the help of penoizol you can insulate containers and use it to make all kinds of foam products:

- baguettes;

- skirting boards;

- plates;

- relief elements and much more.

When making such products with your own hands, you should carefully check all materials. Do not use liquid foam from unknown manufacturers at a suspiciously low price. This is usually a poor quality product that can negatively affect your health. It is advisable to monitor online reviews of a particular brand of penoizol before buying, and only then make your choice.

Liquid foam, which is sold in cylinders, can be used as glue... In form and scope of use, it resembles polyurethane foam, although it has a higher level of thermal conductivity and vapor permeability.

With the help of liquid foam, insulation boards can be fixed to walls and other surfaces. When working, you need observe a number of the following rules:

- check the surface for defects. It should not have rust, chips and cracks, and it should also be flat;

- the surface is cleaned and all dust is removed;

- in the places of contact of the foam with the board, water must be applied to improve adhesion;

- penoizol can be applied both on a full surface and horizontally and diagonally in order to save money;

- after applying the foam to the surface of the board, it must be immediately pressed against the wall.

Also remember that if you do not take care of ventilation in advance when equipping the surface with liquid foam, this will lead to the formation of condensation later.

Feedback from buyers of liquid foam suggests that one of the reasons for choosing this insulation is the absence of the need to thoroughly prepare the surface before work and the versatility of using penoizol.

So, with its help you can:

- insulate external fences;

- provide thermal insulation of the walls;

- equip three-layer brick structures;

- fill reinforced concrete panels with foam;

- use as insulation for laminated panels;

- provide reliable sound insulation;

- carry out interfloor insulation of houses;

- insulate roofs, attics, attics, balconies, garages, boxes, hangars, open areas, outbuildings and much more;

- carry out thermal insulation and sound insulation of panels that are placed on a metal or wooden frame;

- carry out soil insulation.

Attention to the ceiling and facade

Penoizol is also well suited for ceiling insulation. True, experts recommend using it in rooms with a large area, since the presence and work of professional craftsmen will be required. Insulation of the facade is easier. Due to the fact that penoizol has excellent characteristics, it is able to become a reliable protection for walls. The essence of facade insulation is as follows. First, a supporting structure is mounted on the wall, for example, from a galvanized profile. Magnesite plates are screwed onto it, in which holes are made - it is here that penoizol is poured. After its polymerization and hardening, the walls can be painted or revetted with decorative materials. For the facade, such a solution is quite convenient and functional, since penoizol in combination with magnesite slabs has good vapor permeability. The walls will "breathe", maintaining a favorable indoor climate. In addition, the facade will meet all fire safety and sound insulation requirements.

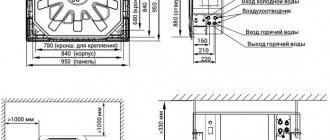

Stages of filling voids and applying to the wall

Drill holes for foam insulation evenly over the entire area This type of insulation is used to insulate and fill three-layer walls, as well as slabs and other structures made of reinforced concrete, which have many layers and voids.

With such insulation, voids are foamed (filled) between the main and facing walls made of reinforced concrete slabs or bricks.

It is necessary to prepare the wall, that is, remove wood, brick, concrete from it, clean it of dust. The great advantage of the material is that you don't need to level the wall to use it.

It is necessary to drill or drill holes in the facing layer, they should have a diameter of 2.5-3 cm, located at an equal distance over the entire area. Penoizol is blown into the holes under pressure up to 5 atmospheres.

Thermal insulation evenly fills the space between the walls. It has poor adhesion (adhesion) to concrete and brick, therefore it fills the voids evenly.

High-pressure insulation with penoizol This method is used to fill voids with penoizol that are more than 5 cm, the walls must be made of durable materials that could withstand high pressure.

After that, the penoizol layer must be leveled, cutting off the excess. Or remove excess with a dry cloth.

Take into account:

professionals advise also to install a reinforced mesh.

To do this, you need to level the layer of material and glue the mesh with mounting glue. Alternatively, you can apply a thin layer of primer to Penoizol and attach a mesh to it.After plaster the surface of the walls with ordinary cement mortar.

Low-pressure insulation of walls with penoizol In order to insulate the walls from the outside, a wooden frame is made or it is made of metal, a fine-grained reinforcing mesh is stretched over it. Insulating material is sprayed under it, after which plaster is applied.

There is also a low-pressure open insulation with penoizol.

In this case, the thermal insulation is poured slowly and gradually into the niche so that the uniformity of the filling can be controlled.

Watch a video that shows in detail the stages of foaming walls with penoizol:

Content

- Why do you need to insulate the house?

- Foaming walls with penoizol

- Insulation of the ceiling and roof

Introduction

A warm home not only makes your life more comfortable, but also allows you to significantly reduce heating costs. For this reason, many owners of country houses insulate walls, ceilings and floors with foam insulation. This insulation is relatively inexpensive and has impressive performance. In this article, we will tell you how to properly insulate a house with penoizol, what are the advantages of this material and what are the nuances in the insulation process.

In one of our past articles, we covered in detail. Today we will talk about why it is necessary to insulate a house and about the very process of insulating various surfaces.

Floor and roof

Penoizol is excellent for floor and roof insulation, but it is important not to forget about the ventilation system. The installation process itself includes several stages:

- Installation of material under the flooring (under the concrete screed or between the joists).

- Laying sheet insulation in the attic, attic, as well as technical floors.

- Installation of penoizol in the suspended ceiling.

- Insulation of the roofing system.

- Filling crumbs of penoizol in the floor, attic.

Depending on the design features of a particular residential building, along with sheet material, penoizol pouring can also be used. This type of foam can be poured directly on the construction site. The effectiveness of this method is that the liquid material does not increase in volume and shrinks slightly. Accordingly, in order to avoid the appearance of cracks in the walls, it is important to strictly follow the technology of its installation. Liquid penoizol should be used at an air temperature of at least +1 degrees. With such a composition, it is quite possible to insulate already operating buildings, filling voids and cavities in structures, which at the same time will remain strong.

Penoizol material: disadvantages

We have already decided on a number of positive characteristics that relate to penoizol, but, like any other material, it also has some disadvantages.

These include the following:

- Over time, the material begins to shrink. This result will not be the case if penoizol is poured between the walls, and it is under pressure.

- Reduced percentage of strength. The density of the material is relatively low, this makes it possible to easily tear the insulation.

- The moisture absorption rate is increased. In some cases, this detail can be considered a disadvantage. Therefore, experts do not recommend laying penoizol under the screed, and it is imperative to use a waterproofing layer.

- Application requires special equipment. This applies only to penoizol in a liquid state. Such equipment can be bought or purchased for rent, as well as a special team has it.

- Installation can only be carried out at optimum temperature. All repair work related to penoizol should be carried out at a temperature above +5.

It should also be added to this list that all work should be carried out exclusively in a protective suit, since there is an option that phenol-formaldehyde vapor will be released.However, this can happen if a poor-quality resin was used in the composition.

How is it produced?

In modern construction, such an insulating material as penoizol is quite in demand. Its production is carried out on the basis of a specially prepared foaming composition with the addition of various components. Due to them, the physical and mechanical properties of the material change, and also its operational characteristics are improved. A foamed mass appears from a special foam-forming sleeve, from which then a heater will turn out. Within 15 minutes, it hardens - this is the first stage. The next stage occurs in about 3-4 hours.

Penoisiol contains approximately 90% of the gas sphere, but the following components are supposed to be used as raw materials:

- phosphoric acid;

- foaming agent;

- resin;

- carbamet;

- water.

Installers reviews

The characteristics of penoizol determine its method of application. After the mass leaves the sleeve of the unit, it solidifies. However, this process takes place gradually. The material sets to the substrate 10 minutes after application. In this state, penoizol remains soft.

After another 4 hours, the mass solidifies. She's getting hard enough. However, penoizol has not yet gained strength. It will take a few more days for the insulation to be ready for subsequent finishing. It gains strength over 3 days. During this time, Penoizol acquires all its positive qualities.

Professional installers claim that thermal insulation of the presented category is mounted much faster than other heaters. The surface treatment speed will be 4-5 times higher. At the same time, the material is characterized by low weight. It makes the structure slightly heavier.

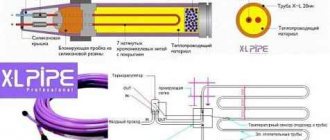

Equipment features

Equipment for the production of penoizol is a number of units that are inexpensive. Firstly, it includes a gas-liquid plant, which directly produces foam insulation. It consists of GZhU, a supply hose, a set of valves for connecting tanks, as well as various application documents. Due to its compactness, the unit can be easily transported. Secondly, you need a compressor that produces compressed air. Thirdly, for the production of penoizol, containers will be required - ideally, there should be three of them. In this capacity, ordinary polyethylene or iron barrels with a volume of 30-200 liters can be used. For the convenience of transporting the unit around the construction site, it is advisable to purchase a trolley with GZhU. Thus, to create such a material as penoizol, the installation must be completely assembled.

How and where is Penoizol used?

Urea foam is used quite widely, while in different countries it is produced under various brands and names. It is due to the manufacturability of the material and its excellent performance characteristics that penoizol is so popular as a heat-insulating material. In most developed countries, it is the filling of the souffle-like penoizol in the cavity that is used. However, this material can be applied in non-standard ways. For example, in the Czech Republic, reinforced concrete panels are used in three layers, one of which is just 50 mm thick foam insulation. In the USA, concrete blocks are used for construction, in which cavities are filled with penoizol.

In Poland and Hungary, the use of this material is due to its resistance to combustion, therefore in these countries it is poured into landfills - a kind of coating protects waste from ignition.

Porous foam is used as a heat-insulating material in the Netherlands, Poland, France, and also in the Baltic States. When building houses, a gap of 40-60 mm is traditionally left between the walls, which is subsequently filled with a foam-insulating mass.

Comparison with other materials

Despite its shortcomings, the product is used to insulate not only external walls, but also internal insulation of residential buildings, vegetable stores, roofs and pipelines. Moreover, it is in demand not only in private, but also in professional construction. Often the granular form of the material is used to insulate attics and floors. The sheet type is suitable for creating sandwich panels.

Along with other types of insulation, penoizol remains one of the best. They have high rates of thermal insulation, in contrast to mineral wool or foam, in which this characteristic depends on the influence of external factors, the level of humidity, mechanical influences. In terms of flammability, this material is superior only to mineral wool, which does not burn at all. The insulation collapses at a temperature of 270 degrees.

Penoizol is superior to other materials in environmental friendliness. It is not an allergen, and after drying it does not emit any harmful substances into the environment. It decomposes into nitrogen fertilizers and carbon dioxide. Another advantage of this material is the variety of shapes, which increases the environment for its use. In addition, it is absolutely not susceptible to damage by rodents.

Why is penoizol so popular?

In search of quality insulation materials, many builders are looking for something that would be not only reliable, but also economical in terms of cost. As a rule, the use of penoizol is explained by the fact that it is good for them to insulate buildings with a wall thickness of about 10-20 mm, since this will reduce the cost of heating the house several times. And the cost of the work carried out on the insulation will pay off already during the first operation of the residential facility. Using urea foam to decorate interior wall openings or insulate the facade of a house, you can effectively protect it even in severe frosts. An important role is played by the cellular structure, which perfectly protects the interior from the penetration of noise.